Choosing the right PCBA main board is very important. The right board improves performance and makes it more reliable. It also helps save money on costs. For example, picking the right PCBA can cut material costs by 18%. It can also increase manufacturing success by 15%. Matching the board to your project’s needs is key. This ensures it works well without losing quality. Companies that make PCBs faster by 30% meet market needs quicker. This makes customers happier. These reasons show why choosing carefully helps you reach your goals.

Key Takeaways

Know what your project needs to pick the right PCBA board. This helps avoid mistakes and ensures it works well for you.

Look at the board’s features like speed, memory, and how it fits with other parts. This makes sure it performs its best.

Think about heat and moisture when choosing a board. These affect how long the board lasts and how well it works.

Make sure the board has safety and quality approvals. This keeps your project safe and helps it succeed.

Test your design with a prototype before making many boards. This finds problems early, saves money, and makes the design better.

Identifying Project Requirements

Define the purpose and scope of your project

The first step is to know your project’s purpose. Think about what your project will do and how the board fits in. Is it for a gadget, factory machine, or medical tool? Each type needs different things. Good projects need clear communication and records. Writing everything down helps your team share info and stay updated. Keeping these files online makes sure everyone sees the latest version. This avoids mistakes and saves time.

Also, think about how complex your project is. A simple project might need a basic board. A harder one may need a multi-layer board. Knowing your project’s purpose helps you pick the right board.

Determine the required functionality and features

Your board’s features affect how well your project works. Make a list of what the board must do. Does it need to work fast, connect wirelessly, or handle many devices? Testing makes sure the board works as planned. It also checks for errors and ensures programs run correctly.

Here are some things to check:

Does the board have enough power and memory?

Does it have the right ports for your devices?

Does it meet your industry’s rules?

Knowing these details helps you avoid mistakes and ensures the board works well.

Consider environmental and operational conditions

Where and how the board will be used matters a lot. Will it face heat, humidity, or dust? Testing ensures the board can handle tough conditions. Things like heat, moisture, and corrosion can cause problems.

Factor | What It Does |

|---|---|

Thermal Expansion | Parts expand differently, causing stress. |

Chemical Reactions | Heat speeds up chemical changes, damaging materials. |

Electrical Parameter Drift | Parts may change how they work over time. |

Corrosion | Moisture can rust metal parts. |

Dielectric Breakdown | Humidity lowers material insulation. |

Delamination | Moisture can make layers come apart. |

By thinking about these factors, you can pick a board that lasts longer. This reduces failures and keeps your project running smoothly.

Evaluating PCBA Main Board Specifications and Compatibility

Know processing power and memory needs

When picking a PCBA board, check its power and memory. These decide how well it handles tasks. For example, complex projects need strong processors and more memory. Simple projects only need basic features.

Read the maker’s specs to learn about the board. Look for processor type, speed, and RAM size. This helps you see if it meets your needs. Think about future growth too. If your project might grow, pick a board with extra power and memory.

Match size and form factor to your design

The board’s size must fit your project’s design. If it doesn’t, it may not work or fit right. Measure the space in your device first. Then, compare it to the board’s size.

Boards come in sizes like ATX, Micro-ATX, and Mini-ITX. Each has its own shape and mounting holes. Pick one that fits your project. For small devices, Mini-ITX is a good choice.

Check compatibility with parts and devices

The board must work with your project’s parts. It should match sensors, connectors, and power supplies. Check the board’s ports and interfaces to be sure.

Follow industry rules like IPC-6011, IPC-6012, and IPC-A-610. These rules help ensure quality and performance. For example:

IPC-6011 sets basic quality rules for boards.

IPC-A-610 checks assembly quality, like soldering and part placement.

Standard | What It Covers |

|---|---|

IPC-6011 | Sets basic quality rules for boards to ensure compatibility. |

IPC-6012 | Lists board requirements for better reliability in projects. |

IPC-A-610 | Focuses on assembly quality, like soldering and placing parts. |

By following these tips, you can avoid problems. This ensures your board works well and lasts longer.

Checking Quality and Reliability of the PCBA Main Board

Check for certifications and standards

Certifications show the board is safe and reliable. They prove it meets high-quality rules and follows industry guidelines. Look for ISO 9001:2015, which ensures good management for quality. For cars, IATF 16949 checks strict quality rules. UL certifications focus on safety, while RoHS limits harmful materials in electronics.

Other certifications, like AS9100 for airplanes, ensure quality in tough conditions. IPC standards, such as IPC Class 3, set rules for reliable boards. These certifications help you pick a board that fits your project.

Certification | What It Means |

|---|---|

ISO 9001:2015 | Rules for managing quality in any company. |

IATF 16949 | Quality rules for making car parts. |

UL | Safety checks for products in the U.S. |

RoHS | Limits harmful materials in electronics. |

AS9100 | Quality rules for airplane parts, improving ISO9000. |

IPC Standards | Rules for making strong and reliable boards. |

Check material strength and durability

The board’s materials affect how long it lasts. Good materials handle stress and tough conditions. Tests like the Thermal Cycling Test check if the board can handle temperature changes. The Vibration and Shock Test checks if it can handle shaking or bumps. The Solderability Test ensures solder sticks well, and the Peel Strength Test checks how strong the copper layers are.

Other tests include the Voltage Withstand Test, which checks if the board handles high voltage safely. The Acid and Alkali Resistance Test ensures the board stays strong in harsh chemicals. These tests show if the board can last in tough situations.

Test Name | What It Checks |

|---|---|

Thermal Cycling Test | Checks if the board survives big temperature changes. |

Vibration and Shock Test | Tests if the board can handle shaking or bumps. |

Solderability Test | Makes sure solder sticks well to the board. |

Voltage Withstand Test | Checks if the board handles high voltage without breaking. |

Acid and Alkali Resistance Test | Tests if the board stays strong in harsh chemicals. |

Read reviews and case studies

Reviews and case studies help you learn about boards. Reviews share real-life experiences, showing which boards are reliable. Case studies explain how boards work in specific projects.

For example, one study shows how boards work in satellites. Another study focuses on upgrading military planes and managing old parts. Comparing strong boards to regular ones shows differences in materials and methods. These resources help you choose the right board for your project.

Case Study | What It Covers |

|---|---|

Design problems, new ideas, testing, and performance in space. | |

Military Aircraft Upgrade Program | Managing old parts, adding new tech, and testing in the field. |

High-Reliability vs. Standard Circuit Boards | Compares materials and methods of strong and regular boards. |

Budget Tips for PCBA Main Boards

Find the right balance between cost, performance, and quality

Choosing a PCBA board needs careful cost and quality balance. Cheap boards may break or work poorly. Expensive boards might have features you don’t need. Think about what your project really requires. For simple tasks, a basic board is enough. For complex tasks, pick a board with more power and memory. This ensures it works well for a long time.

Also, check the materials used in the board. Better materials cost more but last longer. They also lower repair and replacement costs later. Spending wisely now saves money in the future.

Include extra costs like assembly and testing

Don’t forget extra costs like assembly and testing. These depend on the board’s size, materials, and design. Complex designs need more steps and checks, which cost more. Testing is important to make sure the board works safely. Skipping these steps can cause expensive problems later.

Look at cost details for assembly and testing. This helps you find ways to save money without lowering quality. Planning ahead avoids surprises in your budget.

Save money without losing quality

You can save money and still get good quality. The car industry is using new ways to make PCBs cheaper and better. These ideas can help your project too.

Here are some tips:

Use cheaper materials to save up to 15%.

Design smarter to cut costs by 20%.

Buy in bulk to get discounts.

Hire experts to make boards for less money.

Make boards easy to fix to save 25% on repairs.

Eco-friendly PCBs are another good option. They are affordable and better for the planet. Using these ideas helps you save money and keep your project successful.

Choosing the Right Manufacturer and Supplier

Find trusted manufacturers and suppliers

Picking the right manufacturer is very important for good PCBs. Start by looking for companies with a strong reputation and lots of experience. Choose ones that focus on your project needs, like HDI boards or flexible PCBs. A company’s reputation shows how well they make quality products.

Check how manufacturers perform in key areas like testing and technology. The table below shows common tests used by good manufacturers to ensure quality:

Testing Method | What It Does | Why It’s Important | Benefits |

|---|---|---|---|

In-Circuit Testing (ICT) | Checks parts and circuits on the PCB. | Finds problems like shorts or wrong parts. | Accurate, quick, and automated testing. |

Automated Optical Inspection (AOI) | Uses cameras to spot visual problems. | Finds issues like bad solder or missing parts. | Fast checks, fewer mistakes, consistent results. |

Functional Testing | Tests how the PCB works in real conditions. | Makes sure the PCB works as planned. | Confirms design works, full performance testing. |

X-Ray Inspection | Uses X-rays to find hidden problems. | Spots internal issues like cracks or voids. | Important for reliable boards, checks inside layers. |

Impedance Testing | Measures signal paths for proper flow. | Prevents signal problems like reflection. | Needed for fast and RF applications. |

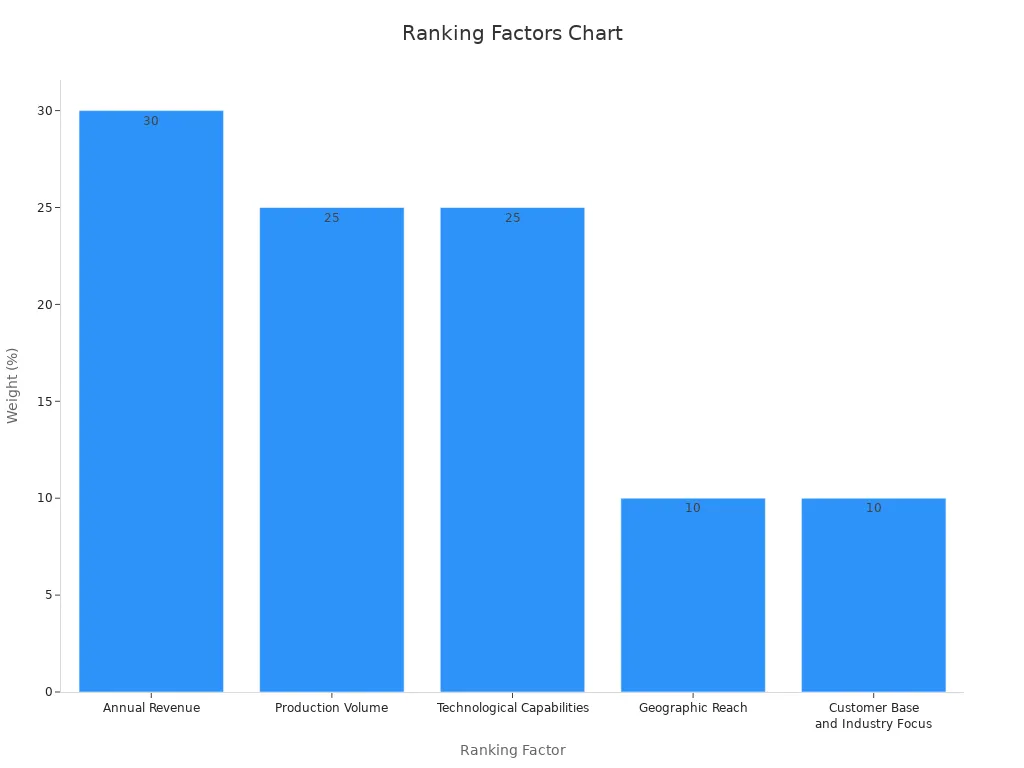

Also, look at rankings that rate manufacturers by revenue, production, and technology. The chart below shows how these factors are weighted:

Check customer service and warranties

Good customer service and warranties are very important. Reliable companies answer questions quickly and clearly. They also help with technical problems during design or production. A strong warranty protects you if the PCB has defects, saving time and money.

Ask about the warranty details, like how long it lasts and what it covers. Companies with great support care about customer happiness and quality.

Think about delivery times and parts availability

Delivery times and part shortages can delay your project. Some parts may take 16 to 52 weeks to arrive. High demand and supply chain issues cause these delays.

To avoid problems, pick a manufacturer with good logistics and supplier connections. Companies with global networks often get parts faster. Plan ahead and stay in touch with your manufacturer to avoid delays and get parts on time.

Testing and Prototyping the PCBA Main Board

Why prototyping is important before mass production

Prototyping helps ensure your PCBA board works well. It lets you test the design, find problems, and fix them early. This step checks if the board works with other parts. It also saves time and money by avoiding big production mistakes.

For example, in wearable devices, prototypes improved power use and durability. They also tested part compatibility and water resistance. In factory systems, prototypes fixed signal issues and improved layouts. The table below shows these benefits:

Case Study | Key Benefits |

|---|---|

Wearable Device Development | – Improved power use and part compatibility |

– Tested durability and water resistance | |

– Gathered early user feedback | |

Industrial Automation System Upgrade | – Fixed signal issues and tested new parts |

– Improved PCB layout for better performance |

Test how the board works and handles stress

Testing checks if the board works and stays strong. Functional tests see if it works as planned. Stress tests push it hard to find weak spots. These tests show if the board is good and reliable.

Here are common tests and what they do:

Testing Method | Purpose | What it Reveals |

|---|---|---|

Power Cycling | Tests turning the board on and off repeatedly. | Finds heat stress and power issues. |

Electrostatic Discharge (ESD) | Checks if the board can handle static electricity. | Shows if static can damage the board. |

Electromagnetic Compatibility (EMC) | Ensures the board doesn’t cause interference. | Finds if it affects other devices. |

Highly Accelerated Life Testing (HALT) | Finds weak spots quickly. | Shows design flaws and ways to improve. |

Highly Accelerated Stress Screening (HASS) | Spots weak parts or factory mistakes. | Finds defects and early failures. |

These tests make sure the board is strong and works well in real conditions.

Improve the design using test results

Testing is just the start. Use the results to make the board better. Fix problems like heat, power flow, or signal issues. For example, moving parts can help with cooling. Changing the layout can reduce interference.

Keep improving by checking factory processes and fixing defects. Advanced tests like stress screening and life testing show where to improve. By making changes, you can create a stronger and more reliable board.

Picking the right PCBA board helps your project succeed. Matching the board to your project’s needs avoids delays and keeps quality high. Using the right parts and materials makes it last longer and work better. It’s important to balance quality, compatibility, and cost for the best results. Researching, testing, and making prototypes can find problems early. This saves time and money. By doing these steps, you can build a strong and effective solution for your project.

FAQ

What matters most when picking a PCBA main board?

The key is matching the board to your project’s needs. Think about how it works, fits, and handles its environment. These factors help the board work well and last longer.

How do you check the quality of a PCBA main board?

Look for certifications like ISO 9001 or IPC rules. These show the board meets high-quality standards. Also, read reviews and case studies to see how it performs in real use.

Why is prototyping important before making many boards?

Prototyping finds design problems early. It checks if the board works with other parts and meets goals. This step saves money and time by avoiding big production mistakes.

How do you pick the best PCBA board maker?

Choose makers with good reputations and experience. Check their testing, customer help, and warranties. Good makers focus on quality and deliver on time.

Can you save money and still get good quality?

Yes, you can. Use cheaper materials, improve the design, and buy in bulk. These tips cut costs but keep the board working well. Eco-friendly boards are also a smart, low-cost choice.

See Also

Essential Advice for Selecting the Ideal Main PCBA

Important Guidelines for Finding a PCBA Manufacturer

Crucial Factors to Evaluate When Selecting PCB or PCBA

Vital Aspects to Assess When Picking Custom PCBA Manufacturer