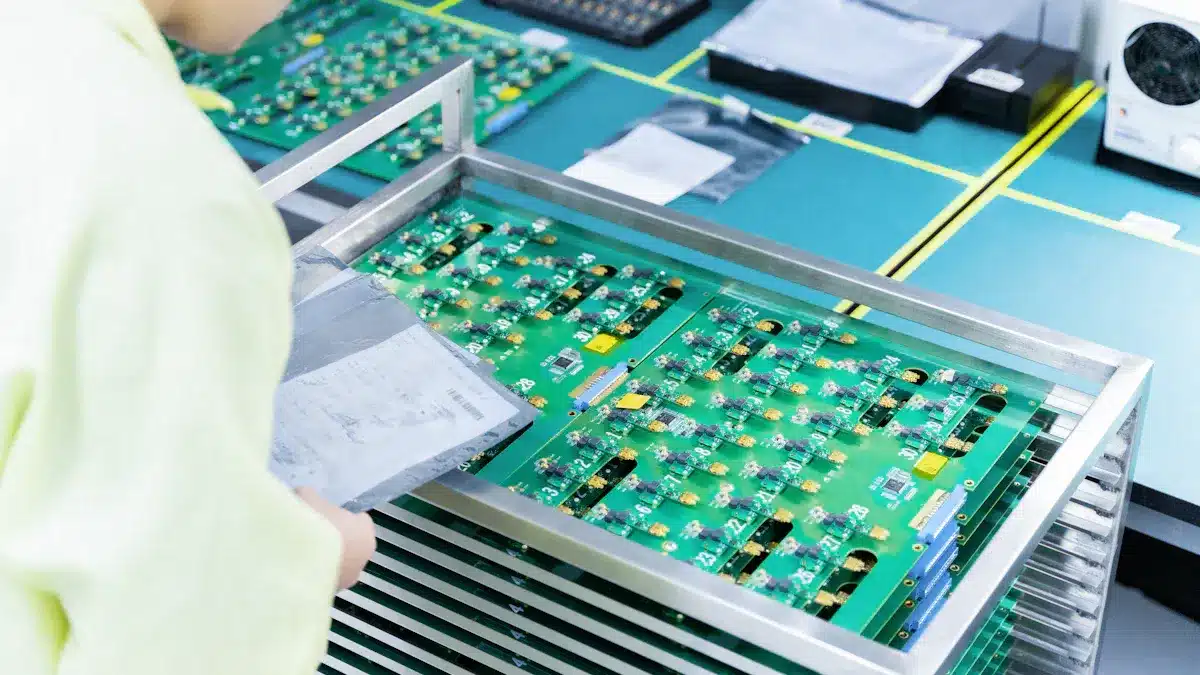

In 2025, electronics manufacturing in the United States remains vibrant and extensive, with 12,808 factories operating nationwide. This industry provides jobs to over 1.1 million people and generates approximately $1.8 trillion in sales annually. Notably, 56% of these factories export their products internationally, demonstrating a strong global presence. For those searching for electronics manufacturing companies near me, understanding the local market is crucial. Local factories not only support the economy but also foster innovation and promote eco-friendly manufacturing practices.

Key Takeaways

Picking a nearby electronics maker helps with communication. It also makes production faster and cuts shipping costs.

Local makers have flexible supply chains. They also have better quality control. This helps businesses react quickly to market changes.

Working with local makers is good for the environment. It reduces transportation distances and lowers carbon emissions.

Local makers give better customer support. They also protect intellectual property more strongly.

Looking into local makers carefully helps businesses find trustworthy partners. This can meet their needs and increase success.

Cost and Quality

When businesses think about electronics manufacturing, they look at cost and quality. Local manufacturing has clear benefits that can improve both.

Local Manufacturing Benefits

Choosing a local manufacturer can bring many big advantages. Companies often notice better communication and teamwork because the design and manufacturing teams are close. This closeness allows for faster feedback and changes, which can improve product quality.

Also, local manufacturing makes the supply chain more flexible. Shorter lead times and quicker shipping make the process more efficient. Businesses also lower risks from political and economic problems by keeping production near stable markets. This plan not only ensures reliability but also helps manage costs well.

Here are some key benefits of local manufacturing:

Better communication and teamwork

More flexible supply chain

Lower risks from political issues

Cost savings from cheaper shipping

Faster innovation with closer R&D work

Using local knowledge for better market fit

Environmental benefits, like less carbon emissions

Real-life success stories showing quicker delivery and lower costs

These points show how important quality and control are in local manufacturing. Companies can keep higher standards when they watch production closely.

National Manufacturer Pricing

On the other hand, national manufacturers usually compete on price. They might offer lower costs because they produce in larger amounts. However, this can hurt quality. When production happens overseas, companies may struggle to keep quality and control.

Overseas manufacturing can cause longer shipping times and possible delays. These issues can affect how quickly products reach the market. While national manufacturers may have lower prices, businesses need to think about the trade-offs. The cost versus speed problem often comes up, making companies choose between lower prices and faster delivery.

Speed to Market

In today’s fast-moving electronics market, getting products to customers quickly is very important. Local manufacturers usually do better in this area than national ones.

Local Production Advantages

Local manufacturers can work faster for a few reasons. First, they have strong teamwork with suppliers and partners. This helps them manage inventory and supply chains better. Because of this close work, they can change production schedules quickly based on what customers want.

Second, local manufacturers often use lean manufacturing and agile methods. These practices make operations smoother, cut down on waste, and allow for more flexibility. This way, companies can quickly adjust to market changes.

Also, good supplier management helps create a reliable supply chain. Local manufacturers can quickly fix any problems that come up, which reduces delays. Using advanced technologies like automation and digital tools also makes production faster and clearer.

All these factors help local manufacturers reduce production delays and improve operations. Companies can quickly meet customer needs, which is very important in a competitive market.

National Manufacturer Timelines

On the other hand, national manufacturers often deal with problems that slow them down. Manufacturing overseas can mean longer shipping times, which affects how fast products get to the market. Companies have to think about possible delays from customs, transport issues, and other logistical challenges.

The cost versus speed issue often comes up when businesses look at national manufacturers. They might have lower prices, but this often means longer lead times and less control over quality. This can make it hard for a company to respond to market changes quickly.

Customer Support

Customer support is very important for manufacturers and their clients. When businesses pick between local and national manufacturers, they need to think about the support each one gives.

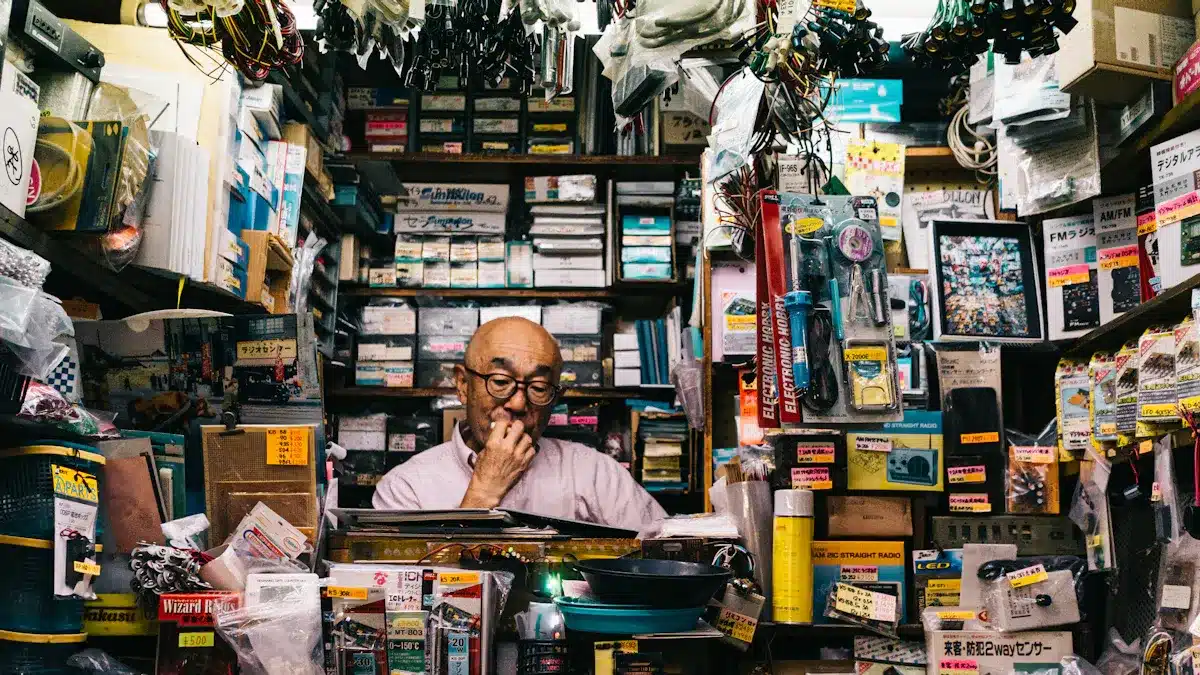

Local Relationships

Local manufacturers usually offer a more personal way to help customers. They create strong bonds with their clients, which builds trust and open talks. This closeness helps manufacturers answer questions quickly and fix problems well. Clients like having direct contact with decision-makers, which helps solve issues faster.

Local manufacturers also know what their community needs. They can adjust their services to fit local demands, making sure clients get good support. This understanding often leads to happier customers and loyalty.

National Support Structures

On the other hand, national manufacturers might have bigger support systems. They often provide many resources, like special support teams and online help centers. But this can sometimes make the experience feel less personal. Clients may find it hard to connect with helpers who understand their specific needs.

While national manufacturers can give lower prices and more products, the support might not feel as personal as local manufacturers. Clients could face longer wait times for help, which can be annoying.

Environmental Impact

Electronics manufacturing has a big effect on the environment. Local manufacturing can help lessen this impact in many ways.

Local Manufacturing Sustainability

Local manufacturing usually means lower carbon emissions. By cutting down on how far products travel, companies can lower greenhouse gas emissions from supply chains. In fact, supply chains are responsible for over 80% of total greenhouse gas emissions for consumer companies. Working with local manufacturers can make logistics easier and further cut emissions. Local supply chains also allow for better teamwork and quality control, which boosts efficiency and helps reduce emissions.

Here are some key benefits of local manufacturing for sustainability:

Shorter transportation distances

Lower logistics costs

Better teamwork and quality control

Big cuts in carbon emissions

Tools like the FORGE CO2 Emissions Estimator help companies find high-emission areas in their supply chains. This way, businesses can make smart choices that help both their operations and the environment.

National Manufacturer Policies

National manufacturers also work towards sustainability, but they do things differently. Many national electronics manufacturers get certifications to show they care about eco-friendly practices. Common certifications include:

Cradle to Cradle Certified™: This certification supports safe and sustainable product design. It looks at material health, renewable energy use, and social fairness.

Energy Star: Managed by the U.S. EPA and DOE, this certification focuses on energy efficiency in products, helping to lower greenhouse gas emissions.

In 2025, national manufacturers must follow important environmental rules. The National Environmental Policy Act (NEPA) requires environmental reviews for federally funded semiconductor manufacturing projects. These reviews include Environmental Assessments (EA) and Environmental Impact Statements (EIS). Public participation is also needed, making sure there is transparency in checking environmental effects.

While national manufacturers follow these rules, local manufacturers can often adapt quickly to local environmental practices. This flexibility helps local manufacturers meet community needs and environmental concerns better.

Environmental Impact Metric | Description / Use in Comparison |

|---|---|

Measures the chance of causing acid rain; used to check emissions from manufacturing processes. | |

Global Warming Potential (GWP) | Measures greenhouse gas emissions; important for comparing transportation and energy use in local vs national. |

Energy and Water Consumption | Measured to look at resource use differences between local and national manufacturing. |

Security and IP Protection

In the electronics manufacturing world, security and intellectual property (IP) protection are very important. Companies face different risks based on whether they pick local or national manufacturers.

Local Control

Local manufacturers usually give better control over IP protection. They can set up strong rules to keep their ideas safe. But they still face some common risks:

Patent infringement: Companies might accidentally use patented technology without permission. This can lead to expensive legal problems.

Trademark disputes: A busy market can cause confusion over similar products, which can hurt a brand.

Copyright issues: Software and digital content need careful handling to protect original works while respecting others’ rights.

Patent trolls: These groups buy patents just to sue others, increasing the IP risk.

To reduce these risks, local manufacturers should get patents, trademarks, and confidentiality agreements. It’s important to raise IP awareness in companies and teach employees about it. Keeping an eye on the market and filing patents wisely also helps protect new ideas.

National Security Measures

National manufacturers usually handle security and IP protection with strong systems. They follow the NIST Special Publication 800-171, which sets up a cybersecurity plan to protect Controlled Unclassified Information (CUI). This plan includes access control, employee training, incident response, and data security methods like encryption. Following rules like the International Traffic in Arms Regulations (ITAR) ensures strict export controls and physical security, especially for defense electronics.

Also, national manufacturers often spread their operations to countries with strong IP laws, like Mexico and the United States. This plan lowers the chances of theft or unauthorized copying. By mixing supply chain diversity, following regulations, and using smart geographic strategies, they build a strong defense against IP theft while supporting national security.

Finding Electronics Manufacturing Companies Near Me

Finding good electronics manufacturing companies nearby can help your business a lot. Here are some smart ways to find trustworthy local manufacturers.

Researching Local Options

To discover local manufacturers, think about these tips:

Leverage Online Resources: Use search engines and business directories to find electronics manufacturing companies close to you. Websites like ThomasNet and Maker’s Row can give you helpful listings.

Network with Industry Contacts: Talk to colleagues, suppliers, and industry groups. They might suggest reliable local manufacturers based on what they know.

Attend Trade Shows and Expos: Going to industry events lets you meet manufacturers in person. This helps you build relationships and see their skills up close.

Utilize Social Media: Sites like LinkedIn can help you connect with local manufacturers. Join groups to talk with industry experts and get recommendations.

Check Local Chambers of Commerce: Many chambers keep lists of local businesses, including manufacturers. They can share information about the reputation and trustworthiness of these companies.

Buying local electronics has many benefits. Companies that work with local manufacturers often save money on labor, real estate, and shipping. Being close to the U.S. market makes supply chains more reliable and reduces risks from global issues. Plus, local brands usually offer better access and lower prices, which are important for startups and smaller businesses.

Evaluating Manufacturer Capabilities

After you find possible manufacturers, check their abilities to make sure they fit your needs. Here are some things to think about:

Supply Chain Management: Look at how well the manufacturer works with their suppliers. Check if they can choose, assess, and measure supplier performance based on quality and delivery.

Purchasing Efficiency: See if they have commodity specialists to use economies of scale and avoid wasting resources.

Technical Capabilities: Make sure they can handle complex electro-mechanical assemblies, not just basic PCBAs.

Responsiveness: Look at their communication during the selection process. Quick and clear replies show they care about customer service.

Quality Audits: Ask about their quality control methods. Regular audits help manage build data and manufacturing controls.

Testing Procedures: Confirm that they include testing throughout the manufacturing process. This means doing in-circuit tests and soak testing to ensure product reliability.

Environmental Responsibility: Check their waste disposal methods and power reliability practices.

By carefully researching and evaluating local options, businesses can find the right electronics manufacturing companies nearby. This method not only helps local economies but also improves operational strength and market response.

Picking the right electronics manufacturer is very important for businesses in 2025. Local manufacturers have advantages like better communication, quicker production, and less harm to the environment. They also give personal support and help keep ideas safe.

Tip: When choosing a manufacturer, think about cost, quality, and how fast they can deliver. Look into local options carefully to find the best match for your needs.

By focusing on local partnerships, companies can improve their work and help their communities. 🌍

FAQ

What are the main benefits of choosing a local electronics manufacturer?

Local manufacturers have better communication. They can finish work faster and save on shipping costs. They also help the local economy and usually have more flexible supply chains.

How can I find reliable electronics manufacturers near me?

You can use online sites like ThomasNet. Talk to people in the industry, go to trade shows, and check with local chambers of commerce for suggestions.

What should I consider when evaluating a manufacturer’s capabilities?

Look at how they manage their supply chain. Check their technical skills, quality control methods, responsiveness, and how they handle environmental issues. These things help ensure they can meet your production needs.

How does local manufacturing impact the environment?

Local manufacturing cuts down on transportation distances. This leads to lower carbon emissions. It also helps with better quality control and efficient resource use, which supports sustainability.

What security measures do local manufacturers implement for IP protection?

Local manufacturers often set up strong rules to protect intellectual property. They might use patents, trademarks, and confidentiality agreements to keep their ideas safe.

See Also

Choosing The Ideal PCB Prototype Maker For Your Project

Finding The Perfect PCBA Manufacturer To Meet Business Goals

Recognizing The Best PCBA Partner For Business Growth

The Importance Of Custom PCBA In Today’s Electronics Industry

Selecting A Reliable PCB Contract Manufacturer For Future Success