A circuit board definition refers to a flat board that connects and supports various electronic components, making it essential for modern electronics. These boards enable devices to function efficiently by providing a platform for electrical connections. From smartphones to smart TVs, almost all consumer electronics rely on printed circuit boards. Their complex multilayer designs allow for compact and powerful devices, highlighting their crucial role in today’s technology world.

Key Takeaways

Circuit boards link and hold electronic parts. This makes devices smaller and better at their jobs.

There are different kinds of circuit boards for special uses. They can be for simple gadgets or complex medical and aerospace tools.

Good design and careful making help circuit boards work well in daily electronics and industries.

Circuit Board Definition

Printed circuit boards (PCBs) are very important for modern electronics. They give support and connect different parts, helping devices work well. The main job of PCBs is to send signals and distribute power among electronic parts. This helps devices run properly. PCBs are needed in everything from computers to home appliances.

Types of Printed Circuit Boards

There are many types of printed circuit boards. Each type is made for different uses and functions. Here is a summary of the main types:

PCB Type | Number of Layers | Structure Description | Key Structural Differences | Typical Applications |

|---|---|---|---|---|

Single-Sided PCB | 1 | Has traces and parts on one side of a non-conductive base (usually FR-4). | One copper layer; simplest design; limited routing. | Simple electronics, prototyping, education |

Double-Sided PCB | 2 | Has conductive layers on both sides connected by holes. | Two copper layers; holes allow connections between layers. | Consumer electronics, industrial control |

Multi-Layer PCB | 3 or more | Has many conductive layers with insulating layers in between, pressed together with heat. | Many layers with power/ground planes; uses special holes; complex to make. | High-speed digital devices, aerospace, medical equipment |

Flexible PCB | Varies | Made from flexible materials like polyimide, allowing bending without breaking. | Flexible material; copper traces stuck with glue. | Space-limited or flexible uses |

Rigid-Flex PCB | Combination | Mixes rigid FR-4 and flexible polyimide layers for support and flexibility. | Rigid parts for strength; flexible parts for bending. | Smartphones, laptops, medical implants |

Single-sided PCBs have parts on just one side. This makes them easier to design and put together. They are cheap for simple uses, like LED lights and home appliances. But they can’t handle complex circuits well.

Double-sided PCBs have parts on both sides. This gives more space and allows more components. This design can support more complex circuits but is harder to make. These boards are often used in consumer electronics and industrial controls.

Multi-layer PCBs have three or more layers of conductive material with insulating layers in between. This design allows for dense circuits and is used in advanced fields like aerospace and medical devices. They are more expensive to make but are needed for high-performance devices.

Flexible PCBs are made from materials that can bend and twist. They are great for places where space is tight. You can find them in wearables and foldable electronics. Rigid-flex PCBs combine rigid and flexible designs. They provide support while allowing some bending. These boards are often used in smartphones and medical devices, where reliability and compactness are very important.

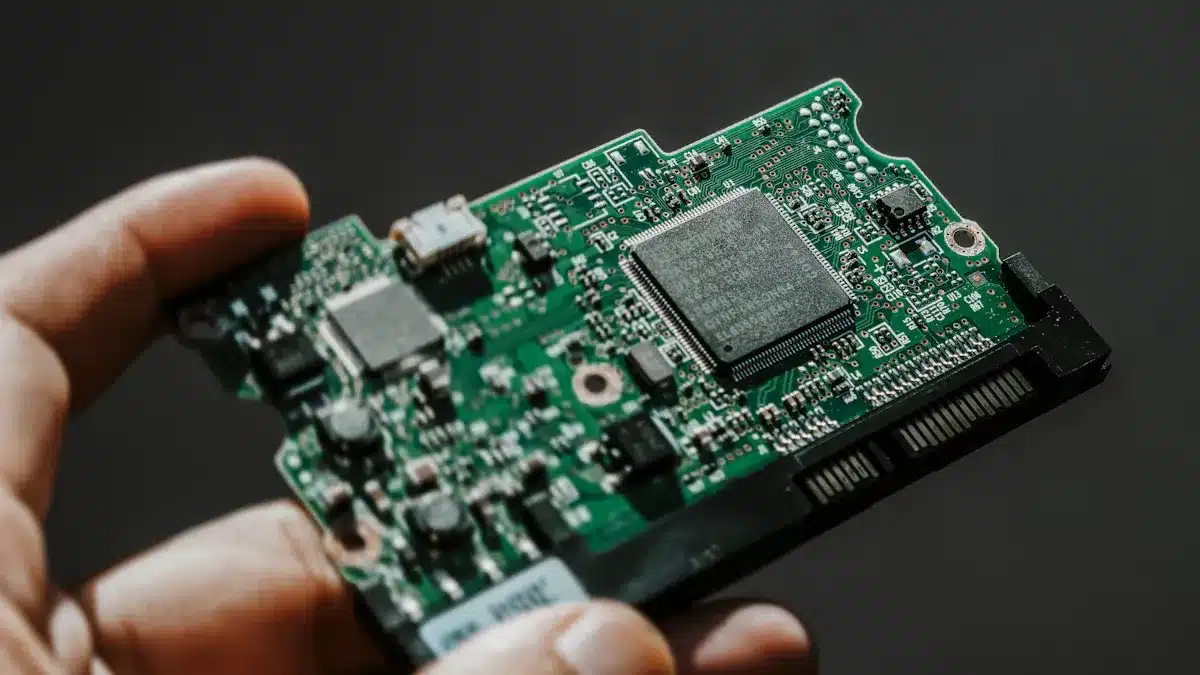

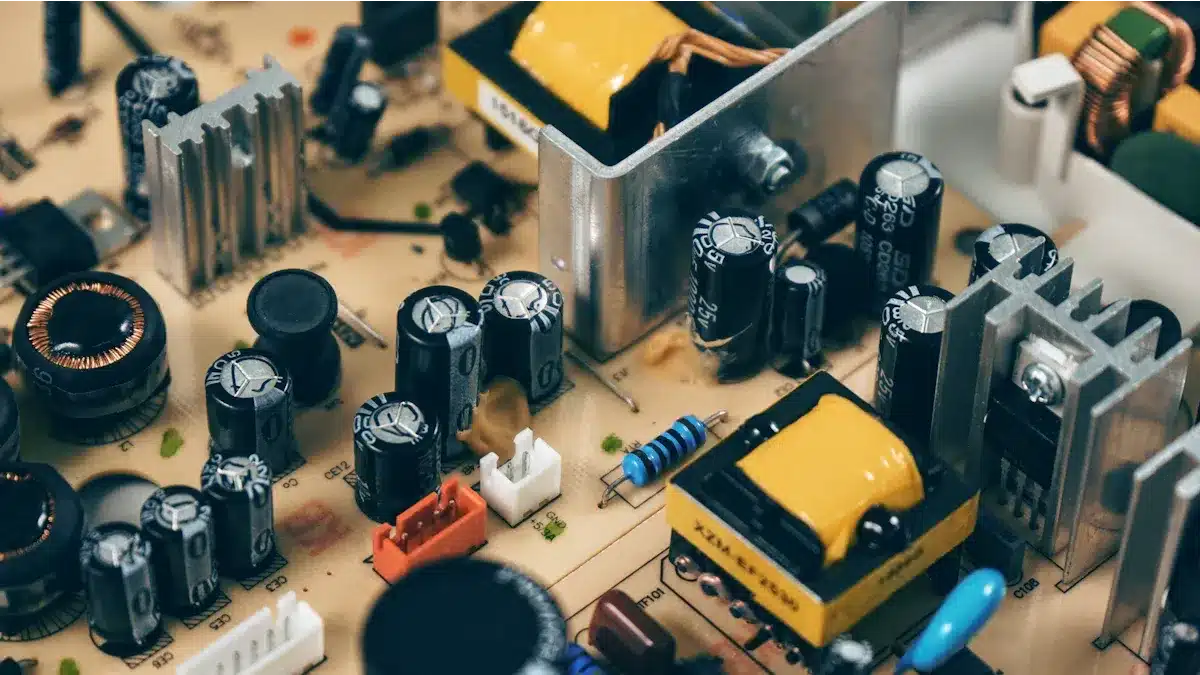

Components of Printed Circuit Boards

Printed circuit boards have many important parts. These parts work together to make sure everything works well. They can be divided into basic and advanced types. Each type has its own special job in the circuit.

Basic Components

Here is a list of basic parts you often find on printed circuit boards:

Resistors: Control electric current and turn power into heat.

Capacitors: Store and release electric charge when needed.

Inductors: Store energy in magnetic fields and block noise.

Diodes: Stop current from going the wrong way, keeping the circuit safe.

Transistors: Work as amplifiers and switches, controlling electronic signals.

Sensors: Notice environmental changes and turn them into electrical signals.

Transformers: Move electrical energy between circuits while changing voltage.

These parts are very important for how PCBs work. Resistors and capacitors are called passive components. They do not need outside power and cannot make signals stronger. Instead, they help the circuit by controlling current and storing energy. Active components like transistors and diodes need power to work. They can make signals stronger or change them, allowing for more complex tasks.

Conductive Pathways

Conductive pathways, also known as copper traces, are crucial for connecting the different parts on a printed circuit board. These pathways replace complicated manual wiring. They let electrical signals move easily between parts. The design of these traces is very important for keeping signals strong and reducing energy loss.

To make sure everything works well, PCB designers follow certain rules when making conductive pathways:

Minimize trace length: Shorter traces lower resistance and signal loss.

Maintain consistent trace width: This helps control impedance and avoid voltage drops.

Provide sufficient spacing: Enough distance between traces cuts down on interference.

Route critical signals first: Focusing on important signals helps keep performance high.

These conductive pathways allow circuits to fit together on the board. This makes the design easier and improves the reliability of electronic devices. By using good materials and careful design methods, manufacturers can create PCBs that work well in many different uses.

Manufacturing Processes of Printed Circuit Boards

Making printed circuit boards (PCBs) involves several important steps. These steps help ensure that the final product is good quality and works well. Here is a list of the main steps in PCB design and prototyping:

Conceptualization and Planning: Decide what the PCB will do, set goals, draw ideas, and look at similar products.

PCB Design: Make diagrams, choose parts, test the design, and check for mistakes.

Layout and Routing: Set the board shape, place parts carefully, connect wires, and organize the layout to avoid problems.

Final Checks and File Preparation: Check the design rules, fix mistakes, and create Gerber files for making the boards.

Selecting Manufacturer: Pick a trustworthy PCB maker based on their experience, skills, and communication.

Prototype Fabrication: Use materials like FR-4, and do imaging, etching, drilling, plating, and add protective layers.

Assembly: Put parts on the board by hand or with machines, solder them, and check for mistakes.

Testing and Validation: Do visual, electrical, and functional tests to make sure everything works right.

Iteration: Get feedback, change the design, and repeat prototyping until it meets the needs.

The methods used to make PCBs are different and fit specific needs. Here are some common methods:

Production Stage | Techniques | Notes |

|---|---|---|

Copper Patterning | Silk screen printing, photoengraving, PCB milling, laser resist ablation, laser etching, EDM etching | The choice depends on how many boards are made and the detail needed; silk screen is for big features, while photoengraving is for small details. |

Etching Methods | Subtractive (immersion, spray, bubble etching), additive, semi-additive | Semi-additive is most common for multilayer boards; subtractive removes copper, while additive adds copper to bare areas. |

Assembly Techniques | Pick-and-place machines, wave soldering, reflow ovens, hand soldering | Automated methods are used for high volume; hand soldering is for prototypes or delicate parts. |

Quality control is very important during the PCB making process. Makers use different methods to ensure the final product is high quality. Here are some common quality control methods:

Solder Paste Inspection (SPI): Checks if the solder paste is applied correctly before placing parts.

Automated Optical Inspection (AOI): Uses cameras to find missing or misplaced parts and solder problems.

X-ray Inspection: Checks hidden connections without damaging the board, especially for BGA parts.

Functional Circuit Testing (FCT): Tests the PCB under real-world conditions to check if it works.

In-Circuit Testing (ICT): Tests individual circuits and sections to check overall functionality.

By following these steps and methods, makers can create high-quality printed circuit boards that meet the needs of today’s technology.

Applications of Circuit Boards in Modern Technology

Printed circuit boards (PCBs) are very important in everyday electronics. They act like a strong base for many devices, making them small and efficient. Here are some common electronics that use PCBs:

Smartphones and Tablets: PCBs hold processors, memory, and other key parts, helping these devices work smoothly.

Computers and Laptops: Motherboards and internal parts depend on PCBs to connect CPUs, GPUs, RAM, and storage, ensuring they perform well.

Televisions and Monitors: PCBs support the complex circuits needed for advanced screens.

Digital Cameras: PCBs help with image processing and storage in small designs, improving photography.

Wearable Technology: Devices like fitness trackers and smartwatches use PCBs to combine sensors, processors, and communication parts, making them useful and portable.

Thanks to improvements in PCB technology, electronic devices can be made smaller. Features like microvias allow more connections in less space, leading to thinner devices. These changes help create compact electronics.

Besides consumer electronics, PCBs are also important in industries. They improve automation systems by providing strong connections for different parts. The benefits of using PCBs in industrial automation include:

Enhanced Precision: Automated placement cuts down on mistakes and boosts reliability.

Increased Production Speed: Continuous operation without tiredness raises manufacturing efficiency.

Reduced Operational Costs: Less labor and waste lower overall costs.

Improved Quality Control: Automated inspection systems make sure outputs are high quality.

PCBs are also key in the automotive and aerospace fields. In cars, they support important functions like electric vehicle power, dashboard displays, and safety systems. These PCBs must handle extreme temperatures and vibrations, ensuring they are strong and reliable.

In aerospace, PCBs are essential for communication, control, guidance, and navigation systems in spacecraft and airplanes. They must survive tough conditions, needing high-quality materials and strict testing to ensure they work well.

Overall, the use of PCBs in both consumer electronics and industries shows how important they are in modern technology. As technology keeps changing, the role of PCBs will grow, supporting progress in many areas.

Printed circuit boards (PCBs) are very important for today’s electronics. They help connect and support many parts. Here are some key points:

PCBs allow devices to be small, like smartphones and machines.

Different kinds of PCBs are made for special uses, improving how they work.

Careful design and making of PCBs make sure they are reliable and work well.

As technology changes, PCBs will keep helping new ideas and improvements in electronics.

FAQ

What is the main purpose of a circuit board?

Circuit boards connect and support electronic parts. This helps devices work well and efficiently.

How do printed circuit boards differ from traditional wiring?

PCBs use copper paths instead of wires. This makes connections easier and saves space while being more reliable.

Can I make my own circuit board at home?

Yes, you can make simple PCBs at home. You can use DIY kits or follow online guides for basic designs.

See Also

Understanding PCBA And Its Importance In Electronics

The Impact Of PCBA On Advancing Modern Electronics

Benefits And Obstacles Of Flex PCBA In Electronics