Choosing the best drone PCB assembly services is very important. A good company ensures that your drone’s circuit board is of high quality, which helps your drone fly better and last longer. Services like fast PCB assembly and quick prototypes speed up your design process and help reduce mistakes. Skilled workers guarantee that your drone’s control board functions well. Selecting a company that offers excellent quality checks and smart designs ensures you’ll be satisfied and your drone will operate reliably for a long time.

Key Takeaways

Pick a PCB service that focuses on good quality. Good boards work better and last longer for your drone.

Find companies with strong skills in drone PCB assembly. Experts know the special needs of different drones.

Make sure the company checks quality carefully. This finds problems early and ensures your drone works well.

Choose a company with clear prices. Simple quotes help you plan costs and avoid surprises.

Look for good customer support and communication. Helpful companies solve problems fast and keep your project moving.

Why Picking the Right Drone PCB Assembly Services is Important

How It Affects Drone Circuit Boards

Your drone works well if its circuit board is good. A properly made board helps parts talk to each other smoothly. This allows your drone to fly steadily and respond quickly. Good PCB assembly keeps signals clear, which is key for sending data in real time. If signals aren’t clear, your drone might lose data or not work right.

Clear signals lower errors when sending data, improving drone performance.

The PCB is like the brain of your drone. It controls everything and keeps it running. Choosing experts to make your PCB ensures it works well, even in tough situations. Badly made boards can break or cause your drone to fail.

Saving Time and Money

Picking the right PCB maker saves you money and effort. High-quality boards mean fewer problems, so you avoid costly fixes. A good company can also make boards quickly, helping you meet deadlines without losing quality.

Efficient factories make sure your board is built right and on time. Clear pricing helps you plan costs and stay within your budget while getting great results.

Why a Trusted PCB Maker Helps Long-Term

Working with a reliable PCB company has many benefits. They focus on quality checks, so every batch works well. They also keep records, like part numbers and safety codes, for easy tracking.

Key Feature | What It Does |

|---|---|

Part number and version | Tracks board types for better quality control. |

Manufacturing origin | Shows where the board was made for traceability. |

Manufacturer’s UL code | Proves the board meets safety rules for reliability. |

Week code of manufacture | Helps check production batches for any issues. |

Technical support contact | Gives quick help for fixing problems or answering questions. |

Good companies always try to improve. They study their work to fix mistakes and make better boards. This ensures your drone stays reliable and supports your projects for a long time.

Key Factors for How to Choose the Best Drone Board Provider

Expertise in Drone PCB Assembly Services

Picking a provider with expertise is very important. They know how to make high-quality drone boards. Skilled companies handle tricky tasks like adding advanced sensors. These sensors help drones navigate on their own and collect accurate data. Experts work with designers to place sensors correctly. This improves how well your drone works.

Experienced providers also understand different drone needs. For example:

Flying Style: Boards for movie drones are different from racing drones.

Open-Source Capabilities: Some boards let you change features to fit your needs.

Price Considerations: Beginner boards cost less, while pro boards last longer.

Choosing skilled providers ensures your drone board fits your exact needs. This works for hobbies or professional use.

Quality Control and Testing Capabilities

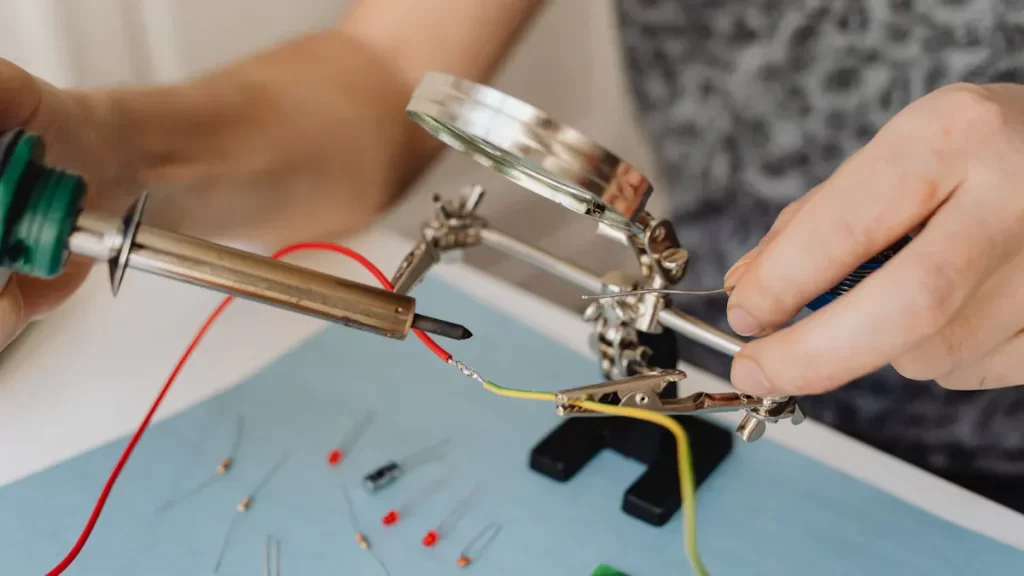

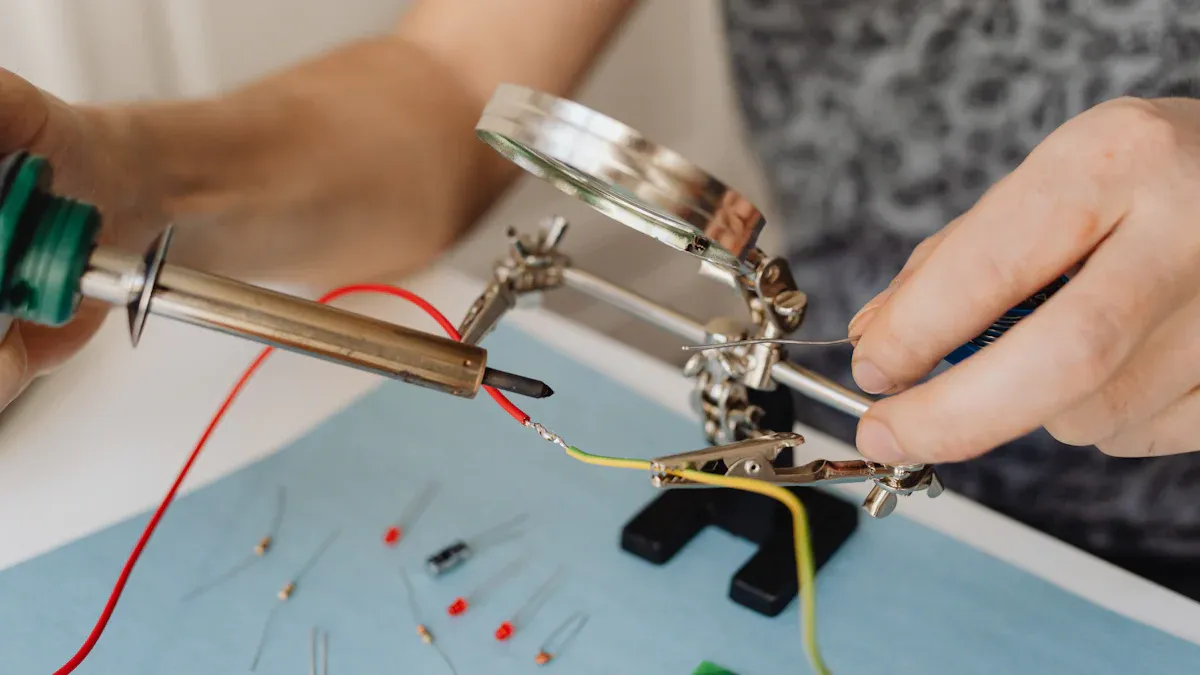

Good quality checks are key for reliable drone boards. Trusted companies follow strict rules to make sure parts meet standards. They inspect boards during production to catch problems early. For example, they check for soldering mistakes before they cause bigger issues.

After making the board, testing confirms it works properly. This step stops problems like short circuits. Providers with advanced testing tools create smart plans to test boards faster and better. In industries like aerospace, these tests are very important.

Benefits of strong quality checks include:

Following strict industry rules.

Finding problems early to avoid fixing later.

Meeting exact design needs.

By focusing on quality checks, you can trust your drone board will work well in real life.

Turnaround Time and Delivery Reliability

Getting your drone board on time is very important. Good companies offer fast assembly without lowering quality. Top providers deliver on time 98% of the time, keeping your project on schedule.

Metric | Value |

|---|---|

On-time delivery rate | 98% |

Quick delivery lets you test and improve your drone faster. This is helpful in competitive fields where new ideas matter. When choosing a provider, ask about their speed and history of meeting deadlines. A reliable company helps you avoid delays and finish your project on time.

Cost-Effectiveness and Transparent Pricing

Cost is a big factor when picking a PCB company. Choose one with fair prices that still delivers good quality. Clear pricing helps you know what you’re paying for. This avoids surprise fees or extra costs.

Top companies often offer affordable options. For example, they might give detailed cost lists for black and white PCBA. Some waive fees for orders over 100 pieces, making bulk buying cheaper. Free shipping on PCBA orders is another way to save money. Providers with full turnkey services handle making, assembling, and testing in one package. This saves both time and money while keeping quality high.

Tier pricing is another helpful feature. It lets you compare costs for different order sizes. Whether you need a small batch or a large one, this helps you budget better and grow your projects.

💡 Tip: Always ask for a full quote. It should list material, labor, testing, and shipping costs. This helps you plan wisely and avoid spending too much.

Customer Support and Communication

Good customer support is very important in PCB assembly. You need a company that listens and keeps you updated. Clear communication ensures your drone board is made just right.

Look for companies with dedicated account managers. These managers are your main contact and make things easier. They give updates on progress and quickly solve any issues. Companies with 24/7 support or live chat are even better, especially if you work across time zones.

Technical support is also key. A good PCB company should have engineers ready to help. Whether it’s fixing designs or solving problems, quick help saves time and avoids delays.

🛠️ Note: Pick a company known for great customer service. Read reviews or ask for references to make sure they value their clients.

Scalability for Future Growth

As your drone projects grow, you’ll need more production. A scalable PCB company can handle your future needs. This is crucial if you move from small prototypes to big orders.

Demand for advanced electronics, like drones, is rising worldwide. For instance, electric cars have boosted electronic manufacturing growth. PCB companies must improve to meet these demands. Those with automated lines and flexible schedules can handle large orders better.

Scalable companies also improve supply chains to ensure quality and on-time delivery. They use advanced tech to work faster and cut costs. By choosing a scalable partner, you can focus on creating new ideas without worrying about production limits.

📈 Insight: The International Energy Agency noted 14 million electric car registrations in 2023. This shows the need for scalable manufacturing, which also applies to drone PCBs.

Common Mistakes to Avoid When Picking a PCB Assembly Company

Only Thinking About Cost

Choosing a PCB company just because it’s cheap can cause problems. Saving money might seem smart, but it often leads to bad drone boards. Cheap companies may skip important steps like using good materials or testing properly. This can result in:

Weak materials that break easily, leading to costly repairs later.

Little or no testing, which lets mistakes go unnoticed.

Bad or missing instructions, causing errors in design and production.

Poor performance, making you spend more on fixes and replacements.

Instead of picking the cheapest option, think about long-term value. A good PCB company focuses on quality and knows what they’re doing. Spending a bit more now can save you from big problems later.

💡 Tip: Don’t just look at price. Check for clear pricing that includes materials, labor, and testing to avoid surprises.

Skipping Certifications and Standards

Certifications show a PCB company’s skill and focus on quality. Ignoring these can lead to unsafe or unreliable drone boards. Important certifications to check include:

IPC-A-610: Ensures good soldering and assembly for different needs.

IPC-A-620: Checks wire and cable quality.

ISO 9001: Proves the company follows quality rules.

RoHS and REACH: Confirms they meet environmental safety laws.

These certifications make sure your drone board is safe and works well. For example, IPC rules help stop electronic failures, and ISO shows the company cares about quality. Without these, you risk working with a company that isn’t skilled enough.

🛠️ Note: Always ask to see certifications. This ensures your drone board meets safety and quality standards.

Forgetting the Need for Expertise

Expertise is very important when picking a PCB company. Without it, your drone board might have design mistakes, delays, or poor performance. For example, Alabuga used old technology, which caused big delays and problems in making drones. They had to get outside help, showing why expertise matters.

Experienced companies know what drone boards need, like adding advanced sensors or keeping signals strong. They use modern tools like HDI boards and heat control to make boards better. Choosing a skilled company ensures your drone works well and lasts longer.

📈 Insight: Expertise not only improves your drone board but also speeds up production, saving time and money.

Not Checking for Scalability and Long-Term Compatibility

Skipping scalability and long-term fit can cause big problems. Scalability means the provider can grow with your needs. Whether you need a few boards or many, this is important. Without it, you might face delays, higher costs, or other issues.

If a provider can’t scale, they may struggle with bigger orders. This can lead to late deliveries or poor quality. You might even need to switch companies mid-project. For example, if your drone business grows, a provider unable to handle more work could hurt your progress. This might damage your reputation and slow down your success.

Long-term fit means the provider should match your future goals. Companies with good planning and advanced tools are better for growth. They can spot risks early and fix problems before they grow. Without this, you might outgrow the provider, causing delays and extra costs.

Here are some key points about scalability and long-term fit:

Check if the provider can handle your growing needs.

Poor scalability leads to higher costs and slower growth.

Strong providers help you expand into new markets with steady quality.

Good risk management avoids problems as your projects grow.

Scalability is key for long-term success. A company that can’t grow with you will hold you back. Picking a scalable provider keeps your drone projects on track as they grow. This saves time, money, and stress while helping your business succeed.

💡 Tip: Ask providers if they can handle bigger orders and scale up. This ensures they can grow with your drone projects.

How to Start with a Drone PCB Assembly Provider

Know What Your Drone Circuit Board Needs

Before starting, figure out what your drone board needs. First, make a schematic. This is a map showing how parts connect. Turn this map into a digital layout. Design the PCB layers to avoid signal problems. Set rules for spacing and wiring. Place parts carefully for better performance. Add holes for mounting and adjust if needed. Draw copper lines to link parts. Label everything for easy reading. Finally, create files for making and assembling the board. These steps help your board work exactly as you want.

Look Up and Compare Providers

Finding and comparing providers is very important. Use different tests to check them. Mechanical tests ensure the board is made well. Electrical tests find faults or signal issues. Stress tests check how the board works under tough conditions. Reliability tests see if it lasts long. Make a chart to compare providers based on these tests. This helps you pick one that makes sure your drone works well.

Test Type | What It Checks |

|---|---|

Ensures the board is built properly and can be assembled well. | |

Electrical Testing | Finds faults, signal issues, or leftover materials during production. |

Stress Testing | Tests how the board performs in extreme conditions. |

Reliability Assessments | Checks if the board will last in different environments. |

Ask for Samples or Prototypes

Getting samples or prototypes is a smart idea. It lets you test the board before making many. Flying probe tests check connections without special tools. In-circuit tests check each part. X-rays look at hidden solder spots. Automated Optical Inspection (AOI) finds mistakes. Functional tests make sure the board works as planned. Visual checks spot obvious problems. These tests show if the board is good and works as expected.

Check Contracts and Terms

Before choosing a drone PCB assembly provider, review their contracts carefully. This helps you understand what both sides must do and deliver. A clear contract protects you and avoids confusion.

Focus on these key points when checking contracts:

What to Look For | |

|---|---|

Technical Skills | Check if they have the right experience for your project. |

Ability to Scale | See if they can handle more work as your needs grow. |

Past Work | Look at reviews or examples of their previous projects. |

Location | Think about how their location affects shipping costs and delivery times. |

Background Checks | Visit their site or do audits to ensure they are trustworthy. |

Make sure they follow strict quality rules and meet industry standards. | |

Performance Metrics | Use measures like delivery time, cost, and customer reviews to judge them. |

By reviewing these factors, you can find a provider that fits your drone project. Pay special attention to their ability to grow with your needs and their quality checks. These are key for long-term success.

💡 Tip: Ask for a full breakdown of terms, including timelines, warranties, and penalties for delays. This keeps everything clear and fair.

Work Together as Partners

Working well with your drone PCB provider is more than just signing a contract. Good teamwork builds trust, improves results, and helps you succeed. Clear communication and shared goals are very important.

Teamwork has many benefits:

Sharing data helps you plan better and avoid having too much or too little stock.

Working together on production makes things faster and more flexible.

Reliable deliveries keep your customers happy and loyal.

But problems can happen if trust is missing or if plans are unclear. Managing many people can also raise costs. To fix this, set clear rules and talk often. Regular updates and feedback help solve issues early.

🛠️ Note: Treat your provider like a partner, not just a seller. This helps both sides grow and improve.

By working closely with your provider, you can handle changes, improve processes, and get better results for your drone projects.

Picking the right drone PCB assembly service is very important. A good circuit board gives steady power to all parts. This is crucial for things like cameras that need clear signals. High-quality boards also make your drone work better and last longer. This helps you stay ahead in a fast-changing market.

To choose wisely, look at expertise, quality checks, and growth options. Don’t just pick the cheapest option or skip checking certifications. Think about what you need and research providers carefully. This helps you find a partner who can grow with you.

Working with a trusted provider makes sure your drone board works well. This lets you create new ideas and succeed for a long time.

FAQ

What matters most when picking a drone PCB service?

The most important thing is quality. A good provider makes sure your drone’s circuit board works well and lasts a long time. Look for providers with expertise, strong quality checks, and certifications like IPC or ISO. These prove the board meets industry rules and works as it should.

How can I make sure the provider meets deadlines?

Ask about their delivery success rate and how much they can produce. Providers with automated systems and a good track record are more dependable. Request a project timeline and confirm they can handle urgent orders without lowering quality.

Why do certifications matter for PCB services?

Certifications like IPC-A-610 and ISO 9001 show the provider follows strict safety and quality rules. These ensure your drone’s circuit board is safe and works properly. Without certifications, you might get poor-quality boards that fail.

Should I pick cost over quality when choosing a provider?

No, choosing cost over quality can cause problems later. Cheap boards often fail and cost more to fix. Pick a provider with clear pricing and high-quality work. Spending a bit more now saves money and trouble in the future.

How do I check PCB quality before making many?

Ask for samples or prototypes. Use tests like Automated Optical Inspection (AOI), flying probe tests, and functional tests to find problems. These tests help you spot issues early and make sure the board works as planned.

💡 Tip: Always test prototypes in real-life situations to check their performance.

See Also

Effective Strategies for Choosing Top PCB Assembly Services

Guidelines for Choosing the Right RF PCBA Provider

Tips for Finding the Ideal PCBA Manufacturer for You

Choosing the Perfect Fusion PCBA Service for Your Requirements

Finding the Best PCB Prototype Manufacturer for Your Project