Why PCBA Test Fixtures Are Crucial for Electronics Production

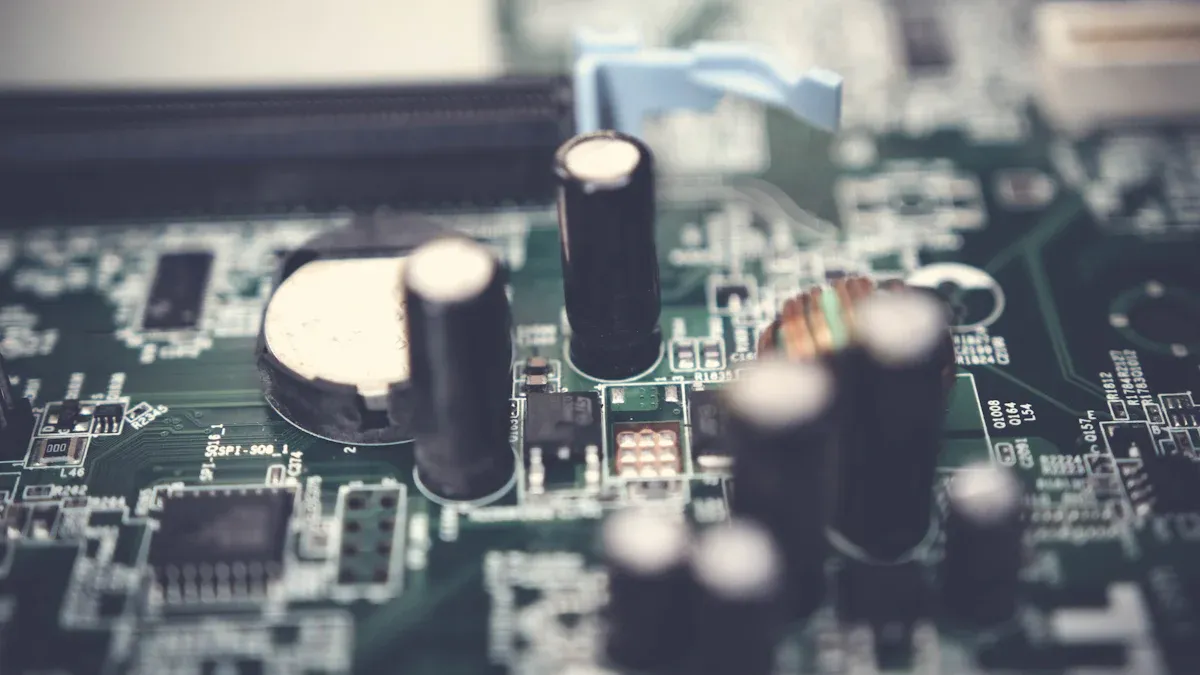

PCBA test fixtures ensure PCB quality by detecting defects, verifying functionality, and streamlining production, making them vital for electronics manufacturing.

PCBA test fixtures ensure PCB quality by detecting defects, verifying functionality, and streamlining production, making them vital for electronics manufacturing.

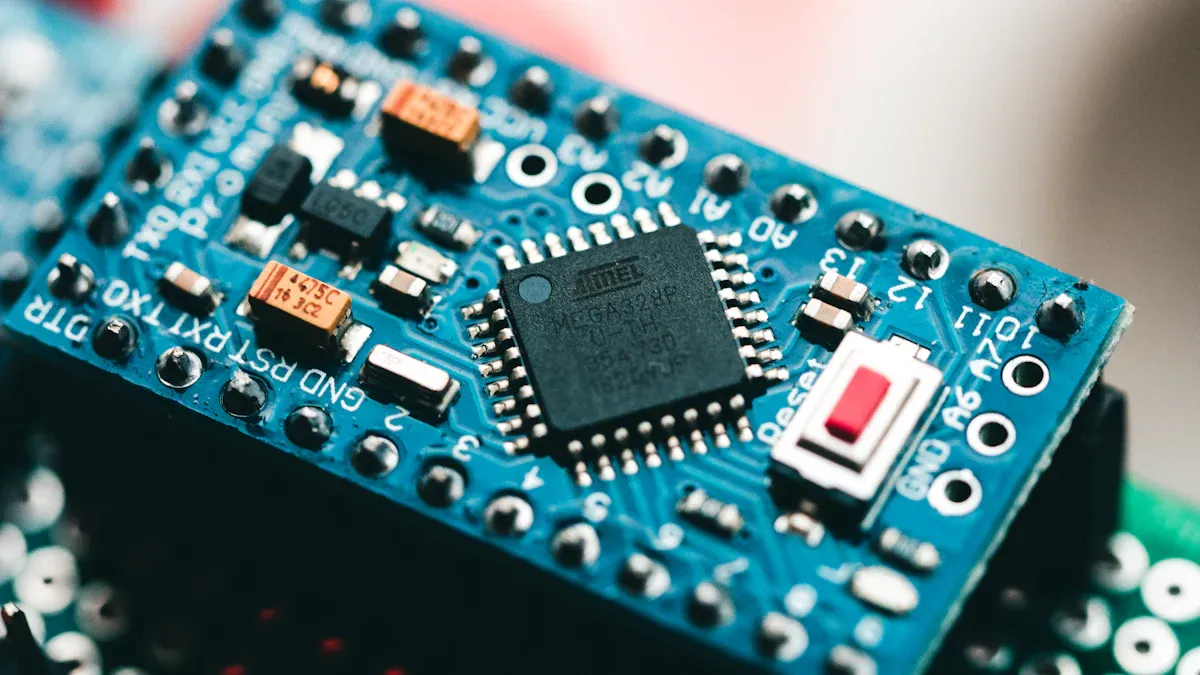

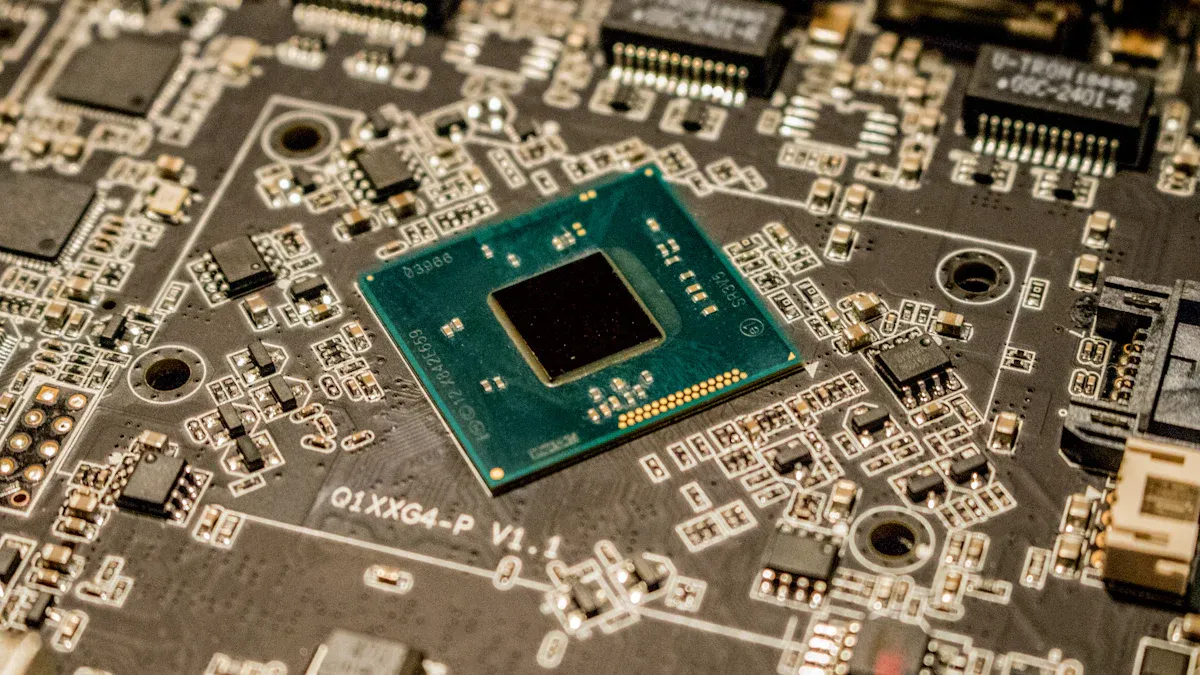

PCBA vs PCB: A PCB is a bare board with copper traces, while a PCBA includes mounted components, making it a functional electronic system.

PCBA is vital in modern electronics, enabling compact designs, reliability, and innovation in devices like phones, wearables, and electric cars.

Overmolded PCBA offers superior protection, durability, and design flexibility compared to potting, conformal coating, and traditional housings.

Understand the key differences between PCB and PCBA circuit boards. Learn when to use each for your project and how they impact functionality and cost.

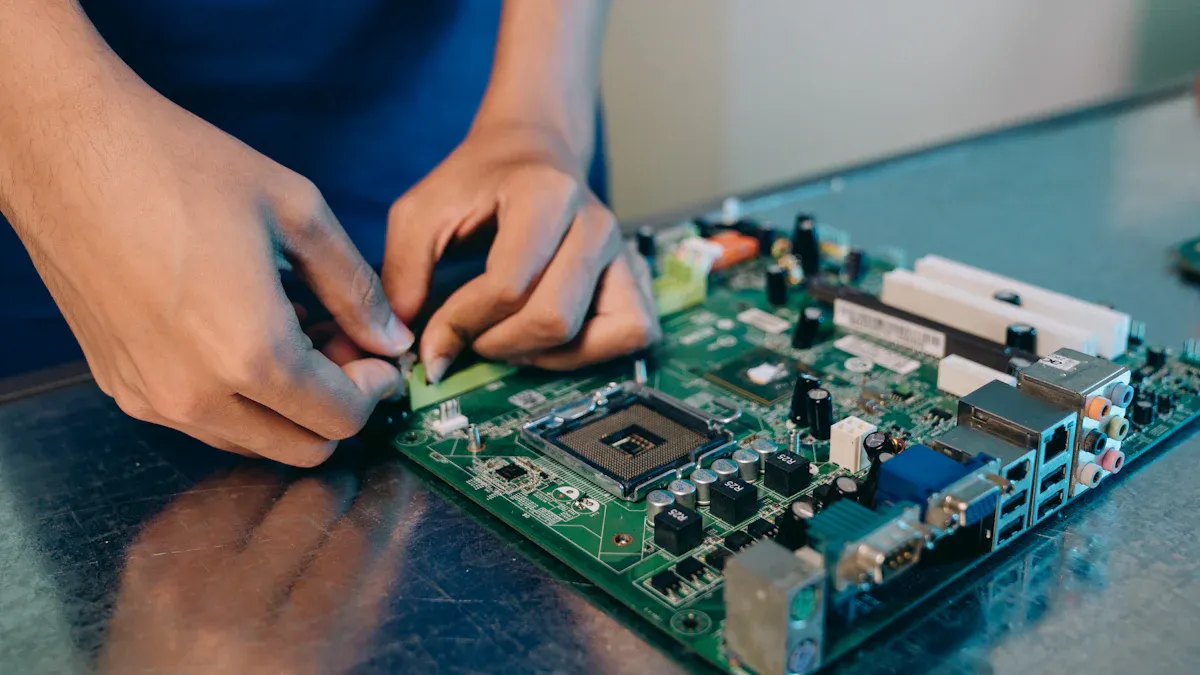

Find the right PCBA manufacturer by evaluating quality, certifications, pricing, and scalability to ensure your business success and meet project demands.

PCBA prototyping is vital for modern electronics, enabling early error detection, cost savings, and faster innovation while ensuring reliable product designs.

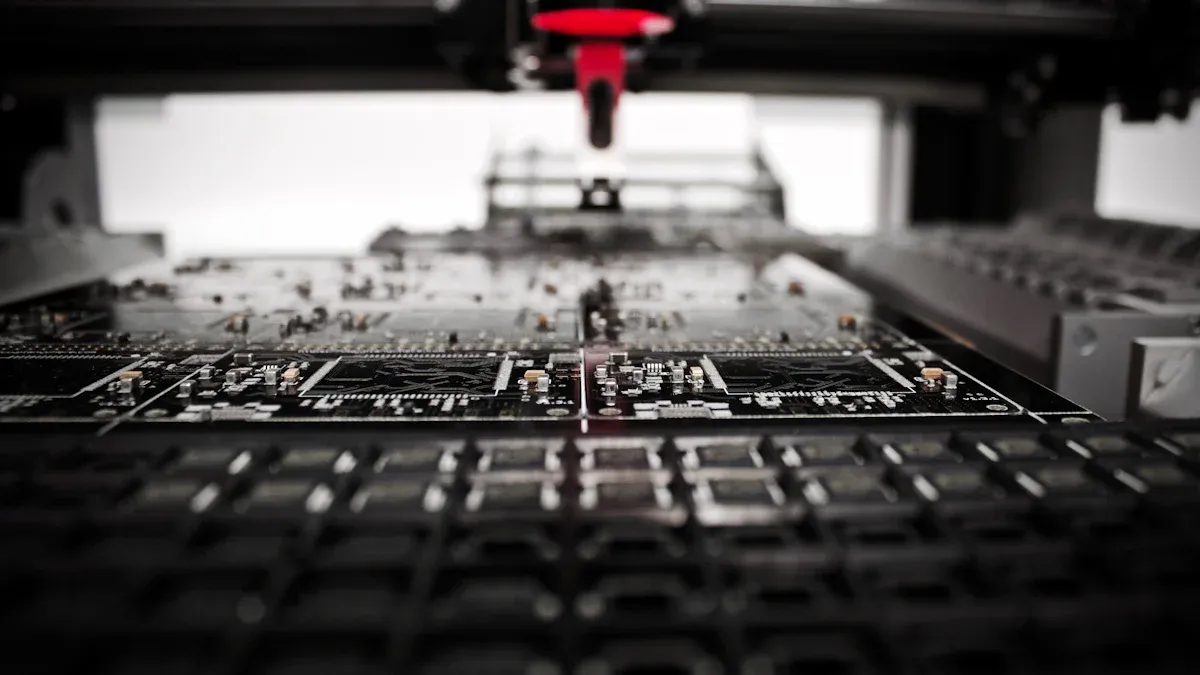

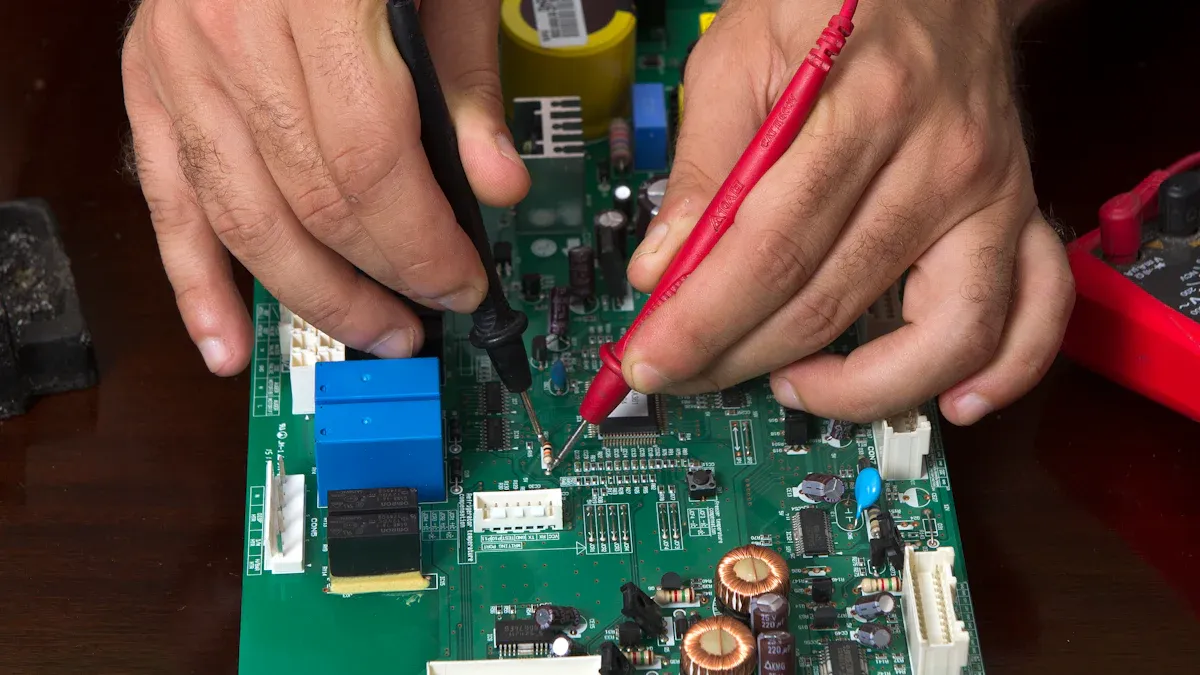

Automate PCBA test processes to boost accuracy, reduce costs, and enhance efficiency. Learn key steps and tools for seamless manufacturing integration.

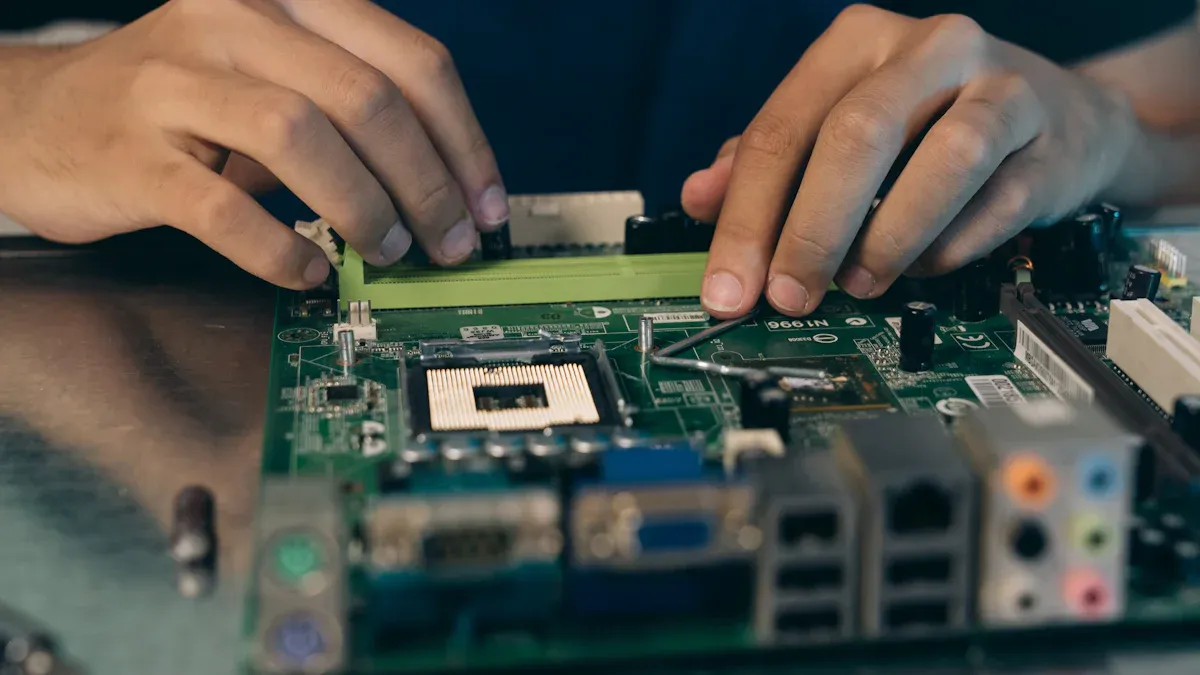

PCBA services involve assembling components onto PCBs, ensuring reliable, high-quality electronics manufacturing for industries like automotive and healthcare.

PCBA meaning: Printed Circuit Board Assembly is vital in electronics, enabling devices like phones, medical tools, and cars to function efficiently and reliably.