Protecting circuit boards from damage is very important. This helps them last longer and work better. Getting sand in a circuit board can lead to significant issues. If you ignore this, it can result in expensive repairs or replacements. By being careful, you can prevent sand from getting into a circuit board. This will help your devices run well for many years.

Key Takeaways

Sand can really hurt circuit boards. It can cause scratches, short circuits, and rust.

Pay attention to your surroundings. Deserts, beaches, and construction sites have more sand.

Use protective coatings, like P2, to protect circuit boards from sand and water.

Cleaning and taking care of your devices can stop sand from building up. This helps them last longer.

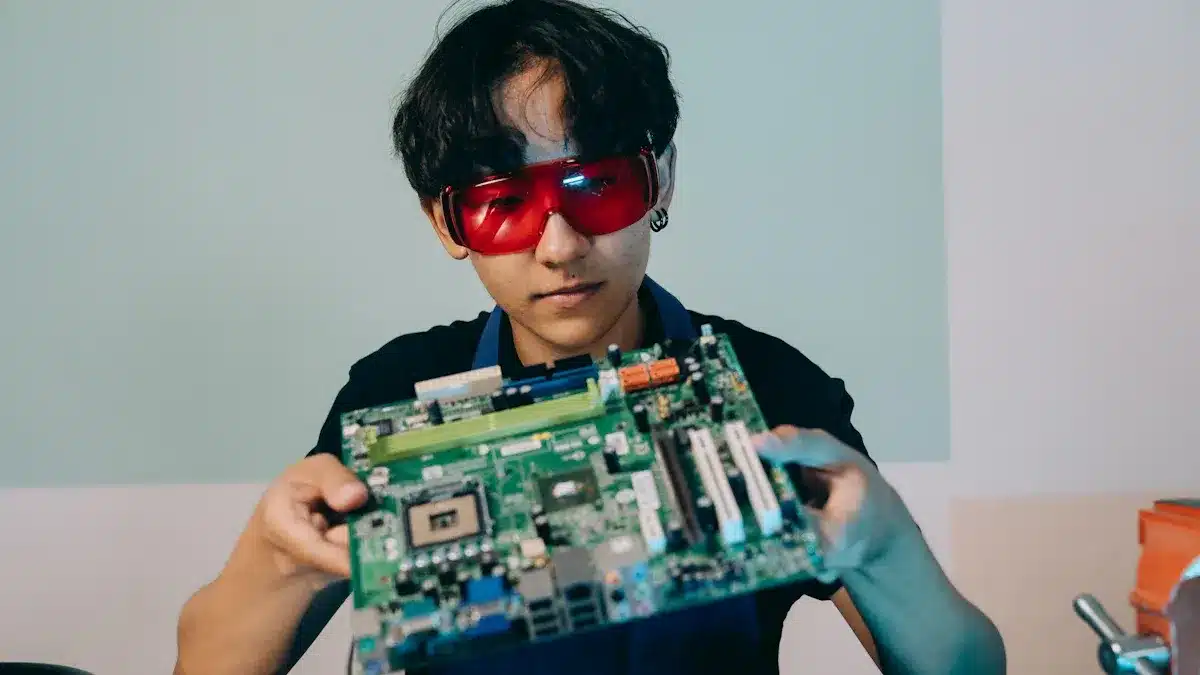

Be careful with circuit boards. Work in clean places and use grounding methods to keep them safe.

Sand Damage Overview

Types of Damage

Sand can harm circuit boards in different ways. Here are some common problems you might see:

Physical Abrasion: Sand can scratch and wear down circuit board surfaces. This can hurt delicate parts and connections.

Short Circuits: When sand gets inside, it can make unwanted connections. These short circuits can cause devices to fail or act strangely.

Corrosion: Sand often brings moisture and other dirt. When these mix with metal parts, they can cause rust over time.

Impact on Functionality

Sand can really hurt how well your electronic devices work. For example, sand can change the electrical properties of circuit boards. When sand touches the device, it creates static electricity from friction. This can change resistance values, making the circuit boards less reliable and stable.

You might see devices with sand acting strangely or not working at all. This is like what happens in microelectromechanical systems (MEMS). So, keeping sand away from your circuit boards is very important for their performance and lifespan.

By knowing the types of damage and their effects, you can take steps to protect your circuit boards from sand.

Sources of Sand Exposure

Environmental Factors

You can find sand in many different places. Here are some important things to think about:

Wind: Strong winds can blow sand far away. This can cause sand to land on your circuit boards, especially outside.

Desert Regions: If you live or work in a desert, sandstorms happen often. These storms can bring a lot of sand into your equipment.

Coastal Areas: Beaches and coastal places usually have sand in the air. Saltwater and sand can mix, making a harmful place for your circuit boards.

Tip: Always pay attention to your surroundings. If you are in a sandy area, take extra steps to protect your devices.

Industrial Settings

Some industrial places have more sand exposure. Here are a few examples:

Construction Sites: These places often have loose sand and dirt. Heavy machines can kick up dust, raising the chance of sand getting in.

Mining Operations: Mining can create a lot of sand and dust. Equipment in these areas is at high risk for sand damage.

Manufacturing Plants: Some manufacturing work creates sand-like particles. If you work in one of these places, make sure to have good protective measures.

By knowing where sand exposure comes from, you can take steps to protect your circuit boards. Being aware is the first step to keeping them safe.

Importance of Prevention

Long-term Benefits

Preventing sand damage to circuit boards has many long-term benefits. If you take steps now, your devices will work well for many years. Here are some important benefits:

Extended Lifespan: Using strong seals and UV-resistant materials can stop damage from sand and moisture. This helps your circuit boards last longer.

Early Vulnerability Detection: Checking seals and cooling systems regularly helps you find problems early. This is important for keeping circuit boards safe from sand.

Enhanced Durability: Using sealing methods with coatings that prevent rust makes your devices stronger against wind, sand, and moisture. This keeps them working well over time.

By focusing on these long-term benefits, you can avoid future problems and expensive repairs.

Cost Implications

Ignoring sand damage can lead to big money problems. Knowing these costs can help you want to invest in prevention. Think about these points:

Repair Costs: If sand gets into your circuit boards, repairs can be very costly. Fixing short circuits or replacing parts can add up fast.

Replacement Expenses: In bad cases, you may need to buy new circuit boards. This cost can be much higher than preventing damage in the first place.

Downtime Losses: If equipment fails because of sand damage, it can cause downtime. This loss of work can hurt your business and lead to lost money.

Investing in prevention not only keeps your circuit boards safe but also saves you money later. By being proactive, you can avoid high costs from damage and keep your devices in great shape.

Effective Protection Strategies

To keep your circuit boards safe from sand damage, you can use some smart strategies. These include using protective coatings, installing things correctly, and taking care of your equipment often.

Protective Coatings

Using protective coatings is one of the best ways to protect pcbs. These coatings form a shield that keeps sand and other dirt away from the circuit board. Different coatings have different strengths against sand wear. Here’s a look at some common coatings:

Coating | Durability | Resistance to Sand Abrasion |

|---|---|---|

P2 | Highest | Highest |

P1 | Lowest | Lowest |

P3 | N/A | Lowest |

Coating P2 is the top choice. It gives the best durability and protection against sand wear. The AHSW abrasion test shows that coatings put on by immersion work better. They lose less weight, meaning they fight off sand damage more effectively than other methods.

Installation Techniques

How you install things is very important for protecting your circuit boards. Here are some good practices to follow:

Elevate the Board: Keep the circuit board up high to avoid sand.

Seal Connections: Use seals to keep sand out of connections and parts.

Avoid Dusty Areas: Set up your equipment away from places with lots of sand and dust.

By using these techniques, you can greatly lower the chance of sand hurting your circuit boards.

Maintenance Practices

Regular care is key to stopping sand from building up on circuit boards. Here are some good routines to think about:

Regular Cleaning: Use compressed air to blow away dust and dirt. Make sure the air is dry to prevent more damage.

Cleaning Solvents: Use safe solvents like Isopropyl Alcohol for cleaning.

Soft Brushes: Use soft brushes to get rid of tough dirt, especially in small spaces.

Conformal Coatings: Put on a protective layer to guard the board from dirt.

Implement Enclosures: Use tight enclosures to keep out big particles and dirt.

Use Filters and Screens: Add filters to catch dirt and stop it from reaching the board.

By following these maintenance tips, you can keep your circuit boards clean and working well.

Getting Sand in a Circuit Board: Prevention Tips

Handling PCBs

You need to be careful when handling circuit boards. This helps stop sand from getting in. Here are some steps to follow for safety during transport and assembly:

Work in Clean Areas: Always work in clean places that do not have static materials.

Ground Yourself: Use wrist straps connected to the ground to stop static electricity.

Edge Handling: Hold circuit boards by their edges. This reduces the chance of contamination and damage.

Here’s a table that shows important handling steps:

Procedure | Description |

|---|---|

Designated Work Areas | Always work with circuit boards in clean, special areas. |

Cleanliness | Keep your work area tidy to avoid contamination. |

Enclosure | Store sensitive parts in protective bags or boxes when not in use. |

Grounding | Use wrist straps or heel grounders to stay grounded. |

Edge Handling | Hold boards by the edges to lower contamination risk. |

Avoiding Creams | Don’t use hand creams with silicone to stop contamination. |

Stacking | Don’t stack circuit boards to avoid physical damage. |

By following these steps, you can greatly lower the chance of sand getting into a circuit board.

Enclosures and Filters

Using enclosures is very important for keeping circuit boards safe from sand and other things in the environment. Enclosures act like barriers that stop dust and moisture from getting in. Here are some good materials for enclosures:

Plastic: Materials like ABS, polycarbonate, and polyethylene give good protection.

Metal: Aluminum and steel are strong and durable.

Composite Materials: Fiberglass Reinforced Plastic (FRP) and carbon fiber are great for lightweight uses.

When choosing materials, think about the environment, protection, and heat transfer.

Enclosure design features help resist sand by sealing and being strong. Seals, like sealing tapes or rings, can block sand from getting in. Advanced methods like multi-component molding and welding make the enclosure even better against environmental issues. By using these protective steps, you can help your circuit board systems last longer and work reliably.

Circuit Board Dirt Damage: Cleaning and Maintenance

Keeping your circuit boards clean is very important. It helps stop dirt damage. Sand can build up on circuit boards. This can cause problems with how they work. You can use different cleaning methods to get rid of sand without hurting the board.

Cleaning Methods

Here are some good ways to clean sand off:

Brushing: Use a small brush to gently clean dust and dirt from the circuit board. This helps you focus on certain spots without damaging sensitive parts.

Compressed Air: Blow dirt and dust out of tight spaces. Be careful with compressed air because too much force can hurt delicate parts.

Electronic Component Vacuum: Use special vacuums made for circuit boards. These vacuums safely suck up dirt without harming the board.

Different cleaning methods work better for different situations. For example, sandblasting is great for tough dirt and grime, especially on complicated surfaces. It works quickly, making it good for heavy cleaning. Ultrasonic cleaning is best for detailed boards because it uses bubbles to clean hard-to-reach spots. Gas phase cleaning is eco-friendly and uses steam from chemicals to dissolve dirt.

Here’s a summary of how well different cleaning methods work:

Cleaning Technique | Effectiveness Description |

|---|---|

Sandblasting | Great for tough dirt and grime, especially on complex surfaces. Works quickly. |

Ultrasonic Cleaning | Very effective for cleaning detailed boards due to bubbles, reaching hard spots well. |

Gas Phase Cleaning | Eco-friendly and good at dissolving dirt using steam from chemicals. |

Regular Maintenance

Cleaning and maintenance are key to stopping dirt damage on circuit boards. You should make a routine to keep your circuit boards in good shape. Here are some important practices to think about:

Schedule Regular Inspections: Look at your circuit boards often for dirt or damage. Finding problems early can help avoid bigger issues.

Implement a Cleaning Schedule: Set a time for cleaning your circuit boards based on how much sand and dirt they see. Regular cleaning helps keep them working well.

Use Protective Measures: Think about using protective coatings and enclosures to limit dirt exposure. These steps can really cut down on how often you need to clean.

By focusing on regular maintenance, you can make your circuit boards last longer and work reliably. Keeping them clean and well cared for will help you avoid expensive repairs and replacements later on.

Keeping your circuit boards safe from sand damage is very important. This helps them last longer and work better. Here are some key points to remember:

Sand can scratch surfaces, cause short circuits, and lead to rust.

Places like the outdoors and factories can have more sand.

Using protective coatings and handling boards carefully is very important.

Using these strategies can give you great benefits. For example, a big telecommunications company found that using Static Intercept bags protected their equipment for up to 15 years from rust and static electricity.

Always pay attention to your maintenance. Regular checks and cleaning can help you avoid expensive repairs. By being proactive, you can keep your devices working well for many years! 🌟

FAQ

What causes sand damage to circuit boards?

Sand damage mostly happens because of things like wind, desert storms, and coastal areas. Places like construction sites and mining operations also add more sand exposure.

How can I tell if my circuit board has sand damage?

Check for signs like scratches, strange device behavior, or rust on metal parts. Regular checks can help you find these problems early.

What protective coatings should I use?

You should think about using coatings like P2. They offer the best durability and protection against sand. These coatings help keep sand and moisture away, making your circuit board last longer.

How often should I clean my circuit boards?

You should clean your circuit boards often, especially in sandy places. Set up a cleaning schedule based on how much sand they see to keep them working well.

Can I use regular cleaning products on circuit boards?

No, don’t use regular cleaning products. Instead, use safe solvents like Isopropyl Alcohol and soft brushes to clean your circuit boards without hurting them.

See Also

Key Strategies to Enhance PCB Assembly Productivity

Effective Solutions for Overcoming PCBA Manufacturing Hurdles

Crucial Advice for Selecting the Ideal PCBA Main Board