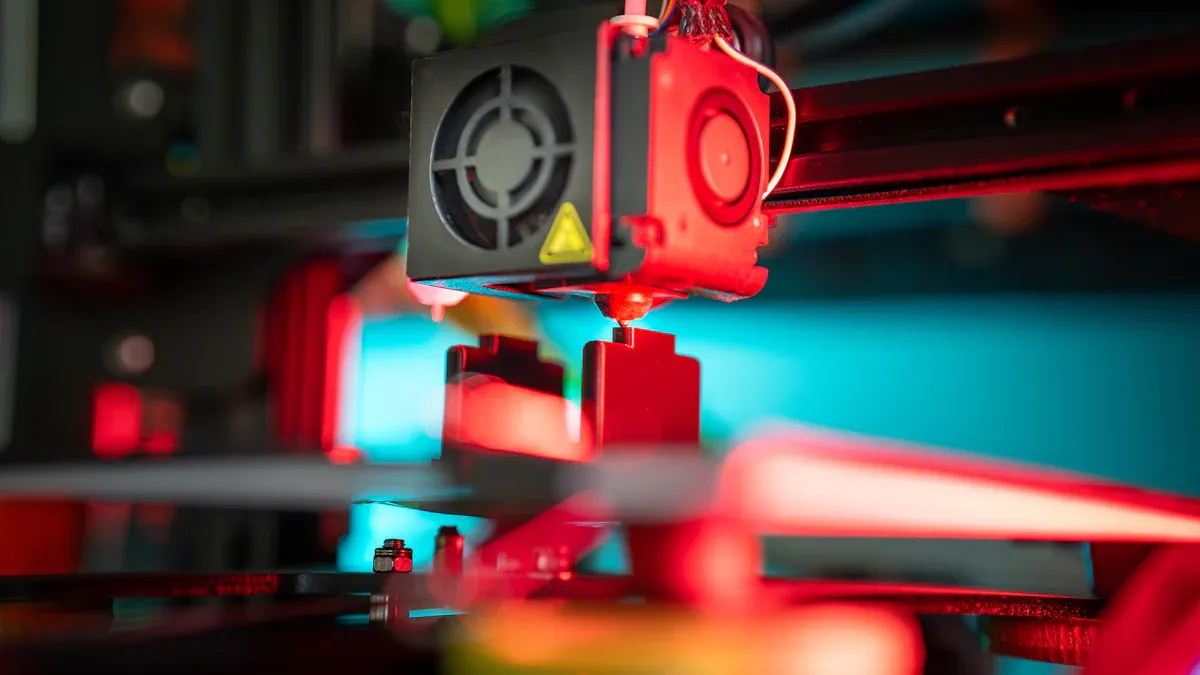

3D printed electronics in the USA utilize 3D printing technology to manufacture electronic devices. This innovative method combines conductive materials with printed shapes, enabling the creation of lightweight and customized designs. In the USA, this technology is enhancing various industries.

The global market for 3D printed electronics USA is projected to reach $4.3 billion by 2034, growing rapidly at a rate of 15.8% each year.

Sectors such as aerospace and consumer electronics are seeking more affordable and smarter devices. 3D printed electronics in the USA have the potential to revolutionize manufacturing processes.

Key Takeaways

3D printed electronics use special materials and 3D printers. This helps make lightweight and custom designs.

Experts think this technology will grow fast. It may reach $4.3 billion by 2034. It is important for new ideas in many industries.

3D printing cuts down on waste. It uses only needed materials and helps the environment by making things locally.

It is used in healthcare, space, and gadgets. These show how it can make personal and smart solutions.

People can now use 3D printed electronics at home. They can easily design and make their own cool gadgets.

What Are 3D Printed Electronics?

Definition and Concept

3D printed electronics are a new way to make devices. This method uses additive manufacturing to add conductive materials into 3D shapes. It combines the accuracy of 3D printing with the use of electronics. This creates exciting and creative designs.

Recent improvements have made this process very flexible. For example:

Plastics mixed with copper, carbon, or graphene are often used.

Parts like resistors, antennas, and sensors can be made.

Special inks help build working circuits quickly.

Uses include testing ideas, making prosthetics, and creating complex shapes.

This process skips old assembly steps. It lets you make devices with special shapes and built-in electronics.

Key Features and Advantages Over Traditional Methods

3D printed electronics have many benefits over older ways of making things.

Material Efficiency: Unlike cutting methods, 3D printing uses only what’s needed. This reduces waste and helps the environment.

Eco-Friendly Materials: Some printers use biodegradable materials like PLA, made from plants. This makes 3D electronics greener.

Localized Production: Electronics can be made closer to where they’re needed. This lowers shipping costs and pollution.

This technology is also great for custom designs and accuracy:

On-Demand Production: Items can be made when needed, saving storage space and money.

Mass Customization: Designs can change fast to meet customer needs.

High Precision: Industries needing tiny parts benefit from 3D printing’s accuracy.

Quality Assurance: Digital checks catch mistakes before printing, ensuring good results.

The step-by-step building of 3D printing gives control and reliability. This makes it perfect for tasks where older methods don’t work well.

How Do 3D Printed Electronics Work?

Additive Manufacturing Process Overview

3D printing for electronics uses additive manufacturing to build items. It creates objects layer by layer with materials like conductive inks and plastics. Unlike older methods that cut or mold, this process only uses what is needed. This saves materials and reduces waste.

In 3D electronics, structural and conductive materials work together. For example, plastic forms the device’s body, while conductive ink makes the circuits. This method allows for creating complex designs that older techniques cannot achieve.

Techniques Used in 3D Printed Electronics

Different methods make 3D printing for electronics more effective. Scientists have improved these techniques for better accuracy and speed. For example, Washington State University used AI to adjust printing settings. This helped create detailed designs like flexible electronics and wearable sensors.

Evidence Description | Details |

|---|---|

Study Focus | |

Key Findings | Better designs for flexible electronics and wearable sensors |

Research Institution | Washington State University |

Publication | Advanced Materials Technologies |

AI Technique Used | Bayesian Optimization |

Benefits | Faster, cheaper, and more efficient 3D printing |

These improvements make it easier to create high-quality 3D electronics faster and at a lower cost.

Step-by-Step Creation Process

Making 3D printed electronics follows clear steps. Each step ensures the product works as planned.

Step | Description | Numerical Data |

|---|---|---|

1 | Material preparation | N/A |

2 | Printer setup | N/A |

3 | Printing layers | N/A |

4 | Post-printing cleanup | N/A |

5 | Final testing | N/A |

Prepare materials: Choose conductive inks and other materials for your design.

Set up the printer: Adjust settings like heat and layer size.

Print the object: The printer builds the item layer by layer.

Clean up the product: Remove extra material and check its function.

Test the product: Make sure it works as designed.

This step-by-step process ensures reliable and creative 3D printed electronics.

Materials and Machines in 3D Printed Electronics

Conductive Materials and Bases

To make 3D electronics, strong and conductive materials are needed. Conductive inks, made from silver, copper, or carbon, are key. These inks help create detailed designs like circuit boards. They can be printed on flexible plastics, ceramics, or biodegradable bases. Special resins that handle high heat are also popular. These are great for advanced uses like soldering without lead.

Mixing materials is another big step forward. For instance, nano-copper paste with lasers lowers resistance. This improves how well electricity flows. These materials help make circuits stronger and more efficient.

Types of 3D Printers and Tools

Different 3D printers are used for making 3D electronics. Inkjet printers place conductive inks very precisely. Aerosol Jet Printing (AJP) is another method. It creates tiny lines, as small as 5–10 μm, for detailed work. Some machines combine methods, like SLA with inkjet printing and laser drilling. These can make complex circuit boards in less than two hours.

Other tools, like plasma systems, make layers stick better. This ensures the final product is strong and works well.

New Ideas in Materials and Machines

New materials and machines are changing 3D printed electronics. Eco-friendly materials, like biodegradable plastics, help the planet. Stronger alloys and metal powders handle heat better, useful in aerospace. Composite filaments let you make parts with special features.

AI is also improving the process. It adjusts settings and fixes mistakes for faster, better printing. Multi-material ideas, like adding copper layers or LDS antennas, mix performance with design. These changes make 3D electronics easier and more useful.

Applications of 3D Printed Electronics in the USA

Healthcare Innovations

3D printed electronics are changing healthcare by making better medical tools. These include wearable sensors, prosthetics, and devices made for each person. Electronics are built into these tools, making them light and useful.

For example, health monitors use soft circuits to check heart rate and blood pressure. These monitors are comfy and easy to wear for a long time. Prosthetics also benefit from 3D printing. They can be made to fit each patient perfectly.

This technology helps create new medical devices faster. Researchers can test ideas quickly, saving time and money. With 3D printed electronics, doctors can offer cheaper and more personal solutions.

Aerospace and Defense Applications

The aerospace and defense industries use 3D printed electronics for big improvements. This method makes strong, light, and detailed parts that old ways can’t.

Key Uses in Aerospace and Defense:

Application Type | Description |

|---|---|

Functional Prototyping | Testing designs before making them fully. |

Jigs and Fixtures | Special tools to help in building parts. |

Lightweighting | Making parts lighter for better performance. |

Fuel Savings | Lighter parts mean using less fuel. |

Maintenance | Easier repairs with custom-made parts. |

Production Components | Directly making parts for planes. |

Unconventional Components | Unique designs not possible with old methods. |

For example, companies like TITAL GmbH use 3D-printed patterns for casting. This makes designs more accurate and flexible, perfect for planes. Big planes use 3D printing to combine parts into one piece. This lowers weight, costs, and fuel use.

By using 3D printed electronics, aerospace and defense improve performance and help the planet. Lighter parts mean less fuel, making flying greener.

Consumer Electronics and IoT

In the USA, 3D printed electronics are changing how gadgets and IoT devices are made. This tech helps create cool, useful, and eco-friendly products.

How 3D Printed Electronics Are Changing Consumer Electronics:

Designers can quickly test and improve products.

Small businesses can make custom gadgets without big factories.

3D printing uses less material, which is better for the planet.

Imagine designing and printing your own smart gadgets at home. With 3D printing, this is possible. IoT devices like smart thermostats and fitness trackers are made faster and better with this tech.

This method also allows for custom designs. You can make items like a special phone case or a wearable device that fits just right. By using 3D printed electronics, gadgets are becoming smarter, greener, and more creative.

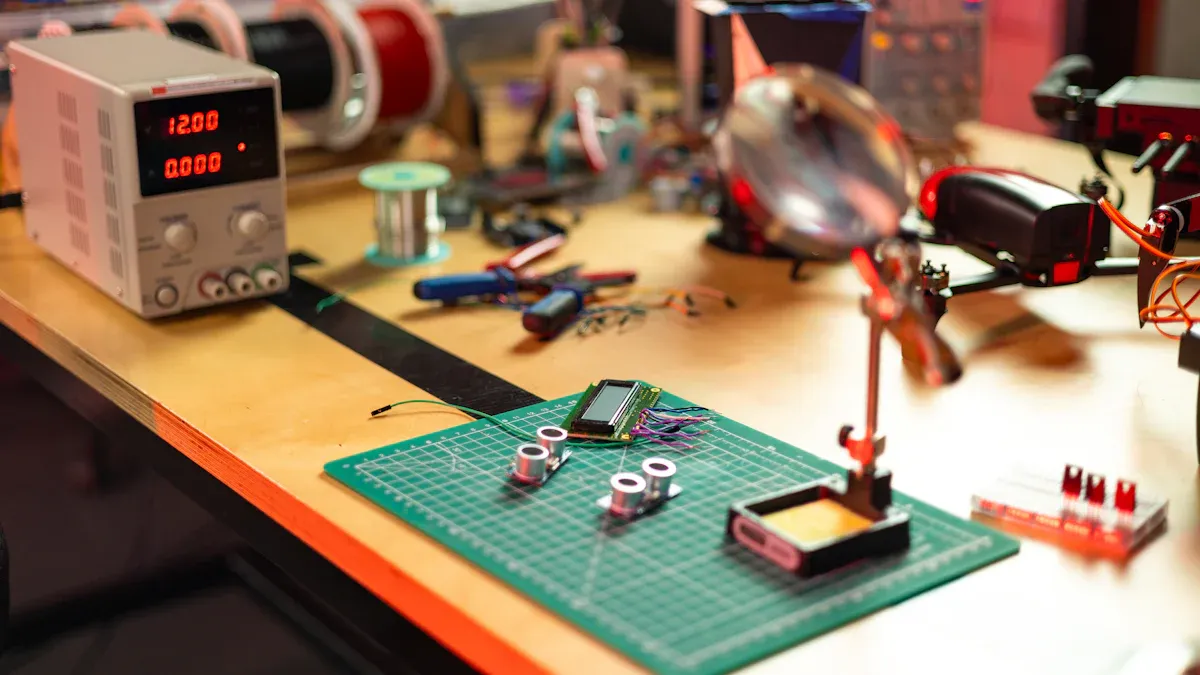

Research and Educational Use Cases

3D printed electronics are changing how people learn and research in the USA. This technology is now used in schools, labs, and programs to teach and inspire. It helps students and teachers try new ideas and learn better.

How 3D Printed Electronics Are Used in Education

Teachers use 3D printed electronics to teach STEM subjects like science and math. This hands-on method makes learning fun and useful. Students can see how circuits work or even create their own devices.

Here are some ways 3D printing helps in education:

Showing students how 3D printing works.

Making teaching tools for classrooms.

Creating models and prototypes for lessons.

Building devices to help students with disabilities.

Inspiring kids through fun outreach activities.

These uses make learning more engaging and easier for everyone.

Benefits for Research

In research, 3D printed electronics help test ideas quickly. Scientists use it to make prototypes and study new designs. For example, a project with future teachers showed that 3D printing improved their skills and confidence in teaching science.

Universities and labs use this technology to explore advanced topics. They can make custom tools or devices for specific experiments. This saves time and money while speeding up discoveries.

Why It Matters

3D printed electronics help people learn faster and think creatively. They make hard ideas easier to understand. This technology also prepares students for jobs in fields like healthcare and aerospace.

Whether you’re a student, teacher, or scientist, 3D printed electronics bring new opportunities. They make learning exciting and help create new inventions.

Benefits and Challenges of 3D Printed Electronics

Customization and Rapid Prototyping

3D printed electronics let you make unique, custom designs. You can create devices for specific needs, like personal gadgets or industrial tools. For example, a wearable device can be made to fit perfectly. Sensors can also be designed for special environments. This ability to customize opens up many new ideas.

Another big benefit is rapid prototyping. You can quickly turn ideas into real objects. This speeds up how fast you can test and improve designs. Instead of waiting weeks, you can see results in just days. This saves time and helps fix problems early, using fewer resources.

Cost Efficiency and Scalability

3D printed electronics help save money in different ways. Traditional methods need expensive molds and tools. With 3D printing, you only need a printer and materials. This lowers starting costs and reduces waste, saving even more money.

It’s also easy to scale production with 3D printing. You can make small batches without spending a lot. This is great for startups or small businesses. If demand grows, you can produce more without big changes to your setup.

Technical and Material Limitations

There are some challenges with 3D printed electronics. One problem is the limited choice of materials. Conductive inks and plastics work well but may not suit tough jobs. For example, some materials can’t handle high heat or heavy use.

Another issue is the precision of 3D printers. They are getting better but may not match traditional methods for detailed designs. Problems like weak layers can also affect product strength. These challenges show why more research is needed to improve this technology.

Sustainability and Accessibility of 3D Printed Electronics

Environmental Benefits

3D printed electronics are better for the environment. They combine electronic parts into materials, removing the need for separate circuit boards. This makes smaller designs that use fewer materials. Smaller and lighter devices need less energy to make and ship. This helps make the process more eco-friendly.

Also, using fewer materials makes recycling easier. While separating materials can be tricky, new recycling methods are improving this. Studies show 3D printed electronics leave a smaller environmental impact than older methods.

Here are some main benefits:

Smaller designs mean less material waste.

Lighter devices save energy during shipping.

Better recycling makes reusing parts simpler.

By using 3D printed electronics, you help the planet while enjoying cool technology.

Challenges in Sustainability

Even with benefits, making 3D printed electronics fully eco-friendly is hard. Recycling items with many materials is tough because separating them is tricky. But dissolvable layers can help. They allow up to 90% of the materials to be reused. This cuts environmental harm by over half.

Problem | Solution | Result |

|---|---|---|

Hard to recycle mixed-material items | Use dissolvable layers for easy reuse | ~90% of materials recycled, cutting harm by 50%. |

To solve these problems, focus on:

Using biodegradable or common materials instead of rare ones.

Reducing e-waste by reusing old parts.

Using advanced tools to make reusable designs.

Fixing these issues makes 3D printed electronics greener and better for the Earth.

Home Use and Accessibility

3D printed electronics are now easier to use at home. Affordable printers and simple software let you make your own devices. You don’t need big factories to create custom gadgets anymore.

Imagine making your own smart devices, like fitness trackers or phone cases. You can design them to fit your needs perfectly.

Here’s why home use is growing:

Cheaper printers make it affordable for more people.

Easy software makes designing simple.

Custom designs let you create items just for you.

Using 3D printed electronics at home opens up endless creative ideas. This tech makes inventing fun and inspires new creators everywhere.

3D printed electronics use additive manufacturing and conductive materials to make new devices. This method builds items layer by layer, allowing for precise and custom designs. Industries like healthcare and aerospace in the USA are changing because of these applications.

Tip: Think about creating and printing your own smart gadgets at home. This technology makes it possible!

The ability of 3D printed electronics to change how things are made and used is huge. Learning about this field can help create smarter, greener, and easier-to-use inventions for the future.

FAQ

What are the main benefits of 3D printed electronics?

3D printed electronics let you make custom designs fast. They help reduce waste and save money. This technology also supports eco-friendly ways of making things.

Can you use 3D printed electronics at home?

Yes, you can! Cheaper printers and easy software make it simple. You can create gadgets like phone cases or smart devices. It’s a fun way to be creative and try new ideas.

What materials are used in 3D printed electronics?

Common materials include conductive inks made from silver or copper. Plastics, ceramics, and biodegradable bases are also used. These materials make designs strong, flexible, and better for the planet.

Are 3D printed electronics environmentally friendly?

Yes, they use less material and energy to make things. Smaller and lighter designs lower shipping pollution. Recycling is getting better, making this technology greener over time.

What industries benefit most from 3D printed electronics?

Healthcare, aerospace, and electronics industries gain a lot. Examples include wearable health sensors, light airplane parts, and custom smart devices. These industries use 3D printing to improve and innovate.

See Also

The Significance of Custom PCBA Production in Today’s Electronics

Benefits and Drawbacks of Flex PCBA in Today’s Electronics

Streamlined PCBA Solutions for Quick Electronics Projects

Why PCBA Manufacturing Skills Are Crucial for Electronics Design

Exploring EMS and PCBA Offerings for Contemporary Electronics