Every PCBA Android device needs a PCBA to function effectively. Custom PCBA designs cater to specific requirements, such as those for smart gadgets or tools. Modifying the hardware and software provides enhanced control. A custom PCBA ensures that your PCBA Android device operates seamlessly. It enables your device to perform its tasks efficiently while maintaining its uniqueness in the market.

Key Takeaways

Changing Android PCBAs makes devices work better and stand out. Design them to fit specific needs for improved use.

Pick the right parts like processors and sensors. This helps your device work well and meet user needs.

Testing is very important for trust. Test in real-life settings to make sure your PCBA handles problems.

Work with experienced makers. Their skills can help you avoid errors and make your PCBA better.

Use free tools and community help. These save time and give useful ideas for your design process.

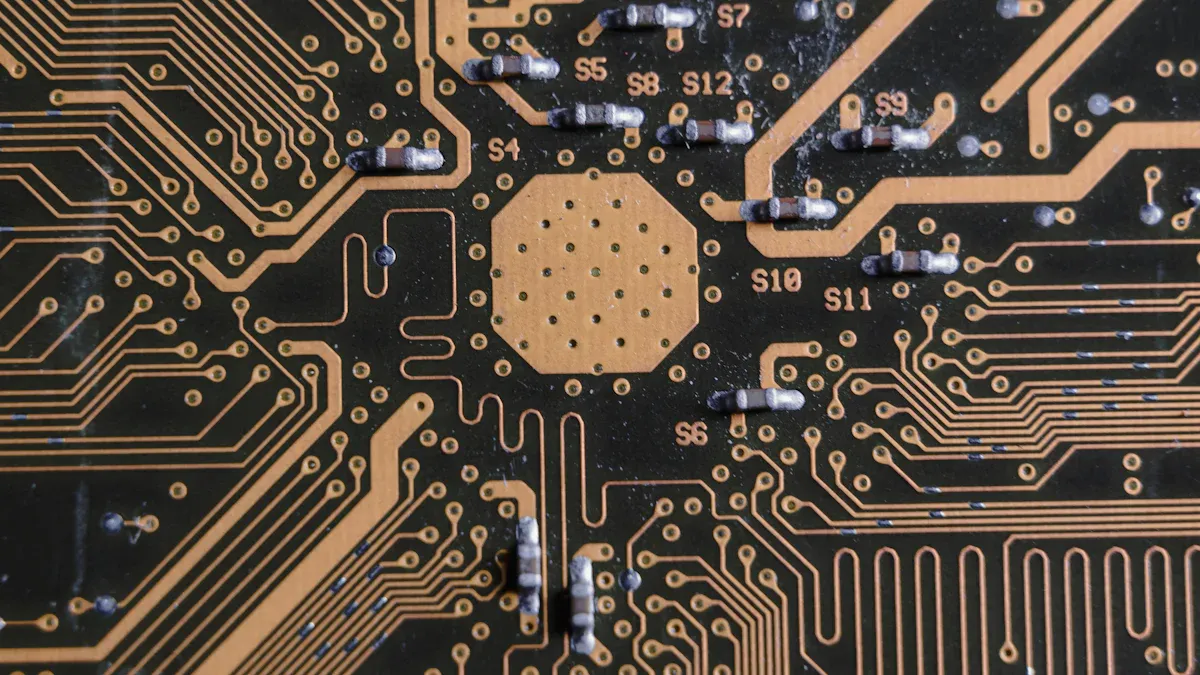

Basics of Customizing Android PCBAs

What is an Android PCBA and why is it important?

An Android PCBA is the main part of any Android device. It links key parts like processors, memory, and sensors. This connection helps the parts work together smoothly. The PCBA combines hardware and software to make the device run well. For example, in smart cameras or fitness trackers, the PCBA handles power, data, and connections. Without a good PCBA, devices wouldn’t work properly or last long.

Why customize PCBAs for different devices?

Custom PCBAs are made to fit your device’s special needs. If you’re building tools like AI cameras or industrial gadgets, custom designs help them work better. Many industries now need faster, cheaper, and better PCBA solutions. Custom designs also make it easier to build devices like payment systems or smart wearables. By focusing on what your device needs, you can make it work better and stand out.

What affects PCBA design for Android devices?

Many things impact how a PCBA is designed. These include the materials used, how it’s made, and how it’s tested. The table below shows why these factors matter:

Benefit | What It Means |

|---|---|

Material Choice | Picks materials that fit the job, like heat-resistant ones for tough uses. |

Better Production | Improves steps like cutting and shaping for good results. |

Careful Testing | Makes sure the PCBA works well by testing it thoroughly. |

Strong and Reliable | Uses tests to check if it can handle heat, electricity, and stress. |

Easy to Upgrade | Designs it so it can be improved later for better performance. |

By thinking about these factors, you can make a PCBA that fits your device now and can improve later. This keeps your Android device useful and competitive as technology changes.

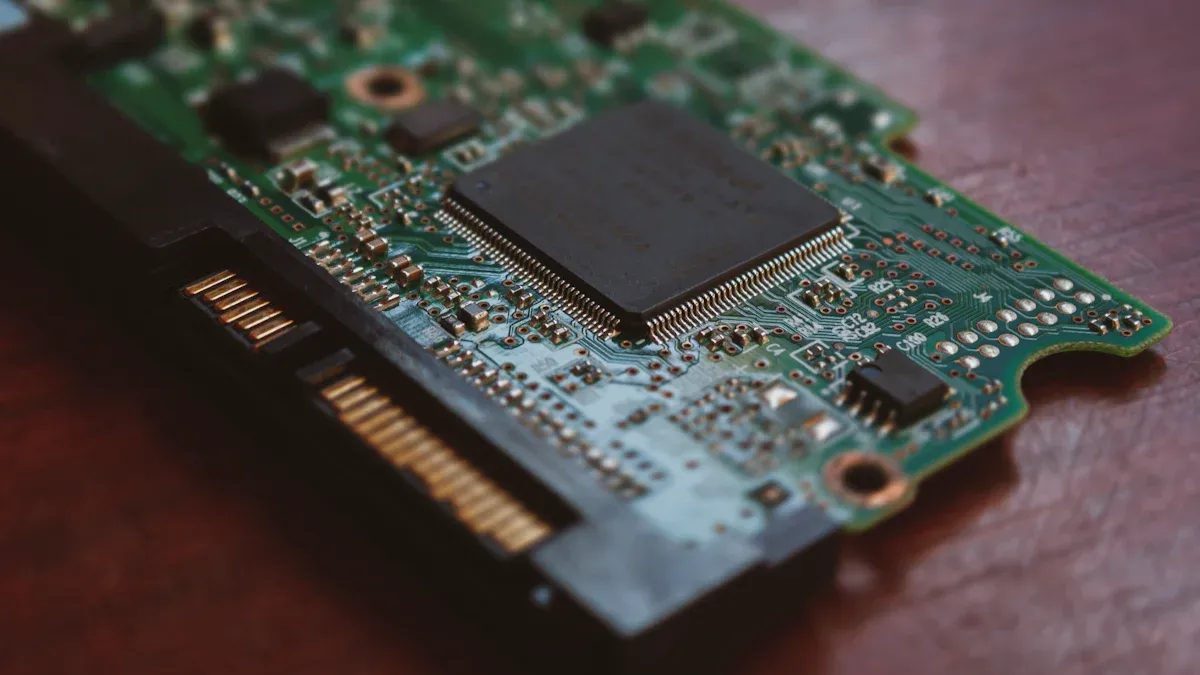

Tools and Components for Android PCBA Customization

Important hardware parts: Processors, memory, and sensors

Picking the right hardware is very important for custom PCBAs. Processors are like the brain of your device. They help run apps and handle tasks well. For Android devices, choose processors that save power but work fast. Memory, like RAM and storage, keeps the device running smoothly. It also stores apps and updates. Sensors, such as motion detectors, add cool features like tracking movement or checking the environment.

Tip: Pick hardware with ISO 9001 certification. This ensures better quality, fewer problems, and more reliability.

What It’s Best For | |

|---|---|

5W to 10W | Great for simple devices that save energy. |

10W to 20W | Good for mid-level devices with balanced power and speed. |

20W to 30W | Best for high-speed devices with advanced features. |

30W to 50W or higher | Perfect for top devices with powerful abilities. |

Software tools for building and fixing

Software tools are key for customizing Android PCBAs. SDKs (Software Development Kits) help you make apps and firmware that fit your device. Debugging tools find and fix problems during building. This makes sure the firmware works well with the hardware. AOSP (Android Open Source Project) gives a flexible base for creating custom designs and updates. Using these tools makes it easier to set up and manage devices.

Note: Using both hardware and software tools helps improve performance and ensures everything works together.

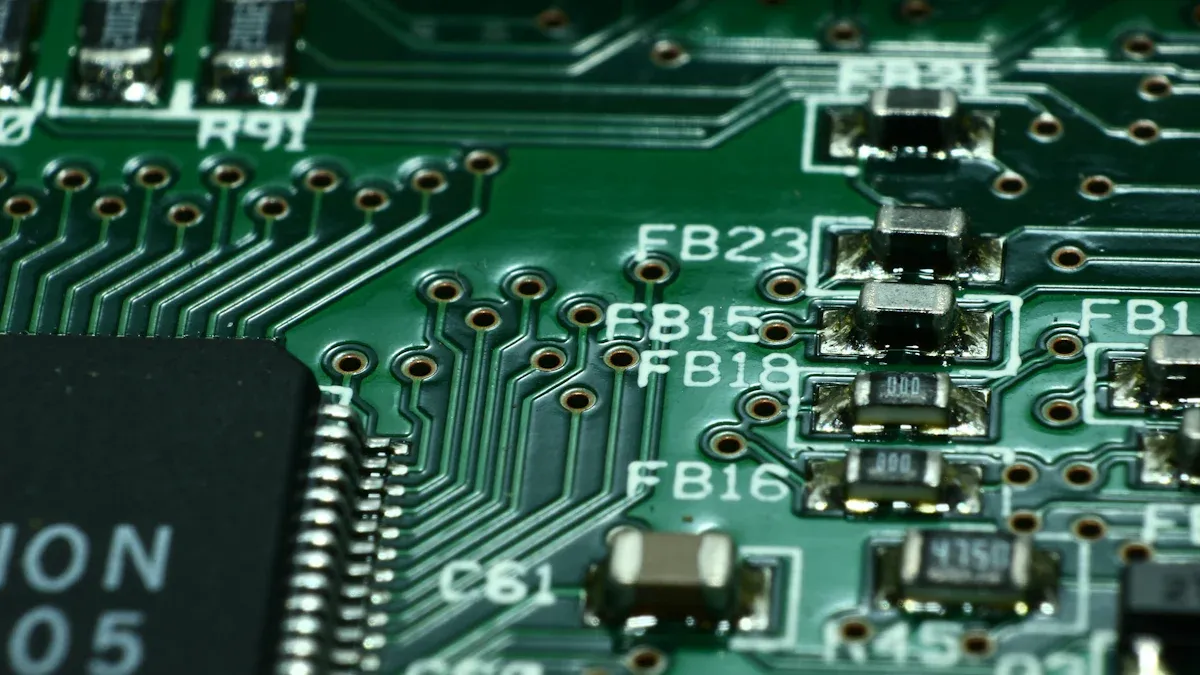

Multilayer PCB designs and why they’re useful

Multilayer PCBs have many benefits for Android devices. They make signals clearer, reduce noise, and improve how circuits work. Special layouts lower interference, making devices like smart wearables work better. High-frequency PCBs are now needed for 5G and modern device updates.

Benefits of Multilayer PCBs:

Clearer signals for better device performance.

Stronger and longer-lasting for custom devices.

Works well with high-speed signals and advanced apps.

Working with experts in multilayer PCBs ensures your device meets standards. It also helps with future upgrades, keeping your device ready for new technology.

Step-by-Step Process for Customizing Android PCBAs

Understanding what your device needs

To customize a PCBA, first know your device’s needs. Think about what the device will do and its key features. For example, a fitness tracker might need motion sensors. An AI camera could require advanced image processing. Also, consider where the device will be used. Will it face extreme heat or strong vibrations?

Make a clear list of needs like power use, connectivity, and supported apps. This list will guide the entire customization process. By focusing on how the device will work, you can make sure the PCBA meets all goals.

Tip: Work with your team to gather ideas from everyone. This helps avoid missing any important details.

Picking the right hardware and parts

After listing the needs, choose the best hardware and parts. Select processors, memory, and sensors that match your device’s purpose. For Android devices, pick parts that save power and work fast. For example, wearables need low-power processors. Devices doing complex tasks need high-speed processors.

Make sure the hardware works well with the software and firmware. Check if it matches the Android Open Source Project (AOSP) and device SDK. This avoids problems between hardware and software. Also, pick parts that allow future updates and improvements.

Note: Always check if firmware updates are available for your hardware. This helps keep your device reliable over time.

Creating and connecting firmware

Firmware links the hardware and software of your device. Build custom firmware that fits your device’s setup. Use an SDK to make firmware that meets your device’s needs. For Android devices, ensure the firmware works smoothly with apps and updates.

Add features to improve the user experience, like over-the-air updates. These updates make managing the device easier. After creating the firmware, connect it to the hardware and test it. Testing ensures everything works well together.

Pro Tip: Use debugging tools to find and fix problems during testing. This saves time and makes the process easier.

Testing and validating the customized PCBA

Testing your customized PCBA ensures it works well and meets needs. This step finds problems and makes sure the final product is reliable. A clear process helps confirm the PCBA fits with the device’s hardware and software.

Steps for Testing and Validation

Functional Testing

Check if the PCBA does its job correctly. Test parts like processors, memory, and sensors to see if they work. For example, make sure the processor handles tasks and sensors give correct data. This testing ensures the PCBA supports the device’s features.Firmware Validation

Test the firmware to see if it works with the hardware. Make sure it supports apps and runs smoothly. Check if firmware updates work to keep the device reliable. Use debugging tools to find and fix problems during this step.Environmental Testing

Test the PCBA in real-life conditions. Try extreme heat, cold, or vibrations to see if it holds up. For example, if it’s for a wearable, test it with sweat or quick movements. This ensures the PCBA can handle tough environments.Power Consumption Testing

Measure how much power the PCBA uses. Devices like wearables need to save power for longer battery life. Make sure the PCBA works well without wasting energy.Provisioning and Connectivity Testing

Test how the PCBA connects to other devices or networks. Check features like Bluetooth, Wi-Fi, or cellular connections. Proper setup ensures the PCBA works smoothly with the device.

Best Practices for Testing and Validation

Use Automated Testing Tools

Automated tools make testing faster and more accurate. They catch problems that manual testing might miss.Perform Iterative Testing

Test the PCBA at different stages of building. This helps find problems early and avoids big mistakes later.Document Results Thoroughly

Write down all test results clearly. These records help track progress and plan for future updates.Collaborate with Experts

Work with skilled engineers or manufacturers. Their knowledge can help find problems and suggest fixes.

Testing and validating your PCBA is key to making a strong and reliable device. By following these steps and tips, you can ensure the PCBA meets all needs and supports future improvements.

Tackling Problems in Android PCBA Customization

Fixing hardware and software compatibility problems

Making hardware and software work together can be tricky. If they don’t match, devices might not work well or stop working. To fix this, check that all hardware parts work with the Android Open Source Project (AOSP) and the apps your device will use. Test how hardware and software fit together early to find any problems.

Use debugging tools to test real-life situations. These tools show how software works with hardware in different conditions. For example, if your device uses sensors, make sure the software reads sensor data correctly. Solving these problems early saves time and avoids expensive fixes later.

Improving and fixing firmware

Firmware connects hardware and software, so it must work well. Fixing firmware problems means finding and solving issues that slow things down. Follow these steps to make it easier:

Find the problem and decide what you want to fix.

Add tools to measure how the firmware is working.

Recreate the problem in a safe setting.

Look at the code to find mistakes.

Fix the mistakes and test the changes.

Keep repeating until the firmware works perfectly.

For devices that need to last long, test them in tough conditions. Try heat or shaking to see if the firmware stays stable. Updating firmware often can also make devices better and add new features.

Keeping costs low and planning for growth

It’s important to control costs while making devices that can grow. Pick parts that do the job but don’t cost too much. Choose hardware that can be updated later to keep up with new technology.

Think about making lots of devices if needed. Design your PCBA to work well for mass production. Work with skilled manufacturers to find affordable ways to build without losing quality. By managing costs and planning for growth, you can make a strong and budget-friendly product.

Best Practices for Successful Android PCBA Customization

Working with skilled manufacturers

Teaming up with skilled manufacturers helps improve your Android PCBA project. These experts know how to design and build PCBAs for Android devices. They can help you pick the right parts that match your device’s needs. Their knowledge ensures your PCBA works well and meets industry rules.

When picking a manufacturer, choose one with proven success. Ask for examples of their past work or client reviews. Good communication is key. Share your device’s details and goals so they understand your needs. Working with experienced manufacturers reduces mistakes and speeds up the process.

Tip: Choose manufacturers who offer help after production, like updates or fixes.

Using open-source tools and community help

Open-source tools and community help are great for customizing Android PCBAs. Platforms like the Android Open Source Project (AOSP) give you a base to build firmware and apps for your device. These tools save time and money by offering ready-made solutions you can adjust.

Joining online groups can also help your project. Forums and developer communities share advice, tips, and the latest trends. You can learn from their experiences and avoid common mistakes. Open-source tools let you create unique devices without starting from zero.

Note: Always check if open-source tools work with your hardware for smooth use.

Focusing on testing and quality checks

Testing and quality checks are very important for Android PCBA success. Testing makes sure your PCBA works well in different situations. Start by testing parts like processors, sensors, and memory. Then, check how the hardware works with the software and firmware.

Testing in real-world conditions is also needed. Try extreme heat or strong vibrations to see if the PCBA holds up. Write down all test results to find areas to improve. Quality checks lower the chance of problems and make users happier.

Pro Tip: Use automated tools to test faster and get better results.

Changing Android PCBAs is key to making special devices. It helps improve how they work, perform better, and stay useful longer. Begin by focusing on one part or feature. Then, make it better step by step.

Tip: Learn about new tech and industry updates. This helps you choose wisely and keep your devices ahead.

Work with skilled makers and use community tools for success. By doing this, you can create cool devices that shine in the market.

FAQ

Why is customizing Android PCBAs helpful?

Customizing Android PCBAs lets you match hardware and software to your device. This boosts how well it works, adds special features, and ensures it fits your needs. It also helps your device stand out from others in the market.

How can you pick the best processor for your PCBA?

Choose a processor based on what your device does. For simple tasks, use low-power processors. For harder tasks, pick faster processors. Make sure the processor works with Android firmware and allows updates later.

Tip: Check how much power the processor uses. This helps match it to your device’s battery needs.

Can old PCBA parts be used again?

Yes, you can reuse parts if they fit your device’s needs. Reusing saves money and cuts down waste. But always check that the old parts work with your new design and software.

How do you make sure your PCBA works in tough places?

Test your PCBA in extreme conditions like heat or shaking. Use tools to copy real-world challenges. This makes sure your PCBA stays strong and reliable in hard situations.

What tools help fix firmware problems?

Use tools like JTAG debuggers or software analyzers. These tools find mistakes in firmware and hardware connections. They help you fix issues fast and improve how your device works.

Note: Debugging often during building stops big problems later.

See Also

Selecting The Ideal PCBA Manufacturer For Your Needs

The Importance Of Android PCBA In Today’s Tech Landscape

Streamlined PCBA Solutions For Quick Electronics Development

Essential Considerations For Selecting A Custom PCBA Provider