Quality control is very important for ensuring a successful PCBA process. Strong quality checks help lower mistakes and make production faster. For example, better methods can cut the reject rate from 5500 parts per million (PPM) to 900 PPM. They can also reduce errors by 0.76%. Without good quality checks in the PCBA process, faulty boards may be produced. This could lead to a 1.5% failure rate in the first year. Such problems hurt your reputation and cost money for recalls. They also harm the environment. A complete plan for the PCBA process keeps production steady and products reliable.

Key Takeaways

Use strong quality checks to find mistakes and work faster. This helps reduce rejected products a lot.

Get design and manufacturing teams to work together. They can spot and fix problems early in the PCBA process.

Use smart tools like Automated Optical Inspection (AOI) and x-ray checks. These help find mistakes quickly and correctly.

Follow improvement methods like Statistical Process Control (SPC). This helps watch production quality and fix issues early.

Train workers to improve their skills and knowledge. This helps the quality team find and solve problems better.

Design for Manufacturability in the PCBA Process

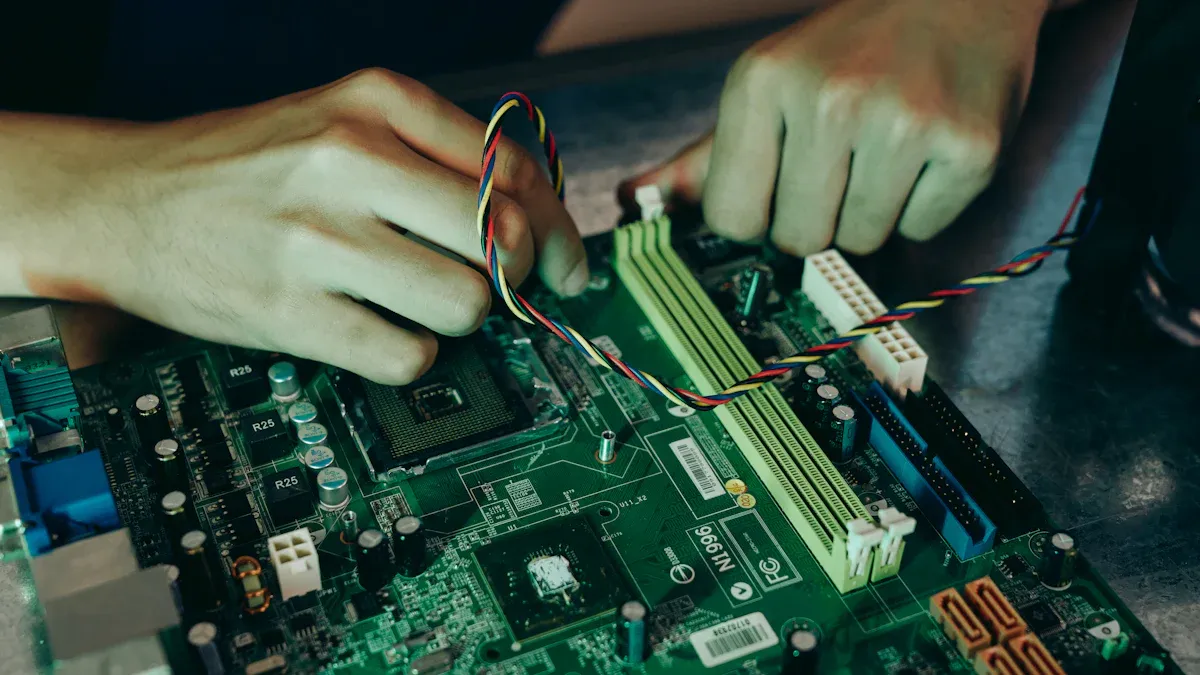

Improving PCB Layout and Component Placement

Making a good PCB layout and placing parts well is key. It helps the board work better and avoids problems. Good placement improves how electricity flows and keeps the board cool. Bad placement can cause issues like noise, timing errors, or power problems. For example:

Poor placement makes wiring harder and increases noise risks.

Parts too close to wires might cause shorts from solder.

Parts near edges can break during handling.

A good layout also makes fixing and testing easier. Tools like AI can check designs and suggest better layouts. These tools improve signals and heat control. This saves time by reducing design changes.

Teamwork Between Design and Manufacturing Teams

Good teamwork between design and manufacturing teams solves problems early. Designers focus on how things work, while manufacturers think about making them. Working together creates designs that are easy to build and use.

DFM rules help both teams speak the same language. They find design problems that may cost more or cause defects. Early talks can fix issues like wrong pad sizes or bad part spacing. This teamwork cuts waste and saves time and money.

Using DFM Rules for Better Manufacturing

Following DFM rules makes manufacturing easier. These rules simplify steps and reduce mistakes. Finding design problems early stops costly errors later.

Benefit | What It Means |

|---|---|

Saves Money | |

Better Quality | DFM fixes designs that might cause defects, improving quality. |

Faster Production | DFM speeds up production, helping companies compete better. |

Improved Performance | DFM makes products work better by using good designs and materials. |

By using DFM rules, you can make your PCBA process faster, cheaper, and better while creating high-quality products.

Advanced PCB Inspection Techniques

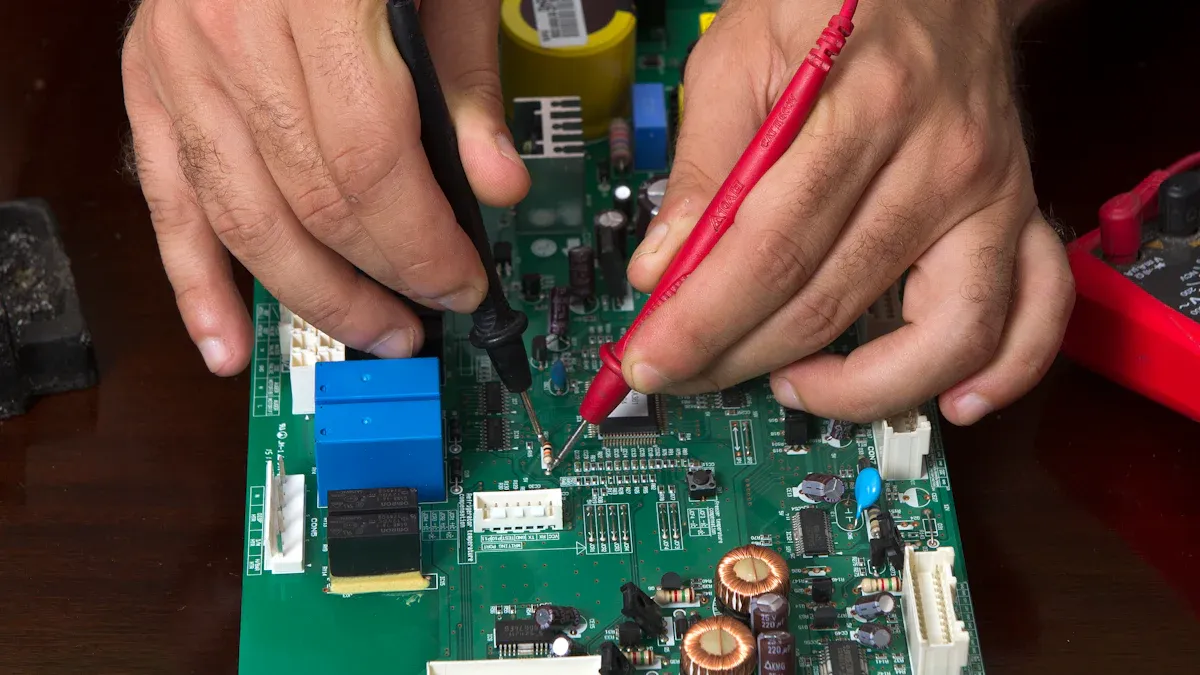

To make sure PCBA assembly is high-quality, strong checks are needed. Modern methods like automated optical inspection (AOI) and x-ray inspection find problems early. This saves time and materials. These tools make defect detection more accurate and improve product dependability.

Automated Optical Inspection (AOI) for Finding Problems

AOI is great for spotting issues in PCB assemblies. It uses cameras and smart software to check for problems like solder bridges or missing parts. AOI finds surface issues fast without harming the board.

One big benefit of AOI is its speed. It can check many boards quickly, perfect for large production runs. It also reduces mistakes by replacing manual checks with automation. This keeps quality steady across all boards. Adding AOI to your process helps find defects faster and boosts efficiency.

X-Ray Inspection for Hidden Solder Joints

AOI works well for surface checks, but x-ray goes deeper. It looks at hidden solder joints and inside layers of the PCB. This is helpful for parts like BGAs, where solder joints are hard to see.

X-ray inspection finds problems like solder gaps, tiny cracks, and misaligned layers. These issues can weaken the PCBA. The table below shows what x-ray inspection can do:

Inspection Focus | What It Finds |

|---|---|

Hidden Solder Joints | Spots soldering problems in BGA components. |

Inner Layer Issues | Finds cracks and misaligned layers in multi-layer boards. |

Solder Gaps | Shows empty spots in solder that weaken connections. |

Automated x-ray inspection is precise and fast, making it vital for modern PCB checks.

Using Multiple Methods for Better Quality Control

Using just one inspection method might miss some problems. Combining AOI and x-ray inspection gives better results. AOI finds surface issues, while x-ray checks hidden ones. Together, they cover more defects.

New methods like ultrasonic imaging and electrical testing add extra layers of quality control. For example:

Visual checks find misaligned parts and solder bridges.

Automated tools catch errors humans might overlook.

Electrical tests confirm the PCBA works properly.

In the past, inspections were done by people. As production grew, manual checks couldn’t keep up. This led to advanced tools like AOI and x-ray. By using these together, you can make your PCBA process more accurate and reliable.

Rigorous Testing for High-Quality PCBA Assembly

Testing is key to making high-quality PCBA assemblies. Careful testing finds defects, boosts reliability, and cuts waste. Using advanced testing methods improves PCB performance and keeps quality steady.

In-Circuit Testing (ICT) for Electrical Performance

In-circuit testing (ICT) checks each part on the PCB. It ensures parts are in the right place and working well. ICT uses special tools designed for specific PCB layouts, making it flexible.

ICT finds serious problems that could ruin the whole board. For example:

It spots wrong part values, open circuits, or short circuits.

It checks solder joints to ensure they are strong and defect-free.

When paired with tools like AOI and x-ray, ICT works even better. Each method looks at different issues, creating a strong quality system. Together, they ensure your PCBs meet top quality standards.

Functional Testing for End-Use Reliability

Functional testing checks how a PCBA works in real-life situations. It ensures all parts work together as they should. This step is vital before sending products to customers.

This test is crucial for products needing high reliability. It mimics real-world use to find hidden problems. For example:

It tests if the PCBA handles expected electrical loads and signals.

It checks if it works well with other system parts.

Data shows functional testing lowers failure rates a lot. Products tested this way fail only 0.0003% of the time. Without it, failure rates rise to 0.03%. This testing improves customer trust and avoids costly recalls.

Testing Method | Failure Rate |

|---|---|

With Functional Testing | 0.0003% |

Without Functional Testing | 0.03% |

Adding functional testing helps you deliver reliable products that customers trust.

Environmental Stress Testing for Durability

Environmental stress testing (EST) checks how tough a PCBA is. It tests the board under tough conditions like heat, moisture, and shaking. This finds weak spots that might cause failures later.

EST ensures PCBs can handle harsh conditions without breaking. For example:

Heat tests check if solder joints stay strong during temperature changes.

Vibration tests see if parts stay in place when shaken.

Moisture tests check if the board resists water damage.

These tests show how long a PCBA will last. Fixing problems early makes products stronger and reduces failures.

Metric | Description |

|---|---|

Counts defects per million chances, helping compare quality. | |

First Pass Yield (FPY) | Shows the percentage of PCBs passing all tests the first time. |

Rework Rate | Tracks how many PCBs need fixing after assembly. |

Scrap Rate | Measures unusable PCBs due to defects, showing waste levels. |

By using ICT, functional testing, and EST, you build a strong testing plan. This ensures high-quality PCBA, less waste, and happier customers.

Using Industry 4.0 in the PCBA Process

AI for Finding Defects and Improving Processes

AI is changing how PCBA is done. It predicts problems and improves production. AI tools find issues before they cause delays. For example, special algorithms improve signals and fix connection problems. These methods help find defects and lower mistakes.

AI systems also check boards automatically. They spot problems like crooked parts or bad soldering. Machine learning gives instant feedback to fix errors fast. This keeps quality steady for all boards. AI also adjusts assembly in real-time. This makes products more consistent and saves money. Adding AI to your process speeds up production and improves results.

IoT for Watching Quality in Real-Time

IoT helps track PCBA quality as it happens. IoT tools collect data from machines and show how they perform. This finds problems faster than manual checks. The table below shows IoT benefits:

Benefit | What It Does |

|---|---|

Better Accuracy | Finds more defects than human checks. |

Faster Production | Speeds up inspections with real-time tools. |

Saves Money | Cuts waste by reducing rework and scrap. |

Handles Large Volumes | Checks many boards with the same high accuracy. |

IoT also shares data across teams, helping them work together. Using IoT makes production smoother and products better.

Using Data to Improve Quality

Data helps make PCBA better over time. Statistical tools like SQC increase good boards and reduce fixes. For example, Pareto charts show the biggest problems causing rejects. Fixing these first improves quality fast.

Looking at daily production data shows where things go wrong. It highlights areas needing improvement. Companies with lower quality levels spend more fixing mistakes. Using data solves these issues and boosts performance.

Evidence Description | Source |

|---|---|

Poor quality at lower sigma levels costs more, showing the need for data-driven improvements. | |

Pareto Analysis finds main defects, proving data’s role in quality control. |

Using data helps you fix problems, waste less, and keep high standards in PCBA.

Supplier Quality Management and Material Selection

Checking Supplier Reliability and Certifications

Picking trustworthy suppliers is key for good quality control. Check if suppliers have certifications and follow industry rules. Certifications like ISO 9001 show they have strong quality systems. Following IPC standards like IPC-A-600 and IPC-6012 ensures top-quality circuit boards. For aerospace, AS9100D proves they use standard quality systems. The table below explains these certifications:

Certification | Why It Matters |

|---|---|

ISO 9001 | Shows the supplier has a strong quality system. |

IPC standards | Ensures circuit boards meet high-quality standards. |

AS9100D | Proves quality systems meet aerospace industry needs. |

Working with certified suppliers keeps parts consistent and lowers defect risks.

Why Good Materials Matter in PCBA

Using good materials reduces problems and makes boards reliable. Substrates with great dielectric properties improve signals and performance. Picking materials that meet needs avoids issues like bending or soldering errors. For example:

Good solder paste spreads evenly, cutting down defects.

Correct reflow soldering heat stops soldering mistakes.

Quality materials prevent weak solder joints from failing.

Top materials also make boards last longer, even in tough conditions. Checking material quality early avoids heat and reliability problems. This ensures products meet industry rules.

Setting Clear Quality Rules with Suppliers

Clear rules with suppliers improve PCBA results. Set performance goals to track supplier work and stay clear. Talking often helps solve problems early. Supplier checks find areas to fix and ensure they follow rules. By agreeing on expectations, you improve part quality and speed up production.

Tip: Strong supplier relationships improve quality and cut delays and costs over time.

Employee Training and Skill Development

Regular Training Programs for Quality Assurance Teams

Regular training helps your quality team improve their skills. These programs teach the latest methods and quality rules. With updated knowledge, your team can find and fix problems faster. For example, trained inspectors spot defects quickly and more accurately. This lowers the chances of making faulty PCBA boards.

Training also boosts skills like data analysis and project management. Studies show formal training improves communication and problem-solving. Using tools like Statistical Process Control (SPC) makes performance checks better than old methods. This proves that regular training is worth the investment.

Quality Improvement Method | Description |

|---|---|

Employee training and certification | Training helps workers learn best practices, improving PCBA quality checks. |

Cross-Functional Knowledge Sharing

Sharing knowledge between teams helps everyone understand the PCBA process better. When departments share ideas, it creates a stronger and smarter team. For example, designers can explain how layouts affect production. Meanwhile, manufacturers can share assembly challenges. This teamwork leads to smarter choices and fewer mistakes.

Knowledge sharing also improves communication across your company. It helps solve problems faster and keeps everyone focused on quality goals. Encouraging this practice builds a workplace where learning and improving never stop.

Fostering a Culture of Quality

A quality-focused culture starts with strong leadership. When leaders value quality, the team follows their example. Encourage workers to take pride in their tasks and aim for excellence. Rewarding their efforts motivates them to keep quality high.

Open communication is key to a quality culture. Give your team the tools they need and listen to their feedback. This creates accountability and ensures everyone works toward the same goals. Building a quality-focused culture leads to reliable results and happy customers.

Tip: Check your training and quality programs often to keep them effective and up-to-date.

Continuous Improvement Practices in the PCBA Process

Continuous improvement is key to keeping high-quality PCBA standards. Using clear methods helps lower defects, improve speed, and ensure reliable products.

Using Statistical Process Control (SPC)

Statistical Process Control (SPC) is a helpful tool for tracking production. It uses charts to spot changes and fix problems early. For example, SPC can find issues with solder joints or part placement. Fixing these quickly keeps quality high.

SPC also shows if processes are stable. By studying data, you can see if changes are random or need fixing. This stops defects and keeps quality checks working well.

Performance Indicator | What It Shows |

|---|---|

Defect Rate | Counts how many defects happen per product. |

Yield Rate | Shows the percentage of good products made. |

Customer Complaints | Tracks customer feedback about quality problems. |

Using SPC can improve yield rates up to 95%, making customers happier.

Solving Defects with Data Analysis

Data analysis helps find and fix problems in PCBA production. Tools like defect tracking and Pareto analysis focus on big issues. Pareto analysis ranks problems by how often they happen and their impact. This helps fix the most important ones first.

Predictive analytics makes quality control even better. It uses past data to predict future problems. This helps stop defects before they happen. A data-driven approach improves both quality and efficiency.

Method | What It Does |

|---|---|

Defect Tracking | Finds patterns and fixes root causes of problems. |

Statistical Process Control | Tracks changes in production to fix issues early. |

Pareto Analysis | Focuses on the biggest problems based on impact and frequency. |

Predictive Analytics | Predicts future problems and helps prevent them. |

These tools keep quality control strong and flexible.

Creating Feedback Loops for Better Results

Feedback loops are important for improving the PCBA process. Checking quality at every step, from materials to finished boards, finds problems early. Regular reviews also help add new tools and methods.

Root cause analysis is another key part of feedback loops. It finds why problems happen and fixes them. Setting clear goals and tracking progress helps catch issues early. This makes the process more reliable.

Tip: Feedback loops and regular checks build accountability and encourage innovation.

By using these practices, you can create a system that adapts and delivers high-quality PCBA products every time.

Improving quality control in PCBA needs several smart steps. You can improve designs, use better inspection tools, and test carefully for steady results. Adding technologies like AI and IoT makes the process stronger. These tools help watch production live and predict problems early.

Some companies have succeeded with these ideas:

Company E used data to work better and cut mistakes.

By using all these methods together, you can make high-quality PCBA, build reliable products, and keep customers happy.

FAQ

What is the difference between PCB and PCBA?

A PCB is just the plain board with layers and pathways. A PCBA is a PCB with all its parts added and soldered. This makes it ready to work in electronic devices.

Why is quality control important in PCBA?

Quality control makes sure your PCBA works well and lasts long. It lowers mistakes, saves money, and avoids fixing or recalling products. This ensures your product works as planned.

How does automated inspection improve PCBA quality?

Automated tools like AOI and x-ray find problems faster than people. These tools check boards accurately and keep quality steady. They save time and reduce mistakes during production.

What role does material selection play in PCBA?

Good materials make your PCBA stronger and work better. For example, good solder paste makes strong connections. Proper board materials improve signals and stop bending or breaking.

How can you ensure supplier reliability for PCBA production?

Check if suppliers have certifications like ISO 9001 or IPC standards. These show they follow quality rules. Regular checks and clear talks about quality help keep standards high.

See Also

Best Practices for Achieving Quality and Efficiency in PCBA

Innovative PCBA Testing Methods for Modern Electronics Production

Ensuring Quality and Reliability Through PCBA Functional Testing

Maximizing Accuracy with Automated PCBA Testing Procedures

Enhancing Workflow Efficiency in PCBA Manufacturing Processes