Automated optical inspection for PCBA utilizes smart cameras and advanced software to identify mistakes on circuit boards during the manufacturing process. This technology is crucial for ensuring that every board meets high-quality standards. With the electronics industry growing over 6% each year, the demand for effective inspection methods has surged. Automated optical inspection for PCBA significantly reduces false error rates by up to 70%, making it essential for the rapid production of various products. Companies that implement AI-powered automated optical inspection for PCBA experience a 30% increase in efficiency, enabling them to achieve consistent results and maintain the reliability of their products.

Key Takeaways

Automated Optical Inspection (AOI) uses smart cameras to spot errors on circuit boards, making sure products are high quality.

Adding AOI can boost production speed by 30%, helping companies keep up with the growing electronics market.

AOI systems are 99.7% accurate, finding tiny mistakes that people might not see, saving both time and money.

Using AOI lowers the need for manual checks, cutting costs over time and keeping quality steady.

Mixing AOI with other tools, like X-ray, helps find more defects and makes products even better.

What is Automated Optical Inspection for PCBA?

Definition and purpose of automated optical inspection

Automated optical inspection (AOI) is a smart technology. It checks printed circuit board assemblies (PCBA) for mistakes during production. AOI uses special cameras and software to take clear pictures of PCBs. These pictures are analyzed to find problems like missing parts or soldering errors. This ensures every board meets strict quality rules before moving forward.

AOI does more than just find mistakes. It helps make the manufacturing process better. Catching problems early saves time and money by avoiding rework or waste. AOI also gives useful feedback to improve production and prevent repeated errors. This makes it a must-have tool in electronics manufacturing today.

Importance of AOI in the PCBA process

In PCBA, accuracy and quality are very important. AOI checks every step of the assembly process carefully. Unlike human inspection, which can miss things, AOI is consistent and reliable. This is especially important in industries like cars, planes, and gadgets, where small mistakes can cause big problems.

AOI uses smart algorithms to study images and spot issues. It can find problems like solder bridges or misplaced parts. It also ranks problems by how serious they are, so fixes can be prioritized. Adding AOI to your process improves accuracy and ensures top-quality products.

The need for AOI is growing fast. By 2024, the AOI market could reach $1.16 billion, growing at 20.7% yearly. This shows how important AOI is for better quality control and faster production.

Key role of AOI in modern electronics manufacturing

AOI is very important in making modern electronics. As devices get smaller and more complex, precise inspections are needed. AOI offers fast and accurate checks to meet these demands.

One big benefit of AOI is finding mistakes that humans might miss. For example, it can spot parts standing on one end or dirt on the board. These problems can harm how devices work if not fixed. AOI catches them early, helping you make reliable products.

New technologies like AI and IoT make AOI even better. They allow real-time problem detection and process improvements. This reduces waste and boosts efficiency. AOI is now a key part of modern electronics manufacturing, ensuring high-quality products and driving innovation.

How Does AOI PCB Inspection Work?

Image capture and optical scanning process

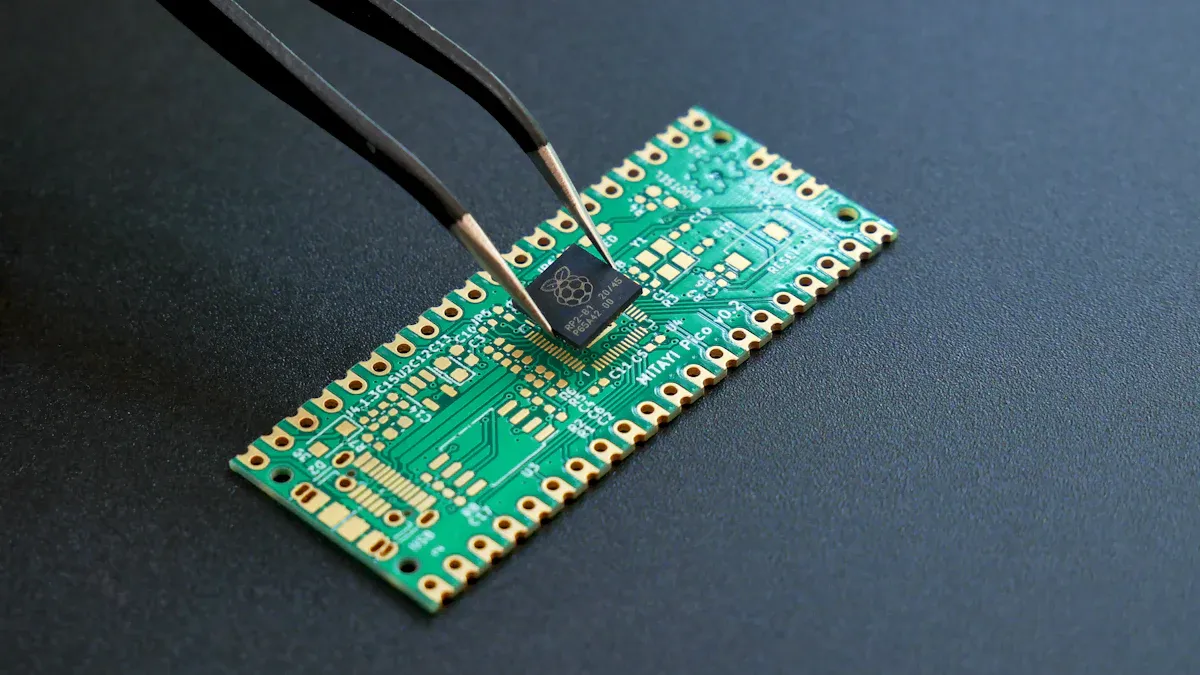

The first step in AOI PCB inspection is taking clear pictures of the circuit board. Special cameras and lenses are used to get sharp images. These cameras can be simple 2D ones or advanced 3D sensors. They turn light into digital data to find problems.

Here’s how the scanning works:

Lenses adjust to see all parts of the board clearly.

Cameras take pictures and compare them to a saved reference image.

Differences between the pictures are marked as possible issues.

This process finds small problems, like misplaced parts or soldering mistakes, early.

Software-based defect detection and analysis

After capturing images, software checks them for errors. It uses smart algorithms to spot tiny problems, like parts that are slightly out of place. If something is wrong, the software flags it for review.

The software is very accurate. It can find defects too small for people to see. The table below shows key features of software-based defect detection:

Feature | Explanation |

|---|---|

Detects tiny shifts in parts that could cause problems. | |

High Accuracy and Consistency | Finds even the smallest issues with reliable results. |

Early Defect Detection | Spots problems early to save time and money. |

Finding errors early helps keep products high-quality and reduces waste.

Classification and reporting of defects

After finding problems, the system organizes and reports them. This helps you know what’s wrong and how serious it is. Tools like charts and graphs make the information easy to understand.

A main chart tracks how well the inspection is working.

Scatter plots and Pareto charts show problem areas.

FPY charts display how many boards pass inspection the first time.

Detailed charts explain the types of problems, like missing parts or soldering mistakes. Some systems use advanced methods, like special lighting and AI, to improve detection.

For example:

The system checks inspection data for shiny parts.

It uses special techniques to find surface flaws.

Operators study the results to make production better.

This reporting process gives you the details needed to keep your products top quality.

Benefits of Automated Optical Inspection

Precise and accurate defect detection

Automated optical inspection (AOI) systems find defects with great accuracy. They use smart cameras and AI tools to spot tiny problems on circuit boards. For example:

AOI systems are 99.7% accurate, ensuring excellent results.

They need only a few perfect samples to train AI models.

They can find scratches or marks using special detection methods.

AOI reduces wrong defect reports and catches all real issues. This improves product quality and avoids expensive mistakes during production.

Fast and efficient inspection process

AOI systems work much faster than human inspectors. They can check circuit boards nonstop without getting tired. Unlike manual checks, AOI gives steady results and instant feedback.

For example:

AOI systems scan each section in just 10 milliseconds.

They run all day and night, ensuring constant inspections.

This speed helps meet deadlines while keeping quality high. AOI is a must-have for modern circuit board manufacturing.

Reliable and consistent quality control

AOI systems are always reliable and consistent. Human inspectors can miss defects due to tiredness or distractions. AOI uses advanced learning tools to find hidden flaws and tricky patterns.

This technology ensures every circuit board meets strict quality rules. AOI also provides helpful reports to improve production over time. With AOI, you can keep products top-notch and earn customer trust.

Long-term cost savings in PCBA manufacturing

Automated optical inspection (AOI) helps save money in PCB manufacturing. It finds problems early, stopping defective boards from moving forward. This avoids wasting materials and time on fixing errors.

Using AOI means less need for human inspectors. People need training, breaks, and supervision, which cost money. AOI systems work nonstop with little help, cutting labor costs. They also keep quality steady during production.

The money saved with AOI adds up over time. Fewer mistakes and less waste mean big savings. Companies can use this extra money for research, new projects, or making more products.

Here’s how AOI helps save money long-term:

It catches problems early, so boards don’t need fixing or tossing.

Automated checks reduce the need for workers, lowering costs.

Less waste and fewer fixes save a lot of money over time.

Adding AOI to your process makes production cheaper and better. It improves accuracy and ensures high-quality products. Over time, this leads to a more successful and eco-friendly business.

Limitations of AOI in PCBA Manufacturing

High initial investment costs

AOI systems cost a lot to set up. Buying cameras, software, and hardware can be expensive. Small businesses may find this hard to afford. Adding AOI might also need staff training and process changes. These extra costs can make it tough for some companies.

Even though AOI saves money later, the starting price is high. To get the best value, pick a system that fits your needs. This way, the benefits of better inspections will be worth the cost.

Challenges with false positives and negatives

AOI systems are accurate but not perfect. Sometimes, they flag problems that aren’t real. Other times, they miss actual defects. These mistakes can cause trouble. False positives mean fixing things that aren’t broken. False negatives let bad boards pass through.

Adjusting the system’s settings can help reduce these errors. For example, fine-tuning improves defect detection and lowers mistakes. Regular updates to AOI technology also make it more reliable over time.

Inability to detect certain internal defects

AOI is great for spotting surface problems like missing parts. But it can’t find hidden issues inside circuit boards. Problems in multilayer boards or hidden solder joints go unnoticed. This happens because AOI only scans what it can see.

To fix this, use AOI with other tools like X-ray inspection. This combo checks both surface and internal defects. Using multiple methods improves the quality of your boards and your production process.

Types of Defects Detected by AOI

Soldering defects like bridges and not enough solder

Soldering problems are common and often found by AOI. One issue is solder bridges, where extra solder connects two points. This can cause short circuits and make devices fail. Another problem is not enough solder. Without enough solder, parts may not stick well to the board. Weak connections can make the circuit stop working.

AOI systems are great at spotting these problems. They use sharp cameras to check solder joints. The system compares them to set standards. If the solder looks uneven, too thin, or messy, it flags the issue. Catching these problems early saves money and keeps products reliable.

Missing or misplaced parts

Missing or misplaced parts can break a circuit board. A missing part leaves a gap, while a misplaced one can cause bad connections. These problems often happen during fast assembly lines.

AOI systems find these issues by comparing parts to a reference image. If a part is gone or out of place, the system marks it. This ensures all parts are in the right spot. With AOI, you can keep quality high, even in big production runs.

Wrong direction or placement of parts

Parts like diodes and capacitors must face the right way. If placed wrong, the circuit won’t work and could cause big failures. This is a serious problem in production.

AOI systems help stop these mistakes. They check if parts follow IPC rules for direction and placement. This accuracy prevents orientation problems and ensures products meet standards. Fixing these issues early makes production smoother and products more reliable.

Tip: Update your AOI software often. It helps find tricky defects, like those with part direction or placement.

Surface-level defects on the PCB

Surface problems on a PCB can harm how it works. Issues like scratches, dirt, or bumpy surfaces can break circuits. Automated optical inspection (AOI) systems are great at finding these problems. They make sure every board is high quality.

AOI systems use smart tools to spot surface problems. They work in three main ways: comparing images, using rules, and machine learning. Image comparison checks PCB pictures against saved templates to find flaws. But this needs good templates and extra setup. Rule-based methods use simple rules to find defects but might miss big issues. Machine learning, like decision trees, improves accuracy but also needs setup and tuning.

AOI systems can find even tiny surface problems. For example, they catch scratches that block connections or dirt that causes short circuits. Fixing these early keeps products reliable and avoids expensive fixes.

To make AOI better, update and adjust it often. This keeps it sharp and ready to find new problems. With AOI, you can make top-quality PCBs that follow industry rules.

AOI vs. Other Inspection Methods

Comparing AOI to manual inspection

Manual inspection depends on people to find PCB problems. This method has been used for a long time but has issues. People can get tired or distracted, leading to missed mistakes. This lowers the quality of the final product.

AOI systems are faster and more accurate. They use cameras and software to check boards quickly and reliably. For example:

People make mistakes, which lowers inspection reliability.

Manual checks are slower and need more workers, taking more time.

AOI finds problems faster and improves quality control.

Aspect | AOI | Manual Inspection |

|---|---|---|

Speed | Slower due to human effort | |

Consistency | Very consistent with automation | Inconsistent due to human errors |

Error Rate | Fewer mistakes | More mistakes from fatigue or judgment |

Cost | Costs more at first, saves later | Cheaper at first, costs more in labor |

Using AOI increases production speed and saves money over time. Manual inspection may cost less at first but cannot match AOI’s efficiency and accuracy.

Comparing AOI to X-ray inspection

X-ray inspection is another way to check PCBs. It works well for finding hidden problems, like solder voids or issues in multilayer boards. But X-ray systems are slower and cost more to run. They also need trained workers, which adds to expenses.

AOI focuses on surface problems like missing parts or solder bridges. It uses clear images to find these issues quickly and accurately. Unlike X-ray, AOI gives instant results, so you can fix problems fast and keep production moving.

For surface checks, AOI is cheaper and faster. Using both AOI and X-ray together can ensure all defects, inside and out, are found.

Why AOI is great for PCBA manufacturing

AOI systems are made for today’s PCB challenges. They find surface problems like scratches, open circuits, and bumps with high accuracy. This improves product quality and speeds up production.

Feature | AOI Benefits | Other Methods |

|---|---|---|

Speed | Checks hundreds of boards per hour | Slower manual checks |

Precision | Finds defects with clear images | Limited by human ability |

Flexibility | Works with many PCB designs | Less adaptable |

Immediate Feedback | Quickly shows problems for fast fixes | Delayed results in manual checks |

Cost Efficiency | Saves money by reducing waste | Higher costs from errors |

AOI detects many issues, like misplaced parts or solder bridges. New tools like machine learning make it even faster and smarter. Adding AOI to your process ensures better quality, less waste, and smoother production.

Automated optical inspection (AOI) is key to making quality products. It works better than humans, who can get tired and make mistakes. AOI checks boards nonstop and much faster than people can. This saves time and money during production. Industries like cars and defense use AOI to find small problems and speed up work. Adding AOI to your process helps you make more products, keep quality high, and meet the needs of today’s electronics.

FAQ

What does AOI do in PCBA manufacturing?

AOI helps make sure circuit boards are high quality. It finds problems early, saving money and reducing waste. This keeps products reliable and consistent.

Can AOI fully replace manual checks?

AOI is faster and more accurate for surface checks. But it works best with manual checks for hidden or tricky defects needing human skill.

How does AOI make production faster?

AOI scans many boards quickly, checking hundreds every hour. It shows problems right away, so fixes happen fast. This keeps production smooth and avoids delays.

Is AOI good for small manufacturers?

AOI costs a lot to start, which can be hard for small businesses. But it saves money over time by reducing mistakes and waste, making it worth the cost.

What problems can AOI miss?

AOI can’t find hidden issues, like inside multilayer boards or solder joints. For these, use tools like X-ray to check deeper.

Tip: Use AOI with other tools to find more defects and improve quality.

See Also

Understanding PCBA Manufacturing And Its Significance In Industry

Exploring PCBA Services And Their Importance In Electronics

Defining PCBA In Electronics And Its Critical Role