PCBA test ensures that products are both reliable and high-quality. Manual testing can lead to errors, wasted time, and slower progress. By contrast, automation improves the accuracy and consistency of the PCBA test process. Advanced tools like real-time checkers and ATE quickly identify issues and minimize mistakes. This approach enhances efficiency and reduces costs.

Key Takeaways

Using machines for PCBA testing makes it more accurate and reliable. It also reduces mistakes made by people.

Finding problems early with tools like AOI and X-ray saves money and makes products work better.

Automation can cost a lot at first, but it saves money later and helps get more work done.

The Role of PCBA Testing in Manufacturing

Ensuring Quality Assurance and Reliability

PCBA testing is important for keeping products high-quality. It checks if circuit boards work properly and meet standards. Tests like in-circuit testing (ICT) and functional testing (FCT) check connections and parts. The ‘Worldwide PCBA Test Service Market Research Report 2025, Forecast to 2031‘ says ICT finds problems early. Real-time monitoring with ICT helps keep quality steady. Metrics like First Pass Yield (FPY) and Mean Time Between Failures (MTBF) show how well these tests work. This ensures products meet what customers expect.

Detecting Defects Early in the Production Process

Finding problems early stops bigger production issues later. Automated Optical Inspection (AOI) and X-ray inspection are helpful tools. AOI uses cameras to find visible mistakes. X-ray inspection finds hidden problems like bad solder joints. The article ‘PCBA Manufacturing: Revolutionizing Modern Electronics Assembly‘ explains how these tools lower failure rates. One company cut soldering mistakes by 10% using automated testing. Catching problems early makes products better and avoids expensive fixes.

Reducing Costs Associated with Faulty Products

Bad products can cost a lot of money. Adding PCBA testing to manufacturing lowers defects and saves money. Metrics like Cost of Quality (COQ) and Return Rate track these savings. Fewer defects mean fewer repairs and replacements, saving costs. Using eco-friendly methods like lead-free soldering and AOI also helps. These methods save money over time and support green manufacturing goals.

Key PCBA Electronics Testing Methods

In-Circuit Testing (ICT)

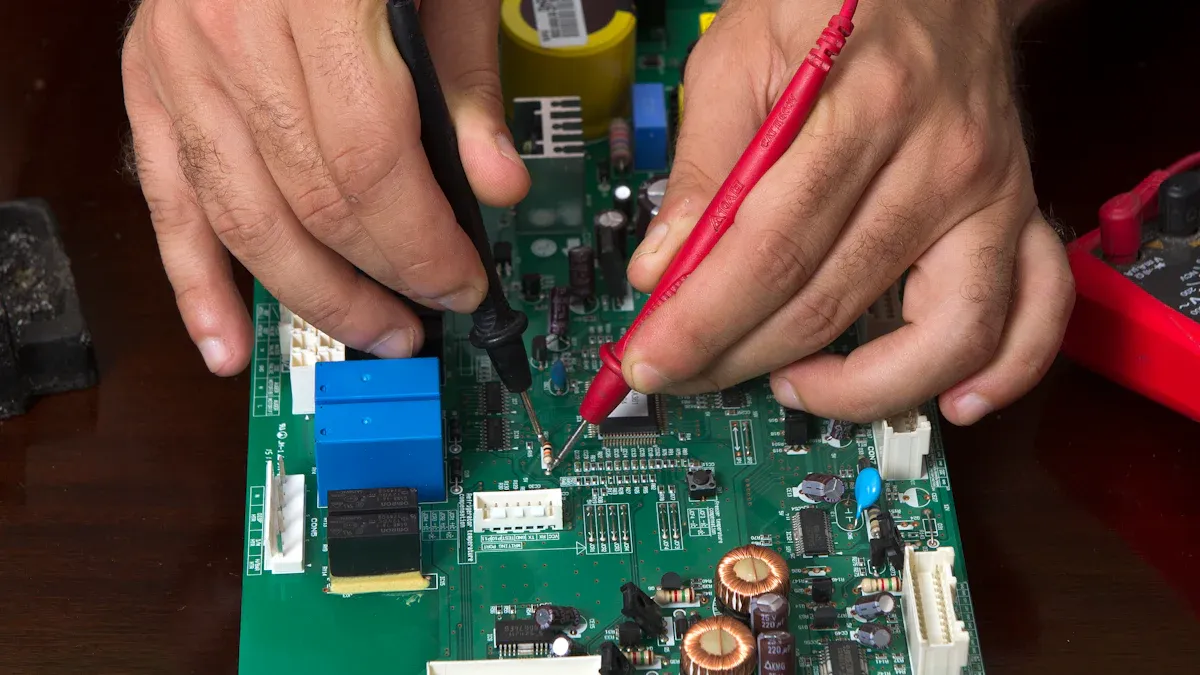

In-circuit testing is a trusted way to check PCBAs. It tests parts and their connections on the board. Probes are used to find shorts, opens, or wrong values. ICT makes sure each part works before moving forward. It is great for finding defects and works well for large production runs.

Testing Method | Description | Key Outcomes | Standards/References |

|---|---|---|---|

Checks if parts handle electrical stress. | Tracks failures and system performance. | ||

Electrostatic Discharge (ESD) Tests | Tests how PCBA handles static electricity. | Shows no failure, soft failure, or hard failure. |

Functional Testing (FCT)

Functional testing checks if the whole PCBA works as it should. It tests the board by mimicking real-life use. FCT helps find and fix problems before mass production. This testing lowers defects, meets standards, and avoids expensive recalls.

Benefits of FCT include:

Ensuring all parts are connected correctly.

Catching problems early in production.

Making products more reliable and avoiding recalls.

Automated Optical Inspection (AOI)

AOI uses cameras to find visible problems on PCBs. It spots solder issues, missing parts, and alignment mistakes. Unlike people, AOI doesn’t get tired and stays consistent. This makes it better at finding errors.

Aspect | Human Inspectors | |

|---|---|---|

Consistency | Drops with fatigue | Stays steady |

Error Detection Capacity | Falls after 15 minutes | Stays reliable |

Inspection Efficiency | Affected by tiredness | Not impacted by fatigue |

Boundary Scan and X-Ray Inspection

Boundary scan testing finds internal PCB problems using a standard interface. It’s cheaper than some methods and detects hidden faults. X-ray inspection finds both surface and inside defects. It’s great for complex boards with hidden solder joints.

Method | Coverage Level | Cost Efficiency | Defect Detection Capability |

|---|---|---|---|

Boundary Scan | High | Cheaper than ICT | Finds internal problems well |

X-Ray Inspection | Moderate | Expensive tools | Finds surface and inside issues |

Both methods work together to ensure high-quality PCBA testing.

Benefits of Automating PCBA Testing

Improved Accuracy and Consistency

Automation makes sure every PCBA test is done correctly. Unlike people, machines don’t get tired or make mistakes. They follow programmed steps for the same results every time. Studies show that automation lowers costs and improves quality. This method boosts accuracy and reliability. With automation, you can trust your products meet top standards.

Enhanced Efficiency and Speed

Machines work faster than people. High-speed pick-and-place machines place many parts quickly. Automated soldering applies solder evenly and speeds up production. AOI scans boards fast to find problems, reducing delays. The table below shows how automation improves speed and efficiency:

Automation Technology | How It Improves Efficiency and Speed |

|---|---|

High-Speed Pick-and-Place Machines | Places many parts quickly, saving time and boosting production. |

Automated Soldering Processes | Applies solder evenly and quickly, reducing mistakes. |

Automated Optical Inspection (AOI) | Finds errors fast, allowing quick fixes and less downtime. |

Automated Testing Equipment (ATE) | Runs detailed tests repeatedly, ensuring quality for large batches. |

Robotic Material Handling | Moves materials faster and more accurately than people, avoiding delays. |

Cost-Effectiveness in the Long Run

Automation costs more at first but saves money later. It reduces the need for workers, lowers mistakes, and avoids expensive recalls. Some companies in Europe saw 30% better productivity with automation. These savings lead to lower costs and higher profits. Automating helps you save money while keeping quality high.

Scalability for High-Volume Production

Automation helps you grow your production easily. Automated lines handle big orders while keeping quality steady. Using strategies like DFM and lean manufacturing makes scaling smoother. Strong quality checks and process improvements also help. Automation lets you meet demand and stay competitive.

Tip: Scaling with automation means handling small or big orders without losing quality or speed.

Steps to Automate PCBA Testing Processes

Review Current Testing and Find Problems

Look at how you test PCBAs now. Find slow steps or common mistakes. Use methods like visual checks, ICT, or flying probe tests to spot issues. Each method has pros and cons. ICT is very accurate but needs special tools. Flying probe tests are flexible but take more time. Make testing easier by improving access to test points, simplifying designs, and grouping PCB parts by function. These changes make testing faster and better.

Testing Method | Pros | Cons |

|---|---|---|

Visual Inspection | Fast and cheap | Misses hidden problems |

In-Circuit Test (ICT) | Very accurate, good coverage | Slow, needs special tools |

Flying Probe Test (FPT) | Flexible, no contact needed | Slower, less coverage |

Pick the Best Automation Tools

Choose tools that fit your production needs. Automated test equipment (ATE) is great for testing many boards quickly. New tech like AI systems makes testing faster and more accurate. Compare features like speed, reliability, and how easy they are to use. Some tools work better for mobile testing, while others are faster or more reliable. Pick tools that help you grow and need less manual work.

Feature | Cypress | Selenium | Playwright |

|---|---|---|---|

Speed of Execution | Very fast | Slower | Fast with parallel testing |

Test Reliability | Reliable results | Can have flaky tests | Auto retries for errors |

Setup and Ease of Use | Easy to set up | Harder to set up | Simple with Node.js |

Connect Testing Tools to Manufacturing Systems

Link automated test tools to your manufacturing systems for smooth workflows. Studies show automation can save a lot of time. For example, one company cut production time from hours to 30 minutes by using in-line testing. Test small systems first before using them fully. This avoids problems and ensures everything works well together.

Case Study Type | Description |

|---|---|

Continuous vs. Batch Process Systems | Cut production time from hours to 30 minutes with in-line systems. |

Fully Automated Systems | Handles large volumes with steady quality checks. |

Train Workers and Set Rules

Training is key for successful automation. Teach workers new skills and industry rules. Cross-training helps workers do different tasks. Focus on quality training to lower mistakes and make products better. Set clear rules to keep testing consistent and efficient.

Builds technical skills.

Keeps work running smoothly.

Lowers mistakes and improves quality.

Watch and Improve Automated Systems

Check automated systems often to keep them working well. Use advanced tools to monitor production and finished products in real time. Study data to find ways to improve. For example, improvement programs can make processes faster and products better. Watching raw materials and production steps also keeps quality high.

Aspect | Description |

|---|---|

Raw Material Quality Control | Checks materials to ensure they are good quality. |

Production Process Monitoring | |

Continuous Improvement | Uses data to make processes better and improve quality. |

Overcoming Challenges in Automating PCBA Test Processes

Tackling High Initial Costs and ROI Worries

Automation needs a lot of money at the start. You may need to buy machines, update systems, or train workers. These costs can feel big, but long-term savings make it worth it. Automated tools cut mistakes, save time, and lower worker costs. For example, companies using automation often boost productivity by 30% in one year. Tracking numbers like ROI and COQ shows how automation saves money. By studying these, you’ll see how it helps your business grow.

Making New Tools Work with Old Systems

Adding automation to old systems can be tricky. New tools must fit with what you already use. Many companies fix this by using smart tech. For example:

Scania uses smart glasses to check data quickly.

Volvo CE updates old machines with digital tools.

Both use “smart teams” to handle short-term and long-term needs.

These examples show careful planning makes it work. Start small by testing tools on a few tasks first. This keeps problems low and makes switching easier.

Helping Teams Learn New Skills

Automation means workers need to learn new things. This can slow work at first. But practice helps them get faster and better over time. To make this easier:

Check how well training works by tracking test scores.

Measure how fast workers learn new skills.

Change training plans based on feedback from workers.

Good training and clear goals help teams adjust. This keeps work moving while they learn.

PCBA testing is key to making sure products work well. Using automation makes testing more accurate, faster, and cheaper. The PCBA Test Service field is growing quickly because of new technology and customer needs. Automation helps companies stay creative, handle changes, and stay competitive for a long time in a fast-changing market.

FAQ

What is the biggest benefit of automating PCBA testing?

Automation makes testing more accurate and faster. It reduces mistakes people make. Over time, it saves money and helps with large production.

How can you pick the best tools for PCBA testing?

Think about your needs, budget, and current systems. Choose tools that are fast, reliable, and can grow with your production. Advanced tech like AI can make testing even better.

Can automation fully replace manual PCBA testing?

Automation is great for repeated tasks but not everything. People are still needed for tricky problems and checking overall quality.

See Also

Innovative PCBA Testing Methods for Cutting-Edge Electronics Production

Significance of PCBA Test Jigs in Today’s Electronics Manufacturing

Essential PCBA In-Circuit Testing Tools You Should Familiarize With

Understanding PCBA Test Fixtures: Their Functions and Uses

The Critical Role of PCBA Prototyping in Electronics Development