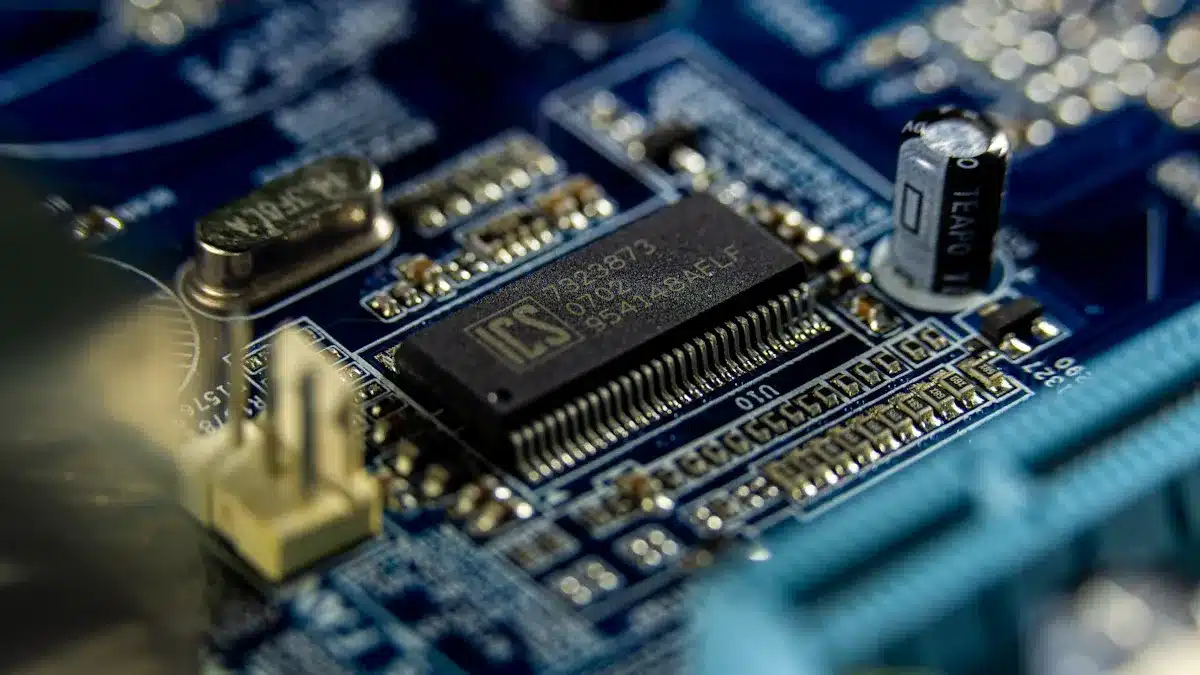

The print circuit board (PCB) industry is very important in today’s electronics. As you learn about this field, you will see that many things affect the prices of print circuit boards. For example, the global market size for print circuit boards is expected to be about USD 82,248.74 million by 2024. It is also expected to grow to USD 113,734.26 million by 2033. Knowing what affects these prices can help you make smart choices in your projects. Here are some important factors to think about:

Circuit board size and shape

Board complexity

Type of print circuit board

Delivery lead time

Custom design requests

By understanding these factors, you can better manage the print circuit board market and save money.

Key Takeaways

PCB prices depend on size, complexity, and materials. Knowing these helps you budget better.

Choose good materials for your PCBs. They may cost more at first but save money later by reducing failures.

Plan your PCB design carefully. Fewer layers and wider traces can lower costs a lot while keeping performance.

Think about production methods that save money. Using standard materials and designs helps keep your project on budget.

Be aware of turnaround times. Standard orders are cheaper than rush orders, so plan ahead to save money.

Materials

The materials you choose for printed circuit boards are very important. They can change the total costs. Different materials have different features. These features can affect how well the board works, how long it lasts, and how much it costs. Knowing about these materials helps you make good choices for your projects.

Types of Materials

Many materials are used to make printed circuit boards. Here’s a quick look at some popular ones:

Polyimide: This material is flexible and works well with heat. It is often used in planes and cars.

PTFE (Teflon): PTFE is very flexible. It is good for high-frequency uses because it has a low dielectric constant.

Metal Core: Made from copper and aluminum, metal core PCBs are strong and manage heat well.

Copper Layer: Copper layers are needed for electricity to flow. They are key parts of PCB designs.

PCB Core (Substrate): Usually made of FR4, this material is good for heat and strength.

Prepreg: This fiberglass material sticks layers together when making PCBs.

Solder Masking Layer: This layer keeps copper safe from the environment.

Surface Treatments: Different finishes, like HASL and ENIG, stop oxidation and help with soldering.

Choosing the right substrate material affects the cost of the PCB board. For example, FR-4 is a common choice in PCB making. It usually costs between USD 0.10 to USD 0.50 per square inch. This helps set a standard for figuring out material costs, which is important for budgeting your project.

Substrate Material | Cost per Square Inch | Thermal Conductivity | Stability at High Temperatures |

|---|---|---|---|

FR-4 | USD 0.10 to USD 0.50 | Limited | Unstable at higher temperatures |

Polyimide | Higher than FR-4 | Enhanced | Stable at higher temperatures |

Quality vs. Cost

It’s important to know how material quality relates to costs. Better quality materials usually mean better performance and reliability. Here are some things to think about:

High-quality materials make PCBs more reliable and perform better, lowering failure rates.

Low-quality materials can cause problems, raising the chances of PCB failures.

The type of substrate material affects how well electricity flows, which impacts signal quality and function.

Choosing the right materials helps manage heat, preventing overheating and making parts last longer.

Spending more on better materials can help save money in the long run for printed circuit boards. Even though high-quality materials may cost more at first, they often last longer and lead to fewer warranty issues. This means lower overall production costs and longer product lifespans.

Design

The design of your printed circuit board (PCB) is very important for its costs. When you look closely, you will see that the number of layers and the width of the traces affect the price of your PCB a lot.

Layer Count

The number of layers in your PCB design changes the manufacturing costs. A single-layer PCB is the cheapest to make. But when you add more layers, it gets more complex and costs more. Here’s how layer count affects pricing:

A 2-layer board may cost about $0.10 per square inch.

A 4-layer or 6-layer PCB can cost 2-3 times more because of extra materials and complexity.

Each extra layer needs more lamination cycles, which take time and money.

Here are some cost increases based on layer counts:

1-Layer to 2-Layers: 35% to 40% cost increase

2-Layers to 4-Layers: 35% to 40% cost increase

4-Layers to 6-Layers: 30% to 40% cost increase

6-Layers to 8-Layers: 30% to 35% cost increase

8-Layers to 10-Layers: 20% to 30% cost increase

10-Layers to 12-Layers: 20% to 30% cost increase

A good stack-up design can help lower costs and make manufacturing easier. By planning your layer count carefully, you can manage your budget while still getting the features you want.

Trace Width

Trace width is also very important for PCB costs. The width of the traces on your PCB affects how it is made and how well it works. Here’s how trace width impacts costs:

Trace Specification | Cost Impact |

|---|---|

Default Trace Width | Lowest Cost |

Wider/Narrower Traces | Increased Cost due to specialized techniques |

If you choose trace widths smaller than 5 mils (0.005”) or if you want trace spacing closer than 5 mils, expect higher costs. Also, using via holes smaller than 8 mils or changing trace thickness can raise costs too.

Fine-pitch components need careful alignment in multi-layer boards. This can make the design harder. Inspecting these components can be tough. Regular visual checks might not work well, which can lead to problems in important areas like automotive or aerospace electronics.

By knowing how trace width and layer count affect your PCB costs, you can make smart choices that balance performance and budget.

Manufacturing

Making printed circuit boards (PCBs) is very important for their costs. Different ways to produce PCBs can change how much you spend. Knowing these things helps you make smart choices.

Production Techniques

There are many ways to make PCBs that can save money. Here are some good methods:

Use the cheapest acceptable materials.

Remove extra layers.

Combine parts to make the board smaller.

Increase routing densities while keeping clearances.

Relax tolerances when you can.

Use standard materials, board sizes, parts, and finishes.

Reuse successful methods.

Work with manufacturers to improve production.

These methods help you cut costs while keeping quality. For example, smaller designs use less material and take less time to make, which helps your budget.

Technology Used

The technology you pick for making PCBs also affects costs. Here are some common technologies and what they mean for costs:

Technology Type | Description | Cost Range |

|---|---|---|

Most popular for its efficiency and reliability. | $0.0015 to $0.002 per patch point | |

DIP Post-Welding | Used for parts that can’t be surface mounted; takes more labor. | More expensive than SMT, varies by complexity |

Testing | Checks the reliability and performance of the PCB. | About $0.30 per PCB |

Using machines and robots in PCB making can really lower costs. Automation helps make more boards faster. This saves on labor costs and reduces mistakes during assembly. As a result, you get better quality and lower costs.

By knowing about manufacturing methods and technologies, you can better control your PCB assembly costs and overall project expenses.

Assembly Costs

Assembly costs are very important for the total price of printed circuit boards (PCBs). These costs can make up 30% to 60% of the total cost for making electronics. Knowing what affects assembly costs can help you manage your budget better.

Labor Costs

Labor costs are a big part of PCB assembly expenses. The average pay for workers changes based on how complex the assembly is. Here are some common labor costs:

Labor for surface mount technology (SMT) assembly is about $15 to $30 per hour.

For special or prototype assembly, labor can go up to $20 to $50 per hour.

Skilled workers may ask for higher pay.

Labor costs greatly affect how competitive PCB makers are. Countries with lower labor costs, like China, used to have an edge. But this is changing as wages in China go up. Lower labor costs can help a country be more competitive in making PCBs.

Equipment Costs

The costs for setting up a PCB assembly line can be very different. Here are some important points about equipment costs:

Equipment for PCB making can cost between $100,000 and $5 million, depending on what type and quality it is.

Key equipment includes:

Printing machines

Etching machines

Drilling machines

Plating machines

Testing equipment

Buying good equipment is very important for making reliable PCBs. Better assembly machines help production run smoothly and lower labor costs. Technologies like surface-mount technology (SMT) help make smaller components, which improves PCB quality. Also, automated inspection systems help lower mistakes and downtime, ensuring steady product quality.

By knowing about labor and equipment costs, you can make smart choices to lower PCB costs while keeping quality high.

Turnaround Times

Turnaround times are very important for the costs of printed circuit boards (PCBs). When you place an order, how long it takes to make the boards can change your budget a lot. Knowing the difference between standard and rush orders helps you decide better.

Standard Orders

Standard orders usually take about 20 working days. This time lets manufacturers plan their work well. If you can wait for a 3-to-4-week lead time, you can save a lot of money. Here are some important things about standard orders:

Standard lead times help you avoid extra fees.

Costs stay lower when you plan ahead.

Manufacturers can use their resources better with longer lead times.

Choosing standard orders can help you save money while keeping quality high.

Rush Orders

Rush orders cost more money. If you need your PCBs fast, expect to pay 20-50% more than the regular price. Here’s what to know about rush orders:

Shorter lead times can be 5-10 times more expensive than standard times.

Quick-turn options can make lead times as short as 48 hours for simple designs.

Manufacturers focus on rush orders, which can raise prices and cause resource issues.

While rush orders can help with urgent needs, they can hurt your budget. Planning ahead with standard times is usually the best way to keep PCB costs down.

By knowing about turnaround times and how they affect costs, you can make smarter choices for your PCB projects.

Knowing what affects the price of printed circuit boards (PCBs) is very important for your projects. Here are some key things to think about:

How many layers your design has.

The kind and quality of materials used.

The thickness of copper and surface finishes.

How many you want to make and how fast you need them.

By making designs simpler and ordering more at once, you can lower costs a lot. Working with suppliers and planning well can help you keep quality and budget in check. Make smart choices to improve your PCB buying plan.

FAQ

What factors influence the print circuit board price?

The price of a print circuit board depends on materials, design, layers, and how it is made. Each of these things adds to the total cost of the PCB.

How does the layer count affect the PCB board price?

More layers in a PCB design make the price go up. Extra layers need more materials and steps to make, which raises costs.

What are custom printed circuit board prices based on?

Prices for custom printed circuit boards depend on the design, materials, and how many you want. Special designs usually cost more.

How can I reduce my custom PCB cost?

To lower your custom PCB cost, make your design simpler, pick standard materials, and order more at once. These tips help cut overall costs.

What is the flexible PCB cost compared to rigid flex PCB cost?

The cost of flexible PCBs usually changes based on design and materials. Rigid flex PCBs may cost more because they are more complex to make.

See Also

Important Factors To Consider For PCB Or PCBA Selection

In-Depth Comparison Of PCBWay And Competing PCB Makers

Emerging Trends Shaping PCB And PCBA Design And Manufacturing

The Importance Of Custom PCBA Production In Today’s Electronics