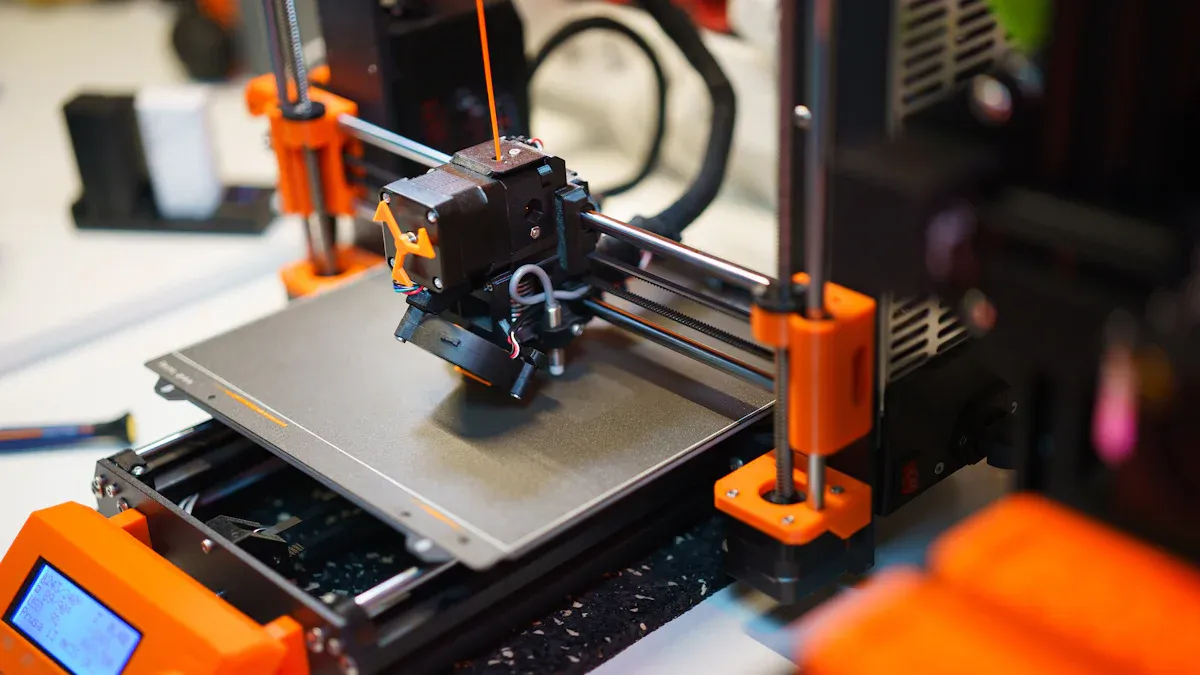

Why Custom 3D Printed Circuit Boards Matter

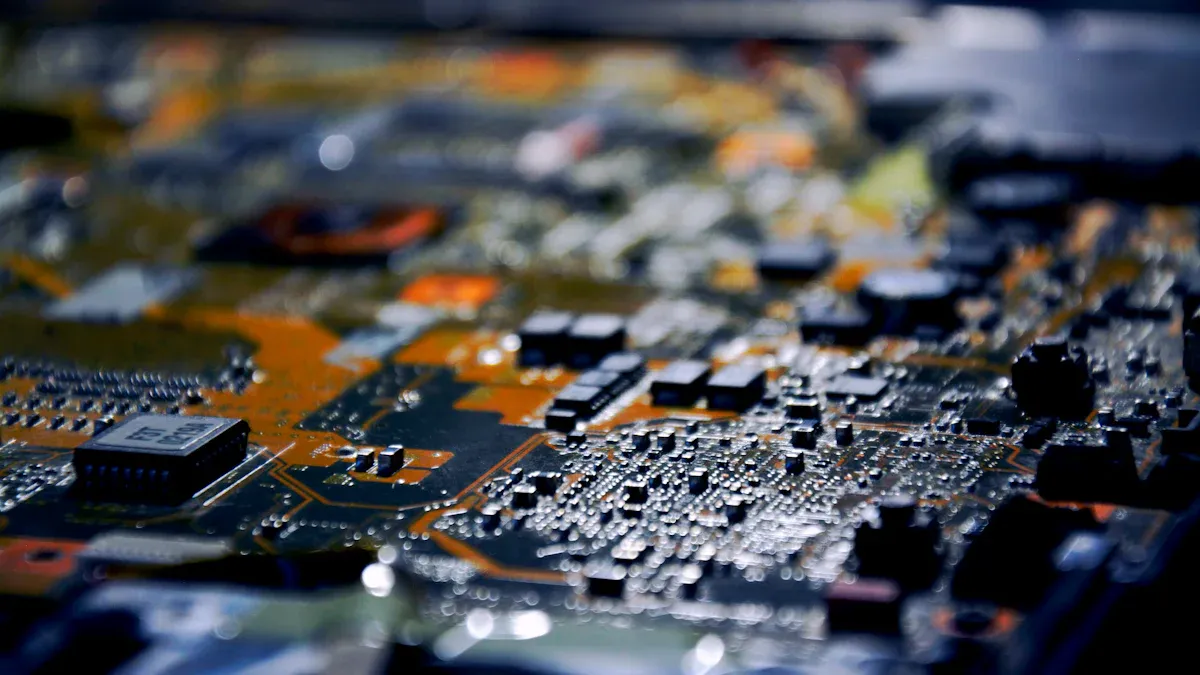

Custom 3D printed circuit boards enable faster prototyping, eco-friendly manufacturing, and innovative designs, revolutionizing electronics production.

Custom 3D printed circuit boards enable faster prototyping, eco-friendly manufacturing, and innovative designs, revolutionizing electronics production.

Advancements in additive manufacturing for PCBA in 2025 enable faster prototyping, multi-layer designs, flexible circuits, and eco-friendly production methods.

3D printed electronics USA enable custom designs using conductive materials. Applications include healthcare, aerospace, and IoT, revolutionizing manufacturing.

Compare water-soluble flux and no-clean flux in PCB assembly. Learn how cleaning, reliability, and costs differ for water-soluble flux PCBA assembly.

Sustainable electronics manufacturing in the USA reduces e-waste, uses eco-friendly materials, and promotes energy-efficient production for a greener future.

Energy-efficient PCBA manufacturing reduces costs, cuts waste, and lowers emissions. Discover how green practices enhance sustainability and profits.

Low VOC conformal coating PCBA enhances PCB protection, reduces VOC emissions, ensures compliance with regulations, and improves workplace safety.

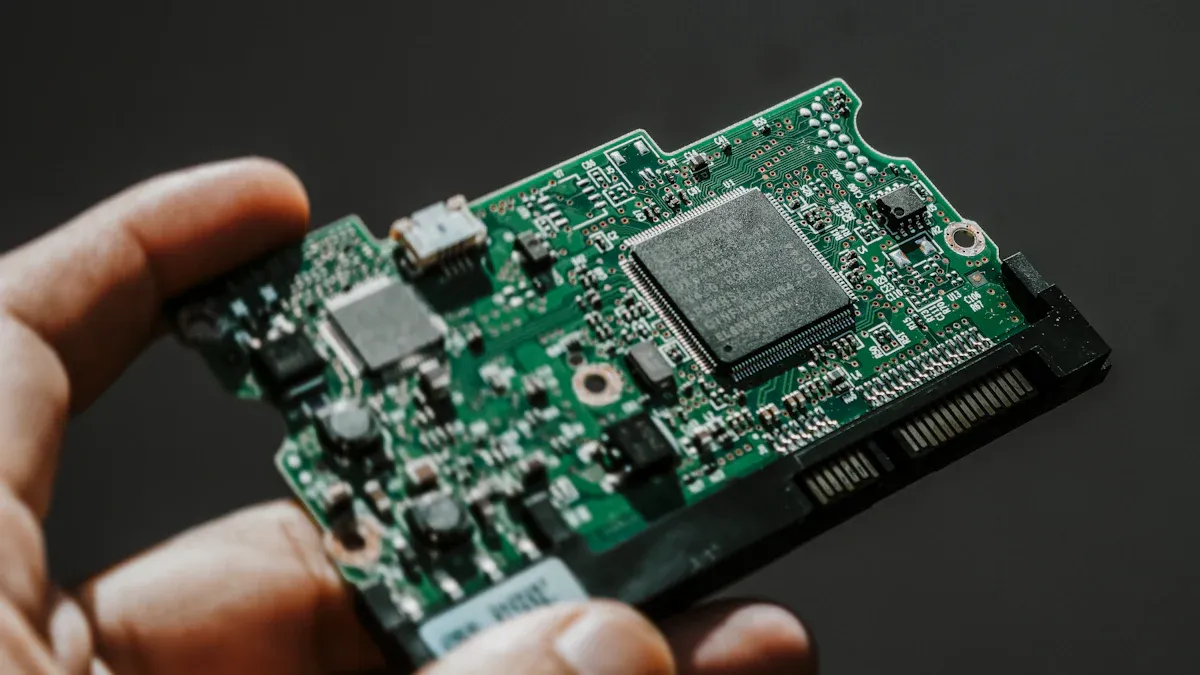

Recyclable PCB assembly processes reduce e-waste, conserve resources like copper and gold, and lower environmental harm, making them vital for sustainability.

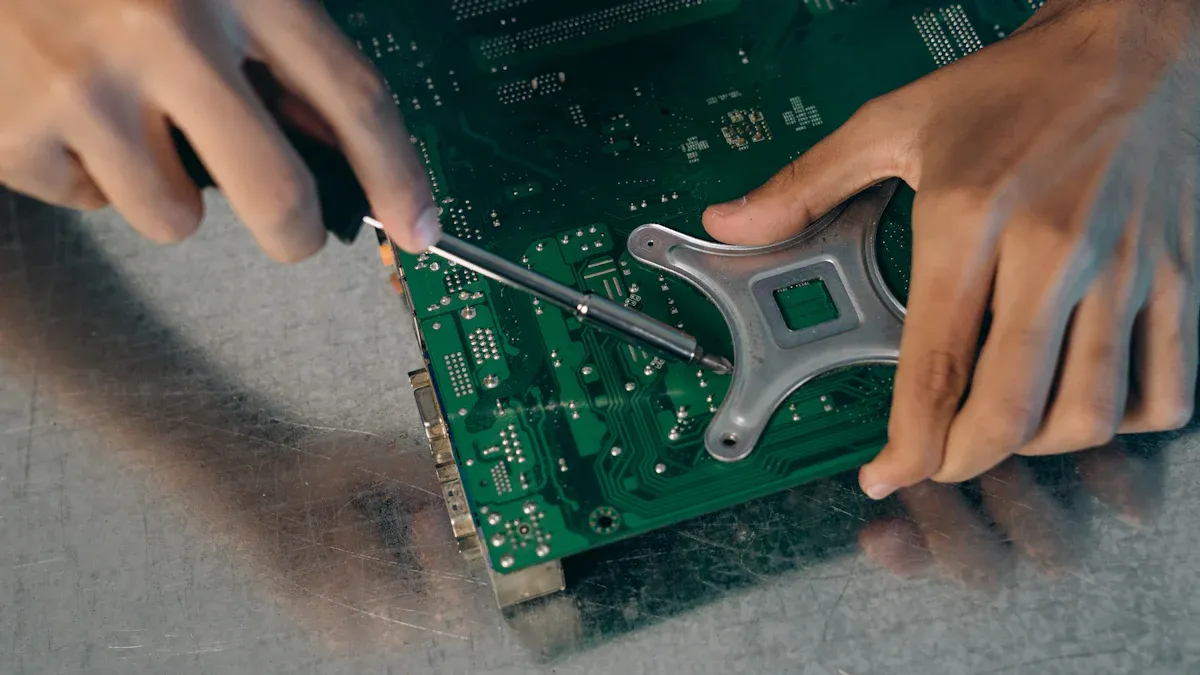

Choose the best prototype to production PCBA services provider by evaluating technical expertise, certifications, quality assurance, scalability, and cost-effectiveness.

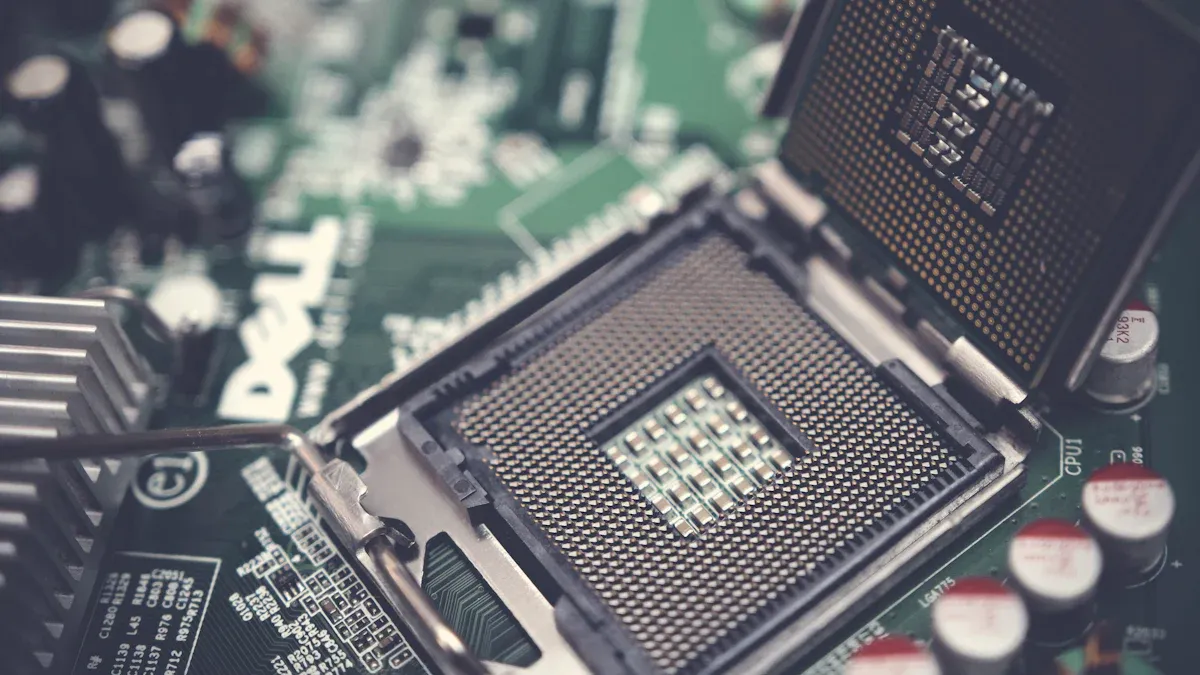

High-density interconnect (HDI) PCBA offers better performance, space-saving designs, and reliability, making it superior to traditional PCBs for modern electronics.