Choosing the right flex circuit manufacturer is very important for your project. A good manufacturer can improve how well your product works. Important things to think about are quality, cost, and communication. For example, companies with a lot of experience can fix problems better. Also, having advanced tools helps make high-quality products. Don’t forget to check your project needs, like design help and quality checks, as you look at your choices.

Key Takeaways

Pick a manufacturer that has good technical skills and important certifications. This helps make sure you get high-quality flex circuits.

Check the production capacity to see if the manufacturer can handle your order size and delivery times.

Choose the right materials for your flex PCBs. They greatly affect how long they last and how well they work.

Keep in touch with your manufacturer. This helps avoid mistakes and keeps the project on track.

Begin working together early in the design process. This helps find problems and makes it easier to manufacture.

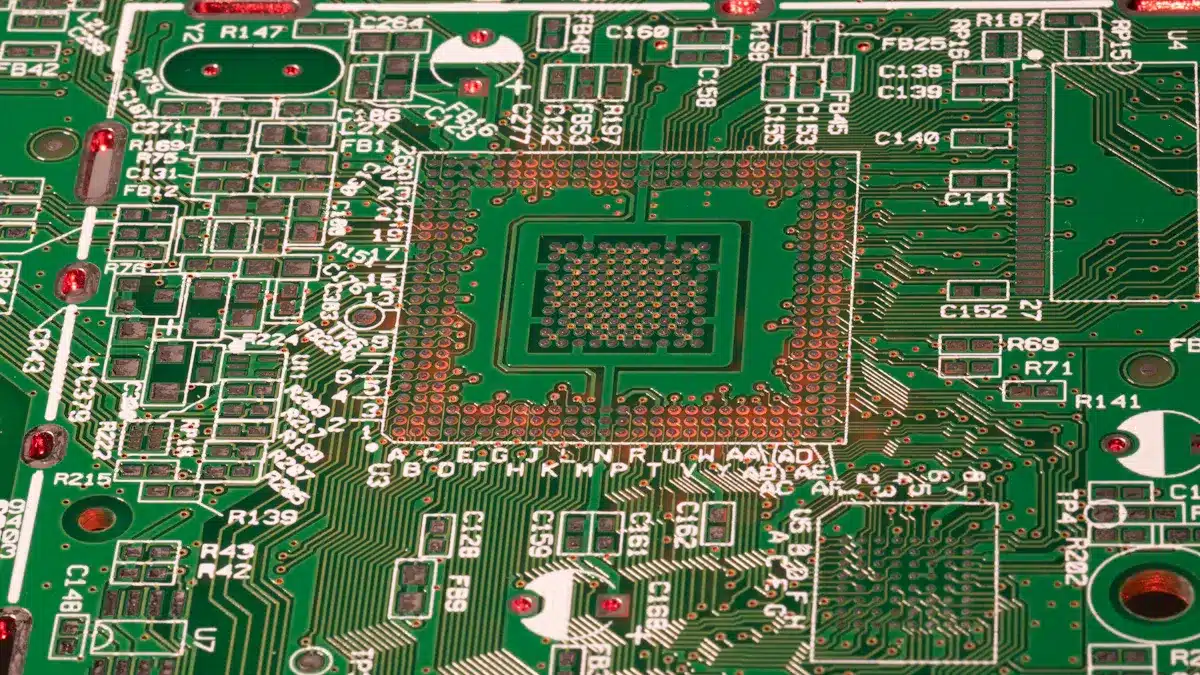

Manufacturer Capabilities

When you choose a flex circuit manufacturer, check their skills. Two important areas to look at are technical knowledge and how much they can produce.

Technical Expertise

Technical knowledge is key for making good flex PCBs. Look for manufacturers with the right certifications. These show they know what they are doing and follow industry rules. Here’s a table of key certifications for flex circuit makers:

Certification/Standard | Description |

|---|---|

IPC-6011 | General rules for printed circuits. |

IPC-6012 | Rules for rigid circuit boards. |

IPC-6013 | Rules for flexible circuit boards. |

IPC-FC-2221 | Guide for designing printed circuit boards. |

IPC-FC-2223 | Guidelines for flexible printed circuit boards. |

IPC-4202 | Rules for flexible materials in circuit boards. |

IPC-A-600 | Acceptable quality for printed boards. |

IPC-A-610 | Quality standards for printed board assemblies. |

IPC/EIA J-STD001 | Rules for soldered electrical assemblies. |

Also, think about how long the manufacturer has been in business. Top manufacturers usually have many years of experience. For example, here’s a table showing how long some top manufacturers have been around:

Manufacturer | Years of Experience |

|---|---|

All Flex | |

Technotronix | 40+ |

Sierra Circuits | 37+ |

This experience helps them handle different types of flex PCBs and uses.

Production Capacity

Production capacity is another important point. You need a manufacturer that can meet your order size. The best manufacturers often have high monthly production numbers. Here’s a table showing the production abilities of some top manufacturers:

Manufacturer | Monthly Production Capacity |

|---|---|

Topfast-PCB | |

Wus Printed Circuit | 1.5 million square feet |

It’s important to know how manufacturers can increase production for large orders. Here are some common ways they do this:

Description | |

|---|---|

Advanced Manufacturing | Uses new technologies to improve flexible circuits. |

Roll-to-Roll Manufacturing | A process that makes production easier and cheaper for large orders. |

Batch Production | Increases order size to lower costs per unit. |

By looking at both technical knowledge and production capacity, you can choose the best flex circuit manufacturer for your project.

Flex Circuit Materials and Technologies

When you pick a flex circuit manufacturer, nowing the materials and technologies they use is very importankt. The right materials can greatly affect how well your flex PCBs work and last.

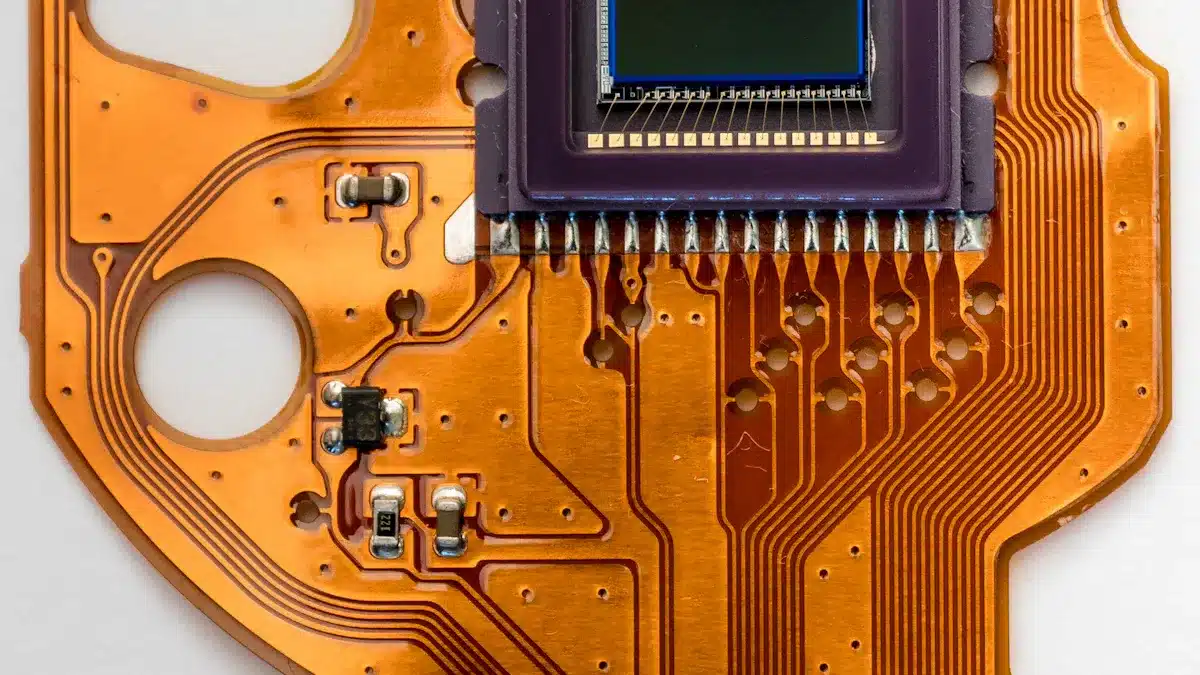

Material Selection

Flex circuits use different materials, and each has special features. Here are some common types of flex PCBs:

Type of FPCB | Description |

|---|---|

Single-sided FPCBs | Have one layer of conductive material on one side of a flexible base. |

Double-sided FPCBs | Have conductive material on both sides for better designs and connections. |

Multilayer FPCBs | Have many layers, allowing for complex designs and more components. |

Rigid-flex FPCBs | Mix flexible and rigid materials for uses needing both flexibility and support. |

Choosing the right material is key for your design. The best flex circuit board material affects how long it lasts and how flexible it is. For example, polyimide and polyester are popular choices. Their thickness changes how well the circuit can bend and handle stress.

Thinner boards bend more easily but may not last long with constant bending.

A 0.1 mm thick flex PCB can bend with a radius of 1 mm, but bending too much can cause damage.

Designers often add stiffeners in areas that need extra strength without making the board thicker.

Advanced Technologies

Top manufacturers use advanced technologies to make flex circuits better. Here are some important technologies used today:

Technology/Capability | Description |

|---|---|

High-density interconnections | Helps create compact designs for moving parts. |

Durable materials | Materials like polyimide and polyester improve signal quality and reduce interference. |

Laser drilling and AOI | Modern methods for precise PCB making and quality checks. |

Support for 5G and 6G technologies | Important for new communication devices with complex designs. |

Flex, Flex-rigid, and Transparent Flex PCBs | Different designs to fit various needs. |

These technologies make assembly easier, which lowers material and labor costs. Flexible circuits need fewer materials because of their small size, which cuts down on raw material costs. Easier assembly also saves on labor costs and time.

By knowing the materials and technologies in flex circuits, you can make smart choices that help your project succeed.

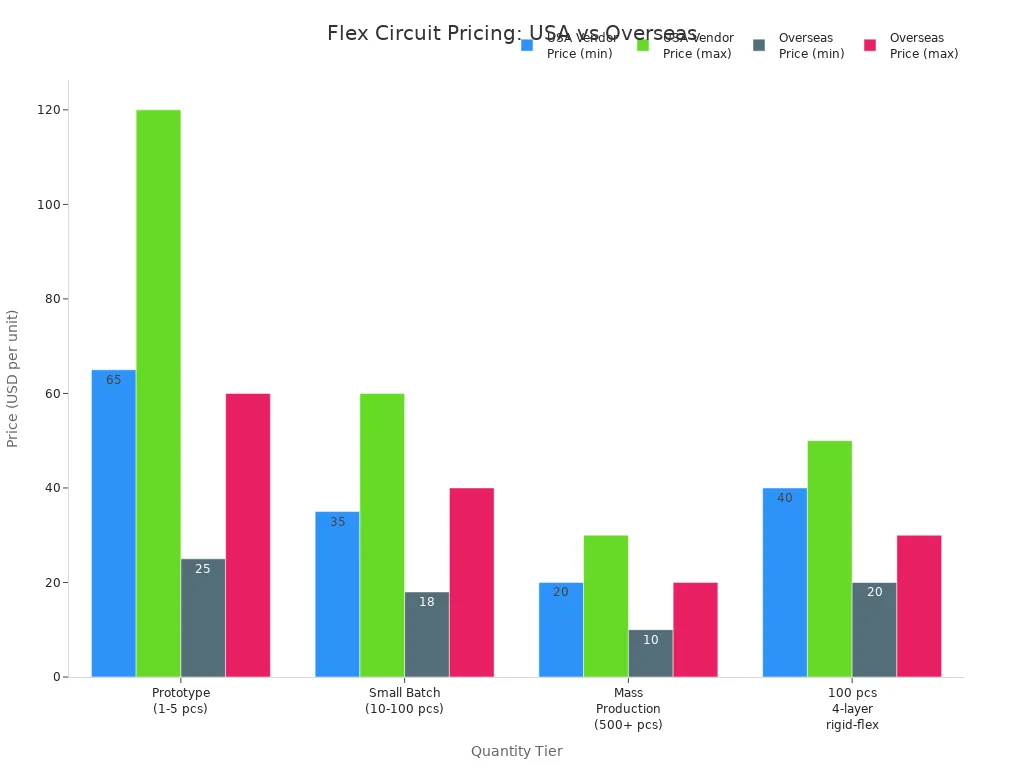

Cost and Turnaround Time

When you pick a flex circuit manufacturer, knowing about cost and turnaround time is very important. These things can greatly affect how well your project does.

Pricing Structures

Prices for flex circuits change based on how complex they are and how many you need. Here’s a list of typical price ranges for different kinds of flex circuits:

Type of Flex Circuit | Price Range (per square inch) |

|---|---|

Single-sided | $0.50 to $5 |

Double-sided | $1.50 to $10 |

Multi-layer | $5 to $50 |

You should also think about how prices are different between local and overseas manufacturers. The table below shows the price differences based on how many you order:

Quantity Tier | USA Vendor Price | Overseas Price | Notes |

|---|---|---|---|

Prototype (1-5 pcs) | $65-$120 | $25-$60 | USA faster & compliant |

Small Batch (10-100 pcs) | $35-$60 | $18-$40 | Volume lowers cost gap |

Mass Production (500+ pcs) | $20-$30 | $10-$20 | Overseas cheaper |

100 pcs – 4-layer rigid-flex | $40-$50 | $20-$30 | Notable quality difference |

Timely Delivery

Getting your order on time is key to keeping your project on track. The average time for flex circuit orders is usually 3-5 days for quick prototypes. But, if you need a lot of them, it can take 2-3 weeks. How complex your design is and how many layers it has can really change these times.

Manufacturers make sure to deliver on time by using different methods:

Evidence Description | Details |

|---|---|

Standard Lead Times | Manufacturers give lead time expectations for flex and rigid-flex circuit boards. They note that complexity and materials can change these times. |

Production Processes | Rigid-flex parts often go through many lamination steps, which can really slow down production. |

Design Considerations | Certain design choices, like not using vias in bend areas, can help avoid delays in engineering and production. |

Production Speed | Factories in China can make parts in as little as 7 days, while a factory in Dallas can do it in 10 days, depending on complexity. |

By knowing about pricing structures and making sure you get timely delivery, you can make smart choices that fit your project needs.

Communication with Flex Circuit Manufacturers

Talking clearly with your flex circuit manufacturer is very important for your project to succeed. Good communication can really change how well your project does. It can make your product work better and keep costs down. You should create strong ways to communicate so everyone knows the project goals and needs.

Clear Communication

Clear communication helps you and your manufacturer stay on the same page. When you give detailed information, it lowers the chances of mistakes. Here are some good things about keeping communication clear:

Faster Production Times: Working closely with your manufacturer during design can speed up production.

Early Issue Identification: Sharing detailed information helps find problems early, which cuts down on errors.

Alignment Among Stakeholders: Clear communication about project goals makes sure everyone understands what to do.

By focusing on clear communication, you can make your project run more smoothly. The progress in rigid-flex circuit board technology shows how good communication can lead to better results.

Early Collaboration

Starting to work together early in the design process is very important. Talking with your flex circuit manufacturer from the start lets you review design files carefully. This helps fix any problems before they become expensive. Here’s why starting early is important:

Manufacturability: Early talks make sure your flex circuit design can be made. This is key to avoiding issues later.

Design Improvements: Manufacturers can give helpful tips for improvements, which can stop costly mistakes.

Successful Implementation: Careful design choices and working with manufacturing partners are crucial for successfully making flex and rigid-flex boards.

But, there can be challenges when starting early. Here are some common mistakes to avoid:

Charging Ahead Without Design Assistance: Many companies don’t know how to design flex circuits well, which can cause problems.

Considering Flex at the End of System Design: Designing without thinking about flex circuits early can lead to expensive and complicated designs.

Not Utilizing Design for Manufacturability (DFM) Practices: Not using DFM can create designs that are hard to make.

Excessively Tight Tolerances: Many designs don’t match material realities, making production harder.

Improper Revision Control: Not having proper revision control can cause confusion and mistakes in the design process.

By tackling these challenges and encouraging clear communication and early collaboration, you can help your project succeed.

Design Considerations for Flex PCBs

When you design flex PCBs, think about bending needs and reliability features. These things really affect how well your circuits work and how long they last.

Bending Requirements

Flex PCBs have special bending needs to work well in electronics. The IPC-2223 standard gives rules for minimum bend radius ratios. Here’s a table that shows these requirements:

Category | Minimum Bend Radius Ratio |

|---|---|

Flex to Install | 6X for 1-2 layers, 12X for 3+ layers |

Dynamic Flex | About 100X for 1-2 layers |

One Time Crease | 0 radius for 1-2 layers, with special material needs |

You should also remember these tips when designing your flex PCB:

The neutral bend axis position changes how force spreads.

Smaller bend angles lower the chance of damage.

Thinner circuits are less likely to get damaged.

Bigger bend radii lower the risk of damage.

How often you flex affects design choices.

Choosing the right material is key for performance.

Don’t put weak features near bend areas.

Adding strain relief designs can help stop damage when bending. Techniques like putting a strain relief bead at junctions between flexible and rigid parts can help reduce stress.

Reliability Features

To make your flex PCB design more reliable, think about these features:

Material Selection for Durability and Flexibility: Pick materials like polyimide for their high heat stability and flexibility.

Define Bend Radius and Flex Areas Early: Keeping a proper bend radius is key to avoid damage during use.

Optimize Trace and Via Design for Flexibility: Use wider traces in flex areas to lower the chance of breakage. Avoid vias in flex zones to keep integrity.

Also, using coverlay and stiffeners can greatly boost reliability:

Coverlay protects circuit parts from damage and outside factors.

It stops current flow between surfaces, making sure the circuit works right.

The flexibility of coverlay helps keep the bending performance of the PCB.

Stiffeners add strength, improving solder joint quality and stopping fatigue damage during movement.

By focusing on these design points, you can make flex PCBs that work reliably and handle the demands of their uses.

Choosing the right flex circuit manufacturer is very important for your project to succeed. You need to match what the manufacturer can do with what you need. Here are some key steps to follow:

Work closely with your manufacturing team when designing.

Focus on prototyping to check bend radii and heat performance.

Use advanced inspection tools to find defects early.

Write down each step of the assembly process to spot problems.

Keep up with industry standards to make sure you follow the rules.

By following these steps, you can improve your project’s results. Contact possible manufacturers and ask the right questions to find the best one for your needs.

FAQ

What is a flex circuit?

A flex circuit is a kind of flexible printed circuit board. It can bend and fold easily. It connects electronic parts while saving space and weight. You can use flexible circuits in many areas, like consumer electronics and medical devices.

Why should I choose a flexible circuit board?

Choosing a flexible circuit board has many benefits. They save space, cut down weight, and allow for better design options. They also work well in tight spaces, making them great for modern electronic devices.

How do I select a reliable flex circuit manufacturer?

To find a reliable flex circuit manufacturer, check their skills, production ability, and communication. Look for manufacturers with experience in making flexible PCBs and a good history in your field.

What factors affect the cost of flexible PCBs?

The cost of flexible PCBs depends on things like how complex they are, what materials you choose, and how many you order. More complex designs and better materials usually raise costs. Also, local and overseas manufacturing can change prices.

How long does it take to produce a prototype?

The time to make a prototype can change based on how complex the design is and what the manufacturer can do. Usually, you can expect it to take 3 to 5 days for simple designs. More complex prototypes might take longer.

See Also

Selecting The Ideal PCB Fabrication Partner For Your Requirements

Finding The Right PCB Prototype Manufacturer For Your Project

Choosing The Appropriate Fusion PCBA Service For Your Needs

Identifying The Best PCB Contract Manufacturer For Future Success