Energy monitoring IIoT device manufacturing utilizes smart tools to assess energy consumption. These tools contribute to energy savings and improved efficiency. Predictive AI can reduce energy usage by 10% and decrease carbon emissions by 40%. For example, a semiconductor factory achieved annual savings of $1 million and cut down 10,000 tons of carbon emissions. By quickly identifying issues, energy systems save costs, consume less energy, and benefit the environment. With eight billion IIoT devices anticipated by 2025, energy monitoring in IIoT device manufacturing will continue to expand.

Key Takeaways

Energy monitoring in IIoT manufacturing makes work more efficient. It gives live data to find waste and fix processes.

Using energy monitoring can save a lot of money. Companies can cut energy use by up to 30%, lowering costs.

Meeting sustainability goals is easier with energy monitoring. Factories can track energy and emissions to meet green targets.

Predictive maintenance with energy monitoring reduces unexpected stops by 50%. This saves money and keeps machines working longer.

Analytics with energy monitoring shows useful information. This helps improve work, cut waste, and make more profit.

Why Energy Monitoring Matters in IIoT Manufacturing

Enhancing Efficiency with Energy Monitoring

Energy monitoring helps make factories more efficient in the IIoT world. It gives detailed energy use data for smarter decisions. For example, new tools let you see how energy flows in real time. This helps improve production and cut down on waste.

Studies show that IoT makes energy management better by focusing on monitoring. Watching energy use in real time finds wasteful areas. Fixing these areas boosts productivity and shortens work times. This keeps operations running smoothly.

Tip: Automated energy monitoring collects data in one place. This helps match energy use with business goals while staying efficient.

Reducing Costs Through Energy Optimization

Energy monitoring helps cut costs in IIoT manufacturing. By studying energy data, you can find problems and fix them. For instance, switching old machines for energy-saving ones can lower electricity use by 10%. This saves your business money.

Better production processes also use less energy and work faster. The Armal case shows this well. After using IoT tools, the company cut energy costs by 40%. This made them more competitive and saved money.

Note: Energy monitoring shows where to save energy. This lowers bills and uses resources wisely.

Achieving Sustainability Goals in Manufacturing

Energy monitoring helps meet sustainability goals by tracking results. For example, you can measure CO2 emissions or energy use. This data helps set goals, like cutting emissions by 10% in two years. Real-time data lets you check progress and make changes.

Sustainability also means tracking water use, nature, and social impacts. Using energy data, you can create plans that fit your green goals. One example is cutting emissions by 9% in 18 months with constant updates.

Tip: Use energy monitoring to measure carbon emissions and track goals. This keeps your factory eco-friendly.

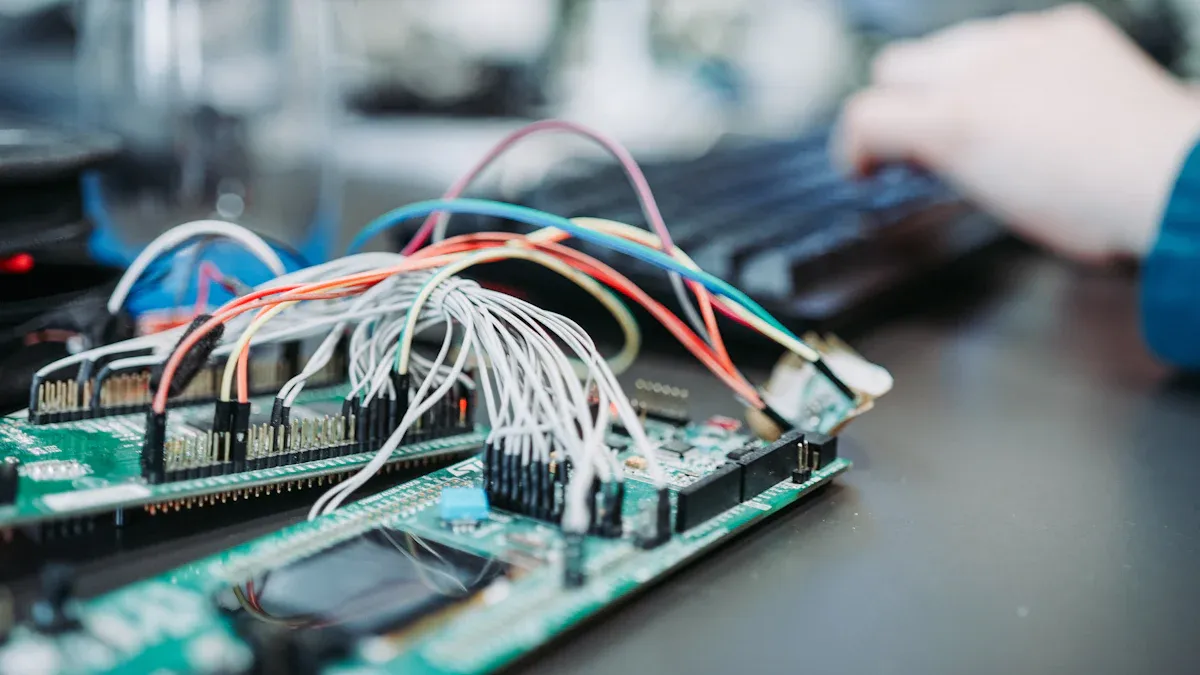

How Energy Monitoring Works in IIoT Manufacturing

Role of Sensors, Data Loggers, and Software

Energy monitoring in IIoT uses sensors, data loggers, and software. Sensors check how much energy machines and processes use. They measure things like voltage, current, and power. Data loggers gather this information and store it for later use. These tools work with many sensor types, making them flexible. For example:

Feature/Application | Description |

|---|---|

Compatibility | Data loggers work with many sensors for easy data collection. |

Environmental Monitoring | Tracks weather, air quality, and soil using various sensors. |

Industrial Applications | Useful for energy tracking, process checks, and finding equipment issues. |

Data Access | Real-time data is available through Ethernet, making it simple to use. |

The software takes the data from sensors and loggers and processes it. It helps you see, analyze, and report energy use. Together, these tools create a smooth system for energy tracking. You can use them for energy checks, power quality tests, and predicting maintenance needs.

Tip: Pick systems with strong tracking features for better energy data and decisions.

Real-Time Data Collection and Monitoring

Real-time data is key to energy monitoring in IIoT. Sensors and loggers track energy use nonstop and send updates to the software. This lets you see energy use as it happens. Alerts warn you about problems, like sudden power spikes, so you can act fast to fix them.

For instance, a car factory used a dashboard to track power use, costs, and carbon output live. By comparing current and past data, they found waste and improved energy use. Similarly, Carlsberg used IoT tools to watch machine performance. Real-time data helped them work better and make smart choices.

Note: Watching energy in real time saves energy and prevents delays by fixing issues quickly.

Generating Actionable Insights with Analytics

Analytics turns raw energy data into useful ideas. Smart tools study patterns to find ways to improve. For example, real-time analysis can predict when machines might break. This lets you fix them before they stop working, saving time and money.

Here’s how analytics helps energy monitoring:

Benefit/Functionality | Description |

|---|---|

Real-time Monitoring | |

Predictive Maintenance | Cuts downtime and repair costs by spotting issues early. |

Shows ways to improve processes and reduce waste. | |

Actionable Insights | Analyzes data to give clear ideas for better decisions. |

Resource Optimization | Lowers energy use and downtime, saving money. |

Increased Profitability | Makes workflows smoother, boosting efficiency and profits. |

Using these insights, you can improve factory work, save energy, and meet green goals. Analytics helps you make smart choices that boost efficiency and profits.

Tip: Use analytics to find hidden problems and get the most from energy monitoring.

Practical Applications of Energy Monitoring IIoT Device Manufacturing

Predictive Maintenance and Equipment Longevity

Energy monitoring in IIoT helps with predictive maintenance. It studies energy data to find patterns of possible equipment problems. Fixing these issues early can cut unplanned downtime by 50%. For example, Shell saved 25% on maintenance costs and improved equipment use by 5%. This shows how energy monitoring can make machines last longer and lower costs.

Unplanned downtime is very expensive. In power plants, it can cost $10,000 to $1 million per hour. Predictive maintenance avoids these costs by planning repairs better. With a 10:1 return on investment, this method saves money and keeps factories running well.

Tip: Use energy monitoring to spot problems early and save time and money.

Optimizing Production Lines for Energy Efficiency

Energy monitoring in IIoT helps make production lines more efficient. Real-time data shows where energy is wasted. You can then adjust processes to fix these problems. For example, factories in Italy use systems to collect machine data and create reports. These systems are easy to connect and work with factory IT setups.

The process includes gathering data, studying it, and making changes to improve. Newmont Corporation used a ventilation system that cut underground costs by 50% and surface costs by 73%. This proves energy monitoring can save energy and improve factory performance.

Note: Real-time energy data helps meet energy rules and cut costs.

Improving Resource Utilization Across Processes

Energy monitoring in IIoT improves how resources are used. It tracks energy use to find waste and fix it. For example, some factories cut energy use by 6% and energy costs by 5.3%. Overused machines, like presses, were used 21% less.

These changes save energy and make factories work better. Using resources wisely reduces waste and increases productivity. This supports green goals and helps businesses save money.

Tip: Use energy monitoring to manage resources better and save energy long-term.

Benefits of Energy Monitoring in IIoT Manufacturing

Boosting Productivity with Data-Driven Decisions

Energy monitoring systems help you make better choices using data. Real-time energy data shows where processes can improve. For example, factories using advanced tools for quality checks achieve 98.6% success rates. This is much higher than the 89.2% rate with older methods. It proves that data-based decisions improve productivity.

Companies with strong data practices are 4% more productive. They also earn 6% more profits than others. Energy monitoring can lower energy costs without reducing output. One car factory cut energy costs by 17% in six months while keeping production steady. These examples show how energy monitoring boosts productivity and saves money.

Tip: Use energy data to find hidden problems and make smart choices.

Lowering Operational Costs Through Energy Savings

Energy monitoring helps cut costs by finding wasteful energy use. Fixing these issues lowers bills and manages energy better. Businesses using energy-saving tools can reduce energy use by 30%. This leads to big savings.

For example, U.S. buildings waste about 30% of their energy. Fixing this could save millions each year. Also, delaying energy transmission upgrades saves $3.08/kW-yr and $6.85/kW-yr. These savings show how energy monitoring helps financially.

Note: Using less energy cuts costs and improves your profits.

Reducing Environmental Impact with Smarter Energy Use

Energy monitoring reduces your environmental impact by using energy wisely. It lowers emissions and supports sustainability goals. Studies show connected devices and smart tools reduce emissions a lot. For example, sensors improve energy use and save resources, helping the environment.

Research shows digital tools collect detailed environmental data. This improves both business and environmental results. Using energy monitoring aligns your factory with global green standards while boosting efficiency.

Tip: Track and cut emissions with energy monitoring to stay eco-friendly.

Energy monitoring in IIoT manufacturing changes how factories work. It helps factories run better, save money, and stay eco-friendly. For example:

Predictive maintenance stops 70% of equipment failures and saves 25% on repairs.

Watching steam traps nonstop gives a 700% return in three months.

Factories cut over 20,000 metric tons of CO₂ every year.

These examples show how useful energy monitoring is. Using these systems makes factories work smarter and succeed in tough markets.

FAQ

What is energy monitoring in IIoT manufacturing?

Energy monitoring in IIoT uses smart tools to watch energy use. It finds waste, improves processes, and cuts energy loss. This boosts productivity and helps meet eco-friendly goals.

How does energy monitoring improve efficiency?

Energy monitoring shows live energy data. It spots wasteful steps and helps fix them. This reduces delays and keeps work running smoothly.

Can energy monitoring help reduce costs?

Yes, it finds where energy is wasted. Fixing these saves money on bills and repairs. It also prevents costly machine breakdowns with early warnings.

Is energy monitoring suitable for all industries?

Energy monitoring works for many industries, especially factories. It fits well in places like power plants and energy-heavy jobs. Its tools can adjust to different needs.

How does energy monitoring support sustainability?

Energy monitoring tracks energy use and pollution. It helps set green goals, like cutting carbon emissions. Using less energy protects the planet and saves resources.

See Also

The Importance of PCBA Numbers in Streamlining Production

Strategies to Enhance Workflow Efficiency in PCBA Production

The Significance of Inverter Circuits in Power Electronics

The Role of Custom PCBA Manufacturing in Today’s Electronics

Understanding the Differences Between Active and Passive Components