A potentiometer is an electrical part. It works like a variable resistor. This part lets people change resistance in circuits. Many circuits use potentiometers. This post looks at the good and bad things about using potentiometers this way. Knowing these things helps design circuits well. It also helps pick the right parts. A pot variable resistor is flexible. Potentiometers are useful tools. This potentiometer gives exact control. Potentiometers are still very important.

Key Takeaways

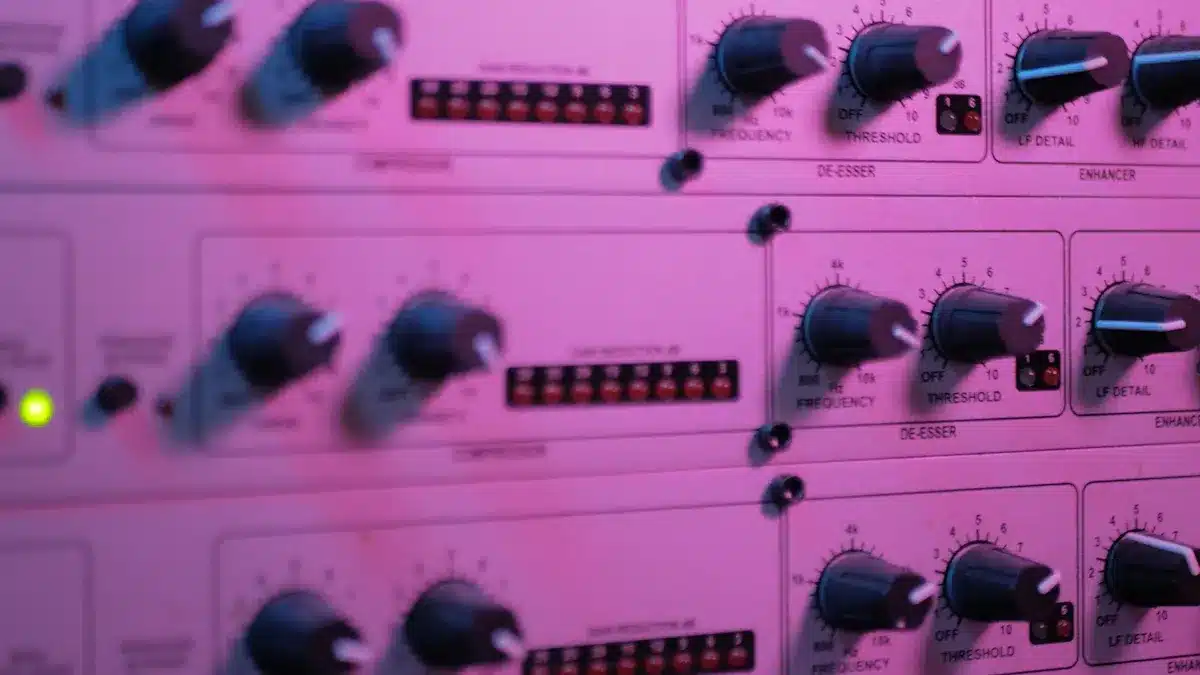

Potentiometers are simple parts. They let you change resistance in a circuit easily. They are good for things like volume knobs.

Potentiometers are cheap and easy to use. They give smooth control. They do not need extra power to work.

Potentiometers have moving parts. These parts can wear out over time. They can also make electrical noise when you use them.

Potentiometers are not good for very exact control. They are also not good for high-power circuits. They can be too big for small devices.

Choose potentiometers for simple, manual adjustments. For very exact or high-power needs, other parts might work better.

Potentiometer as a Variable Resistor

Defining the Potentiometer

A potentiometer is an important electronic part. It has three terminals. A resistive track is inside. A wiper slides on this track. This movement changes the electrical path. Engineers use it to change resistance. Or they use it to change voltage. People often mix up “potentiometer” and “variable resistor.” Knowing the difference is key. A potentiometer can become a variable resistor. This happens when wired right. Potentiometers are basic for many controls. They give simple, direct control. They are easy to find. They work in many electronics. This includes audio gear and factory controls. This makes the potentiometer a main part.

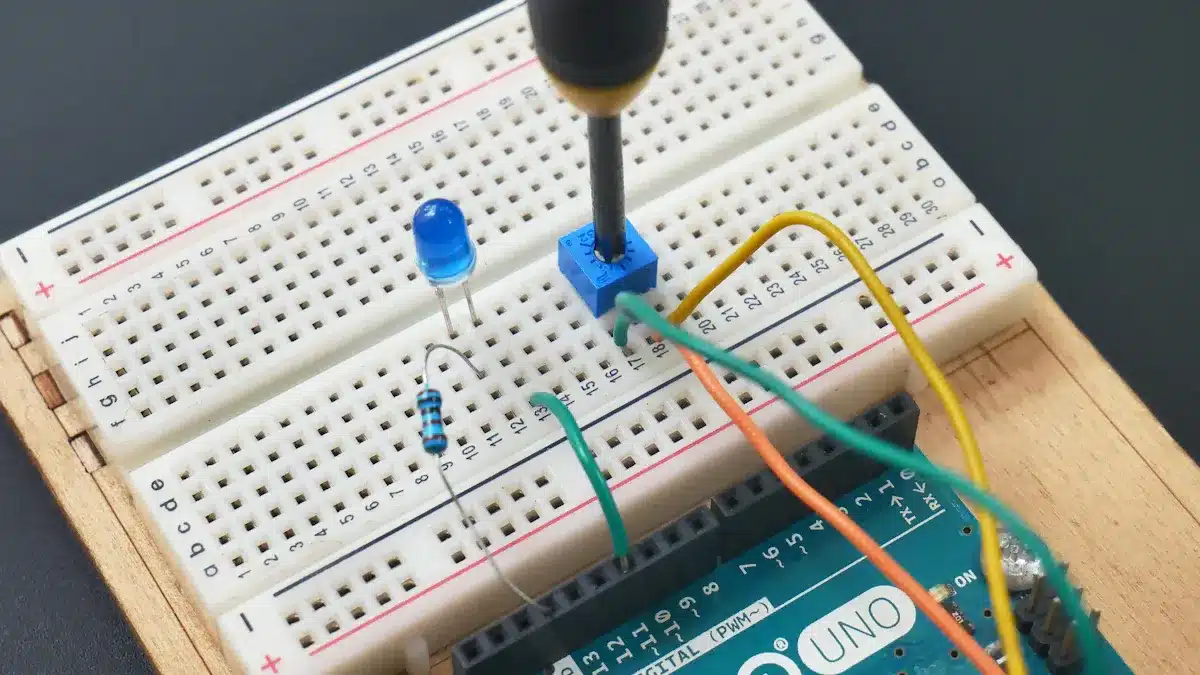

Basic Circuit Setup for Variable Resistance

To use a potentiometer as a variable resistor, engineers wire it a certain way. This is called the rheostat setup. A potentiometer has three terminals. For variable resistance, one outer terminal connects to the circuit. The middle wiper terminal also connects. The third outer terminal can be open. Or it can connect to the wiper. This makes a two-terminal device. The wiper moves on the track. The resistance between the two connected terminals changes. This gives adjustable resistance. For example, turning a knob changes resistance. This simple setup makes it a good pot variable resistor. It allows exact control over current. Or it controls signal strength. Potentiometers offer an easy way to add variable resistance. They are vital for many designs. They work well. They are still liked for manual changes. They are easy to use and give instant feedback.

The Good: Advantages of Potentiometers

Potentiometers have many good points. They are simple. They are cheap. They give smooth control. These advantages make them popular. They are used in many electronic designs. A pot variable resistor works simply.

Simple Design and Easy Use

Potentiometers have a very simple design. Engineers can easily put them in circuits. Users can turn a knob. Or they can slide it. This changes things directly. It feels natural to use. Users get instant feedback. This ease of use is a big plus. It makes circuits much simpler. The potentiometer directly controls adjustable resistance.

Cost-Effective Solution

Potentiometers are very cheap. They cost less than digital controls. They are a low-cost way to change resistance. Many projects use them. Their low price helps budgets. This makes them a good choice. A potentiometer is affordable. This helps it be used everywhere. This is why they are still popular.

Smooth Analog Adjustment

Potentiometers make changes smoothly. They allow exact tuning. Think of volume knobs. Or light dimmers. An analog potentiometer changes things without steps. This exactness is good for sensors. These applications use this control well. Digital steps are not always as smooth.

Wide Resistance Range

Potentiometers come in many resistance values. This wide range fits many applications. Designers can pick the best one. This flexibility is a big plus. It helps match circuit needs. This wide choice means a part exists for almost any job.

Proven Technology and Availability

Potentiometers are old technology. Engineers have used them for years. They are reliable. People understand them well. Many are made. They are easy to buy. Most electronic stores have them. These advantages make them a common part. Potentiometers are reliable. This shows their good design.

No External Power Needed

Potentiometers are passive parts. They do not need power to work. This makes circuit design easier. It also saves power. This helps devices that use batteries. The potentiometer works without extra power. This is different from active parts.

Potentiometer vs Variable Resistor

They are often used the same way. But the potentiometer has special advantages. This is when it acts as a variable resistor. It has a strong mechanical part. This makes it a top choice. The potentiometer design allows many uses.

The Bad: Disadvantages of Potentiometers

Potentiometers have some bad points. This is true even with their good points. These bad points can limit their use. They may not work for some jobs. Knowing these bad points helps engineers. They can pick the right parts.

Mechanical Wear and Tear

Potentiometers have moving parts. A wiper moves on a track. This movement causes rubbing. Over time, parts wear out. The track can get bad. The wiper can get weak. This wear makes the part not last long. Moving it a lot makes it wear faster. It can break or not work right. So, they are not good for jobs. These jobs need many quick changes.

Electrical Noise Generation

Potentiometers can make noise. This noise gets into the circuit. It often happens when you move it. The wiper moves on the track. This makes a “sliding noise.” This noise comes from inside. Engineers see this noise. It happens when the part moves. It is only steady when still. Noise can also be on the lines. This happens even with no motors. Motors can also send noise back. This changes its readings a lot. This noise can harm sensitive systems.

Limited Precision and Repeatability

It is hard to get an exact value. You move it by hand. This is not very exact. Users may find it hard. They cannot set a value perfectly. It is also hard to go back. You cannot get the same value again. This limits its use. It is not good for very exact jobs. Digital parts are better. They are more exact. For important changes, this is a big problem.

Physical Size Constraints

Potentiometers are often big. They are bigger than new digital parts. This can be a problem. Small circuits cannot use them. Designers must think about size. Common sizes are 9mm, 12mm, 16mm, and 24mm. Shafts are 10mm to 20mm long. Shafts are often 6mm or 6.35mm wide. These sizes make them too big. They do not fit small devices. When space is tight, size is a big issue.

Power Dissipation Limitations

Potentiometers have power limits. They can only handle so much power. Too much power makes them hot. Getting too hot can break them. Many common ones are 1/2W or 1W. Small ones are about 200 mW. Power ratings are 0.05 W to several watts. This limits their use. They cannot be used in high-power jobs. Designers must check the rating. It must match the circuit’s power.

Environmental Susceptibility

Potentiometers are weak to nature. Dust, wetness, and shaking can hurt them. Dust makes them work badly. It makes them not last long. This is true for open designs. These designs get dust and water. This causes bad signals or breaks. Sealed ones protect against nature. They have a cover. This stops dirt and wetness. The QXJR part has IP65 protection. This stops dust and water. For dusty places, use special ones. These have strong covers. They have IP65 or better.

Temperature Drift Issues

Heat changes can make values shift. This is called temperature drift. A number shows how much it shifts. It is parts per million per degree. Heat changes can make carbon ones shift. This hurts how the circuit works. Plastic ones shift about -1000 ppm/°C. This shift can make circuits unstable. For heat-sensitive jobs, designers may fix this. They might use more stable types. This is key when comparing parts. This is for places with changing heat.

When to Use Potentiometers

Ideal Applications for Potentiometers

Potentiometers give simple control. They are great for volume knobs. Light dimmers use them well. Simple sensors use them to set things. Basic voltage dividers have them. These are common uses. Designers pick them for instant analog output. This avoids digital delays. They are cheap. This makes them good for big systems. They are easy to add. This makes them good for old systems. They are small. They fit well in some uses. Industries like aerospace and medical use them. They are used for important jobs. They are exact, cheap, and easy to use.

Situations to Avoid Potentiometers

But, designers should not always use them. They are not good for very exact circuits. Their moving parts limit exactness. Bad factory places are a problem. Dust, water, and shaking can hurt them. High-power jobs are too much for them. They can get too hot. Digital ways are better for remote control. These are more flexible. Digital parts give better control here. Knowing good and bad points helps engineers. This makes for good circuit design. Potentiometers are not always best. They work for hand adjustments. But for automatic or exact jobs, other parts are better. Engineers think about good and bad points. They pick the right part. Potentiometers are still useful. They are a simple answer. They are good for many interactive designs. But their limits push designers to digital for complex systems. Potentiometers have a special place. They give a touch interface. People often like this for using devices. Many devices still use them. They are a trusted way to change settings. Engineers think about each project’s needs. Then they decide if potentiometers fit. This careful choice makes good designs. Potentiometers still do many jobs. They are a basic part. Many designs still gain from them.

Potentiometers are simple. They cost little. They give smooth control. These good points make them useful. But potentiometers also have bad points. They wear out. They make electrical noise. They are not super exact. A pot variable resistor is easy to use. It changes resistance cheaply. But they have moving parts. So, they work best for certain jobs. Knowing good and bad points is key. This helps design circuits well. It helps pick parts. Potentiometers are still helpful. Designers pick them carefully.

FAQ

What is the main difference between a potentiometer and a variable resistor?

A potentiometer has three terminals. It can work as a variable resistor. You wire it in a special way. It uses only two terminals then. This lets it control current. Or it controls resistance in a circuit.

Can these devices handle high power?

No, they cannot handle high power. Most types have low power ratings. They are often 0.5 to 1 watt. Too much power makes them hot. They can then break. For high-power jobs, use other parts.

Why do potentiometers sometimes create electrical noise?

Electrical noise often happens. It is when the wiper moves. It moves across the track. This can stop the signal. Or it changes resistance. These changes make unwanted signals. This noise is louder in audio circuits.

Are potentiometers suitable for very precise control?

They offer smooth changes. But exact settings are hard to get. You move it by hand. This is not as exact as digital. For very accurate settings, other parts are better.

See Also

Exploring Flex PCBA: Benefits and Hurdles in Today’s Electronics World

The Essential Role of Inverter Circuits in Modern Power Electronics Explained

Understanding the Key Distinctions Between Active and Passive Electronic Components

Streamlining Your Electronics Projects: A Guide to Fast PCBA Assembly

PCBA Prototypes: Essential Insights and Practical Applications for Development