Choosing the right PCB manufacturer is very important for your electronic projects. The global PCB market is worth USD 84.4 Billion in 2023. It is expected to grow to USD 139.63 Billion by 2032. This shows that the stakes are high. Almost 65% of electronics manufacturers get their PCB production from other companies, highlighting the importance of selecting a reliable PCB manufacturer. Knowing what to consider can help you make smart choices for your business.

Key Takeaways

Learn about the different types of PCBs. Pick the right one for your project, like rigid, flexible, or multi-layer PCBs.

Look at the manufacturer’s quality control steps. Find certifications like ISO 9001 to make sure they meet high standards.

Check the customer support options. Fast and helpful support can improve your experience and fix problems quickly.

Think about prices and delivery times. Get clear quotes and know how costs are figured out to avoid surprises.

Look at the manufacturer’s experience and ability to grow. Choose a partner that can change with your needs as your business grows.

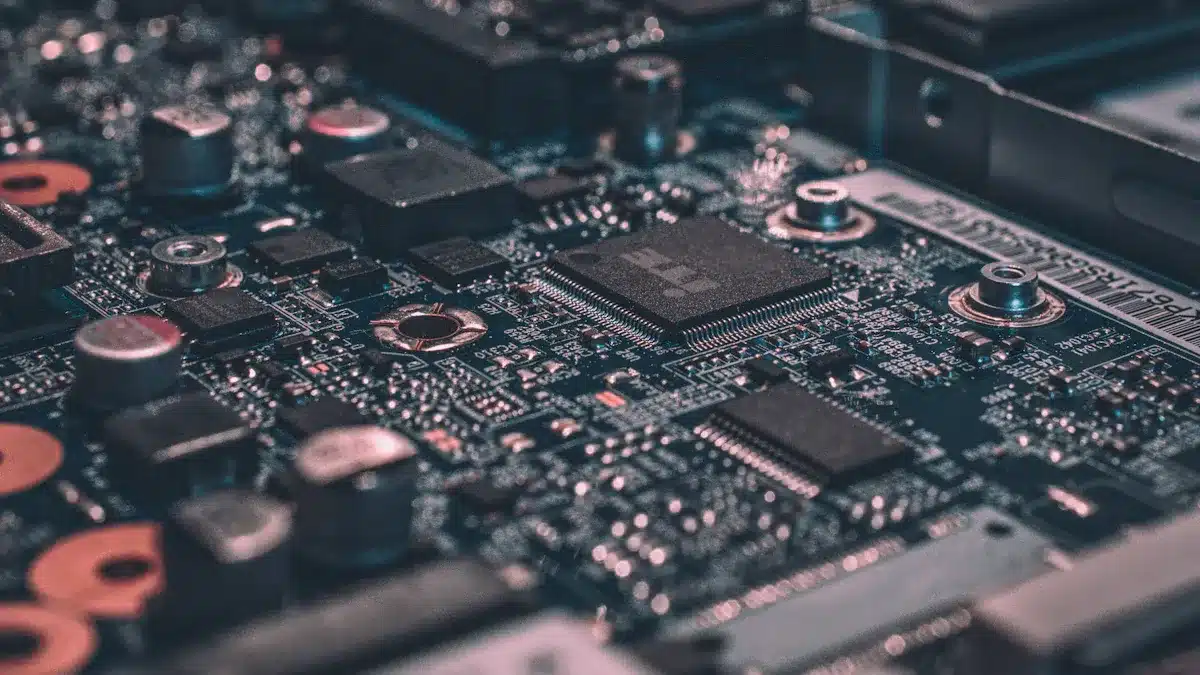

PCB Capabilities

When you choose a PCB manufacturer, knowing their PCB capabilities is very important. This means understanding the kinds of PCBs they make and how they can be customized.

Types of PCBs

Different projects need different types of PCBs. Here are some common types you might see:

Rigid PCBs

Flexible PCBs

Flex-Rigid PCBs

Single-Layer PCBs

Multi-Layer PCBs

High-Frequency PCBs

Each type has special uses. For example, flexible PCBs work well in tight spaces. Multi-layer PCBs can manage complicated circuits.

Customization Options

Customization helps meet your project needs. Top PCB manufacturers offer many ways to change your circuit boards. Here’s a table showing some common customization options:

Customization Option | Details |

|---|---|

Gold/Nickel Thickness | Immersion gold: 1U”, Hard gold: Au:10U”/Ni:120U” |

Via Process | Tenting vias, Plugged vias with solder mask, Vias not covered |

Finished Copper | Options from Bare board (0 oz Cu) to 13 oz Cu |

Inner Copper | Options from 1 oz to 6 oz |

Peelable Soldermask | None, Top side, Bottom side, Both sides |

UL Marking | Options for marking on various layers |

Date Code | Options for adding date codes |

Package Box | With PCBWay logo, Neutral box |

Serial Number Printing Location | Follow factory’s default or specified format and position |

Customized Services and Advanced Options | Castellated holes, Edge plating, Impedance control, Halogen-free, etc. |

When you check a PCB assembly company, think about their manufacturing abilities. Look for new technologies they use, like High-Density Interconnect (HDI) and multilayer PCB technology. These technologies improve how well your circuit boards work and last.

By knowing the types of PCBs and customization choices, you can make smart decisions that fit your project needs.

Quality Control

Quality control is very important when picking a PCB manufacturer. You want to make sure the manufacturer has strong quality control steps. This ensures that the PCBs you get are high quality and work well.

Testing Procedures

To check quality, manufacturers use different testing methods. These tests find problems and make sure the PCBs work reliably. Here’s a table showing some common testing methods:

Testing Procedure | Objective | Importance |

|---|---|---|

Bed of Nails Test | Check connections and how components work on the PCB. | Important for large production, finds open/short circuits, and assembly problems. |

Automatic Optical Inspection (AOI) | Find problems like soldering mistakes and misaligned parts. | Automates checking, making sure no faulty boards go to production. |

Functional Testing | Make sure the PCB does its job under certain conditions. | Confirms overall function, stopping bad products from being sold. |

Visual Inspection | Manually look for clear problems. | Finds defects early, helping automated systems. |

Electrical Testing | Check electrical features to confirm design specs. | Ensures the PCB will work correctly in its use, making it reliable. |

Aging Testing | Test PCB under stress for a long time to find possible failures. | Predicts long-term reliability, spotting parts that might fail early. |

Flying Probe Testing | Use movable probes to test the PCB electrically. | Flexible for different designs, good at finding various issues. |

Solderability Testing | Check if pads and leads can make strong solder joints. | Makes sure it works well with soldering, avoiding weak joints and bad connections. |

Microsection Analysis | Look at the PCB’s inside structure with a microscope. | Finds internal problems that could affect reliability. |

Continuity Testing | Ensure all electrical paths on the PCB are complete. | Confirms all connections are intact, which is key for functionality. |

By looking into testing methods, you can learn how manufacturers keep their PCBs reliable. Good quality control includes smart design, consistent manufacturing, and a dependable assembly process. These things help improve the overall quality of the PCBs you receive.

Standards and Certifications

Certifications and standards are very important in PCB manufacturing. They make sure manufacturers follow strict rules, which helps provide high-quality products all the time. Here are some key certifications to check for:

Standard | Description |

|---|---|

A well-known standard for Quality Management Systems worldwide. | |

AS9100 | An international standard for Quality Management System needs in the Aerospace industry. |

ISO 17025 | Requirements for Testing & Calibration Laboratories’ Competence. |

Manufacturers usually have several certifications, such as:

IPC: Sets accepted practices for PCB assembly.

ISO: Ensures strict quality management standards.

RoHS: Limits harmful materials in electronics.

UL Listing: Covers safety rules for PCB manufacturing.

ITAR: Protects sensitive military technology.

MIL: Sets performance and environmental rules for PCBs.

These certifications show a commitment to quality and reliability. When you choose a PCB manufacturer, make sure they have the right certifications and standards. This will help you trust their quality control processes.

Customer Support

When you pick a PCB manufacturer, think about their customer support. Good support can really change your experience. You want to be sure you can get help easily when you need it.

Support Availability

PCB manufacturers usually have different ways to contact customer support. Common options are:

Phone

Email

Live chat

Dedicated account managers

These ways are important for quick help and fixing problems fast. In the busy world of PCB manufacturing, quick answers are important.

To check how fast a manufacturer responds, look at these things:

Aspect | Description |

|---|---|

Fast answers to after-sales questions are key for checking reliability. | |

Technical Support | Help with design and DFM feedback improves customer support. |

Communication Tools | Using different platforms (email, online portals) helps with good communication. |

Time Zone Compatibility | Plans for handling time zone differences for overseas manufacturers. |

By looking at these factors, you can see how well a manufacturer will help you during your project.

Post-Production Assistance

After production, many PCB manufacturers provide helpful post-production services. These services make sure your PCBs meet quality standards and work as they should. Here are some common types of post-production help:

Service Type | Description |

|---|---|

Testing | Includes functional testing, durability testing, and visual checks to ensure quality. |

Inspection | Advanced inspection methods check the quality and performance of the PCBs. |

Conformal Coating | Adding a protective coating stops copper on PCBs from rusting. |

Component Sourcing | Help in finding components ensures they are available and good quality for assembly. |

You might also find services like parts management, aging testing, and temperature and humidity testing useful. These services help keep your products reliable and high quality.

Choosing a PCB manufacturer with great customer support can really improve your experience. You will feel more sure knowing that help is close by when you need it.

Pricing and Turnaround

When you pick a PCB manufacturer, knowing about pricing and turnaround time is very important. You want to get good products at a fair price and finish your project on time.

Cost Breakdown

PCB manufacturers set their prices based on different things. Here’s how various factors affect costs:

Factor | Cost Impact |

|---|---|

Material Selection | |

Layers and Thickness | $1–$20 per unit |

Design Complexity | $2–$5 per board |

Assembly Process | $0.5–$2 per board |

Testing & Quality Control | $0.3–$1 per board |

Many things can change the cost of making PCBs:

Board Size and Complexity

Quantity and Production Volume

Lead Time Requirements

Testing and Quality Control

Labor and Location

The materials you pick affect both how well the board works and its cost. For example, using FR4, aluminum, or polyimide can change the price. Bigger boards need more material, which raises costs. High-density, multi-layer boards also need more work to make. Ordering more usually lowers the cost for each board.

It’s important to have clear pricing. You should ask manufacturers how they set their prices. This helps you avoid surprises later. Look for details on how they make the boards, test them, and follow rules. These things can change the final price a lot.

Quick-Turn PCB Manufacturer

If you need PCBs fast, think about a quick-turn PCB manufacturer. These companies focus on fast production without losing quality. Here are some important points about quick-turn PCB services:

Normal production runs usually take 5-15 business days.

Some manufacturers have faster services, with lead times as short as 48 hours.

Most PCB manufacturers in the U.S. take 5-15 days. But quick-turn manufacturers can make PCBs in just 24 hours. They do this by controlling build time and quality completely. This ensures reliability and performance that meet high industry standards.

Here’s a comparison of some top quick-turn PCB manufacturers:

Manufacturer | Key Quality Control Methods | Turnaround Time |

|---|---|---|

JHYPCB | Visual Inspection, AOI, Flying Probe Testing | |

Candor | In-house production, rigorous testing | As little as 24 hours |

AdvancedPCB | Comprehensive inspection procedures | Quick service available |

Choosing the right quick-turn PCB manufacturer can help you meet tight deadlines. They reduce possible delays in making the boards while ensuring high-quality products.

Choose the Best PCB Manufacturer

When you pick the best PCB manufacturer, think about their experience and how they can grow. These things can really affect the quality and reliability of your PCBs.

Industry Experience

Experience is important when choosing a PCB manufacturer. A company with a good history shows they know how to design and assemble PCBs. Here are some key points to check:

Expertise and Experience: Find manufacturers who have a good record in making the type of PCB you need. For example, if you want high-density interconnect (HDI) boards, make sure they know how to make those.

Quality Assurance and Certifications: See if the manufacturer has certifications like ISO 9001 and AS-9100D. These show they follow high-quality rules.

Advanced Manufacturing Capabilities: Make sure the manufacturer has the right technology for complex boards. This includes special methods for RF or HDI boards.

Factor | Description |

|---|---|

Manufacturing expertise | Check if the manufacturer can make the specific type of PCB you need, like HDI boards. |

Quality assurance and certifications | Make sure the manufacturer has certifications like ISO 9001 and AS-9100D for high-quality standards. |

Advanced manufacturing capabilities | Look for special methods needed for complex boards, like RF or HDI, to ensure they have the right technology. |

By looking at these points, you can feel sure about the manufacturer’s ability to provide high-quality PCBs.

Growth Potential

As your business grows, your PCB needs might change. So, you should think about how the manufacturer can grow too. Here are some ways top manufacturers increase production:

Design Optimization: Manufacturers make designs easier to produce. This speeds things up and cuts down on mistakes.

Supply Chain Management: Good management of materials helps avoid delays. This makes sure needed materials are always ready.

Quality Control: Using automated testing keeps quality steady during large production runs.

Automation in Manufacturing: Using machines makes production faster and more efficient.

Strategy | Description |

|---|---|

Design Optimization | Making designs easier to produce to speed things up and reduce mistakes. |

Supply Chain Management | Managing materials well to avoid delays and ensure everything is available. |

Quality Control | Using automated tests to keep quality steady during large production runs. |

Automation in Manufacturing | Using machines to make production faster and more efficient. |

Also, think about how much the manufacturer can produce. Some focus on small orders, while others can handle big ones. Here’s a look at some top manufacturers:

Manufacturer | Specialization | Turnaround Time | |

|---|---|---|---|

A-TECH CIRCUITS | Multilayer, HDI, Flexible PCBs | Low volume | Quick |

ALLPCB | Multilayer, Advanced Technology | 5 to 1,000 pieces | Quick |

JLCPCB | Single and Double-layer PCBs | 5 to 1,000 pieces | 24-hour |

Advanced Circuits | Multilayer, Advanced Technology | Low volume | Quick |

Seeed Studio | Multilayer, Flexible, Rigid-Flex | Low volume | Quick |

Eurocircuits | Multilayer, Complex PCBs | Low volume | Quick |

By checking both industry experience and growth potential, you can find the best PCB manufacturer for your needs. This way, they can meet your current needs and adjust to future ones.

Choosing the right PCB manufacturer is very important for your project’s success. Here are some key points to help you decide:

Focus on quality and reliability with good records and certifications.

Check lead time and turnaround for on-time delivery.

Balance cost with overall value, including material quality.

Look at capabilities and specializations for different PCB types.

Find strong customer support for quick problem-solving.

Consider environmental responsibility and sustainability practices.

Use design and engineering services to improve performance.

Pay attention to testing and inspection methods to ensure quality.

Look at reputation and feedback from other customers.

By following these tips, you can build a successful partnership with your PCB manufacturer. Good teamwork improves product quality and helps your business grow. Remember, a reliable manufacturer not only meets your current needs but also helps with your future ideas. 🌟

FAQ

What should I think about when picking a PCB manufacturer?

You should look at their skills, quality checks, customer help, prices, and how fast they work. Find out if they have experience with the type of PCB you need and if they can grow with your business.

How can I make sure my PCBs are good quality?

Check the tests they do and their certifications. Look for standards like ISO 9001 and IPC. These show they care about quality and reliability in how they make PCBs.

What are quick-turn PCB services?

Quick-turn PCB services mean fast production, usually in 24 to 48 hours. These manufacturers work quickly while keeping quality high, which is great for urgent projects.

How do I ask for a quote from a PCB manufacturer?

You can contact the manufacturer through their website or customer support. Share details about your project, like specifications, amounts, and any special needs. They will give you a quote based on what you need.

Can I change my PCB design?

Yes, most PCB manufacturers let you customize your design. You can choose materials, layer counts, and other features to fit your project’s needs. Always talk about your requirements with the manufacturer before starting production.

See Also

Selecting the Right PCB Fabrication Company for Your Requirements

Finding the Ideal PCB Prototype Manufacturer for Your Project

Choosing the Most Suitable PCBA Manufacturer for Your Business

Essential Advice for Selecting a Trustworthy PCBA Manufacturer in China