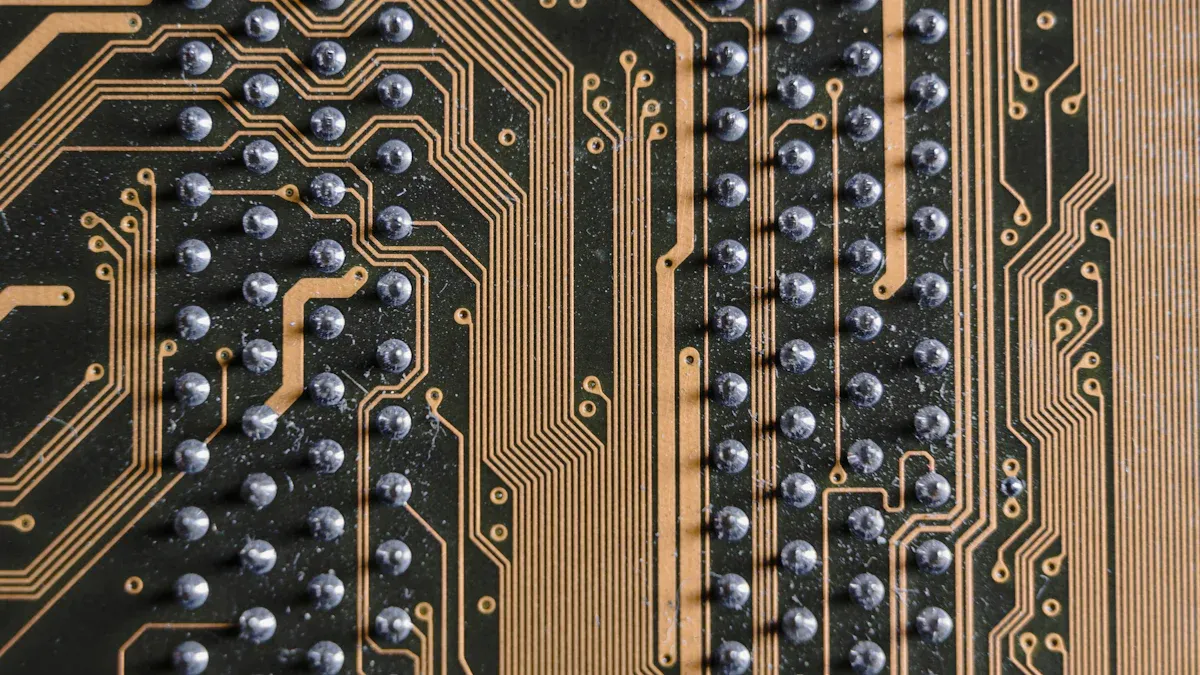

Ball Grid Array (BGA) and micro-BGA assembly services are crucial in the production of modern electronics. BGA is a type of packaging that utilizes tiny solder balls to connect a chip to a circuit board, while micro-BGA represents a smaller and more advanced version designed for high-tech applications. These technologies contribute to making devices smaller, faster, and more efficient, aligning with current consumer demands.

By 2025, BGA and micro-BGA assembly services will become even more significant. The global BGA market was valued at $3.5 billion in 2022 and is projected to reach $5.9 billion by 2032. This anticipated growth is driven by the demand for smaller designs, smart devices, and advancements in AI technology. Additionally, micro-BGA is increasingly being integrated into automotive electronics and 5G networks, underscoring its vital role in the future of electronics.

Key Takeaways

BGA and micro-BGA tech help make smaller, faster devices.

People want smaller gadgets, so demand for these grows.

These assemblies boost performance by improving signals and cooling.

They are important in healthcare and cars to avoid failures.

Using good materials and checks can stop production problems.

Understanding BGA and Micro-BGA Assembly

What is Ball Grid Array (BGA)?

Ball Grid Array (BGA) is a way to attach chips to boards. Instead of pins, it uses tiny solder balls in a grid under the chip. This design saves space and works better. It was made in the 1990s to fix problems with older pin designs like Pin Grid Array (PGA).

BGA is used in small, reliable devices. It has benefits like better heat control, stronger electrical connections, and smaller size. These features make BGA important for today’s smaller, faster gadgets.

What is Micro-BGA?

Micro-BGA is a smaller version of BGA. It packs parts closer together by shrinking the space between solder balls. This makes it perfect for things like smartphones and smartwatches.

Micro-BGA has special designs to handle stress and last longer. For example, it uses a soft layer to handle heat changes. This helps it work well in devices needing more memory and speed. Micro-BGA is key for advanced electronics.

Key Features of BGA and Micro-BGA

BGA and Micro-BGA have special features tested by experts. These features make sure they are reliable, fast, and efficient.

Key Feature | How It’s Tested |

|---|---|

Assembly | X-rays check for mistakes like shorts or misalignments. |

Electrical Testing | Tests like JTAG and ICT check if circuits work properly. |

Thermal Management | Patterns are improved to lower heat, proven by studies. |

Long-Term Reliability | Heat and cold tests ensure they last long, following standards. |

Mechanical Stress Management | Extra support is added to handle shocks, tested in tough uses. |

These features show why BGA and Micro-BGA are so important. They help make small, strong, and fast devices for the future of technology.

Why Making Electronics Smaller Matters in 2025

Making electronics smaller is shaping the future of technology. Devices are getting tinier, lighter, and stronger as tech improves. This change isn’t just about looks. It’s about making gadgets easier to carry, more useful, and better for the planet.

Reasons for Smaller Electronics

Here’s why shrinking electronics is so important in 2025:

People want smaller gadgets like phones and smartwatches for daily use.

Powerful devices need tiny, efficient parts to work well.

New manufacturing methods make it easier to build small designs.

Companies aim to lower costs by using fewer materials.

Eco-friendly designs save energy and help protect the environment.

These reasons show why smaller electronics are not just a trend—they’re essential.

Cool Tech Helping Miniaturization

New ideas are making smaller, better gadgets possible. Here are some examples:

Bendable circuit boards can be used in wearables and medical tools.

HDI tech helps create tiny designs with more features.

ALE tech builds super-small parts with great precision.

Startups like AlixLabs and Spectricity are leading these changes. They’re creating amazing tools like ALE for tiny parts and sensors for better gadgets. These ideas are key to making electronics smaller.

Why It’s Important for You

Smaller gadgets make life easier. They’re portable and save energy, helping the planet. Compact designs also pack more power into everyday devices like phones and watches.

By 2025, smaller electronics will keep improving technology. They’ll meet your needs while solving big problems like saving energy. Expect smarter, faster, and greener gadgets in the future.

Benefits of BGA and Micro-BGA Assembly Services

Better Performance and Signal Quality

BGA and micro-BGA help devices work better. They improve signal quality by lowering resistance and interference. This makes signals move faster and more smoothly. Even in fast devices, these assemblies reduce signal loss.

Engineers use special tests to check signal quality. These tests make sure signals stay strong:

What It Does | |

|---|---|

Time Domain Reflectometry | Finds breaks in signal paths that may cause problems. |

Vector Network Analysis | Adjusts signals for better performance. |

Eye Diagram Analysis | Checks for clear signals by measuring noise levels. |

Bit Error Rate Testing | Tests how well signals handle errors during transmission. |

These tests ensure BGA and micro-BGA provide strong and reliable connections for modern devices.

Excellent Heat Control

Good heat control helps devices last longer. BGA methods are great at managing heat. They use materials like silicon or ceramic, which cool better than older materials.

Here’s a comparison of how different BGA types handle heat:

Substrate Type | Heat Control | Durability | Performance |

|---|---|---|---|

Traditional BGA (FR-4, BT resin) | Lower | Average | Standard |

FCBGA (Silicon, Ceramic) | Higher | Stronger | Better |

Using BGA and micro-BGA keeps devices cool and working well for a long time.

Small Size for More Space

BGA and micro-BGA save space in devices. Their small design fits more parts into tiny gadgets like phones and watches. They don’t need big pins, so they take up less room.

This small size matches the trend of making smaller devices in 2025. Tiny gadgets look cool, use fewer materials, and are better for the planet. With BGA and micro-BGA, you can build smart, compact, and eco-friendly electronics.

Reliability in High-Demand Applications

Reliability is crucial for important devices. Industries like aerospace, healthcare, and telecommunications need devices that work perfectly, even in tough conditions. BGA and micro-BGA assemblies help ensure this reliability.

Why Reliability Is Important

We depend on electronics daily, from phones to medical tools. In critical situations, even small failures can cause big problems. For example:

In healthcare, a broken pacemaker could risk someone’s life.

In aerospace, a tiny failure might affect navigation or communication.

In telecommunications, bad parts could lead to network problems.

BGA and micro-BGA assemblies are built to handle these issues. Their strong design and careful testing meet the highest standards.

Features That Make Them Reliable

Here’s why BGA and micro-BGA assemblies are so dependable:

Strong Connections: Solder balls create tough electrical links. These links stay strong, even with constant movement or shaking.

Heat Resistance: Materials like ceramic help them survive extreme heat or cold. This makes them great for space or heavy machinery.

Water Protection: Special coatings keep them safe from moisture and rust, ensuring they last longer.

Tip: Always pick tested components for devices used in critical jobs.

Real-Life Uses

Car Electronics: Micro-BGA assemblies power safety systems like ADAS in cars.

5G Networks: BGA assemblies keep fast networks stable, even during heavy use.

With BGA and micro-BGA technologies, devices can stay reliable no matter the challenge.

The BGA Assembly Process

Solder Paste Application

The first step is adding solder paste to the board. This paste sticks parts together and helps electricity flow. It’s important to apply it carefully. Machines or stencils are used to place the paste exactly where needed.

Studies show that the type of solder paste affects the results:

Paste A spreads better but has more uneven spots.

Paste C is better than Paste A but not as good as Paste B.

Picking the right paste helps make strong and repeatable connections. This is key for a good BGA assembly.

Component Placement and Alignment

After the paste is added, the BGA parts are placed on the board. This step needs to be very precise. Modern machines can place parts with tiny errors, as small as ±40 microns.

Here’s how accurate placement is for different parts:

Component Type | Placement Accuracy |

|---|---|

BGA and FBGA | |

Fine-pitch ICs | ±40 micron |

Small outline ICs | ±70 micron |

Passive devices | ±70 micron |

Flip-chip/WLCSP | ±20 micron |

BGA parts can adjust themselves during heating. This means even if placement isn’t perfect, they can still align correctly.

Reflow Soldering

The last step is reflow soldering. The board is heated to melt the solder paste and connect the parts. The heating process follows a set temperature plan to avoid mistakes:

Stage | Temperature Range (°C) | Ramp Rate (°C/second) | Duration (minutes) |

|---|---|---|---|

Ramp to Soak | 150-160 | 1-5 | 1-3 |

Reflow | 180-200 (liquidus) | 20-40 above liquidus | 15-60 |

Cooling | <100 | 1.5-6 | N/A |

This careful heating stops problems like overheating or weak connections. By following these steps, you can build reliable BGA assemblies.

Inspection and Quality Assurance

Inspection and quality checks are very important for BGA and micro-BGA assemblies. These steps make sure every product is reliable and works well. By using careful tests, manufacturers create assemblies that work perfectly in tough situations.

Key Inspection Metrics

Manufacturers use different methods to check quality. Each method looks at a specific part of the process. Here’s a simple table of inspection types and what they check:

Inspection Type | What It Checks |

|---|---|

Final Quality Inspection | Makes sure the product meets all rules before delivery. |

Appearance and Cosmetic Attributes | Looks at how the product looks on the outside. |

Dimensional Accuracy and Tolerances | Checks if the product size matches the required measurements. |

Functionality and Performance Testing | Tests if the product works as it should. |

Safety Features and Compliance | Makes sure the product follows safety rules. |

Packaging and Labeling Integrity | Checks if the packaging is correct and undamaged. |

These checks make sure the product looks good, is the right size, and works properly.

Advanced Inspection Techniques

New tools help find hidden problems in BGA and micro-BGA assemblies. X-ray machines can see inside and find issues like bad solder joints. Automated Optical Inspection (AOI) quickly spots missing parts or surface flaws. Functional tests check if the product works in real-life situations.

Tip: Pick products from companies that do strict testing. This ensures you get safe and high-quality assemblies.

By focusing on inspections, manufacturers make sure their products are safe, reliable, and ready for modern technology. These steps guarantee that every product can handle today’s challenges.

Challenges in BGA and Micro-BGA Assembly

Inspection Complexities with Hidden Solder Joints

Checking hidden solder joints in BGA and micro-BGA assemblies is tricky. The solder balls are under the component, so regular visual checks don’t work. Special tools like X-rays and heat tests are needed to find problems like missing balls, dents, or weak joints.

Problem | What Happens | Why It Happens | Result | How to Fix It |

|---|---|---|---|---|

Missing Solder Balls | Some parts don’t have solder balls. | Mistakes during making, not enough solder paste, or stress. | Broken circuits, bad connections, or device failure. | Use enough solder paste and protect parts during shipping. |

Solder Ball Dents | Dents appear in solder balls. | Stress from heat or handling. | Weak joints, bad reliability, or device failure. | Watch heat cycles and handle parts carefully. |

Tip: Pick manufacturers that use tools like X-rays and shear tests to make sure assemblies are strong and reliable.

Environmental Sensitivity

Weather conditions like temperature and humidity affect BGA assembly. Dry air can make solder paste hard, while wet air causes clumps and bridges. Hot or cold temperatures change how the paste spreads, leading to smears or bad printing.

Dry Air: Makes paste hard, causing weak joints.

Wet Air: Adds water to paste, creating clumps and bridges.

Cold Temperatures: Thickens paste, making it hard to spread.

Hot Temperatures: Thins paste, causing smears and rust.

Keeping the right conditions is important. Experts say the best temperature is 74-78°F, with humidity around 60%.

Note: Keeping humidity at 60% and temperature between 74-78°F helps solder paste work better and reduces mistakes.

Cost and Equipment Requirements

The price of BGA assembly depends on materials and tools. Old materials cost more upfront but work better with fewer problems. New materials seem cheaper but cause jams, waste, and delays.

Material Type | Problems Found | Cost Effects |

|---|---|---|

Old Material | Few jams, no defects | Lower costs overall |

New Material | Many jams, defects | Higher final costs |

High-tech tools like X-ray machines and ovens cost a lot but are needed for good assemblies.

Tip: Spending money on good materials and tools saves money later by reducing mistakes and speeding up production.

Repair and Rework Challenges

Fixing BGA and micro-BGA assemblies is not easy. These parts are tiny and fragile, so fixing them can cause more harm. Special tools and skills are needed to do it right.

Why Fixing BGA Assemblies is Hard

Hidden Solder Joints: Solder balls are under the part. This makes them hard to see or reach during repairs.

High Precision Needed: Fixing requires great care. Even small errors can ruin the board or part.

Heat Sensitivity: Too much heat can damage the part or nearby areas.

Tip: Use tools like reflow ovens or hot air stations to control heat and avoid damage.

Tools for Fixing

Regular tools won’t work for BGA repairs. Advanced tools are a must:

Tool | What It Does |

|---|---|

Rework Station | Removes and replaces BGA parts with accuracy. |

X-ray Inspection Machine | Finds hidden problems like gaps or misaligned solder balls. |

Soldering Microscope | Gives a clear view for precise repairs. |

Challenges to Keep in Mind

Even with good tools, some problems remain:

Takes Time: Fixing one part can take hours.

Expensive: Advanced tools and skilled workers cost more.

Risk of Damage: Fixing too often can weaken the board and shorten its life.

Note: If a BGA assembly keeps failing, replacing the whole board might save time and money.

Knowing these challenges helps you decide on repairs. Using the right tools and methods can lower risks, but some issues can’t be avoided.

Applications and Future Trends in BGA and Micro-BGA Technologies

Consumer Electronics and Wearables

BGA and micro-BGA are key for future gadgets. Devices like phones, watches, and trackers are getting smaller. These technologies help fit more features into tiny spaces. This allows sleek designs without losing performance.

People want small, light devices that work well. Micro-BGA is perfect for wearables. These parts save space and handle constant movement. They also keep devices cool during long use.

Market Growth in Consumer Electronics

The electronics market is growing fast with smart devices and IoT. Here’s a quick look at related markets:

Report Title | Market Value (2024) | Projected Value (2035) | CAGR (%) |

|---|---|---|---|

Thermal Silicone Gel Market | $1.5 billion | $2.8 billion | 5.6% |

Optical Digitizer and Scanner | $1,500 million | $3,072 million | 6.7% |

Piezoelectric Materials Market | $1,455 million | $2,420 million | 4.7% |

Telerehabilitation Market | $5,400 million | $14,147 million | 9.2% |

More people want home rehab tools and IoT devices. This shows how important BGA is for electronics.

Automotive Electronics and Autonomous Vehicles

BGA and micro-BGA are vital for car electronics. Modern cars need these for safety, navigation, and self-driving systems. These parts are small but powerful, perfect for high-tech cars.

Why Reliability Matters

Car electronics must work in tough conditions. A small failure can cause big problems, like accidents. That’s why manufacturers test every part carefully.

Aspect | Description |

|---|---|

Importance of NDT | Nondestructive testing ensures the safety and reliability of automotive components. |

Risk of Non-compliance | A single non-compliant part can lead to recalls, legal issues, and safety risks. |

Reliability Requirements | Automotive PCBs must pass ISO/TS 16949 certification and withstand extreme conditions. |

Future Trends in Automotive Electronics

Cars are getting smarter and need better parts. Micro-BGA is now common in systems like ADAS. These ensure cars perform well in critical tasks.

Telecommunications and 5G Infrastructure

5G networks are changing how we connect, and BGA is a big part of it. These parts handle high speeds and large data needs, making 5G faster and more reliable.

Key Features for 5G

BGA is great for 5G tech. Here are some cool features:

The iCana ICAMB2629-A works in the 5G FR2 range (26.5 to 29.5 GHz).

It gives over 10 dBm power per channel in transmit mode.

It has a gain of 27 dB in receive mode and uses only 0.7 W.

Future of Telecommunications

5G demand is growing, and more RF products are needed. These technologies improve connection quality, giving you better internet. As 5G grows, BGA will stay important for fast and efficient networks.

Emerging Trends in IoT and Miniaturized Devices

The Internet of Things (IoT) is changing how devices work together. Tiny, powerful parts are key to this change. These small components help create smart technologies that fit easily into your life.

Why Miniaturization is Important for IoT

Small devices are crucial for IoT. They allow more features in less space. This trend is transforming industries like healthcare, cars, and gadgets. For example:

Wearable health trackers now check your vitals in real-time.

Smart home tools like cameras and thermostats are smaller and save energy.

Key trends in miniaturization include:

Energy Efficiency: Small devices use less power, perfect for IoT.

Better Features: Advanced designs let them do many tasks at once.

Industry Use: From healthcare to cars, small electronics are vital.

Market Growth and Future Potential

The market for small electronics is growing fast. In 2023, it was worth $46.14 billion. By 2030, it could reach $85.44 billion, growing at 9.2% yearly.

Here’s how the market may grow:

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2023 | 46.14 | – |

2024 | 47.25 | 10.2 |

2025 | 52.06 | 10.2 |

2029 | 72.07 | 8.5 |

2030 | 85.44 | 9.2 |

This growth shows how popular and useful small IoT devices are becoming.

New Ideas in Miniaturized Devices

New tech is making small devices better and more useful. Flexible circuits let devices bend, great for wearables. HDI tech helps make tiny, complex boards. ALE tech builds super-small parts with high accuracy.

Both startups and big companies are leading these changes. For example:

AlixLabs is improving ALE technology.

Spectricity makes advanced sensors for IoT gadgets.

These ideas will keep small electronics improving for a connected world.

How This Helps You

Small devices make life easier. They create smart gadgets that are portable, efficient, and eco-friendly. For example:

A smartwatch can track your fitness.

A smart thermostat can save energy.

Tip: Pick IoT devices with advanced small parts. They last longer and work better.

By 2025, small devices will power smarter and greener technologies. They will play a big role in the future of electronics.

BGA and micro-BGA services have changed how electronics are made. They help create smaller, faster, and better devices. These assemblies offer important benefits, as shown below:

Benefit | Explanation |

|---|---|

BGA fits many connections in tiny spaces, perfect for small gadgets. | |

Better Heat Control | Solder balls in BGA help cool parts, great for powerful devices. |

Improved Signal Quality | Shorter paths lower resistance, making signals clearer and faster. |

These features make BGA and micro-BGA vital for things like phones, cars, and 5G networks. As technology grows, they will play a big part in the future of electronics by 2025.

FAQ

What makes BGA and Micro-BGA different?

BGA has bigger solder balls, while Micro-BGA uses smaller ones placed closer together. Micro-BGA works best for tiny gadgets like smartwatches. Both perform well, but Micro-BGA is better for small electronics.

Why is heat control important in BGA?

Heat can harm devices and shorten their life. BGA uses materials like ceramic to spread heat away. This keeps devices cool and helps them last longer.

Can you fix BGA assemblies?

Yes, but fixing BGA assemblies is hard. The solder balls are hidden, so special tools like X-rays are needed. Skilled workers can repair them, but it takes time and costs more.

How does BGA make signals better?

BGA shortens the path for electricity to travel. This lowers resistance and blocks interference, making signals faster and clearer. That’s why it’s great for speedy devices.

Are BGA assemblies good for the environment?

Yes, BGA assemblies use less material and fit into smaller designs. This cuts waste and saves energy, making them a greener choice for today’s electronics.

See Also

A Comprehensive Guide To PCBA Manufacturing And Assembly

Top 10 Strategies For Cost-Effective PCBA Assembly Success

The Benefits And Drawbacks Of Flex PCBA In Electronics

Choosing The Right PCBA Manufacturing Services For Innovation