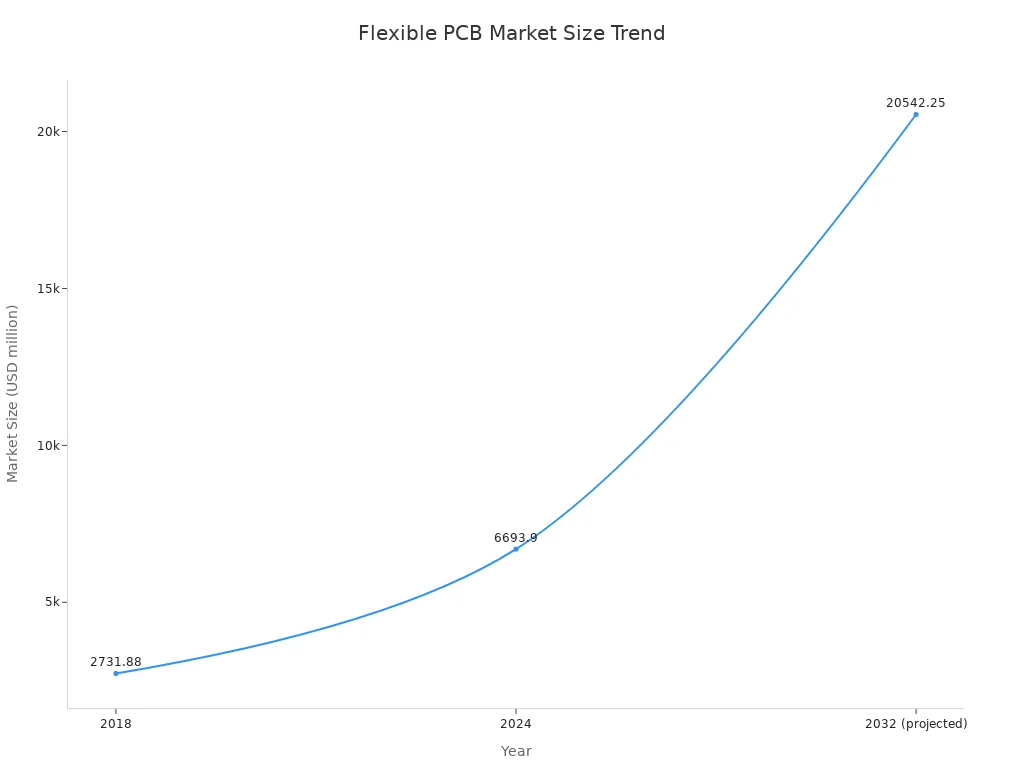

A Flexible PCB (FPCB) possesses the unique ability to bend and twist, conforming to various shapes, a distinct advantage over traditional rigid PCBs. These flexible circuit boards are now ubiquitous, serving as crucial connectors for electronic components and enabling the miniaturization essential for modern electronics. The market for flexible printed circuit boards is experiencing significant expansion, with projections indicating a growth of approximately USD 15.76 billion over the next five years, at a Compound Annual Growth Rate (CAGR) of 10.32%.

The market for flex PCBs is rapidly expanding, with experts forecasting a CAGR of 13.7% for flexible circuits from 2025 to 2030. This blog aims to clarify what is flexible PCB and delve into its primary characteristics. Flex PCBs are instrumental in the development of numerous innovative devices.

Key Takeaways

Flexible PCBs can bend and twist. They fit into small spaces. This makes electronics smaller.

Polyimide is a main material. It helps them bend. It also handles heat well.

Flexible PCBs offer many benefits. They make devices lighter. They allow for creative designs.

Flexible PCBs cost more. This is due to special materials. It is also due to more steps.

Many industries use flexible PCBs. These include phones. They are in medical devices. They are also in cars. They are in many daily items.

What is Flexible PCB: Definition and Core Concept

Understanding Flexible PCB Basics

A Flexible PCB is a circuit board. It can bend and twist. People call it an FPCB or flex circuit. It is different from stiff circuit boards. These boards can fit into many shapes. Special materials give them this ability. Manufacturers use flexible materials. Polyimide (PI) and polyester are common. Polyimide is very important. It makes the base of the PCB. This base is called the dielectric substrate film. This material bends easily. It also handles heat well. This makes the circuits flexible.

Here are some main materials. They give flexible PCBs their special traits:

Polyimide (Kapton) in different thicknesses (0.5 mil to 5 mils)

Adhesiveless copper clad base material (1 mil to 5 mils)

Flame retardant laminate, base material, and Coverlay

High performance epoxy laminate and prepreg

High performance polyimide laminate and prepreg

These materials let the boards bend. They can fit into small spaces. They can also fit special shapes. Cameras are one example. Wearable tech is another.

The Principle of Flexibility

Flex PCBs are flexible. This comes from their design. It also comes from their materials. Stiff PCBs use a fiberglass base. Flexible PCBs use plastic bases. This key difference lets them bend. They do not break. The wires are also different. Flexible PCBs use rolled annealed copper. It bends more easily. Stiff PCBs use electro-deposited copper.

This table shows key differences. It shows how manufacturers make flexible and rigid PCBs:

Feature | Flexible PCBs | Rigid PCBs |

|---|---|---|

Base Material | Flexible materials like polyimide | Non-conductive substrate, usually fiberglass |

Conductors | Rolled annealed copper (more flexible) | Electro-deposited copper |

Protection | Coverlays or other processes | Solder mask layer |

The bending radius is important. It is for flexible circuits. It is the smallest curve. A flexible PCB can handle it. It will not get damaged. A smaller radius means more flexibility. This shows how much a flex PCB can bend. It fits into electronic designs. This allows many uses. For single-layer flexible PCBs with 1 oz copper, the bend radius is 6-10 times the board thickness. For example, a 0.1 mm thick board. It might have a 0.6-1 mm bend radius. Multilayer designs need a bigger radius. It is often 12-20 times the thickness. This is because they are stiffer. Bending too much can crack copper traces. This causes open circuits.

The flex life shows something. It shows how many times a material can bend. It bends before it breaks. Different materials have different flex lives.

Material Type | Flex Life (Cycles) |

|---|---|

PI Film | >1,000,000 |

PET Film | >500,000 |

PEN Film | >800,000 |

LCP Film | >2,000,000 |

For example, PET film can bend. It bends over 1 million times. This is with a 1mm bend radius. This shows how strong these materials are. Knowing these features helps designers. They can make good electronic devices. These devices are small and reliable.

Flexible PCB Structure and Materials

Key Layers of FPCBs

Flexible PCBs have many layers. These layers work together. They make a circuit that can bend. The dielectric substrate is the main part. It keeps things separate. It also gives support. A copper layer goes on top. This layer makes paths for electricity. These paths connect parts. A protective layer covers the copper. This layer stops damage. It also stops electrical shorts. This simple design lets flex pcbs bend.

A single-layer flexible PCB is the simplest. It has one dielectric substrate. Copper paths are on one side. A protective cover then seals these paths. This design is simple. It costs less for many uses.

Common Flexible Substrate Materials

The substrate material is very important. It sets many traits of the board. Two materials are main choices. They are polyimide (PI) and polyester (PET).

Polyimide (PI): This is the most used substrate. It is a thin, soft plastic film. It bends very well. It also handles heat well. This means it works with high heat. This is good for things like soldering. Polyimide is also strong. It resists chemicals. Its size stays the same. It does not change much with heat or wetness. For example, it changes only ±0.02%. These traits make polyimide a top choice. It makes strong, good flexible circuits.

Polyester (PET): Polyester substrates cost less than polyimide. They bend well. They also resist tearing. But polyester does not handle heat as well. This limits its use. It cannot be used where there is high heat. This includes soldering. PET is good for uses. These uses do not need high heat. Cost is also a big factor. It keeps electricity separate. Its size stays the same.

Other materials exist. Fluoropolymer (PTFE) and Liquid Crystal Polymer (LCP) are examples. They are good for special flex pcbs. These materials offer better control. They absorb less water. They also resist heat better. This is for specific needs.

Conductors and Adhesives

Conductors and adhesives are key parts. They are in flexible PCBs. They make sure electricity flows. They also keep the structure strong.

Conductors: Copper is the most common material. It carries electricity. Different types of copper foil exist. They offer different benefits.

Material Type | Description |

|---|---|

Electro-deposited (ED) Copper Foil | This copper is made by plating. It is very pure. It can stretch well. This helps it bend. Its surface can be rough. This might affect signals. This happens at high speeds. |

Rolled Annealed (RA) Copper Foil | Makers make RA copper. They roll and heat it. This makes a smoother surface. It also makes it stronger. It can stretch more. RA copper is better for high speeds. It is also good for bending a lot. It resists breaking from bending. |

Low-profile (LP) Copper Foil | LP copper is a type of ED copper. It has a special finish. This makes its surface smoother. This helps stop signal loss. It also stops changes. This makes it good for high-speed uses. |

Ultra-thin Copper Foil | These foils are very thin. They are often less than 9 µm. They allow for very thin lines. They also allow for small spaces. This helps make flex pcbs smaller. It also makes them more packed. |

Adhesives: Adhesives stick the layers together. They are very important. They make strong, lasting bonds.

Epoxy Adhesives: These glues stick well. They are very stiff. They resist heat and chemicals well. Epoxy adhesives are less flexible. They are not good for constant bending. They work well when the circuit needs strong support.

Acrylic Adhesives: Acrylic adhesives bend more. They also resist the environment well. They are easy to use. They are less stiff than epoxy adhesives. They are good for flexible circuits. These circuits need to move and bend. Special acrylic adhesives are often chosen. They are for hot uses like soldering. They stop layers from coming apart. They also stop bubbles.

Pressure Sensitive Adhesives (PSA): These are easy to put on. They are good for quick, temporary sticking. But they do not resist high heat. They are not good for hot processes. Soldering is one example.

Modified Epoxy Adhesives: These are common. They are in multilayer circuits. They are also in rigid-flex circuits. They do not expand much with heat. Makers add polymers to them. This makes them more flexible. It also helps with Z-axis expansion. They stick very well. They absorb little water. They resist chemicals well.

FPCB Advantages and Limitations

Key Benefits of Flexible Circuits

Flexible PCBs have many good points. They make electronics better. They weigh much less. They can cut weight by 75%. This is compared to old wires. This helps drones and wearables. It also helps planes. These need to be light. They also handle heat well. Normal flexible circuits work from -40°C to 85°C. Special ones can take more heat. Polyimide flex pcbs can handle 150°C to 260°C. This wide heat range is a big plus. These are some main good points.

Design Freedom and Miniaturization

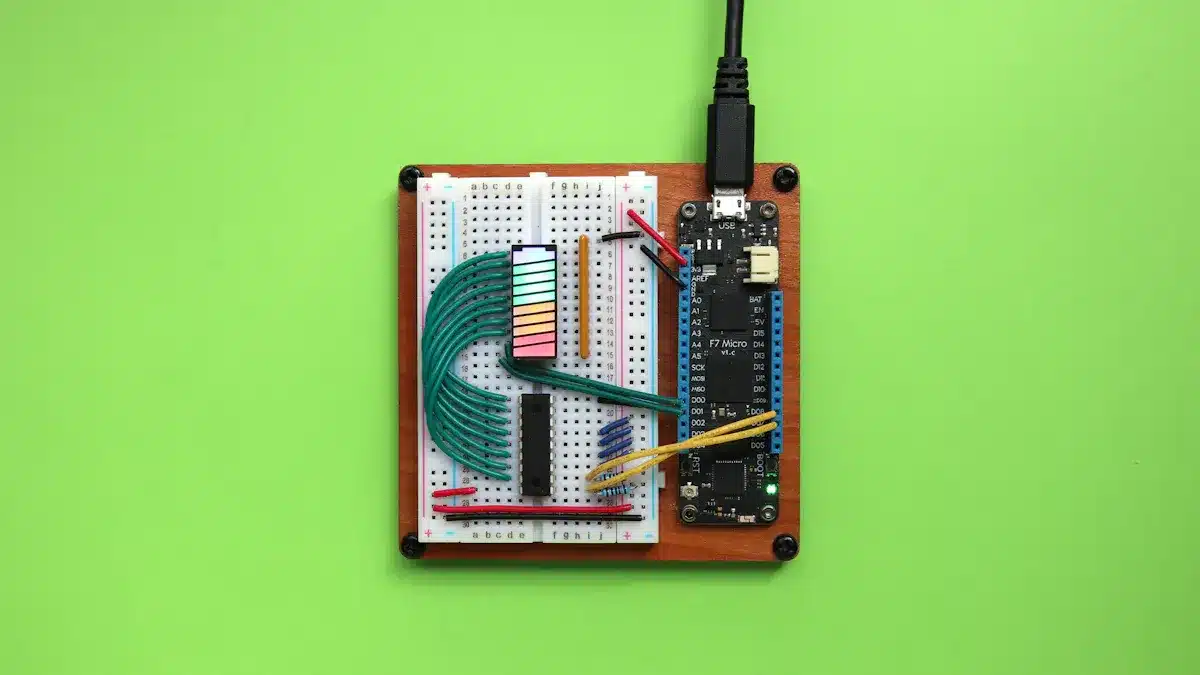

Flex pcbs let designers be creative. They fit circuits in small spots. Designers can use all the space. This is good for IoT devices. Flex circuits get rid of many wires. All parts can go on one flex PCB. This means fewer boards. Circuits can fold into devices. This makes devices smaller. Rigid-flex PCBs mix stiff and bendy parts. They are strong and useful. This makes them good for small devices.

Challenges and Considerations

Flex pcbs have some limits. Cost is a big one. Polyimide films cost more than fiberglass. This makes making flexible PCBs 2-5 times pricier. Making them also takes more steps. These include coverlay lamination and special drilling. This makes it harder. Design costs are also higher. Designers need to know about flexible circuits. They must think about how much they bend. This can make design costs 50-100% higher. Making them also has problems. Thin bases can cause issues when drilling. They can also cause problems when plating. Checking quality is harder. It is tough to find hidden flaws. These include layers coming apart. More flex pcbs get thrown out. It is 5-10% for flex pcbs. It is 3-5% for stiff PCBs. These bad points need careful thought.

Flexible Circuits: Types and Applications

Common Flexible Circuit Configurations

Flexible circuits come in different types. Each type works best for certain uses. Single-sided flexible circuits are the simplest. They have one layer that carries electricity. This layer is on a bendy plastic film. This makes them very flexible. They can bend very tightly. Single-sided flexible PCBs save money. They replace bundles of wires. This makes putting things together faster. It also lowers costs. These circuits are good for simple hookups. They work well in bendy screens. Examples are OLED and E Ink screens. They also fit flexible sensors.

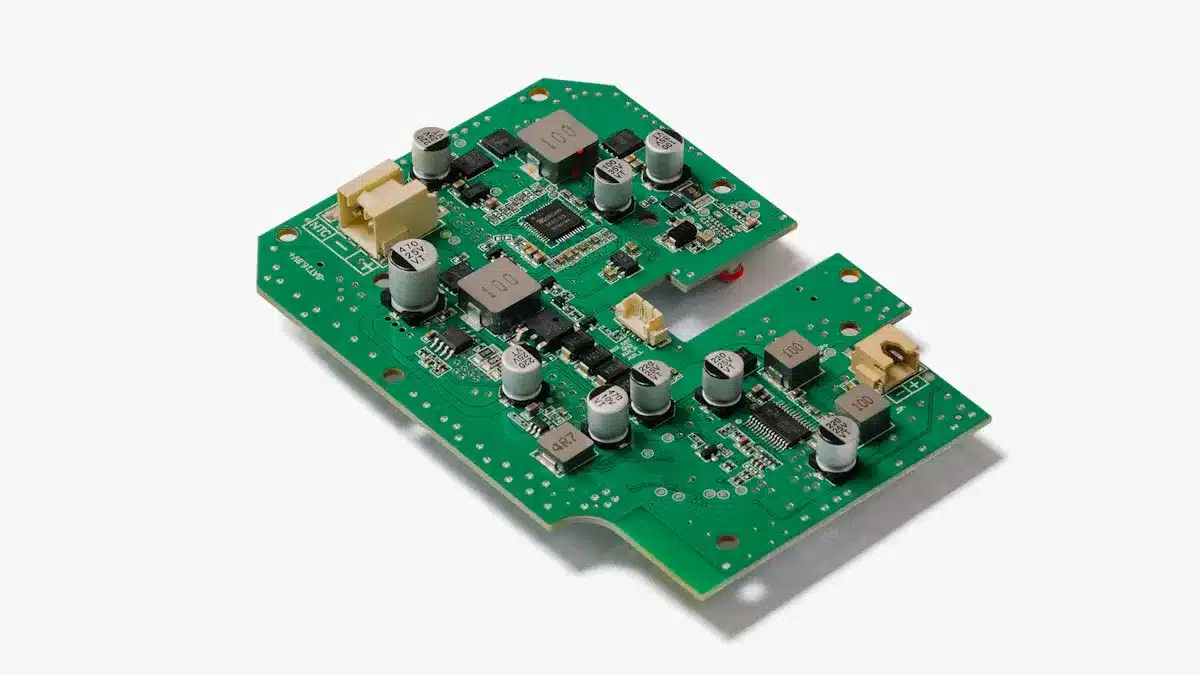

Multi-layer flexible circuits have three or more layers. These layers carry electricity. They are separated by insulation. They can handle complex designs. They also hold many parts. These circuits use stacked designs. They have complex connections. They keep signals clear. They stop signals from mixing. They also control electrical flow. These flexible electronics are thin. They are bendy and light. They allow for packed circuits. They also offer advanced wiring. They are used for fast data. They are also used in military planes.

Rigid-flex circuits mix two types. They have flexible and stiff parts. Flexible parts are joined to stiff boards. These flexible parts bend all the time. They form curves when made or put in. This design saves space. Designers can twist and fold them. This makes the final product the right shape. Rigid-flex circuits save space. They also weigh less. They are more reliable. This is because they have fewer connections. They are great for small, complex devices. They are strong where needed. They are bendy in other spots.

Industries Using Flexible PCBs

Many industries use flexible PCBs. These industries like their special features. Consumer electronics use them. They are in phones and tablets. They are also in smartwatches. These products have little room. Medical devices also use them. Examples are hearing aids. Pacemakers use them too. Their bendiness and small size are key. Cars use flex PCBs. They are in dashboards and sensors. These parts must handle tough places. Airplanes use them in satellites. They are also in aircraft. Being light and small is very important. Factories use them in robots. They are also in automation. Here, being flexible and strong matters. The flexible PCB market keeps growing. It grows in all these areas.

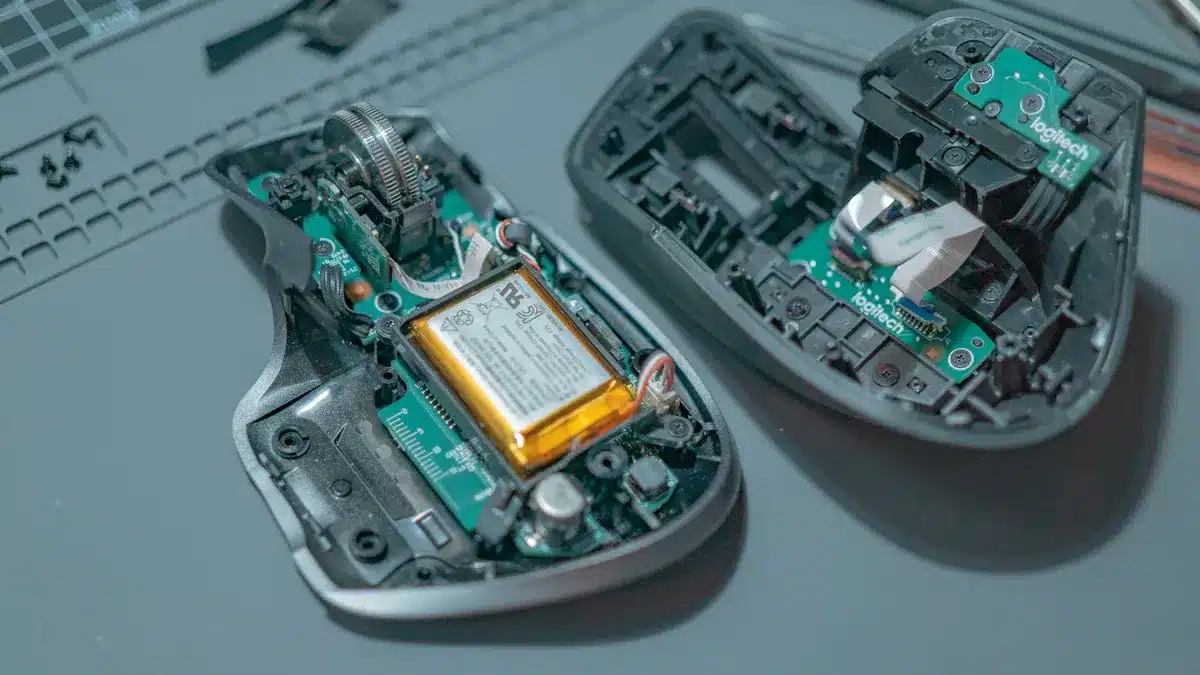

Everyday Device Examples

Flexible circuits are in many daily items. Phones use them in screens. They are in camera parts. They are also in batteries. Foldable devices use them a lot. Samsung’s Galaxy Fold is one example. Wearable tech also uses flex PCBs. Smartwatches and fitness bands fit well. This is because of flex PCBs. Medical monitors use them. Pacemakers use them for reliability. Car parts also use flexible circuits. Infotainment systems use them. Sensors and lights have them. Taillights use flexible PCBs. Cabin lights also use them. Digital cameras use this tech. Airplanes use them in panels. They are also in navigation systems. These common uses show how much flex PCBs are used.

This blog told you what a flexible PCB is. These circuits can bend and twist. They use bendy stuff like polyimide. This makes them thin. They are also light. And they last a long time. Flex PCBs are key for new electronics. They help make small designs. They also help make new designs. Many businesses use them. This includes phones. It includes health devices. It also includes cars. This tech keeps getting better. It will bring even more new electronics.

FAQ

What makes flexible PCBs different from rigid PCBs?

Flexible PCBs use bendy stuff. Polyimide is one example. Rigid PCBs use stiff stuff. Fiberglass is one example. This lets flexible PCBs bend. They can twist. They fit many shapes.

Why do manufacturers often choose polyimide for flexible PCBs?

Polyimide is a good choice. It bends well. It handles hot temperatures. It also fights chemicals. These things make it great. It makes strong, bendy circuits.

What are the key benefits of using flexible PCBs in electronic devices?

Flexible PCBs have good points. They make things smaller. They make things lighter. They give more design choices. They can handle very hot or cold. This makes products better.

Are flexible PCBs more expensive to produce than rigid PCBs?

Yes, flexible PCBs cost more. Their materials cost more. Polyimide is one example. Making them takes more steps. This makes the total cost higher.

See Also

Exploring Flexible PCBA: Benefits and Hurdles in Contemporary Electronics

Deciphering PCBA: Core Definition and Essential Uses in Electronic Devices

Grasping PCBA Coating: Fundamental Principles and Diverse Classification Types

PCBA Unveiled: A Comprehensive Explanation of Its Core Meaning

Defining PCBA: Unpacking Its Crucial Significance in Electronic Systems