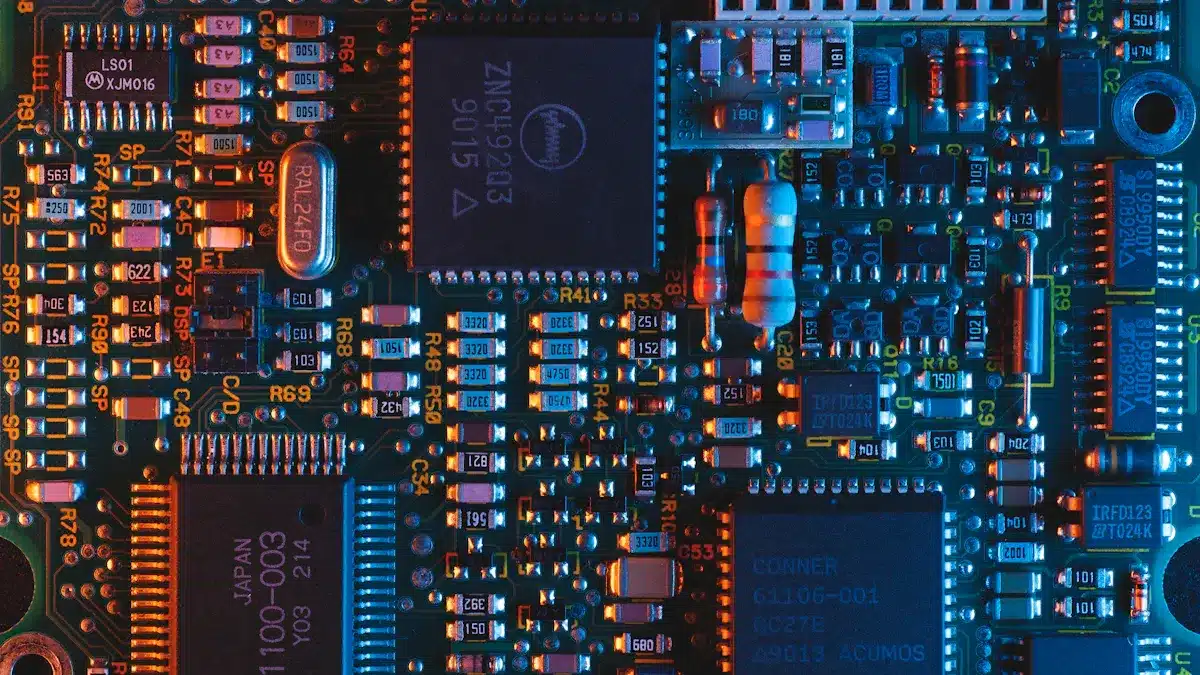

In today’s fast-changing world of electronics, printed circuit boards (PCBs) are very important in circuit design. More people are using PCBs because of better PCB design software. This software helps make circuit board designs better. It saves time and cuts down on mistakes during product development. Because of this, the PCB market is expected to grow a lot. It could reach USD 13.32 billion by 2034. With a growth rate of 13.7% each year, this shows that more efficient and reliable PCB circuits are needed in many uses.

Key Takeaways

PCBs help save money by being made in large amounts. This makes them cheaper for big projects.

Today’s PCBs are very reliable. Their failure rates have gone down a lot over the years.

Using PCBs can make electronic devices smaller and lighter. This is important for designs that need to be compact.

Flexible PCBs allow for creative designs. They can take on different shapes and fit well in layouts.

High costs to make them and their effects on the environment are key things to think about when using PCBs.

Advantages of PCBs

Printed circuit boards (PCBs) have many benefits. These advantages make them a popular choice for circuit design. Knowing these benefits helps you make smart choices when designing electronic devices.

Cost-Effectiveness

One main benefit of using PCBs is that they save money. When you make PCBs in large amounts, you get better prices. Here are some important points to think about:

Prototyping costs a lot per board when made in small amounts.

Making many boards at once lowers costs since fixed costs are shared.

Manufacturers can get discounts when buying in bulk.

It is easier to improve production processes with larger batches.

These reasons lead to lower costs per unit. This makes PCBs a good choice for many projects.

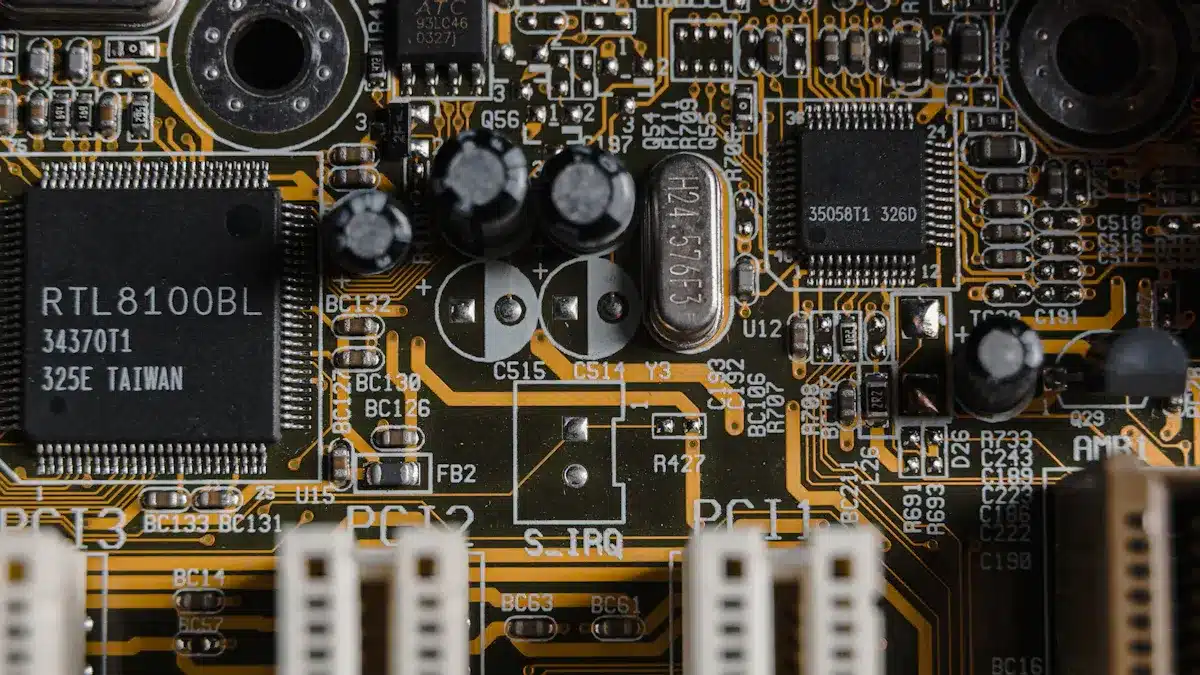

Reliability and Precision

PCBs are known for being reliable and precise. Modern manufacturing has greatly improved PCB quality. For example, the failure rate of PCB circuits has dropped from 2.5% in the 1970s to less than 0.5% today. This reliability comes from several reasons:

Type of Circuit | Failure Rate (Historical) | Current Failure Rate |

|---|---|---|

Hand-Wired Circuits | Not specified | Not specified |

PCB-Based Circuits | 2.5% (1970s) | < 0.5% |

Also, modern PCBs can be very precise. For instance, trace widths can be as small as 0.003 inches, and via diameters can be 0.006 inches. This precision helps your designs work well and efficiently.

Space and Weight Efficiency

Another big advantage of PCBs is that they save space and weight. In small electronic devices, every inch matters. Using PCBs helps reduce both space and weight. Here are some examples:

Application | Weight Reduction | |

|---|---|---|

Foldable Smartphones | Up to 50% | N/A |

Fitness Trackers | Up to 35% | N/A |

Aerospace | N/A | 20% or more |

General Devices | N/A | 25% |

This efficiency allows for smaller designs, which is important in industries where size and weight are very important.

Design Flexibility

PCBs also provide great design flexibility. You can create complex layouts that fit different shapes and sizes. Flexible PCBs, in particular, allow for more design options. They can bend and fit into small or oddly shaped spaces, unlike rigid circuits. Here are some benefits of flexible PCBs:

They take up less space, which reduces weight on the motherboard.

Better thermal management helps reduce heat buildup.

They are often more reliable in places with constant vibrations and stress.

Modern PCB design tools improve this flexibility. They let you optimize trace routing and keep trace widths consistent. This ensures that your designs stay strong while fitting various uses.

Disadvantages of PCBs

Printed circuit boards (PCBs) have many good points, but they also have some downsides. Knowing these problems is important for making smart choices in circuit design.

High Manufacturing Costs

One big problem with PCBs is that they cost a lot to make. Many things add to these costs:

Materials and Components: The type of materials and copper used affects how well they work and how much they cost.

Board Size and Complexity: Bigger and more complicated boards need more materials and special processing, which raises costs.

Quantity and Production Volume: Making more boards at once can lower the cost of each one because of economies of scale.

Lead Time Requirements: Fast production can raise costs because of extra work and quick processes.

Testing and Quality Control: Advanced testing methods increase costs because they need special tools and skilled workers.

Labor and Location: Labor costs can be very different between local and overseas production, affecting total costs.

Making a small number of PCBs is especially costly. You pay more for each board because of fewer units and the need for thorough testing. On the other hand, making a lot of boards helps lower costs per board as automation increases. For example, making more boards can cut costs by 30-40% when you scale up.

Environmental Impact

The effects of making and throwing away PCBs are serious. Here are some main issues:

Soil Contamination: Harmful chemicals like lead can leak into the ground from poorly disposed PCBs, making soil unsafe for farming.

Water Contamination: Rain can wash toxic chemicals from thrown-away PCBs into rivers and lakes, harming fish and other water life.

Air Pollution: Burning PCBs can release harmful gases, which can affect air quality far away.

There are rules to help reduce these problems. The Toxic Substances Control Act controls how PCB waste is cleaned up and thrown away. Recent changes by the EPA focus on important issues in the PCB Cleanup and Disposal Program. Still, challenges are big, and bad waste handling can cause health risks.

Repair and Modification Challenges

Fixing or changing PCB circuits can be hard. Here are some common problems you might run into:

Physical Damage: Pressure or shock can hurt the board.

Component Failure: Parts like capacitors may break, needing replacement.

Trace Damage: Damage to traces can hurt conductivity and overall performance.

You also need special tools and skills to fix them. The complexity of modern PCBs, with tiny and detailed parts, makes troubleshooting harder. Finding short circuits often needs careful checking and a step-by-step method. Compared to breadboards, PCBs are tougher to repair. Breadboards let you easily change things without soldering, while PCBs need new boards for big changes.

Comparing PCB Circuits

When you think about using PCB circuits, you will see different situations where their good and bad sides show up. Knowing these situations helps you make smart choices in your circuit design.

Scenarios Favoring PCBs

PCBs work well in certain electronic products. Here are some examples where they have big benefits:

Type of Electronic Product | |

|---|---|

High-frequency communications | Better performance for RF applications |

Compact consumer electronics | Saves space and cuts costs |

High-current automotive systems | Reliable and strong under high power needs |

Flexible medical devices | Can adapt and be precise in sensitive areas |

In large-scale production, PCBs are also helpful. For example, car parts makers use aluminum PCBs to save energy and lower temperatures. This method leads to better performance and reliability.

Scenarios Against PCBs

Even with their benefits, PCBs have some limits. They might not work for every use. Here are some reasons why:

Complex Circuits: PCBs can get messy and hard to handle in complicated designs.

Soldering Requirements: Errors in soldering can cause problems, hurting circuit performance.

These issues can make PCBs less suitable for testing or experimental projects. In these cases, options like breadboards might work better.

Flexible PCBs in Design

Flexible PCBs have special benefits compared to regular rigid PCBs. They allow for more design freedom, helping you create smaller and lighter circuits. Here’s how they stack up:

Feature | Flexible PCBs | Rigid PCBs |

|---|---|---|

Space Efficiency | Good for small designs | Not as space-efficient |

Weight | Lighter, helping reduce overall weight | Heavier than flexible options |

Dynamic Performance | Can handle bending and movement | Usually stays the same, less adaptable |

Durability | Can struggle with wear from bending | Stronger and more reliable for fixed use |

Flexible printed circuit boards are great for wearables and robots. They fit well in tight spaces and move often. As industries want smaller and tougher electronics, flexible PCBs are becoming more popular.

In conclusion, using printed circuit boards (PCBs) in circuit design has both good and bad points. You gain cost savings, reliability, and design options. But, you also need to think about high production costs and environmental effects.

Advantages | Disadvantages | |

|---|---|---|

Single-layer | Saves money, simple design, good for low-density uses | Limited routing choices, no shielding, higher chance of damage |

Double-layer | More routing choices, better heat control, shielding options | More expensive, takes longer to make, possible issues from vias |

Multi-layer | Best performance, better reliability, more routing space | Most costly, longest to produce, complicated testing and fixing needs |

As you look for eco-friendly choices, think about biodegradable PCB materials. They help cut down on e-waste and reduce your carbon footprint, matching today’s sustainability goals. Weighing these trade-offs will help you make smart choices in your circuit design projects. 🌍

FAQ

What are PCBs made of?

PCBs are made of layers of insulating stuff, usually fiberglass, and copper wires. These materials work together to make a strong and effective circuit board.

How do I choose the right PCB type?

Think about what your project needs. For simple designs, single-layer PCBs are good. For more complicated circuits, choose multi-layer PCBs. Look at cost, space, and performance.

Can I repair a damaged PCB?

Yes, you can fix a damaged PCB. But, it needs special tools and skills. You might have to change parts or fix broken wires to make it work again.

What is the lifespan of a PCB?

The lifespan of a PCB depends on how you use it and the environment. Usually, a well-made PCB can last 10 to 20 years if taken care of properly.

Are there eco-friendly PCB options?

Yes, there are eco-friendly PCB choices. Biodegradable materials and lead-free solder help lessen environmental harm. These options fit with sustainability goals in making electronics. 🌱

See Also

Important Factors To Consider When Selecting PCB Or PCBA

Benefits And Challenges Of Flex PCBA In Today’s Electronics

Understanding The Key Differences Between PCBA And PCB