Factories today need to operate more efficiently while spending less money. Energy monitoring IIoT device manufacturing is playing a crucial role in making this possible. These innovative tools provide real-time insights into energy usage, helping to identify and resolve issues quickly.

Consider this: smart factory tools can lead to a 20% reduction in energy consumption. Additionally, energy monitoring IIoT devices can enhance machine efficiency by 20% and decrease downtime by 30%. Implementing these solutions can minimize waste and contribute to more eco-friendly manufacturing practices.

🌱 Utilizing IIoT devices not only saves energy but also strengthens your factory’s resilience in a rapidly evolving landscape.

Key Takeaways

IIoT devices can cut energy use by up to 20%. This saves factories a lot of money.

Real-time tracking finds wasted energy fast. This boosts factory efficiency and work output.

Predictive maintenance fixes machines before they break. This saves energy and avoids delays.

Automation with IIoT devices uses energy better. It makes work smarter and eco-friendly.

IIoT technology costs a lot at first. But it saves money and helps the environment over time.

Understanding Energy Monitoring IIoT Devices in Manufacturing

What Are IIoT Devices?

IIoT devices are smart tools that connect machines and sensors. They share data using modern methods like MQTT and HTTPS. These tools are wireless and use software gateways, making them easy to use.

A recent study shows their growing use:

62% of factories now use IoT tools.

Popular uses have a 33% average adoption rate in factories.

Adding IIoT devices can turn your factory into a smart system. This system saves energy and works more efficiently.

How IIoT Devices Enable Energy Monitoring

IIoT devices help track energy use in real time. They show how much energy is used and help cut waste. For example:

Data reports help you make better choices.

These features keep your factory energy-smart and lower costs.

The Role of Data in IoT Energy Management

Data is key to managing energy with IIoT devices. These tools use advanced methods to study energy use. Important methods include:

Edge Computing: Makes quick decisions by processing data locally.

Stream Processing: Handles live data for instant updates.

Time-Series Databases: Stores fast-moving sensor data.

Machine Learning: Spots patterns and predicts energy needs.

Using these methods helps you understand energy use better. This lets you plan smarter ways to save energy.

Benefits of IIoT Devices for Energy Management

Real-Time Monitoring for Better Efficiency

Real-time monitoring changes how factories manage energy. With IIoT devices, you can see energy use instantly. This helps find problems and fix them fast. For example, if a machine uses too much energy, you can check and solve the issue quickly.

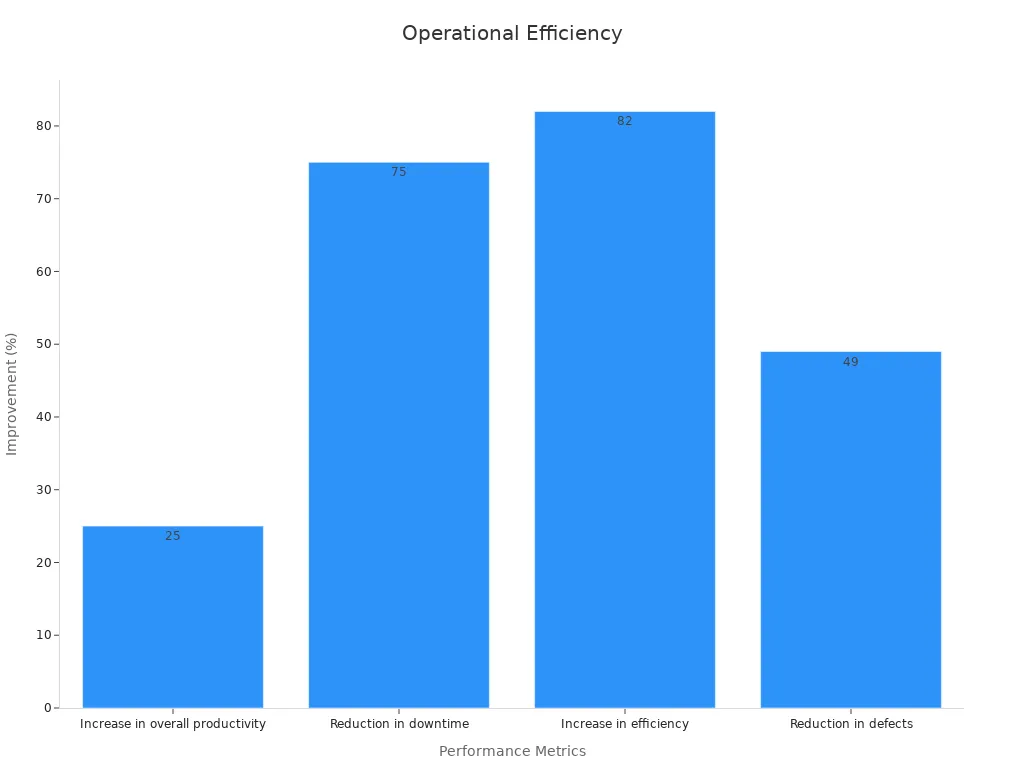

Real-time data improves factory performance in many ways. Factories using IIoT devices report big gains:

Metric | Improvement Percentage |

|---|---|

Higher productivity | |

Less downtime | 75% |

Better efficiency | 82% |

Fewer defects | 49% |

Using real-time data helps save energy, cut waste, and boost factory performance.

Predictive Maintenance to Save Energy

Predictive maintenance is another helpful tool from IIoT devices. These devices predict when machines might break. This lets you fix them before they fail, saving energy and avoiding downtime.

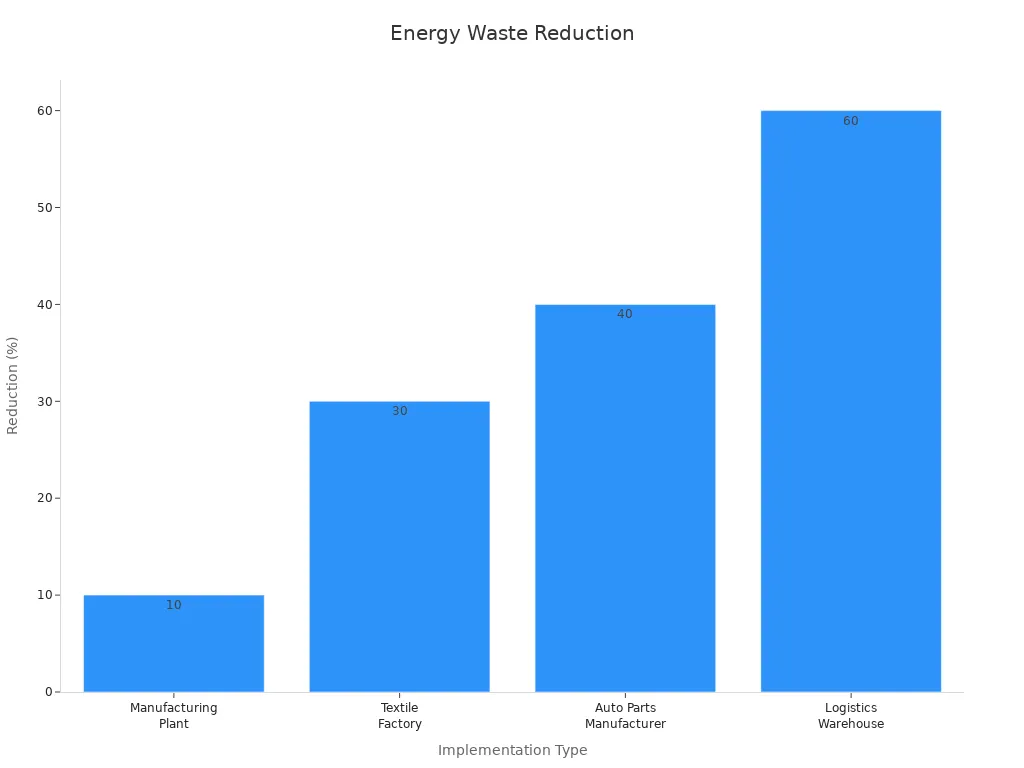

Factories using predictive maintenance see big energy savings:

Implementation Type | Reduction in Energy Waste | Source Link |

|---|---|---|

Manufacturing Plant | ||

Textile Factory | 30% lower energy costs | |

Auto Parts Manufacturer | 40% less energy used | |

Logistics Warehouse | 60% less energy for lights |

Predictive maintenance saves energy, keeps machines working longer, and makes systems more reliable.

Automation for Smarter Energy Use

Automation helps factories use energy better. IIoT devices collect and study data to make smart choices. This reduces energy waste and lowers costs.

Here are some examples of automation with IIoT devices:

Schneider Electric’s EcoStruxure system improves energy use and checks power quality.

Enel in Italy uses 30 million smart meters to track energy use.

IoT-powered smart grids find problems and manage systems better.

Automation makes energy use smarter and easier to control. Adding IIoT devices to your factory helps save energy and supports sustainability.

Cost Savings and Environmental Impact

Using energy monitoring IIoT devices saves money and helps the environment. These tools make factories work better while cutting costs and supporting sustainability.

Lower Operational Costs

IIoT devices save money in many ways. Predictive maintenance stops frequent repairs and keeps machines running longer. Automated systems manage energy better, lowering electricity bills. Better supply chain tracking reduces inventory costs and avoids running out of stock.

Aspect | Description |

|---|---|

Predictive Maintenance | Cuts repair costs and makes machines last longer. |

Uses energy wisely, lowering power bills. | |

Supply Chain Visibility | Reduces inventory costs and avoids stock shortages. |

Return on Investment (ROI) | Costs are high at first but pay off later. |

New Revenue Streams | Data insights can create new ways to earn money. |

These savings make IIoT devices worth the investment. While setup costs may seem high, the long-term benefits are much greater.

Environmental Benefits

IIoT devices also help reduce harm to the environment. They improve energy use, save resources, and cut pollution. For example:

Predictive maintenance lowers fuel use and boosts productivity.

Better supply chains reduce emissions from transportation.

Automated systems cut waste and improve efficiency.

Smart sensors help with recycling and waste management.

A study shows how IIoT devices help the environment:

46% track pollution and contamination levels.

62% report big improvements in sustainability.

🌍 Did you know? IIoT devices track greenhouse gases, helping factories follow rules and cut emissions.

Adding IIoT devices saves money and protects the planet. These tools make factories more efficient and support a cleaner, greener world.

Practical Uses of IIoT in Energy Management

Smart Sensors for Energy Monitoring

Smart sensors are key to improving energy monitoring systems. These sensors collect live data, helping factories track energy use. They also find areas where energy is wasted. By studying this data, factories can make better choices to save energy and reduce waste.

Here are some real-life examples of smart sensors saving energy:

Buildings with energy systems saved $13.5 million in a contract. They cut energy use by 41% and reduced carbon emissions by 3,100 metric tons yearly, says the U.S. General Services Administration.

ASHRAE found that constant energy tracking, with better operations, lowered energy use by 10-20%.

IBM saved 30% energy in data centers using IoT sensors and predictive tools in their Smarter Buildings project.

These examples show how IoT tools can improve energy use in factories. Tools like smart meters and state-of-charge systems help balance energy needs and give useful insights.

🌟 Tip: Adding IoT sensors to your factory can lower energy use and improve efficiency.

Demand Response Systems in Factories

Demand response systems are another way IoT helps manage energy. These systems adjust energy use based on demand. This keeps factories running well during busy times. IoT sensors and smart tools can automate these changes to avoid wasting energy.

Factories using demand response systems gain:

Lower energy bills during high-demand times.

Better grid stability by balancing energy use.

Fewer overloads, keeping operations running smoothly.

AI tools make these systems smarter by predicting energy needs. Together, IoT and AI create flexible systems that save energy and cut costs.

Examples of Energy-Saving Manufacturing Methods

Energy-saving methods are vital for cutting energy use and meeting green goals. Upgrading equipment and improving production can save money and reduce waste.

Here are some ways factories save energy:

Solar-powered buildings need less traditional electricity.

Lights that adjust to daylight save power.

Water-cooled chillers use less energy than air-cooled ones.

Better molding processes run pumps only when needed, saving energy.

Measuring Specific Energy Consumption (SEC) finds where machines waste energy. Fixing these issues saves energy and boosts productivity.

🌍 Note: Energy-saving methods cut costs and help the planet by reducing pollution and saving resources.

Addressing Challenges in IIoT Adoption

Managing Costs and ROI Expectations

Starting with IIoT devices costs a lot upfront. Buying sensors, software, and setting up systems is expensive. Updating old machines to work with IIoT adds more costs. It can take years to see the money saved, which worries some leaders.

To check if IIoT is worth it, look at key results:

Predictive maintenance keeps machines running, reducing downtime.

Lower energy and repair costs save money over time.

Faster production makes more items in less time.

Better use of energy and materials reduces waste.

Switching from testing ideas to proving value shows IIoT’s benefits. Though starting costs are high, saving energy and working better make it worth the price.

Integrating IIoT with Existing Systems

Adding IIoT tools to old factory systems can be hard. Older machines often don’t work well with new IIoT devices. Digital twins help by copying real machines and systems for better control.

Application | Description |

|---|---|

Energy Management | IoT tools find wasted energy and suggest ways to save. |

Software that collects data makes adding IIoT easier. Picking good connection options ensures devices work well together.

Ensuring Cybersecurity in IoT Energy Management

Keeping IIoT systems safe from hackers is very important. Weak passwords, bad networks, and old updates can cause problems. Hackers use these issues to steal data or stop systems from working.

To stay safe, try these tips:

Encrypt data so hackers can’t read it.

Use tools to spot strange activity that might be attacks.

Limit who can access important systems to prevent misuse.

Regular checks and training help keep systems secure. Fixing weak spots protects your factory and keeps everything running smoothly.

Training Teams to Use IIoT Devices Effectively

Teaching your team is key to using IIoT devices well. Without training, workers might find these tools hard to use. A trained team helps the factory run smoothly and saves energy.

Begin by explaining what IIoT devices are and how they help. Show how these tools improve factory work. Use simple demonstrations to teach how to use them. For example, show how to read data from smart sensors. Teach how to set up systems that monitor energy all the time. Hands-on practice makes workers more confident.

Hold workshops often to teach new updates and features. IIoT devices change fast, so staying updated is important. Invite experts to share tips or lead training sessions. These events improve skills and encourage learning in your factory.

Make easy guides and manuals for workers to follow. Use pictures like charts or diagrams to explain tough ideas. For instance, a chart showing how sensor data is processed can help. Keep these guides available for everyone.

Promote teamwork among employees. Pick mentors who know IIoT tools well to help others. Learning from coworkers makes training faster and builds a helpful workplace.

Check if your training works well. Use surveys or track results to find weak spots. Keep improving so your team stays ready for challenges and uses IIoT devices fully.

💡 Tip: A trained team boosts efficiency and ensures your IIoT success lasts.

IIoT devices are changing how factories handle energy use. These tools let factories track energy in real time. This helps find problems and cut down on waste. For instance, ABC Manufacturing used 18% less water. An Indian textile company boosted renewable energy use by 28%.

Company | Sustainability Benefit | Improvement Percentage |

|---|---|---|

ABC Manufacturing | Lowered water usage | 18% |

Indian Textile Company | Used more renewable energy | 28% |

Better efficiency shows why IIoT tools are worth it. Car part makers cut downtime by 30%. Food companies saved 25% on maintenance costs.

Manufacturer Type | Efficiency Gain | Downtime/Cost Reduction |

|---|---|---|

Automotive Parts Manufacturer | 30% less unplanned downtime | 15% longer equipment life |

Food Processing Company | 35% fewer downtime issues | 25% lower maintenance costs |

Even with early challenges, IIoT tools improve energy use and sustainability. They also prepare factories for the future. These benefits make them a smart choice for modern factories.

FAQ

What are IIoT devices, and how do they help factories?

IIoT devices are smart tools that link machines and sensors. They gather and share data to manage energy better. These tools help factories track energy use, cut waste, and improve efficiency.

How do IIoT systems improve energy efficiency?

IIoT systems monitor energy use live. They find problems and suggest fixes to save energy. Predictive maintenance and automation also help factories work more efficiently.

Are IIoT solutions expensive to implement?

IIoT solutions cost a lot at first for setup and tools. But they save money later by cutting energy use, downtime, and improving systems. The savings often make up for the high starting costs.

How do IIoT devices support sustainability goals?

IIoT devices help factories waste less energy and lower emissions. They allow factories to use greener methods, track their impact, and improve processes for eco-friendly operations.

What challenges might you face when adopting IIoT systems?

Challenges include high costs, connecting new tools to old systems, and keeping data safe. Good planning, training, and picking flexible tools can solve these problems.

See Also

Enhancing Workflow Productivity in PCB Assembly Processes

Essential Strategies for Increasing PCB Assembly Productivity

The Importance of Inverter Circuits in Power Electronics