Choosing the right PCBA manufacturer is very important for success. A good partner helps save money, make quality products, and deliver on time. However, poor work or delays from a PCBA manufacturer can lead to fixes, late projects, and lost money. To prevent these problems, use a clear plan that balances price, speed, and quality with your project needs.

Key Takeaways

Know what your PCB needs are. Share clear files like BOM and Gerber to prevent errors and work faster.

Pick a manufacturer that can grow with you. Think about future PCB changes to save time and money later.

Pay attention to quality checks. Choose manufacturers with good quality systems and proper certifications for dependable products.

Understanding Your Business Needs

Know Your PCB Needs

The first step is knowing what your PCB needs. Figure out details like size, layers, and materials. Share clear files like Gerber, BOM, and Centroid data. This helps manufacturers understand your design better.

What It Is | Why It Matters | |

|---|---|---|

Bill of Materials (BOM) | List of parts | Ensures all parts are included, avoiding mistakes |

Gerber Files | PCB layer details | Helps make accurate boards, saving money |

Centroid Data | Part placement info | Ensures correct assembly, improving speed |

Net List | Checks connections | Finds errors, ensuring the board works |

Mechanical Files | Size and shape info | Makes sure the board fits and works |

Knowing your PCB needs lowers mistakes and boosts production efficiency.

Plan for Growth

Think about how your PCB can grow with your business. Choose manufacturers who can handle small and large orders. For example, Kinetic worked with MacroFab to grow from a few boards to thousands. This helped them meet demand while staying fast and reliable.

Also, plan for future changes to your PCB design. Use simulations to prepare for updates, saving time and money. Planning for growth connects your goals with the manufacturer’s abilities, ensuring success.

Make a Smart Budget

A good budget balances cost and quality. Check prices to avoid surprise fees. Building trust with suppliers can lead to better deals and faster deliveries.

Spend wisely on quality. Manufacturers who follow industry rules make better parts, reducing defects. By matching your budget to your needs, you support both current and future goals.

Evaluating the Best PCB Manufacturer

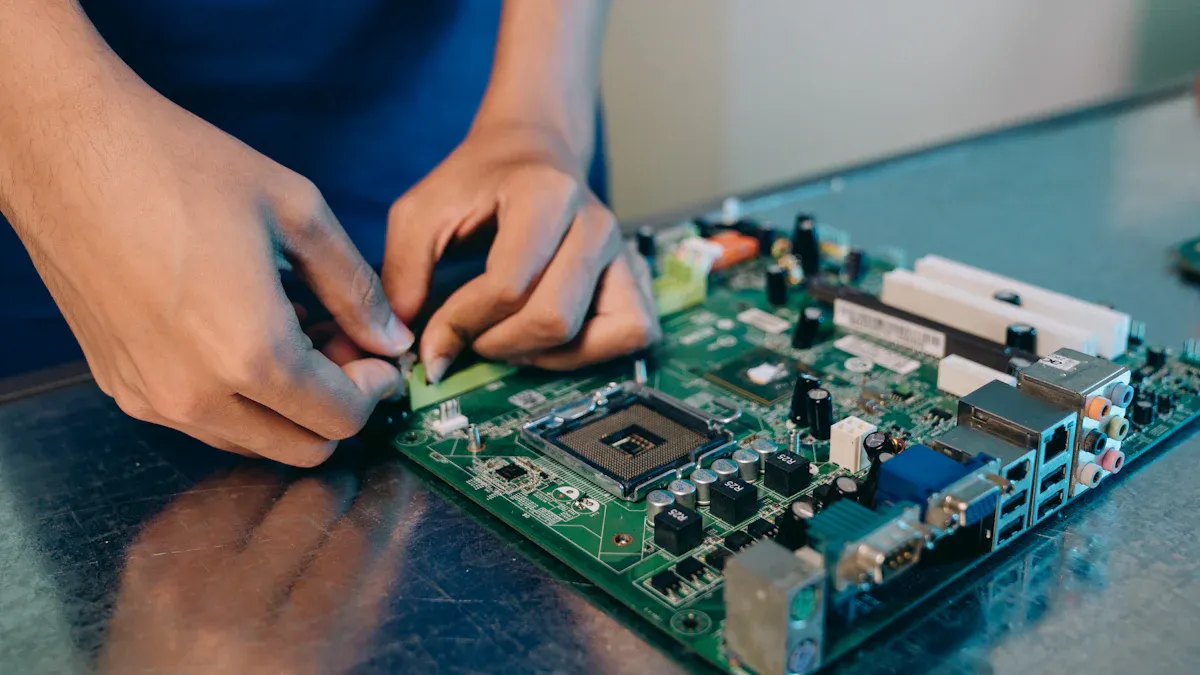

Check Quality Assurance Standards

Choosing a PCB manufacturer means focusing on quality assurance. Good quality comes from strict checks during production. Manufacturers with strong quality processes make reliable and long-lasting PCBs.

Tip: Pick manufacturers using methods like the Plan-Do-Check-Act cycle. These steps improve both efficiency and product quality.

Certifications like ISO, AS9100, and ITAR show high standards. These prove the manufacturer follows strict rules, lowering the chance of defects.

Confirm Certifications and Compliance

Certifications are key to judging a manufacturer’s abilities. They show the company’s focus on making top-quality products. For example:

Certification | What It Means |

|---|---|

Ensures a strong system for managing quality. | |

IPC standards | Confirms compliance with IPC-A-600 and IPC-6012 for great PCB quality. |

AS9100D | Meets aerospace industry quality system requirements. |

Manufacturers who follow updated standards show they care about quality. This builds trust and ensures consistent PCB results.

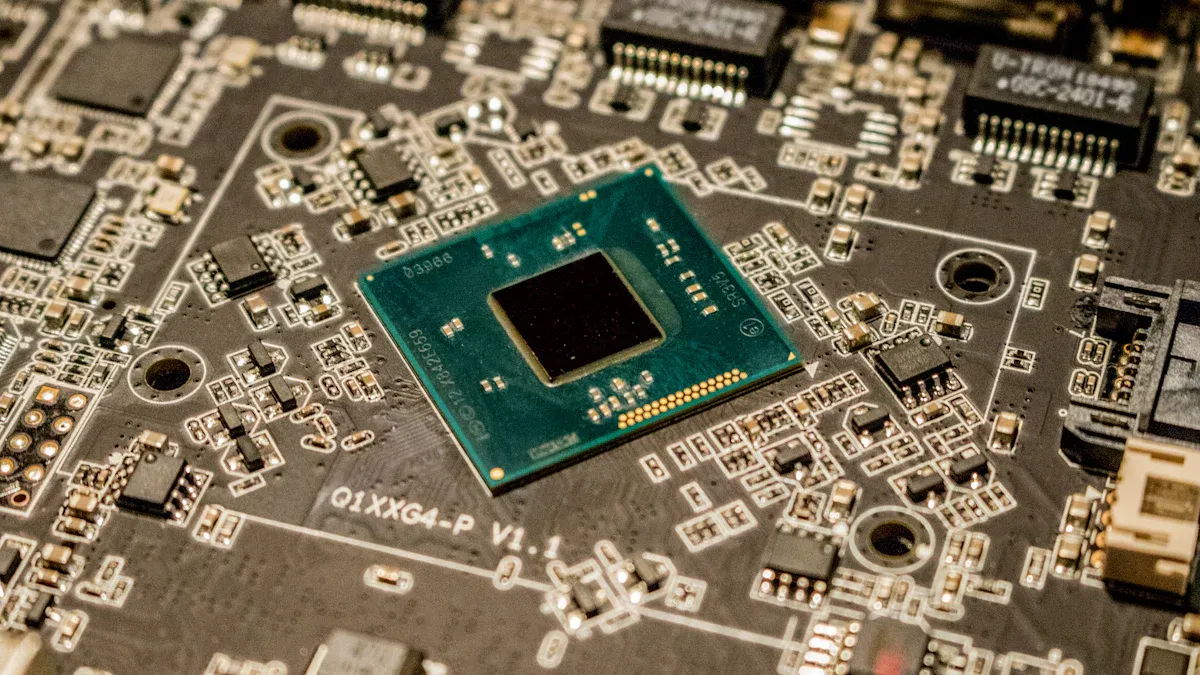

Examine Technological Capabilities

Modern technology is crucial for making quality PCBs. Top manufacturers use advanced tools to meet rules and industry needs. For example, some use a Manufacturing Execution System (MES) to boost efficiency and ensure quality in small-batch production.

Checking a manufacturer’s processes helps you see their abilities. Look at their quality systems, certifications, and controls. This ensures they can make high-quality PCBs that fit your needs.

Comparing Costs and Lead Times

Understand Clear Pricing

Knowing clear pricing is important when picking a PCB maker. Hidden costs or unclear quotes can surprise you later. Always ask for a full cost breakdown, including materials, labor, and shipping. For instance, some companies like JLCPCB charge as little as $2 for 10 boards. Others, like Sierra Circuits, may charge up to $50 for the same amount.

Manufacturer | Base Price (USD) | Lead Time (Days) | Specialization |

|---|---|---|---|

JLCPCB | $2- $5 for 10 boards | 3-7 | Quick prototypes, low prices |

Sierra Circuits | $20- $50 for 10 boards | 7-15 | Advanced tech, complex designs |

This table shows why matching your budget to your project is key. Clear pricing helps you plan well without losing quality.

Check Delivery Times

Delivery time is very important for meeting deadlines. Companies with faster delivery, like JLCPCB (3-7 days), are great for quick projects. But also look at other factors like cycle time and throughput to judge efficiency.

Metric | Description |

|---|---|

Cycle Time | Time to finish making one product. |

Throughput | Number of items made in a set time. |

Lead Time | Time from order to delivery. |

Looking at these factors helps you pick a PCB maker that fits your schedule and keeps quality high.

Balance Price and Quality

Finding the right mix of price and quality is important. Cheap options might save money but could cause problems later. To get the best results, follow these tips:

Choose a trusted PCB maker with certifications like ISO 9001.

Improve your design and prepare a full Bill of Materials (BOM).

Work with manufacturers who have good supplier connections to cut costs.

Change order size and delivery time to save money.

Use strong quality checks to avoid mistakes.

These steps help you get good PCBs at fair prices, ensuring success now and in the future.

Researching PCBA Manufacturer Reputation

Check Reviews and Testimonials

Start by reading reviews and testimonials about the manufacturer. These show what other businesses think about their work. Look for comments on product quality, delivery speed, and customer service. Good reviews mean the manufacturer is reliable. Repeated complaints may show problems to watch out for.

Case studies or success stories can also help you learn more. These examples show how manufacturers handle tough projects or tight deadlines. For instance, a telecom company worked with a manufacturer that held regular meetings. This helped them deliver on time and stay within budget, even with design changes. Clear communication and good service are key to project success.

Assess Communication and Support

Good communication and customer service are very important. Manufacturers who work closely with you understand your needs better. Regular updates and solving problems quickly can avoid delays. This keeps production running smoothly.

Top manufacturers focus on helping their customers. They hold meetings to discuss design changes or parts availability. This support keeps your project on track. When choosing a manufacturer, ask how they communicate and handle unexpected issues.

Look for Long-Term Collaboration Potential

Picking a manufacturer isn’t just about short-term needs. Long-term partnerships bring many benefits. Clear communication reduces mistakes and improves quality. Learning from the manufacturer helps you make better choices and save money.

Working with a trusted manufacturer boosts problem-solving and creativity. This makes your products better and keeps customers happy. Long-term teamwork also lowers risks and helps your business stay strong in the market.

When deciding, think about the manufacturer’s experience and reputation. A good partner will match your goals and help your business grow over time.

How to Choose a PCB Manufacturer

Compare and Shortlist Options

Start by comparing different PCB manufacturers to find the best one. Look at their skills, quality checks, and how fast they deliver. Check if they have the right tools for small or big orders. Make sure their prices are clear and fair.

Also, review their certifications, product variety, and customer feedback. Pick manufacturers with good experience and a strong reputation in similar projects. Comparing these factors helps you choose the right PCB supplier for your needs.

Tip: Use a checklist to make your decision easier and more organized.

Conduct Site Visits or Virtual Audits

Visiting the site or doing virtual audits can show how a manufacturer works. Virtual audits save money and time since you don’t need to travel. They also let you check more often. Onsite visits, however, let you see the equipment and facilities in person.

Advantage | Virtual Audits | Onsite Audits |

|---|---|---|

Data Accessibility | Easy to access from anywhere | Only available during physical visits |

Cost Savings | No travel costs | Travel costs required |

Frequency of Audits | Can be done more often | Limited by budget and time |

Pick the method that fits your goals and resources. Both ways help you check the manufacturer’s quality and abilities.

Build a Strong Partnership

Working closely with your PCBA manufacturer helps you succeed long-term. A good partnership is more than just buying and selling. It means working together to add value. Match your goals with theirs and set shared targets. Regularly check progress using measurable goals to improve where needed.

Talk to the manufacturer early during the design stage to avoid problems. Using shared design tools can make communication faster and easier. Strong partnerships lead to better products that meet customer needs.

Note: Clear communication and good service are key to a strong partnership. Choose a manufacturer who values these qualities.

Picking the best PCBA manufacturer needs careful thinking. Use these steps to make it easier:

Look at skills like SMT and mixed assembly.

Confirm certifications like ISO 9001 are valid.

Check if tools and services are high quality.

Make sure they can handle more production if needed.

Review their supply chain and delivery times.

Match their abilities to your business needs. Use a checklist to compare choices and ask for samples or audits. These steps help you find a trusted partner for long-term success.

FAQ

What matters most when picking a PCB manufacturer?

Focus on quality checks. A good PCB maker follows strict rules. This reduces mistakes and makes products more reliable.

How do you check if a manufacturer is trustworthy?

Read reviews, stories, and feedback from other customers. These show how well the manufacturer handles quality, deadlines, and support.

Why is it important for a manufacturer to scale?

Scaling means the manufacturer can grow with your needs. This helps your business handle more orders as it gets bigger.

See Also

Selecting The Correct Circuit Board: PCB Or PCBA?

PCBA’s Role In Elevating Today’s Electronic Innovations

Essential In-Circuit Testing Tools For PCBA You Should Know

Uncovering The Key Distinctions Between PCBA And PCB

Benefits Of Overmolded PCBA Compared To Other Encapsulation Techniques