Circular economy PCBA ideas are transforming how PCBA manufacturing contributes to environmental sustainability. By minimizing waste and utilizing resources efficiently, these methods offer significant advantages:

72% fewer greenhouse gases emitted.

47% less waste generated during production.

A 145% increase in production speed.

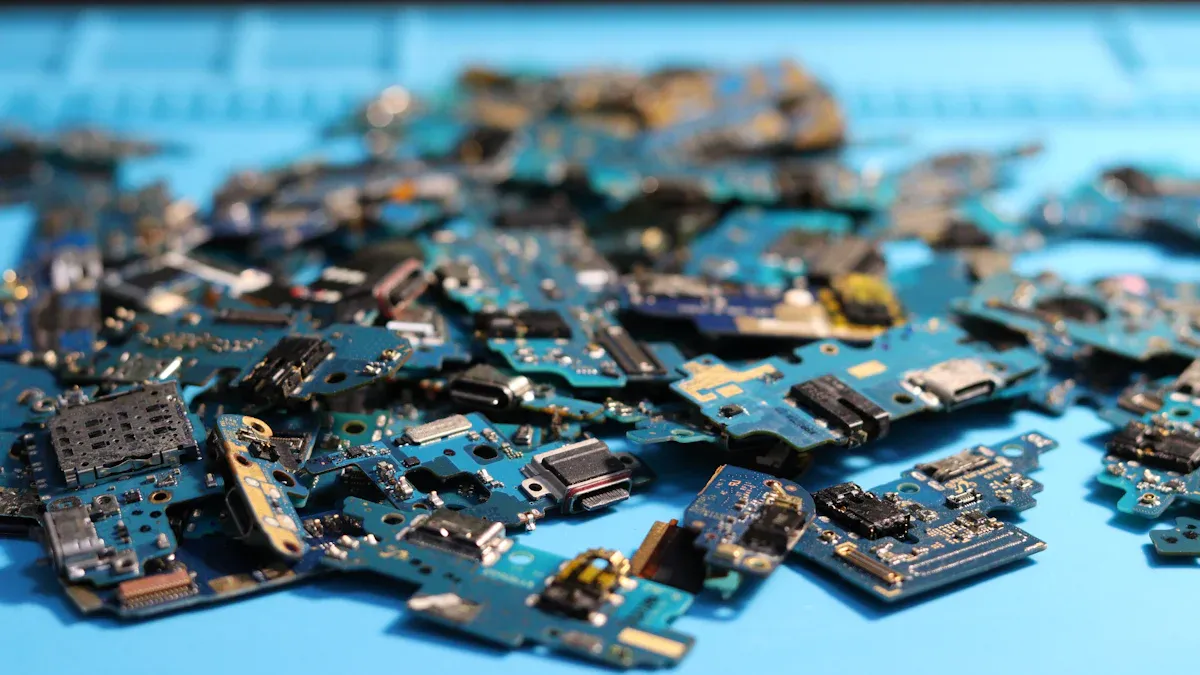

This approach also mitigates electronic waste by enhancing design, repair, and recycling processes. It can reduce e-waste by up to 50%, conserving materials and decreasing the demand for new resources by 32%, which in turn lowers costs by approximately 25%.

Currently, PCBA production emphasizes improved recycling and eco-friendly designs to minimize waste over time.

Incorporating circular economy PCBA principles into manufacturing makes the process greener, smarter, and more efficient.

Key Takeaways

Circular economy ideas help save energy in PCBA making. They use up to 64% less energy for each product.

Using these ideas can lower greenhouse gases by 72%. This makes factories better for the environment.

Making products easy to take apart helps with fixing and recycling. This can cut electronic trash by up to 50%.

Choosing eco-friendly materials and recycling saves resources. It also cuts production costs by about 25%.

Following circular economy methods can help businesses grow. The market will grow a lot and create new jobs.

Circular Economy Principles and Their Role in PCBA Manufacturing

What are circular economy principles?

Circular economy principles aim to cut waste and protect nature. They replace the old “use and throw away” system with smarter, greener methods. In electronics, these ideas focus on making products easier to fix, upgrade, and recycle.

Principle | What It Means |

|---|---|

Cutting waste and pollution | Designs that create less trash and fewer harmful effects. |

Making products last longer | Builds items to be fixed, reused, or upgraded instead of thrown away. |

Helping nature recover | Uses eco-friendly ways to repair damage caused by human activities. |

Using these ideas helps make manufacturing better for the planet and more efficient.

Why circular economy matters for electronics

Electronics create a lot of waste, so these ideas are crucial. They help manage electronic parts better. For example:

Fixing and improving parts makes them last longer, saving materials.

These steps make production smoother and lower pollution from factories.

By following these methods, electronics can be made in a way that’s kinder to the Earth.

Changing PCBA production to a circular model

Switching to a circular system means rethinking how products are made and used. For example, eco-friendly PCBs use materials that can be recycled, which helps the environment. Recycling chips and other parts also boosts sustainability.

This change focuses on better materials, recycling, and green designs. These steps solve problems like running out of resources and too much waste. They also open doors for new ideas and growth in the industry.

Applications of Circular Economy in PCBA Manufacturing

Sustainable materials and recyclable components

Eco-friendly materials are changing how PCBA is made. Using green substrates and recycled materials cuts waste and saves energy. For example, JIVA’s Soluboard® is biodegradable and helps recycle parts and recover metals. Also, recycled tin for soldering shows how reusing materials works. But only 30% of tin is recycled globally, so there’s room to improve.

Evidence Type | Description |

|---|---|

Recycling Impact | More recycling reduces waste and energy use in electronics. |

Sustainable Materials | JIVA’s Soluboard® helps recycle parts and recover valuable metals. |

Soldering Innovations | Recycled tin shows recycling’s potential, though only 30% is reused now. |

Using sustainable materials supports a circular system for PCBA. This method helps the planet and makes manufacturing greener.

Waste reduction through design for disassembly

Designing for disassembly helps reuse parts and cut e-waste. It focuses on making PCBA easy to fix, upgrade, or take apart. For instance, modular designs let you replace broken parts without tossing the whole product. This reduces waste and makes electronics last longer.

When PCBs are designed for disassembly, recycling becomes easier. Parts can be separated and processed better, reducing waste and saving materials. This method follows circular economy ideas, wasting fewer resources.

Closed-loop recycling systems in PCBA production

Closed-loop recycling is key to sustainable PCBA production. These systems reuse materials from old electronics in new products. Studies show their environmental benefits. For example:

Rautela et al. (2021) stress eco-friendly recycling rules for sustainability.

Guo et al. (2021) studied how recycling benefits different areas.

China’s Ministry of Ecology and Environment shares structured recycling plans.

Closed-loop systems cut the need for new parts and reduce e-waste. They save resources and make the PCBA supply chain stronger.

Energy efficiency and green technologies in manufacturing

Energy-saving methods and eco-friendly tools are changing PCBA manufacturing. Using less energy and greener processes helps the planet. These steps also make production faster and more efficient. They follow circular principles to support a sustainable future.

Electronics use a lot of energy and materials. This causes 2% of the world’s greenhouse gas emissions. Green practices like recycling and using clean energy can cut this down. For example, managing energy and using renewables reduces pollution and helps the environment.

Tip: High-efficiency systems and clean energy save money and help nature.

Key Areas of Energy Efficiency and Green Technologies

Aspect | Description |

|---|---|

Use better systems to lower energy use during production. | |

Renewable Energy Usage | Add clean energy sources to reduce harmful emissions. |

Waste Management Practices | Recycle waste to cut pollution and protect the planet. |

These ideas make manufacturing greener and smarter. By using them, you can build a more eco-friendly production system.

Benefits of Green Manufacturing Practices

Less greenhouse gas from factories.

Lower energy use with improved systems.

Better waste handling through recycling programs.

Cleaner energy for more sustainable production.

Using these methods helps the Earth and strengthens manufacturing. Green tools fit with circular principles and bring long-term savings.

Benefits of Circular Economy PCBA Practices

Reducing environmental harm and managing e-waste

Circular economy methods help the planet and reduce e-waste. Reusing materials and designing recyclable products cut trash and save resources. A study in Europe (2010-2020) showed that a higher circular economy index (CEI) lowered waste electrical and electronic equipment (WEEE). But, when CEI grew too much, waste increased again. This shows the need for balanced rules.

Statistic | Value |

|---|---|

E-waste grows | |

E-waste grows | 13% faster than world GDP |

Lost raw materials | US$57 billion |

These numbers show why circular practices are urgent. They can slow e-waste growth, which is faster than population and economy growth. This approach saves resources and reduces waste.

Saving money by using resources wisely

Using circular economy ideas in PCBA saves money. It reduces waste, boosts efficiency, and cuts costs. For example, energy-saving machines and better processes use less power and make fewer mistakes. Recycling and cutting waste also lower disposal costs.

Strategy | Description | Cost Savings |

|---|---|---|

Material Use | Smart layouts and inventory control | Less wasted materials. |

Better Equipment | Fast, automated machines | Lower labor costs, more production. |

Process Fixes | Fewer defects, faster production | Shorter wait times, fewer errors. |

Supplier Deals | Bulk buying, long contracts | Cheaper materials, steady supply. |

Green Practices | Recycling, energy-saving tools | Lower waste and energy bills. |

By managing resources well, you save money and work smarter. Lean manufacturing reduces waste, and energy-efficient tools cut power bills. These methods help both the planet and your budget.

Boosting the economy with new ideas

Circular economy practices grow businesses and create new ideas. They open new ways to earn money and expand markets. Governments support these ideas with grants and tax breaks. The circular economy market is expected to grow from $463.07 billion in 2024 to $798.3 billion by 2029, with an 11.4% annual growth rate.

Urban mining and social responsibility encourage circular practices.

Online resale platforms create new business chances.

Environmental concerns and strong supply chains drive market growth.

These trends show how circular ideas can change industries. By using them, businesses can lead in sustainability and grow in a fast-expanding market.

Making supply chains stronger and eco-friendly

Circular economy ideas make supply chains greener and tougher. They help manage resources wisely, cut waste, and handle problems better. Using these methods builds a supply chain that works well and adjusts easily.

How circular economy helps supply chains stay green

Circular economy focuses on reusing materials and cutting waste. This lowers the harm your supply chain causes to nature and makes it run smoother. For example, recycling parts and using renewable materials reduces the need for new resources. This saves money and keeps supplies steady during shortages.

Important tools like Material Circularity Index (MCI) and Recycling Rate check how green your supply chain is. MCI looks at how well resources are used and recycled. Recycling Rate shows how good your recycling system is. Watching these numbers helps find ways to improve and make your supply chain more eco-friendly.

Indicator | Why It Matters |

|---|---|

MCI | Checks resource use and recycling success. |

Recycling Rate | Measures how well recycling is done. |

Social Impact | Looks at fairness in supply chain practices. |

Making supply chains ready for challenges

Strong supply chains can handle surprises and problems. Circular economy ideas help by reusing materials and needing fewer outside suppliers. For example, a three-step plan improves supply chains even when things are uncertain. This balances being green and working efficiently, so your supply chain can face challenges.

Circular methods also support fair work conditions and sharing money fairly. By using social and eco-friendly measures, you can build a supply chain that is both strong and fair. Tools like Life Cycle Assessment (LCA) and Recycling Rate improve how resources are used and protect the environment.

Compare upstream and downstream strategies with green indicators.

Use MCI and LCA to check resource use and impacts.

Include fairness and ethical practices in your supply chain.

Why circular supply chains are great for PCBA

Circular supply chains bring many benefits to PCBA production. They cut waste, use resources better, and save money. Reusing materials and designing for recycling reduce harm to nature and improve supply chain performance. These methods also help your supply chain adjust to market changes and problems.

Circular economy ideas balance money and fairness. They keep your supply chain efficient while meeting green goals. By using these ideas, you can create a supply chain that is strong and kind to the planet.

Tip: Try circular methods to handle surprises and cut waste. This will make your supply chain better and greener.

Overcoming Challenges in Circular Economy Adoption

Navigating regulatory and compliance requirements

Following rules is crucial for using circular economy ideas in PCBA. Every material and process must meet legal standards. Keeping records is important for products with long lifespans. These records show what materials and steps were used, helping during audits. Clear documentation makes it easier to follow rules and adjust to new ones.

Product Lifecycle Management (PLM) tools can help with this. They organize all stages of product development in one place. PLM systems simplify tasks like keeping data consistent and automating paperwork. They also track changes, making it easier to answer questions during audits.

Following rules needs careful attention to details.

PLM tools improve record-keeping and tracking.

Automated systems save time and reduce mistakes.

Using these tools helps you handle rules better and focus on greener manufacturing.

Addressing technological barriers in recycling and reuse

Recycling and reusing materials in PCBA face some problems. It can be hard to recover materials or separate parts. Advanced methods like chemical extraction can help but need big investments.

Making PCBs easier to take apart is another solution. Modular designs allow parts to be reused or replaced easily. But creating these designs needs teamwork between engineers and manufacturers. Training and new equipment are also needed to make this work.

To solve these issues, focus on new ideas and teamwork. Try out new technologies and work with others in the industry. By tackling these problems, recycling can become more effective, and waste can be reduced.

Promoting industry collaboration and standardization

Working together and setting standards are key to improving circular economy practices. Industry groups create plans for sustainable manufacturing. For example, the Circular Electronics Partnership works with others to solve problems in electronics.

There are also tools and standards to encourage better waste management:

Initiative | What It Does |

|---|---|

RBA Circular Materials Landscape Assessment | Shares e-waste insights and gives tips for sustainability. |

Waste Minimization Toolkit | Offers tools to cut waste, available to RBA members. |

Circular Material and Waste Minimization Working Group | Creates standards to improve circular practices in electronics. |

Ensures recycling is safe and eco-friendly. |

Joining these efforts helps you follow industry standards. Teamwork leads to new ideas and clear rules for circular manufacturing.

Tip: Join groups and use standards like ISO 14001 to show your commitment to sustainability.

Teaching stakeholders about circular economy principles

Teaching stakeholders about circular economy ideas is key to improving PCBA manufacturing. When everyone learns these ideas, they can make smarter choices to save resources and reduce waste.

Why teaching stakeholders is important

Stakeholders like manufacturers, suppliers, and customers are vital for adopting circular practices. Without proper knowledge, they might miss chances to reuse materials or cut waste. Educating them helps everyone work together to lower e-waste and protect resources.

Note: A knowledgeable team spots problems quickly and fixes them, saving time and money.

How to teach stakeholders effectively

Here are some ways to help stakeholders understand circular economy ideas:

Workshops and Training: Host sessions to explain topics like recycling or eco-friendly designs.

Online Tools: Share videos, charts, and guides to simplify tough concepts.

Success Stories: Show real-life examples of companies using circular practices.

Group Discussions: Create spaces where people can share tips and learn together.

Important topics to focus on

When teaching stakeholders, cover these key points:

Topic | Why It Matters |

|---|---|

Sustainable Design | Promotes creating eco-friendly products. |

Recycling Tips | Helps save materials and reduce trash. |

Cost Savings | Explains how circular ideas save money. |

By focusing on these areas, you can help stakeholders understand and support circular economy goals.

Tip: Start with one simple idea at a time. This makes learning easier and builds lasting habits.

Teaching stakeholders gives them the tools to make PCBA manufacturing greener and more efficient. With the right knowledge, they can help lead the industry toward sustainability.

Circular economy ideas are changing how PCBA is made. They make it greener and use resources better. These methods lower waste, save money, and create new chances for growth. For instance, they cut the need for new materials by 32%. They also reduce energy use by up to 30%, helping both the planet and your wallet.

Benefit/Challenge | What It Means |

|---|---|

Saving Resources | Uses 32% fewer new materials, saving about 25% in costs. |

Energy Use and Pollution | Cuts energy use by 15-30%, saving 20% over a product’s life. |

Growing Jobs and Economy | Circular models could boost GDP by 5% and add millions of jobs worldwide. |

There are some challenges, like following rules, but teamwork and smart ideas are solving them. Using circular methods helps you lead in eco-friendly and strong manufacturing.

FAQ

What is the circular economy in simple terms?

It’s a way to cut waste by reusing and recycling. Instead of throwing things away, you fix or repurpose them to last longer.

How does circular economy benefit PCBA manufacturing?

It saves materials, cuts trash, and lowers expenses. Using recyclable parts and energy-saving methods makes production eco-friendly and efficient.

Can circular economy practices reduce e-waste?

Yes! Making products easy to take apart and recycle helps reuse parts. This can lower e-waste by up to 50%, saving resources and helping nature.

What are some challenges in adopting circular economy principles?

Challenges include following rules, buying new tools, and teaching people. Working together and trying new ideas can solve these problems.

How can you start implementing circular economy ideas in PCBA?

Start small by using recyclable parts or designing for repairs. Join industry groups and use tools like PLM systems to track progress.

Tip: Focus on one change at a time for better results.

See Also

Exploring The Benefits And Challenges Of Flex PCBA

The Significance Of Custom PCBA Manufacturing In Electronics

Understanding The Role Of PCBA Manufacturing In Design