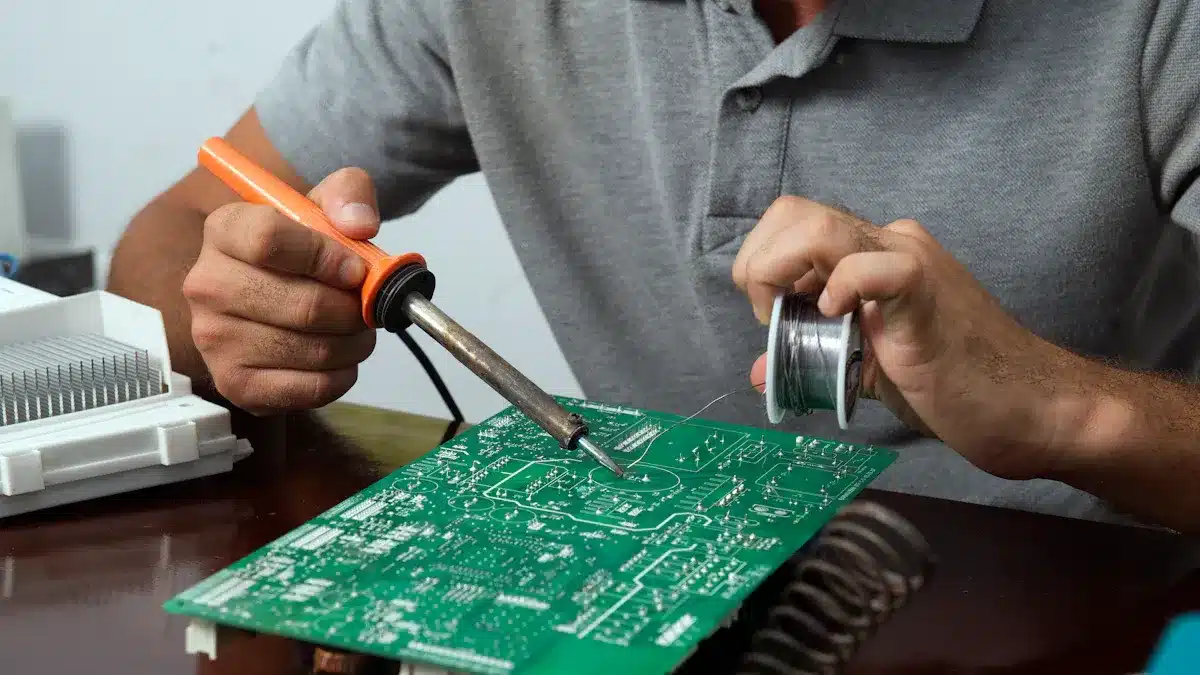

Choosing the right circuit board repair service is very important for how well your devices work and how long they last. Good repairs can make your printed circuit boards (PCBs) work like new again. Think about these things:

Quality: Skilled repairs can help your PCB last longer, like a new one.

Cost: Choosing a service with certified workers can save you time and money later.

Turnaround Time: Fast and good service reduces the time your equipment is not working.

By focusing on these points, you can choose wisely. This will improve your devices’ reliability and functionality.

Key Takeaways

Pick a repair service that values quality. Good repairs can make your circuit boards last longer.

Learn about the different kinds of repair services. Component level repair fixes single parts. PCB rework services fix the whole board.

Find technicians who have certifications and experience. Skilled technicians provide dependable repairs and solve problems better.

Know about pricing models and possible hidden costs. Understanding these can help you avoid surprise charges during repairs.

Think about how long repairs will take when choosing a service. Quick repairs can reduce downtime and boost your equipment’s efficiency.

Types of Repair Services

When you pick a circuit board repair service, it is important to know the types of services they offer. There are two main types: component level repair and PCB rework services.

Component Level Repair

Component level repairs fix broken parts on a circuit board. This means finding problems with each part and using expert skills to fix them. Some common methods are:

Laminating repair

Eyelet replacement

Pad or trace lifting

These techniques help workers fix specific problems caused by outside factors. This way, each part works well again. The results of component level repairs include fixing individual parts and needing high skills.

PCB Rework Services

On the other hand, PCB rework services deal with the whole PCB or certain parts while keeping the original design. This process makes sure everything follows the original setup, which may include:

Solder touchups

Replacing damaged components

Rework can also change things to make them work better, like adding jumper wires or cutting traces. The results of PCB rework services ensure that the board meets its original design while possibly improving its overall performance.

Aspect | Component Level Repair | PCB Rework |

|---|---|---|

Focus | Individual faulty components | Entire PCB or specific components |

Process | Involves diagnosing and resolving issues at the component level | Involves replacing components while maintaining original configuration |

Techniques | Laminating repair, eyelet replacement, pad or trace lifting | Solder touchup, replacing damaged components |

By knowing these two types of repair services, you can make smart choices when picking a circuit board repair service that fits your needs.

Expertise and Experience

When you choose a circuit board repair service, think about the skills and experience of the technicians. Their training and background are very important. They help make sure your printed circuit board repair is done well and quickly.

Technician Qualifications

Good technicians have certifications that show their skills in circuit board repair. Look for technicians with these certifications:

Industrial Electronics (IND) by ETA

EPA Amusement Operators Safety Certification (EPA)

Certified Network Computer Technician (CNCT) by ETA

These certifications mean the technicians have had tough training and follow industry rules. This knowledge is key for doing reliable circuit board repairs, especially for tricky problems.

Industry Experience

Experience is very important in circuit board repair. Technicians with a lot of experience can find and fix problems better. For example, technicians at top companies like Precision Electronics and Renova have over 15 years of experience on average. This experience helps them deal with many circuit board issues, from easy fixes to hard changes.

The role of industry standards in repair quality is very important. Standards like IPC-7711 and IPC-7721 focus on fixing and repairing electronic parts. These rules make sure technicians use the best methods, which improves repair quality. Here’s a quick look at these standards:

Standard | Focus Area | Importance |

|---|---|---|

IPC-7711 | Rework of electronic assemblies | Makes sure components are safely removed and replaced without harming the board or nearby areas. |

IPC-7721 | Repair and modification of printed boards | Covers fixing conductors and laminates, and rebuilding pads and traces. |

Training | Certification of technicians in IPC standards | Ensures they follow industry-approved methods, improving repair accuracy and quality. |

By picking a service with skilled technicians who have a lot of experience, you can make sure your damaged circuit board gets the expert care it needs. This focus on quality PCB repair not only fixes problems but also helps your equipment last longer.

Cost Considerations

When you choose a circuit board repair service, knowing the costs is very important. You want to get good service without surprise charges. Here, we will look at common pricing types and hidden costs that might come up during repairs.

Pricing Models

Circuit board repair services use different pricing models. Knowing these can help you make smart choices. Here are some common pricing types:

Flat Rate Pricing: Some services charge a set fee for certain repairs. This makes costs clear from the start.

Hourly Rates: Many technicians charge by the hour. Typical rates are about $30 per hour.

Cost per Board: Some companies charge a fixed amount for each board they fix. This can be between $50 and $150 based on the damage.

Complexity-Based Pricing: The price may change based on how hard the repair is. More complicated repairs usually cost more.

Remember, fixing a PCB can save you about 70% compared to making a new product. But, repair costs can change a lot depending on how bad the damage is and how much work is needed.

Hidden Costs

Even if you get a quote that looks fair, hidden costs can add up fast. Here are some common hidden charges to watch out for:

Rework Expenses: If the first repair isn’t good enough, you might have to pay more for rework. This can take a lot of labor and materials.

Material Waste: Poor processes can waste materials, which raises costs.

Production Delays: Slow repairs can lead to lost chances and money, especially in busy industries.

Damage to Customer Relationships: Bad boards can hurt your company’s image, causing customer returns and unhappiness.

For example, reworking a board can take from 10 minutes to an hour, which affects total costs. If you need to fix ten boards, labor alone could cost between $50 and $300.

By knowing these pricing types and possible hidden costs, you can better handle the circuit board repair process. Always ask for a clear repair quote and think about getting a free evaluation to see all possible costs.

Turnaround Times

When you think about circuit board repair services, turnaround time is very important. Knowing the difference between standard and fast services can help you pick the best choice for you.

Standard Services

Standard circuit board repair services usually take about three weeks after you send your order and all needed materials. This time can change based on how hard the repair is and if replacement parts are available. If the repair is simple, technicians can fix it quickly. But, if there are complex problems, it may take longer to find and fix them.

Many things can affect turnaround times:

Factor | Description |

|---|---|

Complexity of the issue | Simple issues can be fixed quickly, while complex problems take longer to diagnose and repair. |

Availability of parts | Parts that are easy to find speed up repairs; hard-to-find parts can delay the process a lot. |

Workload at the facility | A lot of repairs can make turnaround times longer, while fewer repairs allow for quicker fixes. |

Testing and QA process | A careful testing phase ensures quality, which can add time to the overall repair process. |

Expedited Services

If you need faster results, there are expedited services. These options can make turnaround times much shorter, often finishing repairs in just a few days. However, this speed costs more. Expedited services usually charge higher rates because your repair gets priority.

Benefit | Description |

|---|---|

Fixing broken PCBs is often cheaper than throwing them away and getting new ones, saving money. | |

Improved Production Efficiency | Finding and fixing errors early helps the manufacturing process, reducing downtime. |

Choosing expedited services can make customers happier. Quick turnaround helps manufacturers avoid long downtimes, which is very important in industries like appliances and cars. By fixing repairs right away, you can stop backlogs and keep things running smoothly.

Customer Support

When you pick a circuit board repair service, good customer support is very important. Clear communication and dependable warranty services can really affect how happy you feel and how relaxed you are.

Communication Channels

You should find different ways to get help for your circuit board repair. Here’s a table showing common options:

Communication Channel | Description |

|---|---|

SMS | Great for booking confirmations, job updates, and reminders. |

Best for sending quotes, invoices, and appointment updates. | |

Lets you message in real-time for quick help. | |

Facebook Messenger | Allows you to chat on social media with fast responses. |

Instagram Direct | Works like Facebook Messenger for social media chats. |

Unified Communication Hub | Brings all communication tools together for a smooth customer experience. |

Using these ways to communicate makes it easy to ask for updates or help. Quick replies can make you feel more sure about the repair process.

Warranty Services

Warranty services can be different among circuit board repair companies. A good warranty can protect what you paid and make sure repairs are done well. Here’s a comparison of warranty options from different companies:

Provider | Warranty Duration | Notes |

|---|---|---|

ACS Industrial | Focus on quality and keeping customers happy. | |

Independent Service Providers | Varies | Depends on skills, tools, and cost savings. |

Picking the right independent service provider can save you up to 70% compared to getting new parts.

Good shops make sure repaired boards work as well as or better than the originals.

Also, customer satisfaction ratings can show how reliable a service is. For example, Upfix has over 6,278 positive reviews, while Circuit Board Medics has more than 6,000 five-star ratings. These numbers show a strong focus on quality and great service.

By focusing on customer support, you can improve your experience with circuit board repair services. Good communication and strong warranty choices will help you feel confident in your decision.

Choosing the right circuit board repair service takes careful thought. First, check the reputation of the providers. Make sure they have good fault monitoring and important certifications like IPC-7711/7721. Also, strong supply chain connections can make repairs more reliable.

Don’t forget to read customer reviews. Good feedback usually shows satisfaction with prices and quick repairs.

When you are ready, ask for quotes. The usual process is to send a request, get a free evaluation of your item, and receive a reply in about two weeks. By following these steps, you can pick a service that fits your needs well.

FAQ

What should I look for in a circuit board repair service?

You should focus on quality, technician skills, and how fast they work. Find services that give warranties and have good customer reviews. This helps make sure you get dependable repairs.

How long does a typical repair take?

Standard repairs usually take around three weeks. But, the time can change based on how hard the problem is and if parts are available.

Are there any hidden costs in circuit board repairs?

Yes, hidden costs can come from rework fees, wasted materials, and delays in production. Always ask for a clear quote to avoid surprises.

Can I expedite my circuit board repair?

Yes, many services have faster options for quicker repairs. Expect to pay more for this priority service, but it can greatly cut down downtime.

What warranties should I expect from repair services?

Warranties differ by provider. Look for services that give at least a one-year warranty on repairs to ensure quality and trustworthiness.

See Also

Guidelines for Choosing the Ideal Fusion PCBA Service

Effective Strategies for Picking Top PCB Assembly Services

Key Advice for Selecting the Perfect Main PCBA