Ensuring safety at work is very important in many industries. Dual-channel safety monitoring boards help keep things safe. These boards feature two separate channels to detect problems and provide backup. If one channel stops working, the system remains secure. By 2025, advancements in technology have made these dual-channel safety monitoring boards better and more dependable. They are now utilized in environments where safety is essential, such as factories and medical equipment.

Key Takeaways

Dual-channel safety boards have a backup system. If one part stops working, the other keeps running to stay safe.

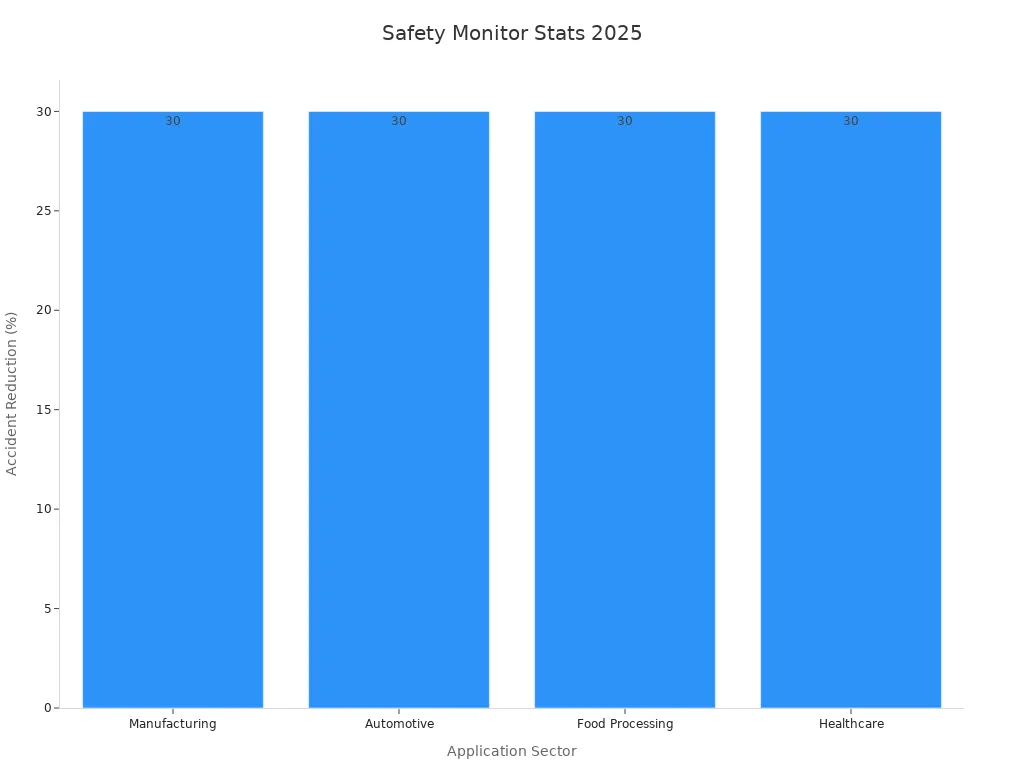

These boards are important in places like factories and hospitals. They have cut workplace accidents by 30%, making work safer and faster.

When picking a dual-channel safety board, check how fast it works and how it handles mistakes. Good boards stop accidents and keep systems steady.

Choose boards that follow safety rules like IEC 61508. Following rules means the board is safe and meets industry standards.

Pick boards that fit with your current systems easily. This saves money and time and lets you upgrade later as needed.

Key Features of Dual-Channel Safety Monitoring Boards

Definition and Purpose

Dual-channel safety boards are tools made to keep systems safe. They have two separate channels to check for problems and add backup. If one channel breaks, the other keeps working to stay secure. This setup is very important in places like factories or hospitals where safety is critical.

The main job of these boards is to stop accidents and follow strict safety rules. They do this by watching inputs and outputs all the time, spotting problems, and fixing them. For example, safety PLCs (Programmable Logic Controllers) are built to handle tough safety needs. They work well even in hard industrial settings. Their ability to find faults and check themselves makes them very reliable and a key part of modern safety systems.

How Dual-Channel Systems Enhance Safety

Dual-channel systems make things safer by adding backup and handling problems. Backup means if one channel has an issue, the other takes over. Problem-handling lets the system keep working even with hardware troubles. These features are very important in risky places.

Different setups, like 2oo3 (two out of three) and 1oo2 (one out of two), make them more reliable. For example, in a gas detection system at a refinery, three detectors work together to find gas. At least two detectors must agree before sounding an alarm. This setup avoids false alarms and ensures correct detection, which is key for safety. Also, hardware fault tolerance (HFT) shows how many problems a system can handle while staying safe. Dual-channel systems usually handle one fault without stopping.

Common Applications in 2025

By 2025, dual-channel safety boards are used in many industries to improve safety and lower risks. They are found in factories, cars, food plants, and hospitals. These boards help reduce accidents and make work smoother.

Data shows their impact. For example, industries like factories and hospitals have seen 30% fewer accidents because of these boards. This drop also cuts downtime, making work more efficient. The table below shows the benefits in different areas:

Application Sector | Fewer Workplace Accidents | Less Downtime |

|---|---|---|

Manufacturing | 30% | Big Improvement |

Automotive | 30% | Big Improvement |

Food Processing | 30% | Big Improvement |

Healthcare | 30% | Big Improvement |

These boards also help keep video quality good in security systems. They stop data loss and keep surveillance footage clear. This is very important in jobs where video safety matters a lot.

Criteria for Evaluating Dual-Channel Safety Monitoring Boards

Performance Metrics

When checking dual-channel safety boards, focus on how they work. Performance metrics show how well the board handles different tasks. Important things to check are speed, error handling, and dependability. A fast board finds problems quickly, which is vital in risky places. Error handling shows if the board can fix issues without failing. Dependability means the board works well for a long time.

For example, in factories, a dependable board stops machine problems that cause accidents. Also, see how the board manages data. Boards that handle data well keep systems steady and improve how they run.

Compliance with Safety Standards

Safety rules are important when picking a dual-channel safety board. These rules make sure the board follows industry guidelines and keeps people safe. Look for labels like ISO 13849 or IEC 61508. These show the board meets global safety rules.

Boards with these labels lower risks and boost safety. For example, in hospitals, following rules keeps medical tools safe for patients and workers. Always check the board’s papers to ensure it meets safety needs.

Ease of Integration and Scalability

How easy the board fits into your system matters a lot. A good board should connect easily to what you already use. This saves time and makes things run smoothly. It should also grow with your needs. As you need more, the board should handle it without big changes.

For instance, in security cameras, a growing board can manage more data while keeping videos clear. This is key for safety jobs where clear footage is needed. Picking a board that fits well and grows with you saves money and lasts longer.

Comparison of Top Dual-Channel Safety Monitoring Boards in 2025

Board A: Features, Pros, and Cons

Board A works well in places needing precision and reliability. It uses dashboards to check system health and fix problems fast. This board is great for factories and hospitals.

Features:

Pre-Certified Safety Solutions: Modules meet IEC 61508 SIL3 rules, saving users time.

Advanced Diagnostics: Tests memory to find over 99% of faults easily.

Scalability: Adjusts safety settings to fit different needs.

Pros:

Builds trust with clear system checks.

Shows system performance using scorecards.

Cuts downtime with smart safety design.

Cons:

Some users find metrics hard to understand.

Setup needs experts, which costs more at first.

Evidence Type | Findings |

|---|---|

Performance Metrics | Dashboards improve safety in critical places. |

Benefits | Clear checks build trust and teamwork. |

Drawbacks | Confusing metrics can hurt evaluations. |

Board B: Features, Pros, and Cons

Board B fits easily into systems already in use. It separates safety tasks from other jobs to avoid problems. This board works well in cars and food plants.

Features:

Partitioned Design: Keeps safety tasks like shutdowns separate from other jobs.

Smart Safety Monitoring: Uses hardware to keep systems running smoothly.

Reusable Safety Libraries: Includes tools like timers to speed up work.

Pros:

Easy to add to current systems.

Saves money by reducing extra parts.

Adjusts to different safety needs.

Cons:

Finds fewer problems than Board A.

Not ideal for jobs needing detailed fault checks.

Tip: Choose Board B for a mix of cost and features.

Board C: Features, Pros, and Cons

Board C is made for security jobs like keeping video clear. It works best in places needing good surveillance footage.

Features:

Optimized Safety Circuitry: Cuts extra parts but stays safe.

High Video Quality: Stops data loss to keep footage sharp.

Expert Safety Consulting: Helps with safety checks and rules.

Pros:

Great for security jobs needing clear videos.

Saves money with smart circuit design.

Offers help with safety certifications.

Cons:

Not flexible for non-security jobs.

Costs more due to special features.

Note: Pick Board C if video quality and security matter most.

Summary Table Comparing Key Specifications

When picking a dual-channel safety board, comparing specs helps a lot. The table below shows features, pros, cons, and best uses for Boards A, B, and C. It makes choosing easier by showing key details side by side.

Specification | Board A | Board B | Board C |

|---|---|---|---|

Key Features | Pre-certified safety solutions, advanced diagnostics, scalability | Partitioned design, smart safety monitoring, reusable safety libraries | Optimized safety circuitry, high video quality, expert safety consulting |

Advantages | Reliable fault detection, reduced downtime, strong compliance support | Easy integration, cost-effective, adaptable to various safety needs | Superior video clarity, cost-saving design, compliance assistance |

Disadvantages | Complex setup, requires expertise for initial configuration | Limited fault detection capabilities, less suitable for detailed diagnostics | High cost, limited flexibility for non-security applications |

Ideal Use Cases | Factories, hospitals, environments needing precision and reliability | Automotive, food processing, systems requiring seamless integration | Security systems, surveillance applications, video-critical environments |

Key Insights from the Comparison:

Board A is great for places needing precision and reliability. Its advanced tools and pre-certified parts work well in factories and hospitals. But, setting it up may need expert help.

Board B balances cost and features. Its design keeps safety tasks separate, making it good for cars and food plants. It’s easy to add to existing systems.

Board C is best for security jobs. It keeps videos clear and uses smart circuits. However, it costs more and doesn’t work well outside security tasks.

Tip: Choose Board C for clear videos in security systems. For general use, Board A or Board B might fit better.

This table helps you find the right board for your needs. Whether you need fault detection, easy setup, or clear videos, this guide ensures you pick the best option.

Choosing the Right Dual-Channel Safety Monitoring Board for Your Needs

Industry-Specific Recommendations

Picking the right safety board depends on your industry’s needs. For factories, choose boards with safety certifications like IEC 61508 SIL3. These boards make setup easier and follow safety rules. In hospitals, boards with fault detection are very important. They keep medical tools working and protect patients.

For cars and food plants, boards with separate safety tasks are helpful. They improve how systems work by keeping safety jobs apart from others. Security jobs, like video monitoring, need boards that keep footage clear. These boards stop data loss and help meet safety rules.

Key Aspect | Description |

|---|---|

Boards must follow safety rules for each industry. | |

Safety Monitoring | Fault detection keeps systems safe and reliable. |

Centralized Databases | Boards should connect easily to safety monitoring systems. |

Budget Considerations

Your budget affects which board you pick. Expensive boards with smart features cost more upfront. But they save money later by reducing repairs and downtime. If money is tight, pick boards that balance cost and features. Boards with separate safety tasks can lower costs by needing fewer parts.

Think about the total cost, including setup and repairs. Boards that grow with your needs save money over time. They stop you from buying new boards as your system expands. Compare the starting price with long-term savings to decide wisely.

Future-Proofing and Scalability

Future-proofing keeps your board useful as technology changes. Pick boards that adjust to new safety rules. Boards with flexible safety levels, like SIL or ASIL, help meet future standards without replacing them.

Reusable safety tools, like timers and checks, also help future-proofing. These tools make upgrades faster and easier. In security jobs, boards should handle more data as systems grow. They must keep videos clear and stay safe.

Choosing a board that grows with your needs protects your money. It also ensures your system stays safe for years to come.

Dual-channel safety boards help keep important systems safe. They have backup and can find problems to stay reliable. New models in 2025 have features for many uses, like factories or hospitals. Think about your needs and industry rules before choosing one. Cost is important too, especially for long-term safety. Picking the right board keeps your system safe now and later.

FAQ

What is the main advantage of dual-channel safety boards?

Dual-channel safety boards have a backup system. If one part stops working, the other keeps things running. This lowers risks and makes them reliable in places like factories or hospitals.

How do dual-channel systems detect faults?

These systems watch both parts all the time. If something doesn’t match, they find the problem and fix it. This keeps things safe by solving issues early.

Are dual-channel safety boards expensive to maintain?

Not really. They might cost more at first, but they save money later. They prevent accidents and reduce repair costs, which helps over time.

Can dual-channel boards integrate with existing systems?

Yes, most new boards fit easily into current setups. They are simple to connect, saving time and effort. Always check if they work with your system before buying.

Do dual-channel safety boards require frequent updates?

No, they don’t need updates often. But regular checks and maintenance keep them working well. Following safety rules also helps keep your system up-to-date.

Tip: Check your board often to keep it working longer and better.