Choosing the right PCB prototype manufacturer is crucial for your project’s success. A reliable manufacturer provides high-quality prototypes, meets deadlines, and maintains clear communication. For instance, fast options for rigid PCBs can significantly save time. Manufacturers can deliver 1-4 layer boards in just 1 to 6 days, which is ideal for projects with tight timelines. Additionally, thorough testing and quality checks ensure that the boards function properly. Selecting a PCB prototype manufacturer with strong expertise and support is essential for achieving your project’s goals.

Key Takeaways

Pick a PCB maker with top certifications like ISO 9001 and UL. These ensure safe and trustworthy products.

Check delivery times and ask about delay handling. On-time delivery keeps your project moving smoothly.

Find makers using the latest tools and machines. New technology makes PCBs faster and better.

Ask for a clear price list from the maker. Knowing costs upfront avoids surprises and saves money.

Test how well the maker communicates with you. Good support helps fix problems and finish your project successfully.

Key Factors to Consider When Picking a PCB Manufacturer

Quality Standards and Certifications

When picking a PCB manufacturer, their quality standards and certifications are very important. These ensure the PCBs are reliable and meet industry rules. Certifications like ISO 9001, RoHS, UL, and IPC-A-600 show they care about quality and follow proper guidelines.

Certification | What It Covers | Why It Matters for PCB Quality |

|---|---|---|

ISO 9001 | Quality system for better processes | Ensures steady quality, good performance, and happy customers |

RoHS | Limits harmful materials in PCBs | Makes production safer and eco-friendly |

UL | Checks safety and fire resistance | Proves PCBs are safe and stable |

IPC-A-600 | Sets rules for PCB looks and strength | Helps reduce defects and meet expectations |

These certifications prove the PCBs are safe, strong, and made with care. Always check if the manufacturer has these certifications to avoid problems and get good-quality PCBs.

Tip: A certified manufacturer is more likely to make PCBs that work well.

Lead Times and Delivery Reliability

Getting PCBs on time is very important, especially for tight schedules. A good PCB manufacturer should give clear timelines and deliver on time.

PCB Type | Time to Deliver | On-Time Delivery Rate |

|---|---|---|

Simple, low-volume PCBs | 1-2 weeks | N/A |

Medium complexity, medium volume | 2-4 weeks | N/A |

High complexity or high volume | 4-8 weeks or more | N/A |

InduControl Electronics (after strategies) | 4-5 weeks (30-35% faster) | 97% |

Manufacturers with quick delivery and good timing help you stay on track. They should also have backup plans for delays. This keeps your project running smoothly without big problems.

Note: Ask about their usual delivery times and how they handle delays to avoid surprises.

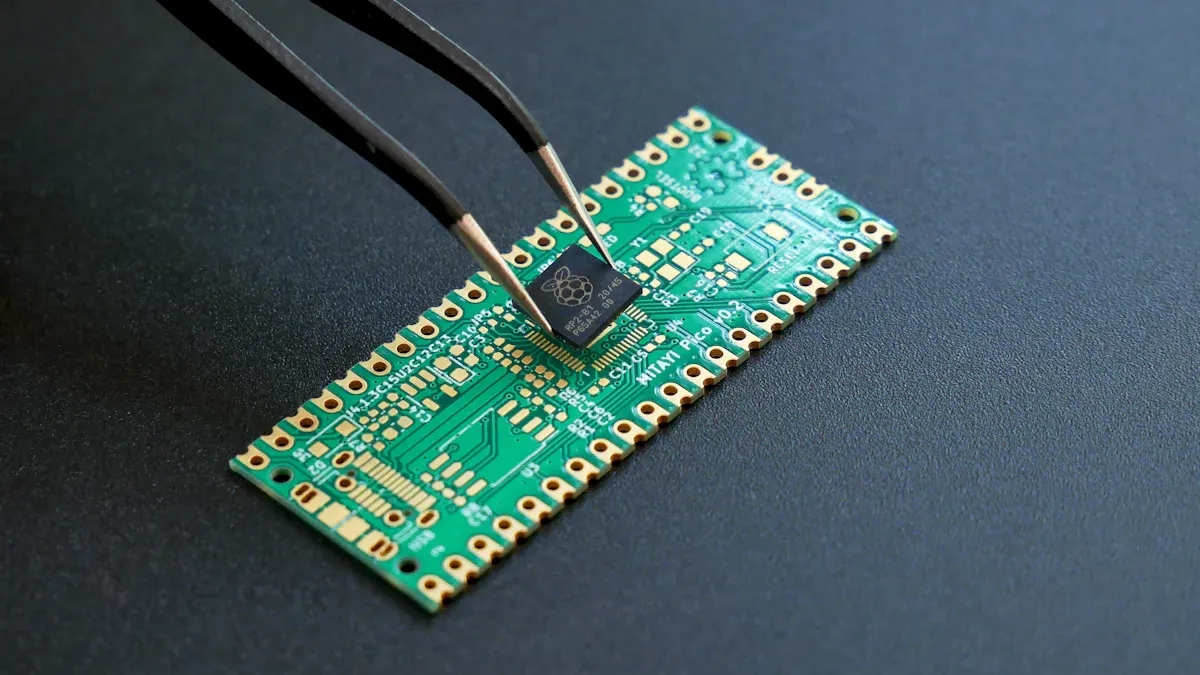

Manufacturing Capabilities and Technology

Modern tools and machines improve PCB quality and speed. Manufacturers using advanced technology like robots, automation, and 3D printing can make PCBs faster and better.

Precision Tools: Lower mistakes and keep PCBs consistent.

Automation and Robots: Make production faster and cheaper.

3D Printing: Speeds up custom designs and small orders.

These tools help manufacturers handle tricky designs and big orders while keeping quality high. Check if the manufacturer has the right tools and skills for your project.

Tip: Pick a PCB manufacturer with the right mix of tools and knowledge to match your needs.

Pricing Transparency and Cost-Effectiveness

Knowing the cost details is very important when picking a PCB maker. Clear pricing helps you see what you’re paying for and avoids surprise charges. A good manufacturer gives a full cost breakdown so you can plan better.

Why Pricing Transparency Matters:

Clear pricing builds trust and helps you compare makers easily. It ensures you get good value for your money. Some companies offer flexible pricing, like discounts or special plans. These options save money while keeping quality high.Cost-Effectiveness Through Technology:

Using machines in PCB making has cut costs a lot. Automated systems can lower production costs by over 30% compared to old methods. This means you pay less for your prototype without losing quality.Market Trends in Cost-Effectiveness:

More people now want fast prototypes, with 65% of tech startups choosing quick PCBs. This shows the need for affordable options that meet tight deadlines. Also, the flexible PCB market is growing fast, expected to hit $37.9 billion by 2031. Makers must offer good prices to stay competitive.

Tip: Always ask for a detailed price list. This helps you understand costs and avoid surprises.

Customer Support and Communication

Good customer support is key to a smooth project. Clear communication helps from the start to the end of your order. Check how quickly a manufacturer answers your questions and solves problems.

Key Metrics for Customer Service:

The best manufacturers do well in these areas:Category

Metric

Current Benchmark

Customer Loyalty

Repeat Order Rate

40% of clients

Service Evaluation

Net Promoter Score

50+

Operational Efficiency

Inquiry Response Time

24 hours

A high repeat order rate shows happy customers who trust the company. A Net Promoter Score above 50 means strong loyalty. Quick replies, within 24 hours, show they care about your time.

Why Communication Matters:

Fast and clear communication fixes problems quickly. If you need to change designs or handle delays, a responsive maker can adjust without messing up your schedule. This keeps your PCB reliable and on time.Building Long-Term Relationships:

Companies with great support often build lasting partnerships. These relationships mean better prices, steady quality, and a better understanding of your needs.

Note: Before choosing a manufacturer, test their communication. Ask detailed questions to see how well they respond. This shows how much they value their customers.

Questions to Ask the Best PCB Supplier

When choosing a PCB supplier, asking smart questions is key. These questions help you check their skills, trustworthiness, and if they fit your needs. Below are important topics to discuss.

What certifications and quality checks do you have?

Certifications and quality checks show a supplier’s promise to make good PCBs. Ask about their certifications and how they keep quality steady during production.

Important Certifications to Know:

IPC Certifications: Shows they follow top industry rules for PCBs.

UL Certification: Confirms safety, important for fields like healthcare or aerospace.

These certifications show the supplier meets strict safety and quality rules. A good supplier also tests and checks their work at every step. This ensures the final PCB works well and matches your needs.

Tip: Always ask to see their certifications. This helps you avoid risks and ensures they meet your quality standards.

Can you meet my project’s special needs?

Every project is different, needing specific materials, designs, or order sizes. Ask if the supplier has the tools and skills to handle your project.

Why This is Important:

Suppliers with advanced tools can manage tricky designs like multilayer PCBs. Experience in different industries shows they can adjust to various needs.What to Ask About:

Do they offer custom designs?

Can they handle large or small orders?

Have they worked on projects like yours before?

These questions help you understand their abilities and build trust. It also ensures they can deliver what you need.

Note: Share your project details early. Ask for examples of similar work they’ve done to see their experience.

How long do prototypes take?

Knowing how fast they make prototypes is vital for planning. Ask about their usual delivery time and how they manage urgent orders.

What Affects Delivery Time:

Design difficulty.

Order size.

Material availability.

A dependable supplier gives clear timelines and sticks to them. They should also have backup plans for delays. A supplier with a good record of on-time delivery helps you avoid problems.

Why This Question Matters:

Knowing delivery times helps you plan better and avoid delays. It also shows how reliable and efficient the supplier is.

Tip: Ask about their delivery success rate and how they handle delays. This will help you trust their ability to meet deadlines.

How do you handle revisions or design changes?

Changes in design happen often in PCB projects. A good manufacturer should manage updates quickly without messing up your schedule or budget. When talking to a supplier, ask how they handle these changes.

Flexible Design Updates:

A reliable manufacturer knows changes can happen anytime. They should adjust easily, whether it’s a small fix or a big redesign. Suppliers with advanced tools can make updates faster and avoid mistakes.Clear Communication During Changes:

Good communication is important for handling design updates. The best suppliers keep you informed during the process. They share regular updates and ask for your approval before making changes. This ensures the final product meets your needs.Impact on Cost and Time:

Design changes can affect costs and delivery times. Honest suppliers explain how updates change the timeline and budget. They should give a clear cost breakdown and work to avoid delays.

Tip: Before choosing a supplier, ask how they manage design changes. This shows their flexibility, communication, and care for customers.

What is your process for resolving issues or delays?

Problems and delays can happen in manufacturing. How a supplier fixes these shows their reliability. Knowing their process helps you see if they can deliver on time and keep quality high.

Finding Problems Early:

Good manufacturers spot issues early. They use strong quality checks and regular inspections to catch problems before they grow. This helps keep production smooth and avoids big disruptions.Steps to Fix Problems:

Suppliers should have clear steps to solve issues. This includes finding the cause, fixing it, and stopping it from happening again. Ask about their process for handling serious problems.Being Honest About Issues:

Trustworthy suppliers tell you right away if something goes wrong. They explain the problem clearly and share their plan to fix it. Taking responsibility shows they care about fixing mistakes quickly.Support During Problems:

Good customer support is important when solving issues. Suppliers should answer your questions and give updates. This builds trust and shows they can handle challenges well.

Note: Always ask suppliers how they deal with problems. This helps you pick one who values quality and customer happiness.

Evaluating the Reputation of a Quick-Turn PCB Manufacturer

Reading Online Reviews and Customer Feedback

Online reviews and feedback show how reliable a manufacturer is. They share real customer experiences and help you decide if the manufacturer fits your needs. Good reviews often mention fast delivery, great quality, and helpful support. Bad reviews can warn you about possible problems.

For example, here are comments from companies that worked with PCBWay:

Customer | Feedback |

|---|---|

Siemens | PCBWay helped us with new projects, showing great quality and teamwork. |

Samsung | Working with PCBWay improved our market position through their tech skills. |

Midea | PCBWay offers fair prices and quick, friendly customer service. |

SnapEDA | Customers like PCBWay for their top-notch services and fair costs. |

These examples show why experience and reputation matter. When reading reviews, focus on patterns of good feedback, not just one or two comments.

Tip: Check reviews on trusted websites to get honest opinions.

Reviewing Case Studies and Previous Work

Case studies and past work show how manufacturers solve problems and meet goals. They highlight how well they stick to deadlines, keep quality high, and handle tough tasks. Looking at these examples helps you see if they match your project needs.

Finish designs on time

Reduce mistakes

Improve first-pass success rates

Lower repair needs

Boost quality and reliability

Ensure good craftsmanship

They use tools like Pareto Charts and Six Sigma to reach these goals. By studying case studies, you can see how these methods work in real projects.

Note: Ask for case studies related to your industry for better insights.

Getting References from Past Clients

Talking to past clients gives you direct information about the manufacturer. References let you ask about their reliability, communication, and problem-solving skills. This step helps you feel more confident in your choice.

When contacting references, ask:

Did they deliver on time?

Were there any quality or communication issues?

Would you work with them again?

These questions confirm the manufacturer’s claims and help you decide wisely.

Tip: Focus on references from clients with projects like yours.

Checking Experience and Time in the Industry

When picking a PCB prototype maker, their experience matters a lot. Experienced companies know how to solve problems in PCB making. They can handle tricky designs, tight schedules, and keep quality steady.

Manufacturers with lots of experience often work with many industries. These include cars, healthcare, and gadgets. This helps them adjust to different project needs. For example, a company with aerospace experience knows the importance of accuracy and safety.

Being in business for a long time shows they are stable and trusted. Older companies usually have good supplier connections and steady material access. They also adapt well to market changes and new technology.

To check a company’s experience, look at their past work. Find case studies or projects like yours. Ask about the industries they’ve worked with and the PCBs they make. Also, see how long they’ve been in business. Older companies often have better processes and skilled workers.

Tip: Pick a manufacturer with a strong history in your field. They’ll understand your needs and deliver great results.

Tips for Picking the Best Quick-Turn PCB Manufacturer

Focus on Your Project’s Needs

Knowing what your project needs is very important. It helps you choose the right quick-turn PCB manufacturer. Pick one that meets your needs without lowering quality or missing deadlines.

Find a manufacturer with fast and dependable production methods.

Check if they can handle urgent orders when plans change.

Look at their certifications and quality checks to ensure good products.

Research their reputation to see if they are trustworthy.

Balancing speed and cost is key. Faster delivery might cost more, so match your budget to your project’s goals. Choose manufacturers with short delivery times and smooth processes to avoid delays.

Tip: Ask about their backup plans for delays to keep your project on schedule.

Compare Different Manufacturers

Looking at multiple manufacturers helps you pick the best one. Each has different strengths, so comparing them side by side is smart.

Look at their prices, delivery times, and production abilities.

Check if they do assembly themselves or hire others, as this affects quality and timing.

Review their testing methods, especially for complicated boards.

Cheaper prices often mean slower delivery. Think carefully about what matters most to you. Knowing what each manufacturer can do ensures they meet your design needs without losing quality.

Tip: Make a list of what’s important to you. Use it to compare manufacturers and make choosing easier.

Ask for a Sample Prototype

Getting a sample prototype is a smart way to test a manufacturer. A prototype shows the quality and performance of their PCBs before you order more.

Property Type | Examples |

|---|---|

Strength, heat expansion | |

Chemical properties | Tg, Td, thermal stability |

Electrical properties | Dielectric constant, flame resistance |

Environmental performance | Water resistance, insulation reliability |

Testing these features ensures the prototype fits your project’s needs. A good manufacturer will give you a sample that shows their quality standards.

Note: Use the prototype to check their attention to detail and ability to meet your needs.

Think About Long-Term Partnerships

Sticking with one PCB prototype manufacturer for a long time has many benefits. It helps you work better together and get good results over time. When you use the same manufacturer often, communication gets easier. This lowers mistakes and makes it faster to get feedback on your designs. They also learn your project needs, which keeps quality steady.

Long-term partnerships can save you money. Manufacturers might give discounts for big or repeat orders. This helps you spend less while still getting great products. Plus, having one trusted manufacturer makes things simpler. You won’t need to deal with many suppliers, which saves time and reduces risks.

Using the same manufacturer also speeds up delivery. They already know your needs, so they can quickly move from prototype to production. This helps you get your product to market faster. If you need to change designs, they can adjust quickly. This avoids delays and makes updates smoother.

Another advantage is better customer support. A strong relationship means the manufacturer will care more about your needs. They can give helpful advice and help you plan for growth. As your business expands, they can increase production to match your demand.

Picking the right quick-turn PCB manufacturer for a long-term partnership ensures things run smoothly. It lets you focus on creating new ideas while they handle making the products. This teamwork can make your projects more successful and help you reach your goals faster.

Tip: Choose a quick-turn PCB manufacturer with a history of building strong partnerships. Their experience and focus on quality will help your projects succeed over time.

Picking the right PCB prototype maker is very important. It can decide if your project succeeds or fails. Look at things like material quality, tools, and delivery time. These help you find a manufacturer that fits your needs. The table below shows key points to think about:

Factor | What It Means | Why It Matters |

|---|---|---|

Material Quality | Type of materials used for making PCBs. | Impacts how strong and reliable the PCB is. |

Technology Capabilities | Ability to handle complex PCB designs. | Ensures they can meet your design needs. |

Fabrication Precision | How accurate the PCB is made. | Important for circuits to work correctly. |

Assembly Options | Services for adding parts to the PCB. | Useful for complete, ready-to-use boards. |

Turnaround Time | Time it takes to finish and deliver. | Affects how fast your project moves ahead. |

Customer Support | How helpful and quick the support is. | Helps solve problems and answer questions. |

Ask smart questions and check reviews about the manufacturer. This helps you avoid mistakes and pick the best one. Focus on what your project needs most. Choosing the right quick-turn PCB maker gives you better results and makes your project easier to complete.

FAQ

What is the difference between a prototype PCB and a production PCB?

A prototype PCB is a test version of your design. It helps find problems and check if it works. Production PCBs are the final versions made in large amounts for real use.

Tip: Always test your design with a prototype to avoid big mistakes later.

How do I know if a PCB manufacturer is reliable?

Look for certifications like ISO 9001 and UL. Read online reviews, case studies, and ask past clients. Reliable manufacturers also communicate clearly and deliver on time.

Note: A high repeat order rate shows customers trust the manufacturer.

Can I request a custom PCB design?

Yes, most manufacturers can make custom designs. Share your project details, like materials, size, and layers. Make sure they have the tools and skills to meet your needs.

Emoji Reminder: 🛠️ Clear communication is key for successful custom designs.

What factors affect PCB prototype delivery time?

Delivery time depends on how complex the design is, the order size, and material availability. Manufacturers with better tools and faster processes deliver quicker.

Quick Tip: Ask about their delivery times and plans for delays to avoid problems.

Why is customer support important when choosing a PCB manufacturer?

Good customer support means clear communication and quick help with problems. Responsive manufacturers handle changes and delays without messing up your schedule.

Reminder: Test their support by asking questions before placing an order.

See Also

Selecting the Right PCB Fabrication Manufacturer for You

Finding the Ideal PCBA Manufacturer for Your Business

Picking the Perfect PCBA Factory for Your Custom Needs