Printed circuit board assemblies (PCBAs) are important parts in today’s electronics. They connect different electronic pieces. This helps devices work well. As technology changes, more people want PCBAs. MarketResearchFuture says the global PCBA market will grow from $40.80 billion in 2025 to $55.33 billion by 2034. This growth comes from more uses in consumer electronics, car systems, and advanced medical devices. Without good-quality PCBAs, your favorite gadgets would not work well.

Key Takeaways

Printed circuit board assemblies (PCBAs) are complete electronic units. They connect and support parts to make devices work.

Surface Mount Technology (SMT) and Through-Hole Technology (THT) are two main ways to attach parts. Each method has unique benefits for different designs.

Quality control steps like inspections and testing help find problems early. This ensures PCBAs work reliably.

Using automated assembly and testing methods makes production faster. It also lowers costs while improving product quality.

Understanding PCBAs and their assembly helps you see how modern electronics get smaller, stronger, and more reliable.

PCBs vs. PCBAs

Definition of PCBs

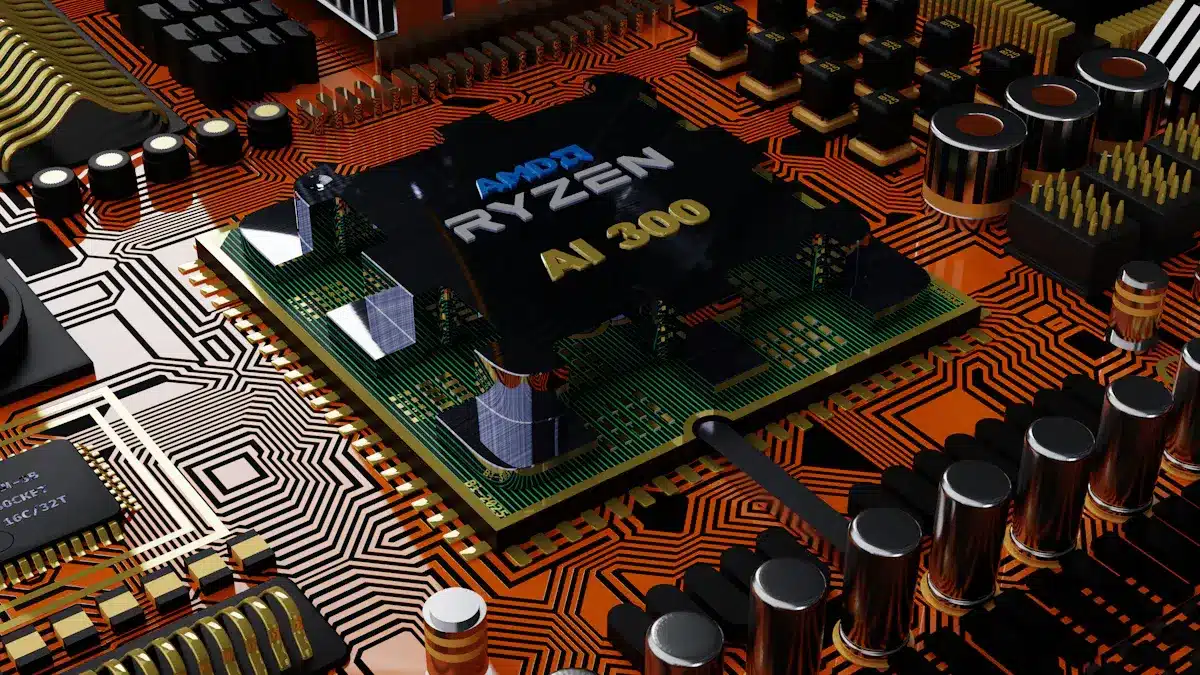

Printed circuit boards (PCBs) are the main part of electronic devices. They are flat boards made from materials that do not conduct electricity, like FR-4 glass epoxy. These boards support and connect different electronic parts. They have copper lines that allow electrical signals to travel. But a bare PCB cannot do anything by itself. It only gives support and connections.

Definition of PCBAs

On the other hand, printed circuit board assemblies (PCBAs) are complete working units. A PCBA has a PCB with all the needed electronic parts attached to it. These parts can include resistors, capacitors, integrated circuits, and connectors. The assembly process changes a simple PCB into a complex circuit that can do specific jobs.

To show the differences between a bare PCB and a finished PCBA, look at this table:

Aspect | Printed Circuit Board (PCB) | Printed Circuit Board Assembly (PCBA) |

|---|---|---|

Structure | Bare board with insulating material and copper lines; no parts mounted | PCB with all electronic parts (resistors, capacitors, ICs, connectors) attached |

Function | Gives support and connections only; does nothing alone | Fully working electronic circuit that can do tasks |

Components | None | Has all attached parts |

Manufacturing Process | Includes preparing the board, etching copper, drilling, and adding solder mask | Includes making the PCB plus placing and soldering parts (SMT, THT) |

Complexity & Cost | Simpler, cheaper | More complex and expensive because of assembly and parts |

Example | Flat green board with copper lines but no chips | Smartphone motherboard with CPU, memory, and other chips attached |

Knowing these differences is important for anyone working with electronics. Moving from a PCB to a PCBA shows the change from a simple board to a complete working assembly. This understanding helps you see how complex and important the PCB assembly process is in today’s electronics.

The PCB Assembly Process

The pcb assembly process has important steps. These steps make sure electronic parts are attached and soldered to printed circuit boards (PCBs) correctly. Knowing these steps is very important for anyone in electronics manufacturing.

Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is a common method in the pcb assembly process. It lets parts be placed right on the surface of the PCB. Here are the main steps in SMT:

PCB Design Basics: Start with a good PCB layout for surface mount devices (SMDs).

Solder Paste Printing: Put solder paste on the PCB pads using a stencil. This paste helps attach the parts later.

Pick and Place: Use machines to place SMDs on the PCB accurately.

Reflow Soldering: Heat the PCB in a reflow oven to melt the solder paste. This permanently attaches the parts.

Inspection and Quality Control: Check solder joints and part placement to make sure everything is right.

SMT has many benefits. It speeds up assembly and allows parts on both sides of the PCB. This technology supports more parts in a smaller space, which is great for compact devices. However, problems like solder joint issues and misaligned parts can happen. Good training and keeping equipment in shape are important to fix these problems.

Through-Hole Technology (THT)

Through-Hole Technology (THT) is another method used in the pcb assembly process. It involves putting component leads through holes in the PCB and soldering them on the other side. Here are the key points about THT:

Component Types: THT works best for larger parts like resistors, capacitors, and connectors. These need strong connections.

Assembly Process: The assembly can be done by hand or with some machines. Parts go into the PCB holes, and wave soldering is often used to solder the leads.

Mechanical Strength: THT gives strong bonds, making it good for things that face physical stress, like car and airplane electronics.

While THT is slower than SMT, it has benefits in strength and easy repairs. The bigger size of THT parts can limit their use in small designs, but their strength makes them good for tough environments.

Importance of Quality Control in PCB Assembly

Quality control is very important for making sure printed circuit board assemblies (PCBAs) work well and are reliable. You need to know about the quality assurance steps that keep high standards during the assembly.

Quality Assurance Processes

In PCB assembly, there are key quality control steps. These steps make sure each board meets industry standards. Here are some important processes:

Solder Paste Inspection (SPI): This step checks if solder paste is applied correctly before placing parts.

Automated Optical Inspection (AOI): AOI uses cameras to find problems like missing or wrongly placed parts. This method is very important for keeping quality in complex assemblies.

X-ray Inspection: This technique is important for checking ball grid array (BGA) parts. It finds hidden connections that other methods might miss.

Functional Circuit Testing (FCT): FCT tests the assembly to see if it works like it should in real life.

In-Circuit Testing (ICT): ICT checks individual circuits for problems, making sure each part works correctly.

These processes help you find problems early, which lowers the chance of failures later. Good quality control can greatly reduce failure rates. This leads to happier customers and more trust in your products.

Testing Methods

Testing methods are very important for checking the quality of PCBAs. Here are some common testing techniques:

In-Circuit Testing (ICT): This method quickly finds problems in individual parts. It is fast and reliable, which is great for making many products.

Automated Optical Inspection (AOI): As mentioned before, AOI finds surface problems early in the assembly. It helps stop faulty boards from moving forward.

Functional Testing: This method checks how well the PCB works. It simulates real-life conditions to make sure the assembly performs as expected.

X-ray Inspection: This technique is key for finding internal problems that you can’t see outside. It ensures reliability in important applications.

By using these testing methods, you can improve the reliability of your PCBAs. This proactive approach lowers the chances of defects reaching customers. In the end, this leads to happier customers and fewer warranty claims.

In conclusion, knowing about printed circuit board assemblies (PCBAs) is very important for anyone in electronics manufacturing. PCBAs are the main support for electronic devices. They help create smaller designs and strong connections. Here are some important points:

PCBAs can make complex circuits that regular wiring can’t.

Automated methods speed up work and lower costs, making things better.

Quality control makes sure parts are placed correctly, reducing failure chances.

As technology grows, think about how these changes will affect electronics manufacturing. New ideas like AI quality control and better testing methods will improve reliability and performance. Accepting these changes will help you succeed in a fast-changing industry.

FAQ

What is the main purpose of a PCBA?

A printed circuit board assembly (PCBA) connects and supports electronic parts. It helps devices work by letting electrical signals move between the parts.

How do I choose between SMT and THT?

Pick Surface Mount Technology (SMT) for small designs and fast assembly. Choose Through-Hole Technology (THT) when you need strong connections for bigger parts.

What are common testing methods for PCBAs?

Common testing methods are In-Circuit Testing (ICT), Automated Optical Inspection (AOI), and Functional Testing. These methods check that each assembly meets quality standards and works correctly.

Why is quality control important in PCB assembly?

Quality control stops problems in PCBAs. It makes sure each assembly meets industry standards. This reduces failures and makes customers happier.

How can I improve the reliability of my PCBAs?

You can make your PCBAs more reliable by using strict quality control steps, advanced testing methods, and good training for assembly workers. This careful approach lowers defects and improves performance.

See Also

In-Depth Look At Testing Methods In PCBA Production

A Clear Overview Of PCBA Assembly And Manufacturing

Effective Strategies To Improve PCB Assembly Productivity