Choosing the best small batch PCB assembly services is very important. The right company helps you get good results and save money. For example, things like part costs and assembly difficulty can affect your budget. Turnkey services make things easier, improve quality, and save time. Also, while assembly costs are $0.02 to $0.05 per square inch, paying for good services gives better accuracy and reliable devices. By checking these factors, you can avoid delays and extra costs.

📌 Tip: Pick services that are flexible and ensure good quality for small batch PCB assembly.

Key Takeaways

Pick a PCB service that is flexible and reliable. This helps your project fit your needs without delays.

Find companies with lots of experience and skill. Their knowledge prevents errors and gives dependable results.

Check for quality certifications like ISO 9001 or IPC. These show the company follows strict quality rules.

Request prototypes before making many units. Testing them finds problems early, saving time and money.

Review customer support and communication. A helpful company keeps you updated and solves problems fast.

Understanding Small Batch PCB Assembly Services

What Makes Small Batch PCB Assembly Unique?

Small batch PCB assembly is special because it focuses on being precise, flexible, and high-quality. Unlike making large amounts, small batches allow for custom designs and fast results. This method works well for testing ideas, new businesses, or projects needing only a few units.

There are many things that make small batch PCB assembly different. These include how many good units are made, how many have problems, and if they follow industry rules. The table below shows what makes this process stand out:

Feature | Description |

|---|---|

Yield rates | Shows how many working units are made. |

Cycle times | Time needed to finish one production round. |

Defect rates | Number of bad units in a batch. |

Cost per unit | Average cost for each unit made. |

Quality levels | How good the products are. |

IPC standards | Follows rules set by the Institute of Printed Circuits. |

ISO requirements | Meets rules from the International Organization for Standardization. |

Environmental regulations | Follows environmental laws and rules. |

Safety standards | Ensures safety during production. |

These features help small batch PCB assembly create great products while following strict rules.

Why Specialized Services Are Essential for Small Batch PCB Assembly

Specialized services are very important for small batch PCB assembly. They bring the skills and tools needed to handle smaller projects. Here’s how small batch PCB assembly is different from making large amounts:

Design Flexibility: You can change designs often to improve them. Large-scale production needs strict design rules.

Quality Priorities: Small batches test basic functions, while large-scale production checks long-term reliability.

Materials and Manufacturing Techniques: Small batches use simple materials for speed. Large-scale production uses stronger materials for lasting products.

Cost Structures: Small batches cost more per unit because fewer are made. Large-scale production lowers costs by making many units.

Manufacturing Tools and Capabilities: Flexible tools help make quick changes in small batches. Large-scale production uses fixed tools.

By using specialized services, you can make sure your small batch PCB assembly fits your project’s needs. These services help you save time, improve accuracy, and manage costs better.

Key Factors to Choose a PCB Assembly Company

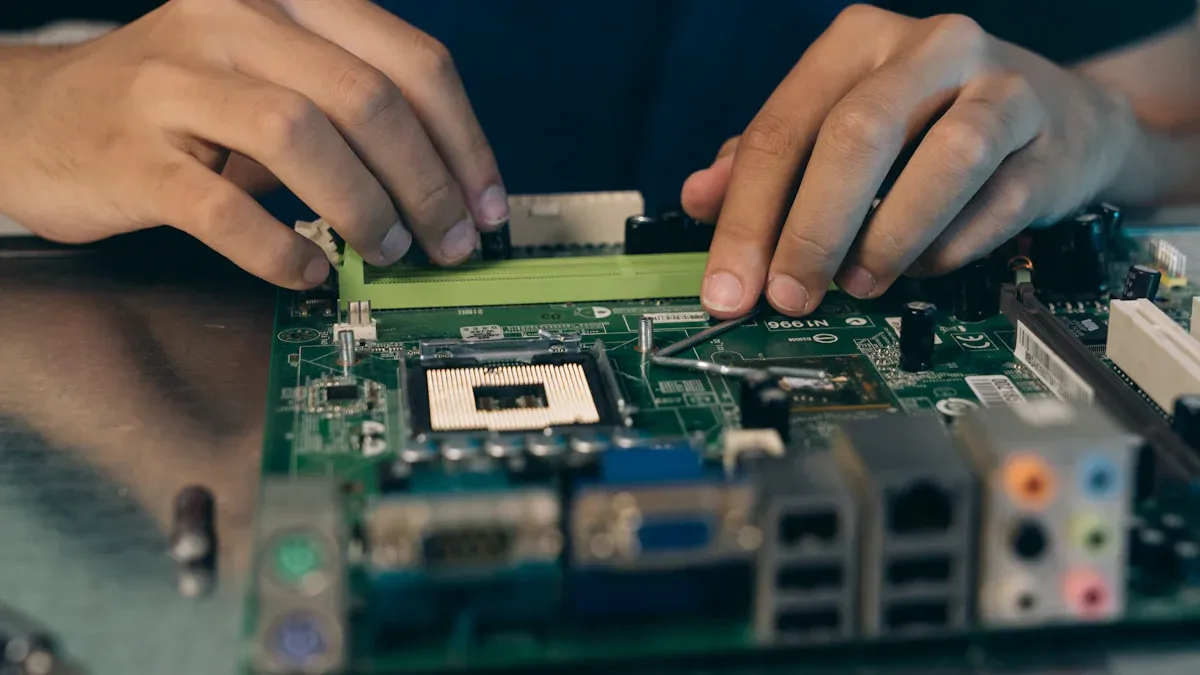

Experience and Expertise in PCB Assembly

When picking a PCB assembly company, experience and expertise matter most. A company with many years of work knows how to handle tricky designs. They also avoid common mistakes that can slow things down. Their skills ensure every step is done carefully and correctly. This is extra important for small orders, where even tiny errors can cause big problems or higher costs.

Studies show that experience leads to better results in PCB assembly. Companies with strong skills keep high standards and deliver dependable products. If they have worked in specific areas like medical devices or aerospace, they can improve your project. But being flexible and open to new ideas is just as important. A company that listens and adjusts to your needs will be a better choice.

💡 Tip: Look at the types of projects the company has done, not just how long they’ve been in business. Ask about their past work and how they solved problems like yours.

Quality Assurance and Certifications

Good quality is a must when choosing a PCB assembly company. Certifications like ISO 9001 and IPC standards show they follow strict rules for quality. These certifications mean their materials, processes, and products meet global standards. If a company follows these rules, you can trust their products will work well.

Strong quality checks make products even better. Companies that meet IPC Class 2 or Class 3 standards offer reliable and consistent results. Many also share detailed reports and certifications to prove their quality. This openness helps you check their work before starting a big order.

📌 Note: Always ask for certifications and reports. These papers show the company can meet your needs.

Flexibility in Handling Small Batch Orders

Flexibility is key for small batch PCB assembly. Small orders often need quick changes and fast delivery. A flexible company can handle these changes without lowering quality or raising costs.

Check the company’s minimum order quantity (MOQ). Some companies require large orders, which might not suit your needs. Others focus on small batches and can make just one unit if needed. This lets you test ideas or make small amounts without wasting money.

Also, look at how the company communicates. Clear and quick communication ensures your needs are understood and followed. A company that values communication will keep you updated, making the process easier and smoother.

🔍 What to expect when working with a PCB assembly company: A flexible company will focus on your needs, communicate well, and adjust quickly. This makes the experience stress-free and ensures great results.

Cost Models and Value for Money

When picking a PCB assembly company, knowing their pricing is key. Companies charge differently, so understanding this helps you decide better. Some have a fixed price per unit, while others charge based on complexity, materials, or speed. Comparing prices helps you stick to your budget without losing quality.

To get good value, choose companies with fair prices and great service. Transparent pricing avoids surprise fees. Always ask for a cost breakdown, including assembly, materials, and testing. This helps you compare options and pick what fits your project best.

Think about long-term savings too. Cheaper services may seem good but can cost more later due to fixes or failures. A trustworthy PCB assembly company makes products that meet standards, cutting down on defects and saving money over time.

💡 Tip: Choose companies with clear pricing and a strong track record for quality.

Customer Support and Communication

Good customer support and communication are very important. A company that cares about customers will keep you updated and meet your needs. Clear and quick communication builds trust and avoids problems.

Here’s what good customer support looks like:

Easy to Contact: The company should reply quickly to your questions.

Honest Updates: Regular updates show they care about your project.

Always Available: They should be ready to help when you need them.

Clear Communication: If working with a foreign company, make sure you understand each other well.

When asking about support, notice how they handle updates and check-ins. A company that values support will make the process easier. They should give clear timelines and fix issues before they grow.

📌 Note: Ask about customer support before choosing a company. Good communication can make your project more successful.

Steps to Research and Identify the Best PCB Manufacturer

Do Research and Make a List of Companies

To find the best PCB manufacturer, start with research. Make a list of companies that match your project needs. Use online directories, trade magazines, or ask experts for advice. Visiting trade shows can also help you find good turnkey PCB assembly providers.

After making your list, narrow it down by checking details. Visit company websites to see their certifications, reviews, and past projects. Focus on companies that handle small batch production or offer turnkey PCB assembly services. This helps you find experts for your project.

Next, send a Request for Information (RFI) to these companies. Share your project details and ask questions about their services. Request references or examples of their work. Review their answers and score them based on experience, certifications, and support. This process helps you pick the best options.

💡 Tip: Use a scoring sheet to compare companies. It makes choosing the right PCB manufacturer easier.

Check Their Services and Skills

Once you have a shortlist, check their services and skills. Start by looking at the testing options they provide. Good manufacturers offer many tests to ensure quality and reliability. The table below shows common tests and their purposes:

Testing Method | Description | Purpose |

|---|---|---|

Automated Optical Inspection (AOI) | Finds assembly mistakes automatically | Quality check |

Electrical Testing | Detects faults and impedance issues | Reliability check |

Continuity Test | Checks for open or short circuits | Fault detection |

Hi-pot Test | Tests isolation between connections | Safety check |

In-circuit Testing | Measures voltage and current | Fault finding |

Resistivity of Solvent Extract (ROSE) Test | Checks for solder residue | Quality control |

Time Domain Reflectometry (TDR) | Measures impedance | Signal quality check |

PCB Stress Testing | Tests under extreme conditions | Long-term reliability |

UL Safety Tests | Ensures safety standards are met | Product safety |

Pick a PCB provider that offers thorough testing. This ensures your PCBs meet standards and work well.

Also, check the manufacturer’s quality levels. PCB makers are grouped into three classes based on quality:

Class | Description | Quality Level |

|---|---|---|

1 | General Electronics Products | Basic Quality |

2 | Dedicated Service Electronics Products | Medium Quality |

3 | High-Reliability Electronics Products | Best Quality |

For important projects, choose a Class 2 or Class 3 manufacturer. This lowers the chance of problems and ensures reliable products.

📌 Note: Always check for certifications like ISO 9001 and IPC standards. These show the company values quality and reliability.

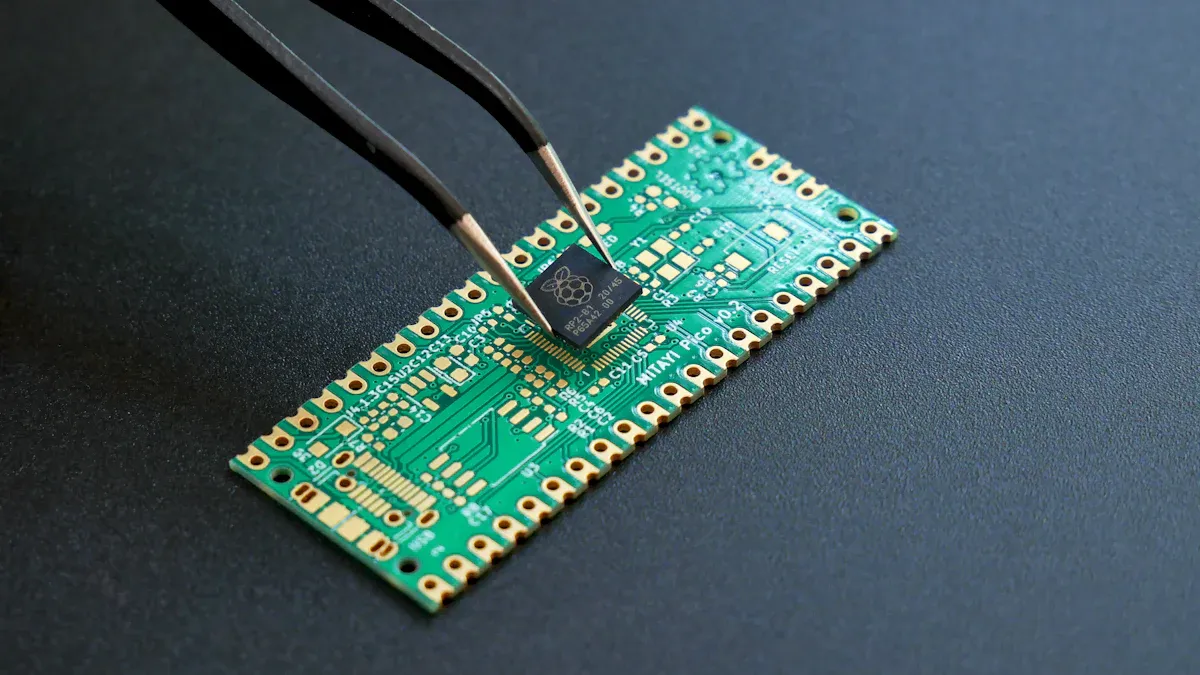

Ask for Prototypes or Samples

Before starting full production, ask for prototypes or samples. Prototypes let you test the design, function, and quality of your PCB. They also help you find problems early, saving time and money.

When testing prototypes, focus on key factors like efficiency, customer satisfaction, and innovation. The table below explains these factors:

Performance Indicator | Description |

|---|---|

Production Efficiency | Shows how well raw materials are turned into products. |

Customer Satisfaction | Measures how happy customers are with the products and services. |

Product Innovation | Checks how well the company creates new and better products. |

Environmental Impact | Looks at how eco-friendly the manufacturing process is. |

Financial Health | Reviews the company’s stability and profits. |

Testing prototypes also lets you see the manufacturer’s testing process. Ensure they do checks like AOI, electrical testing, and stress testing. These tests confirm the PCB’s quality and reliability.

🔍 What to Look For: A good turnkey PCB provider will give high-quality prototypes, detailed test reports, and fix any issues quickly. This shows they care about quality and customer satisfaction.

Check Reviews, Testimonials, and References

When picking a PCB assembly company, reviews and references are helpful. They show what other customers think and how reliable the company is. Start by reading online reviews on trusted websites. Look for common themes in the feedback. If many people praise the quality and delivery, the company is likely dependable. But if there are repeated complaints about delays or bad communication, be cautious.

Testimonials on the company’s website can also give useful information. These often share stories of happy clients and successful projects. However, don’t rely only on these. Check independent reviews for a full view. If you can, ask the company for references. Talking to past clients lets you ask specific questions. For example, you can ask if the company met deadlines or handled problems well.

💡 Tip: Look for reviews about small batch orders. These will show how the company handles projects like yours.

Assess Responsiveness and After-Sales Support

Good communication is very important when working with a PCB assembly company. A responsive company answers your questions quickly and keeps you informed. This helps your project stay on schedule and solves problems fast. Notice how they respond when you first contact them. Quick replies and clear answers are good signs.

After-sales support is just as important. This includes fixing problems, repairs, or replacements after delivery. Good support means you won’t be stuck if something goes wrong. Ask about their after-sales services. Do they help with technical issues? Will they fix defects for free? Knowing this can save you time and money later.

📌 Note: Customer support should continue after delivery. A good company will still help you even after the sale.

Common Mistakes When Choosing a PCB Assembly Company

Only Thinking About Cost, Not Quality

Picking the cheapest option might seem smart, but it’s risky. Low-cost companies may skip important steps, making bad products. This can lead to broken items, delays, and spending more later. For small orders, even small mistakes can ruin your project. Instead of just looking at price, think about value. A good PCB assembly company makes high-quality products, saving you time and money later.

💡 Tip: Don’t pick the cheapest option. Spending a bit more now can save you trouble later.

Forgetting About Certifications and Standards

Certifications are important for making reliable products. Ignoring them can cause problems like:

Fewer supplier choices because uncertified ones may not work for you.

Trouble managing the supply chain, leading to delays.

Extra effort explaining your product’s quality to customers.

Companies with certifications like ISO 9001 or IPC standards follow strict rules. They use good materials and processes. Without these, you might get products that don’t work well.

📌 Note: Always check for certifications. This helps keep your project on track.

Not Checking Customer Support and Communication

Good communication makes the process easier. Poor support can cause confusion, delays, and stress. Surveys show how important communication is in PCB assembly services:

What It Means | |

|---|---|

Customer Service | Do they reply fast and fix problems quickly? |

Dependability | Do they send quotes on time? Do they assign someone to manage your project? |

Feedback Authenticity | Do they ask all customers for feedback, not just happy ones? |

A company with great support keeps you updated and solves problems fast. This helps your project go smoothly from start to finish.

🔍 What to Look For: Pick a company that communicates well and offers strong support. This makes the process easier and stress-free.

Skipping Prototype Testing Before Full Production

Skipping prototype testing can cause big problems in your PCB project. Prototypes help find and fix design mistakes early. Without testing, you might make faulty PCBs that don’t work or meet standards.

Did you know most product failures happen due to PCB design errors? Testing a prototype helps check if your design works well. It also finds problems and allows changes before production. This saves both time and money.

Here’s why skipping prototypes is risky:

Unnoticed Design Errors: Without testing, mistakes in your PCB design may stay hidden. Fixing them later costs more time and money.

More Failures: Faulty PCBs can break products, hurting your reputation and trust.

Wasted Money: Making bad PCBs in large amounts wastes materials and resources. Prototypes help avoid these extra costs.

Prototypes also let you test how your PCB works in real situations. You can check for problems like heat, signal issues, or stress. This step ensures your final product is reliable and high-quality.

💡 Tip: Always ask for a prototype before full production. A small test now can prevent bigger problems later.

By using prototype pcb assembly, you lower risks and improve success. Early testing makes sure your PCBs are ready and meet your needs.

Picking the best small batch PCB assembly service needs careful thought. Look for companies with good experience, strong quality checks, and flexibility to fit your needs. Clear customer support and honest pricing are also very important for smooth work and great results.

Important things to check include:

Equipment Capabilities: Make sure they can handle your project’s needs.

Production Capacity: Check if they can manage small or big orders.

Product Quality: See if they follow rules and do proper testing.

Customer Support: Pick a company that answers fast and fixes problems.

Cost Dynamics: Find a balance between quality and your budget.

By following these steps, you can choose a service that makes reliable, affordable, and high-quality PCBs for your project.

FAQ

What is the smallest order I can place for small batch PCB assembly?

The smallest order depends on the company. Some companies focus on small batches and can make just one unit. Always check with the company to see if their minimum order fits your project.

How long does it take to finish small batch PCB assembly?

The time needed depends on your design and the company’s workload. Some companies offer faster services, delivering in 1–2 weeks. Regular orders usually take about 3–4 weeks.

Can I change my design after production starts?

Yes, many companies let you change designs during production, especially for small batches. But this might cost more and take longer. Talk to the company about changes before starting.

What certifications should a PCB assembly company have?

Look for certifications like ISO 9001, IPC standards, and UL safety certifications. These show the company follows strict quality and safety rules, making reliable PCBs.

Why is testing prototypes important before making all the PCBs?

Testing prototypes finds design mistakes and checks if the PCB works well. It helps avoid expensive problems during full production and makes the final product better.

💡 Tip: Test prototypes first to save time and money later.

See Also

Essential Guidelines for Choosing Top PCB Assembly Services

Key Factors for Choosing the Right PCBA Manufacturer

Crucial Steps to Find the Ideal PCB Prototype Manufacturer