Electric cars are changing fast. These cool machines use lots of fancy electronics. PCBs are very important parts. They make EVs work well. They also make them safe and use less power. The electric car market will grow by 11% each year. This will happen from 2025 to 2034. This growth shows more people want strong electronic parts. How do different automotive PCBs make EVs work better? What is important when making and using them? It is key to know about the different electric vehicle pcb types. We need to know what they do in EV systems. We also need to know about problems and new ideas in making them.

Key Takeaways

EVs use many special PCBs. These PCBs help EVs work well and safely. They are different from PCBs in old cars.

Different PCBs do different jobs. Rigid PCBs manage batteries. Metal-core PCBs control motors and handle heat. HDI PCBs help with smart features like ADAS.

EV PCBs must be strong. They handle high heat, strong power, and shaking. New materials and designs help them last longer.

Future PCBs will be smaller and smarter. They will use new materials. They will even fix themselves. This makes EVs better and more reliable.

The Rise of Automotive PCBs in Electric Vehicles

EV PCB Requirements vs. Traditional Vehicles

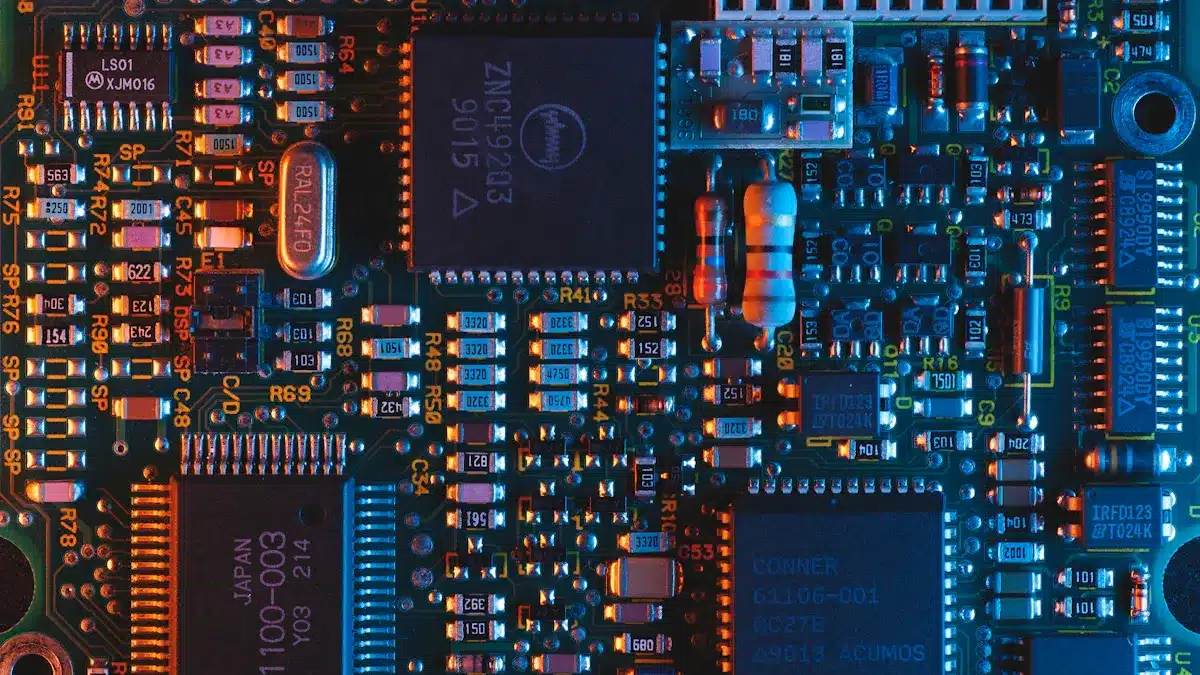

Electric vehicles have more PCBs. They have more than old cars. An EV can have 50% more PCB parts. Some say EVs have five to six times more PCBs. EVs have more electronics. These electronics handle power. They manage batteries. They also condition power. Automotive PCBs for EVs need different things. They are not like old car PCBs. They use better materials. Examples are FR-4 HTG or polyimide. These materials handle heat better. Old PCBs use standard FR-4 fiberglass. EV PCBs must work in tough places. They must handle shaking. They also meet strict fire rules. They resist rust better.

Note: EV PCBs are for tough car places. This means hot and cold. It means wet and shaky. They need to resist these things well.

Key Performance Metrics for EV PCBs

Some things show how well EV PCBs work. Managing heat is very important. EV PCBs get hot and cold fast. This happens when charging batteries. These changes cause stress. They can cause cracks. They can cause layers to split. Materials like polyimide help. High Tg FR-4 also helps. They resist these stresses better. Parts on the PCB can also cause problems. If they expand differently, cracks happen. This leads to broken solder joints.

EV PCBs must handle strong power. They handle high voltage. They handle high currents. Battery systems often use 600V or more. This is between high-voltage and signal layers. High-voltage PCBs in EV chargers handle 100V to 1000V. They can handle even more. Connectors should be stronger. They should be rated above the system’s max. For example, an 800V/100A system. It might use 1000V/150A connectors. This is for safety. Being reliable is also key. A good automotive PCB must last long. It must work in tough places. This means better aging. It means better rust resistance. It means better interference resistance.

Power Electronics PCBs for EV Drivetrains

Rigid PCBs for Battery Management Systems

Rigid PCBs are key for the battery management system (BMS). This is in electric vehicles. A BMS is like the battery’s brain. It checks each battery cell’s voltage. This keeps the battery safe. It also makes it work well. Rigid PCBs in the battery management system do many jobs. They balance cells. This makes sure cells charge evenly. It stops overcharging or undercharging. They also stop overcharging. This keeps the battery from charging too much. Temperature control is another job. The battery management system watches battery temperature. It stops it from getting too hot or cold. Both can hurt how it works. Voltage regulation is also key. It keeps power output steady. It keeps the battery charge just right. This stops over and undercharging. Also, the BMS makes current flow well. It sends power to parts efficiently. This makes the battery last longer. It also stops problems like too much current. Finally, battery management systems protect the battery. They guard against common issues. These include overcharging and short circuits.

Metal-Core and DBC PCBs for Motor Control

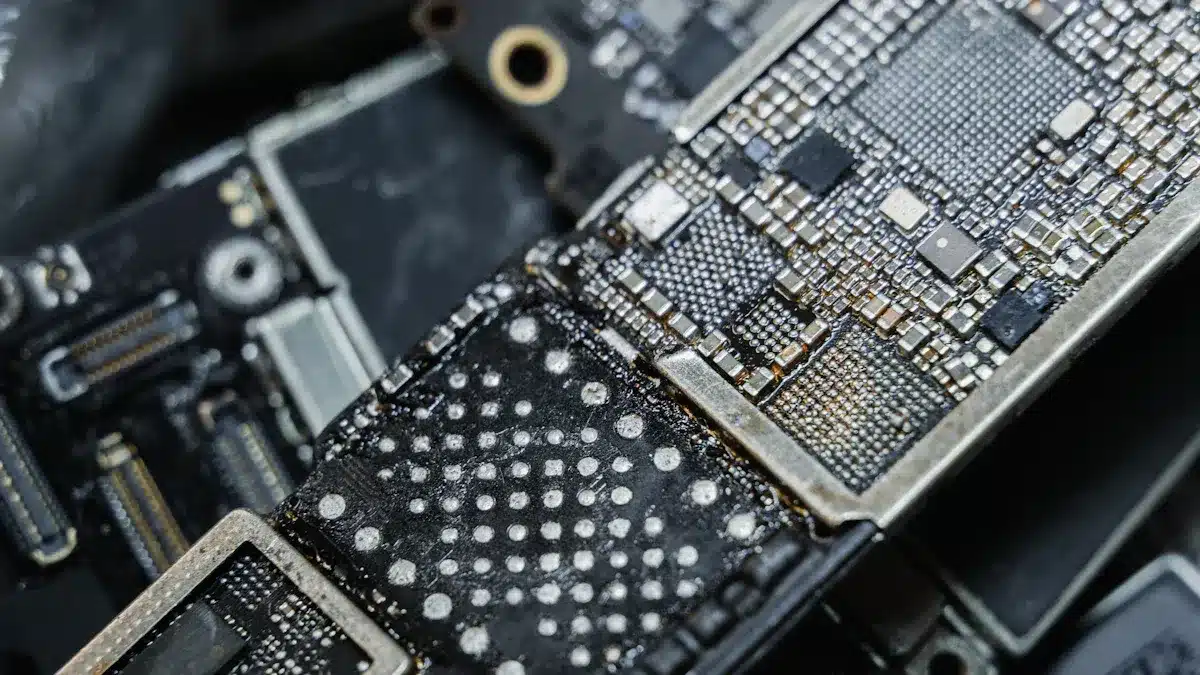

Motor control units are vital for an EV’s powertrain. They change DC power from the battery. This becomes AC power for the motor. These units get very hot. Metal-core PCBs are great for heat. They use metal instead of FR-4. Aluminum and copper are common metals. Aluminum cores are a good choice. They are light and not costly. They also move heat well. This makes them good for motor control. Copper cores move heat even better. They are for high-power uses. This includes motor drives. Some use a mix of cores. This balances heat movement and strength. Aluminum PCBs move heat well (205 W/mK). They are light. They also conduct electricity well. They cost less. Copper PCBs move heat very well (385 W/mK). They also conduct electricity well. They are strong. They are good for high-power uses. Motor drives are an example.

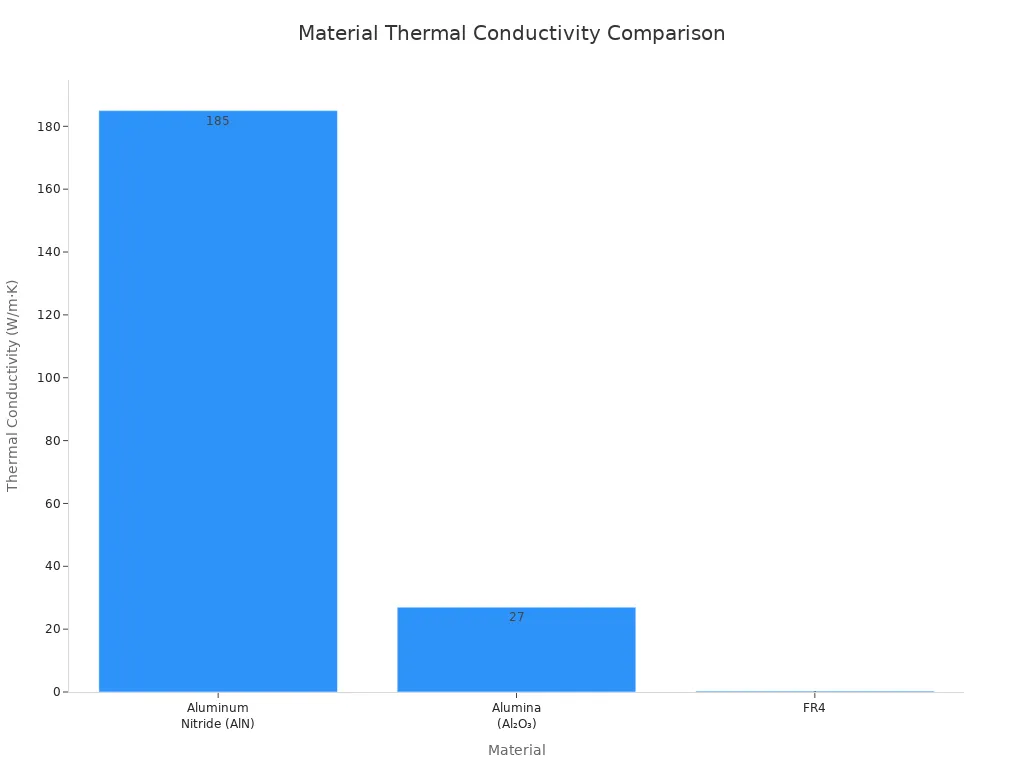

Direct Bonded Copper (DBC) PCBs help with heat even more. They are great for power inverters. This is in electric vehicles. DBC PCBs bond copper right to ceramic. This happens with high heat. This way removes glue layers. Glue layers are in normal PCBs. These glues stop heat from moving. The direct link moves heat very well. It moves heat from hot parts. These include IGBTs or MOSFETs. This stops overheating. It also makes devices more reliable. Picking the right ceramic is key. It makes DBC heat work best. Aluminum Nitride (AlN) moves heat better (up to 200 W/m·K). Alumina (Al₂O₃) costs less (24-30 W/m·K). Copper layer thickness also affects current. Thicker copper (e.g., 0.3 mm) helps high-current designs. It also helps spread heat. Making copper patterns right lowers electrical resistance. It spreads heat evenly on the PCB. Working with cooling systems is a must. The bottom copper of a DBC PCB often becomes a heat spreader. Thermal interface materials (TIMs) with low resistance (below 0.5 K/W) move heat better.

High Current PCBs for Power Distribution

High current PCBs are key for power in EVs. They handle big amounts of electricity. This power flows between the battery and motor. It also goes to other strong parts. These PCBs have thicker copper lines. This lets them carry more power. They do this without getting too hot. For example, EV inverters use copper lines. These are often 3–10 ounces thick. They can handle 100–300 Amperes. Automotive PCB designs for EV Battery Management Systems may use 5-ounce copper. This handles about 20 Amperes. Aerospace and Defense Power Distribution Units (PDUs) use 5–10 ounces of copper. They handle 50–100 Amperes. These PCBs are built strong. This makes sure power is sent well. It also keeps the system steady.

Copper Trace (oz) | Current Handled (A) | |

|---|---|---|

EV Inverters | 3–10 | 100–300 |

EV Battery Management Systems | 5 | 20 |

Aerospace & Defense PDUs | 5–10 | 50–100 |

Smart PCBs for EV Brains and Safety

HDI PCBs for ADAS and Fun

Electric cars use smart systems. These are ADAS and infotainment. ADAS helps drivers be safe. It has auto-braking. It also has lane keeping. Infotainment gives maps and music. It also connects things. HDI PCBs are key for these systems. They let engineers put more parts. These parts go in a small space. This is good for ADAS. ADAS is complex. It has little space. HDI PCBs make things small. They work better. They make signals clear. They allow more parts in a small area.

HDI PCB tech is in radar for ADAS. It is also in LiDAR for ADAS. These PCBs are key for ADAS. They also help manage power. This is for self-driving cars. It is also for electric cars. These PCBs help process data fast. This makes ADAS work well.

Flexible and Rigid-Flex PCBs for Sensors

Sensors are like EV eyes and ears. They see what is around. They check the car’s status. They collect info. These sensors must fit in small spots. They must fit in odd shapes. They must handle shaking. They must handle movement. Flexible PCBs are good for this. Rigid-flex PCBs are also good. Flexible PCBs bend. They twist. They fit where stiff boards cannot. They use fewer big cables. They use fewer connectors. This saves space. It saves weight.

Rigid-flex PCBs mix the best parts. They have stiff parts. These hold components. They have flexible parts. These are for connections. They are for bending. This design is great for sensors. Sensors are in doors. They are in seats. They are around the car’s body. They make strong connections. They resist shaking well. This makes data from sensors reliable. These PCBs help put many sensors. They are all over the car. They make the car smarter. They make it respond better.

Clear Signals in Fast Systems

Modern EVs use many fast signals. These come from radar. They come from LiDAR. They come from fast data. Keeping signals clear is key. This is for these uses. Clear signals mean they are good. They are not messed up. Bad signals cause errors. They can make systems fail. This affects car safety. It affects how well it works.

Some things make signals unclear. This is in fast systems. Impedance mismatches happen. This is when lines do not match. Signals bounce back. This causes data errors. Crosstalk is unwanted signal mixing. It is between nearby lines. It causes problems. Signal reflections happen. This is when signals hit a change. It causes overshoots. It causes undershoots. It causes ringing. EMI is another worry. Fast signals make radiation. This radiation can bother other parts. It causes issues. Power problems also affect signals. These are voltage drops. They are ground bounce. They are noise. Timing skew means signals arrive at different times. This causes sync problems. Good PCB design helps fix these. It includes good line routing. It includes impedance control. It includes shielding.

PCBs for EV Charging Systems

Robust PCBs in Onboard Chargers

Onboard chargers are key for electric cars. They change AC power from a wall. This becomes DC power. This DC power charges the EV battery. Onboard chargers must work well. They work in tough spots. Their PCBs need special design. These strong PCBs handle many stresses.

Extreme Temperatures: Onboard chargers must work from -40°C to 85°C. Tests can go up to 130°C. This checks long-term use.

High Humidity: PCBs fight humidity up to 95%. Tests include 85% humidity with power. Fast tests are done under pressure.

Significant Vibration: Onboard chargers handle strong shakes. These shakes come from bad roads. They come from long drives. Tests check they meet rules.

These PCBs use strong stuff and plans. This makes them safe and good.

High-Power PCBs for Fast Charging Stations

Fast charging stations give power fast. They give it to electric cars. These stations use high-power PCBs. These PCBs handle huge power. DC Fast Chargers can be 350 kW. They give 500 A to a battery. Chargers with 300 kW can charge a battery fast. It takes under 15 minutes. This means little power loss is needed. These systems give much power. The PCBs in these stations must handle high current. They must handle high voltage. They also need good heat control. This stops them from getting too hot. Engineers make these PCBs with thick copper. They also use good cooling. This makes power delivery safe and good.

Making EV PCBs: Hard Parts

Handling Heat in Strong Power Uses

EV PCBs get very hot. Strong power makes much heat. This heat can break parts. It can make them work badly. Engineers use ways to cool them. They use bigger copper lines. They put parts farther apart. Thicker PCBs help too. Special hot-proof stuff is key. Thermal vias are tiny holes. They are under parts. They move heat down. They send heat through the PCB. Filling these holes helps more. Heat sinks also move heat. They often sit on metal plates. This helps control heat. Materials that handle heat well are vital. Rogers PCBs cool better than FR-4.

Making Them Last in Tough Spots

EVs run in hard places. It gets very hot or cold. There is shaking and bumps. These can break PCBs. High heat causes stress. Cold makes things break easily. Shaking and bumps stress parts. They can crack inside wires. This makes them work sometimes. Or they stop working. Less air high up means more arcing. Bad heat control is a big problem. Heat stress breaks power PCBs. Car PCB makers must use strong plans. They must use tough stuff. This makes them last long.

Dealing with Electronic Noise

EVs have many electronics. These can mess with each other. They can mess with other things. Electronic noise control is vital. It makes sure things work well. Rules help guide car PCB design. ISO 11451 and 11452 are key. They cover EV noise rules. CISPR 22 sets noise limits. These are for PCB design. IEC 61000 has many noise rules. It has tests for static. It has tests for radio waves. It has tests for quick power changes. Car PCB makers follow these rules. This makes them safe and good.

Future Trends in Electric Vehicle PCB Technology

Miniaturization and Enhanced Integration

Future electric cars will have smaller PCBs. These PCBs will be more powerful. Engineers are making PCBs with other parts. These parts are like batteries and motors. This creates embedded power electronics. Strong parts are built right into the board. Special materials also help. They move heat better. They stop high voltage. This handles more power. The PCBs do not get bigger. New ways to pack parts help. SiP and 3D stacking make PCBs smaller. They put many chips together. This can cut PCB size by half. Flexible PCBs bend. They fit in tight spots. Dashboards and battery boxes are examples. SMT uses tiny parts. Small resistors are an example. Machines place them well. This makes connections exact. This makes parts up to 30% smaller. This is for EV chargers.

Innovations in Materials and Substrates

New materials make EV PCBs better.

Material Type | Description |

|---|---|

Aluminum Oxide (Al2O3) | This is a common ceramic. It moves heat well. It stops electricity. |

Aluminum Nitride (AlN) | It moves heat much better. It is good for strong power. |

Silicon Nitride (Si3N4) | It is very strong. It resists breaks. It moves heat well. It is good for tough places. |

Beryllium Oxide (BeO) | It moved heat very well in the past. But it is toxic. So it is not used much now. |

Insulated Metal Substrate (IMS) | It has a metal base. It has a layer that stops electricity. It has a copper layer. The metal base moves heat away. It moves heat from parts well. IMS boards are good for power parts. They handle much heat. They stop electricity well. They cost less than ceramic. |

Glass-reinforced PTFE boards are also used. Car PCB makers use them. They are for safety and lights. These PTFE boards handle heat well. They are better than resin boards. They work up to 200 Celsius. DBC PCBs move heat very well. The ceramic in DBC is special. Aluminum nitride moves heat very well. It is much better than FR4.

Smart and Self-Healing PCB Solutions

Future PCBs will be smarter. They will have sensors built in. These sensors will check how they work. They will check their health. Systems will guess problems. They will find failures early. This makes them more reliable. It makes them safer. Materials that fix themselves are also being made. These materials can fix small cracks. They fix damage by themselves. This makes PCBs last longer. It means less fixing. These new ideas will make PCBs stronger. They will make them work better. Car PCB makers are looking at these. They want to make smart systems. These new ideas will make car PCBs even better.

Different types of automotive PCBs are crucial for electric vehicles. They ensure cars operate efficiently, safely, and with reduced power consumption. Specialized printed circuit boards are utilized, with rigid and metal-core boards managing power, while HDI and flexible boards support ADAS. These designs meet the specific requirements of EVs. Continuous innovation in PCB design, materials, and manufacturing processes contributes to improved driving range, faster charging, and enhanced autonomous capabilities. The overall performance of an EV is significantly influenced by its PCB components.

FAQ

What makes EV PCBs different from traditional vehicle PCBs?

EV PCBs handle more power. They handle more heat. They use new materials. These are like polyimide. Or they are high Tg FR-4. These materials fight extreme heat. They fight vibrations better. Old PCBs use regular FR-4. EVs also have many more electronic parts.

Why are metal-core and DBC PCBs crucial for EV motor control?

Metal-core and DBC PCBs handle heat well. Motor control units get very hot. These PCBs move heat away fast. This stops parts from getting too hot. It makes power inverters reliable. It makes motors reliable too.

How do HDI PCBs enhance ADAS and infotainment systems in EVs?

HDI PCBs fit more parts. They fit them in a small space. This is key for ADAS. It is key for infotainment systems. They make signals clearer. This helps process data fast. It helps process data correctly. HDI PCBs make small designs. They have advanced features.

What are the main challenges in designing PCBs for electric vehicles?

Designing EV PCBs has challenges. One is handling high heat. This heat comes from power parts. Another is making them reliable. They must work in tough places. They must handle shakes. They must handle extreme heat. Controlling electronic noise is also key.

What future trends will shape EV PCB technology?

Future trends include making PCBs smaller. They will have more parts together. New materials will make them better. They will handle heat better. They will last longer. Smart and self-healing PCBs are coming. These will make them more reliable. They will last longer.

See Also

Streamlining PCBA Manufacturing: Boosting Workflow Efficiency for Optimal Production

Flexible PCBA: Exploring Its Benefits and Hurdles in Electronics

PCBA’s Impact: Revolutionizing Electronics Performance and Innovation Significantly

Accelerated PCBA: Simplifying Electronics Projects for Rapid Development

Achieving Excellence: Best Practices for Quality and Efficient PCBA Production