Quick turn PCBA services in USA are essential for accelerating product development. These specialized services enable the rapid assembly of printed circuit boards (PCBs), often within 24 hours or just a few days. This speed allows you to meet tight deadlines without compromising functionality. Unlike traditional PCB services, which may take weeks, quick turn PCBA services in USA offer significantly faster and more adaptable solutions.

Comparison of Quick Turn PCBs and Traditional PCB Manufacturing:

Aspect

Quick Turn PCBs

Traditional PCB Manufacturing

Lead Time

24 hours to a few days

1 to 8 weeks

Flexibility

High (small batches)

Low (large batches required)

Ensuring quality is critical to guarantee the boards perform effectively. For example, a medical device company leveraged quick turn PCBA services in USA to produce prototype boards within 48 hours. This rapid turnaround allowed them to identify design flaws early and stay on schedule for testing. When selecting a provider, it’s important to evaluate their expertise, quality assurance processes, and certifications.

Key Takeaways

Quick turn PCBA services build boards fast, often in 24 hours. This helps you meet deadlines without losing quality.

Pick companies with good experience and certifications like ISO 9001. These ensure they follow high standards and are trustworthy.

Good quality checks, like testing and inspections, are very important. They help make sure the boards work well and last long.

Think about cost versus value. Spending on good materials and processes can avoid repairs and delays later.

Ask providers about their skills, experience, and support. This ensures they can handle your project needs properly.

Industry Experience in Quick Turn PCBA Services

Proven Track Record of Success

When choosing a quick turn PCB service, their history matters. Reliable providers show success in delivering fast PCB solutions. They can complete projects in just 24 hours, unlike traditional methods that take weeks. This speed helps meet deadlines without lowering quality. These services are great for prototypes and small production runs, perfect for quick changes.

Metric | Quick-Turn PCBA Services | Standard PCB Fabrication |

|---|---|---|

Turnaround Time | 2 to 8 weeks | |

Production Focus | Prototypes, low-volume | High-volume, complex |

Design Complexity | Simpler designs preferred | Complex designs possible |

R&D Investment Efficiency Gain | 20% faster to market | N/A |

This efficiency makes quick turn PCB services useful for startups, hobbyists, and big companies.

Benefits of Working with Established Providers

Picking an experienced PCB maker has many perks. Skilled providers ensure good quality and dependable results. They use advanced tools and hire trained workers to handle tough projects. For example:

Startups can quickly test wearable tech ideas to stay ahead.

Hobbyists can easily create smart home gadgets.

Big companies can quickly make medical device prototypes to meet rules.

These advantages lead to faster launches, lower costs, and better products.

How to Verify Industry Experience

To check a provider’s experience, look at their certifications, tools, and past work. Certifications like ISO 9001 ensure steady quality. AS9100 is key for aerospace projects. IPC standards show they aim to reduce errors.

Certification/Standard | Description |

|---|---|

ISO 9001 | Ensures steady product quality. |

AS9100 | Quality standard for aerospace. |

IPC Standards | Rules for PCB quality. |

Also, see if they use modern tools and have skilled staff. Reading reviews and case studies can show how well they perform.

Technical Capabilities of the Best PCB Manufacturer

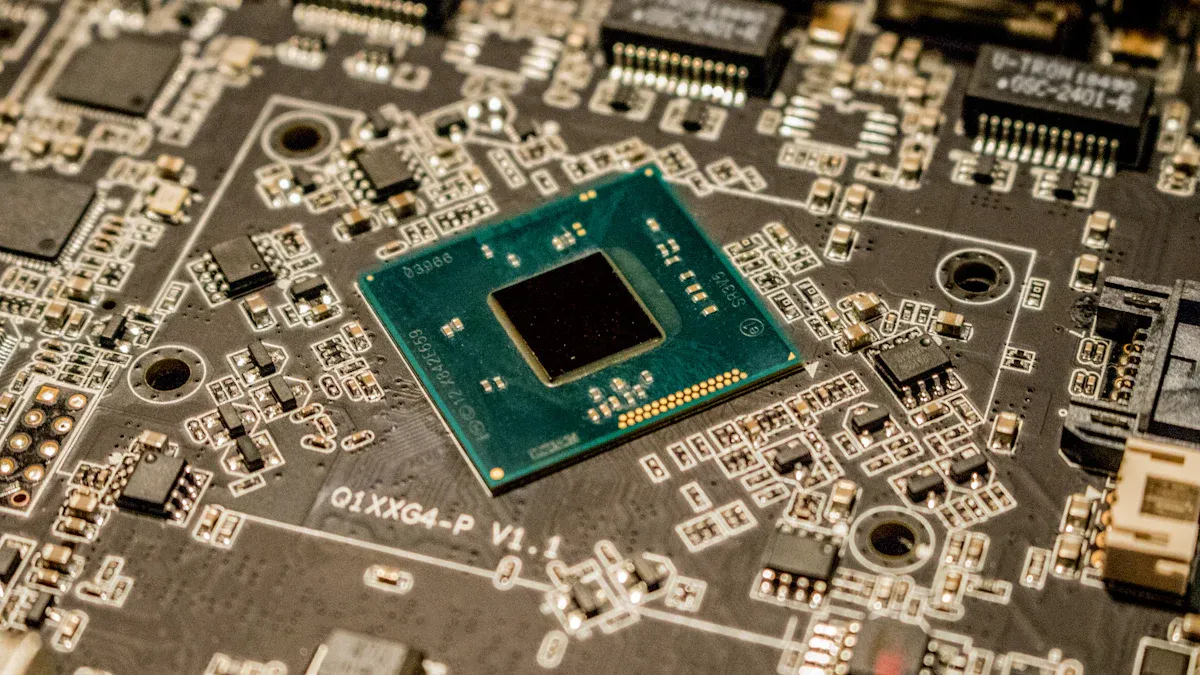

Modern Tools and Technology

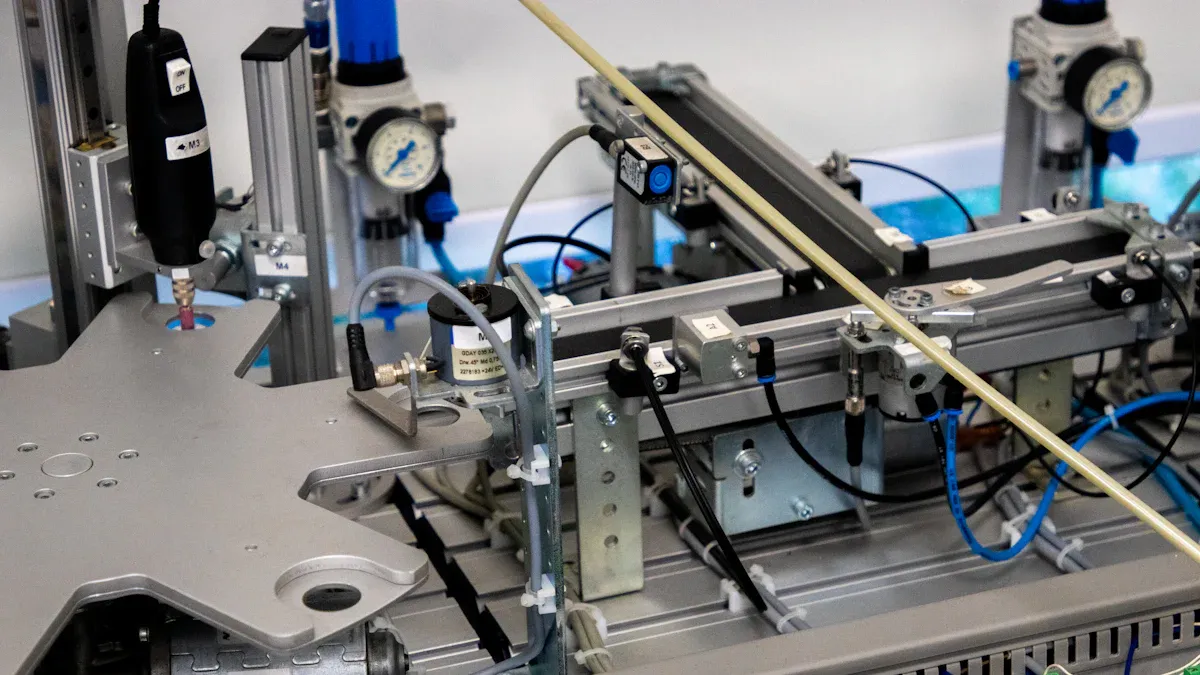

Top PCB makers use advanced tools for speed and accuracy. Laser imaging helps create clear, detailed patterns on boards. Automated machines drill holes and shape boards with little human help. These tools save time and reduce mistakes.

Fast lamination presses join PCB layers quickly for faster production. Surface finishes like ENIG and HASL make soldering easier. Quick testing methods, like automated optical inspection (AOI), check quality fast. These technologies help meet tight deadlines without losing quality.

Technical Benchmark | Description |

|---|---|

Laser Imaging | Creates clear, detailed patterns on circuit boards. |

Automated Drilling and Shaping | Machines drill holes and shape boards with precision. |

Fast Lamination | Joins PCB layers quickly to save time. |

Surface Finishes | Adds solderable layers like ENIG and HASL efficiently. |

Quick Testing | Uses AOI to check board quality in less time. |

Skill in Complex PCB Designs

Making complex PCBs needs special skills and smart tools. Top makers use a Complexity Index (CI) to measure design difficulty. This helps them improve processes for tricky designs.

For example, they can build multi-layer boards with great care. 3D X-ray tools find hidden problems inside layers. Solder paste checks ensure parts are placed correctly. These skills are vital for industries like aerospace and healthcare, where quality is key.

Flexible for Any Project Size

Good PCB makers can handle both small and big projects. They can adjust to your needs, whether it’s a few prototypes or a large order. They also offer discounts for bigger orders, saving you money.

Aspect | Description |

|---|---|

Handles All Sizes | Works on small prototypes or big production orders. |

Manages Complex Designs | Handles tricky designs like surface-mount technology. |

Cost Savings for Big Orders | Offers better prices for larger orders. |

Choosing a skilled provider ensures your PCBs are made right, no matter the project size.

Quality Assurance in PCB Assembly Services

Why Testing and Inspections Matter

Testing and inspections are key to ensuring quality in PCB assembly. They check if every board works as it should before delivery. Without testing, bad boards might pass through, causing expensive fixes and product failures. Finding problems early saves time, money, and improves product reliability.

Different tests help catch issues. For example:

Functional tests find missing parts or electrical shorts.

Power tests check for voltage errors or signal problems.

Automated optical inspection (AOI) spots assembly mistakes fast.

Inspections happen at three main stages:

Incoming Inspection: Checks parts for quality before assembly starts.

In-Process Inspection: Finds errors during assembly to stop bigger problems.

Final Inspection: Makes sure the finished board meets all rules.

These steps improve customer happiness and protect your brand by delivering great products.

Why Good Materials Are Important

The materials used in PCB assembly affect how well boards work and last. High-quality materials help products handle tough conditions and stay reliable. Certifications like ITAR show a company uses top-grade materials and meets strict industry rules.

For instance, surface finishes like ENIG and HASL make soldering easier and prevent rust. Using certified materials boosts board reliability and ensures they follow industry standards. This focus on good materials helps create products that meet your needs.

How to Check Quality Assurance Processes

Strong quality assurance processes are needed for reliable quick turn PCB assembly. These processes include many checks to ensure every board is high-quality. Important parts of these processes are:

Trained Staff: Workers must be skilled and qualified.

Data Accuracy: Production data must be correct and traceable.

Equipment Care: Machines need regular maintenance to work well.

Process Rules: Steps must follow clear guidelines.

Fixing Problems: Errors must be corrected and verified.

Advanced tests also check if these processes work. For example:

Electrical tests, like continuity checks, ensure circuits work.

Stress tests, such as heat and vibration tests, check durability.

Field tests confirm boards work in real-world conditions.

Choosing a provider with strong quality control means your quick turn PCB projects will meet deadlines and work as expected.

Certifications and Standards for Quick Turn PCB Providers

Important Certifications to Check (e.g., ISO 9001, ITAR)

Certifications are crucial for ensuring quality and trust in quick turn PCB providers. When picking a provider, look for key certifications that show they follow high standards. Examples include:

ISO Standards:

ISO 9001 confirms the provider uses a strong quality system.

ISO 13485 is needed for making medical prototype circuit boards.

IPC Standards:

IPC-A-600 and IPC-A-610 explain what makes boards and assemblies acceptable.

IPC-A-6012 focuses on rules for rigid PCBs.

UL Standards: UL 94V-0 ensures the PCB meets fire safety rules.

RoHS Compliance: This ensures no harmful materials are used in the boards.

These certifications prove the provider follows strict rules for safety and consistent quality.

Following Industry Standards

Meeting industry standards shows a provider can make reliable and high-quality PCBs. Providers must follow rules like ISO 26262 for safety and AEC-Q100 for car parts. Testing is also important to check compliance. For example:

Testing Method | Purpose |

|---|---|

Checks if the PCB works electrically. | |

Flying Probe Testing | Finds shorts and open circuits. |

Functional Testing | Tests for contamination and solder issues. |

Burn-in Testing | Checks reliability under stress. |

X-ray Inspection | Finds hidden solder problems. |

Automated Optical Inspection | Ensures parts are placed correctly. |

Providers should also keep detailed records of designs and tests. This helps track and fix any issues during production.

How Certifications Show Quality Focus

Certifications are not just labels; they show a provider’s focus on quality. Research proves certified companies perform better than those without certifications. For example:

Study | Findings | Impact on Quality Focus |

|---|---|---|

Certified companies perform better | Shows focus on quality through better results | |

Zuckerman (1995) | Certification improves customer satisfaction | Proves focus on meeting customer needs |

Gotzamani and Tsiotras (2002) | Certification improves processes | Shows commitment to better operations |

Choosing a certified provider ensures your PCBs meet standards and work well. Certifications also show the provider cares about customer satisfaction and top performance.

Turnaround Time for Quick Turn PCBA Services in USA

Finding the Right Balance Between Speed and Quality

Quick turn PCBA services need both speed and quality. Fast production is important, but quality ensures the product works well. Manufacturers use smart methods to balance these needs. For example:

Inspections give feedback to improve processes.

Automated checks find mistakes quickly and save time.

These steps make sure products are made fast and work well. Design for Manufacturability (DFM) is also important. Fixing design issues early makes assembly and testing faster. This saves time and keeps quality high.

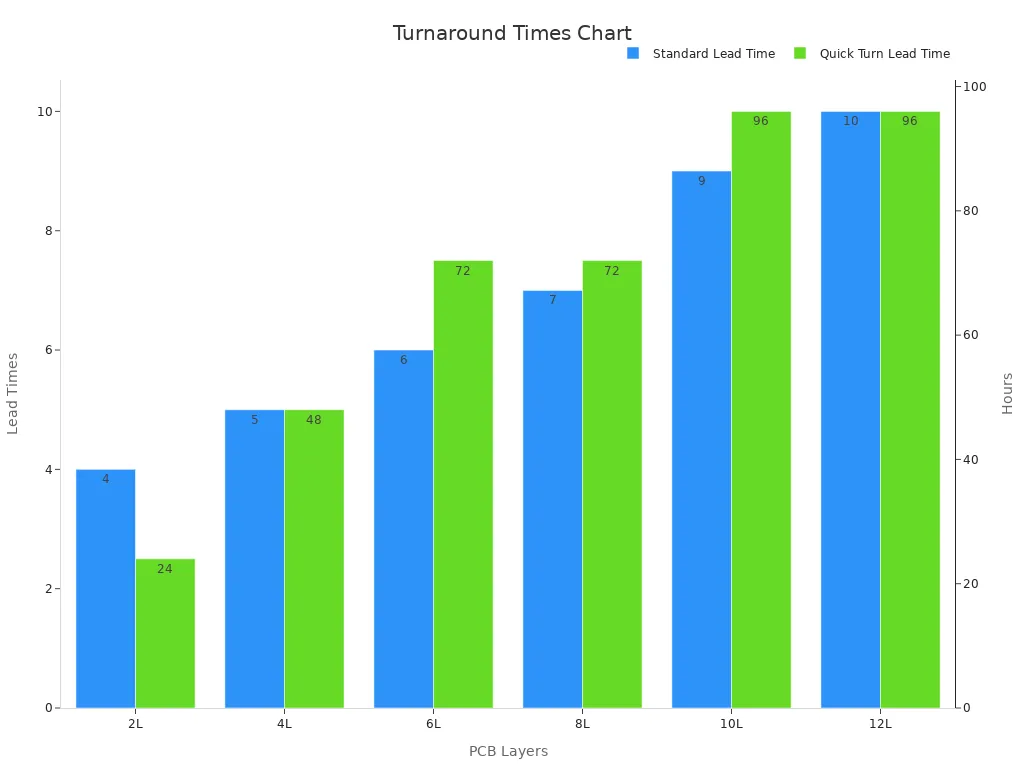

Checking Delivery Times

Knowing delivery times helps you plan your projects better. Quick turn PCB providers offer flexible schedules based on project needs. The table below shows how long it takes for different PCB layers:

Layers | PCB Order Size (m2) | Standard Time (Days) | Quick Turn Time (Hours) |

|---|---|---|---|

2L | <0.5m2 | 4 Days | 24H |

4L | <0.5m2 | 5 Days | 48H |

6L | <0.5m2 | 6 Days | 72H |

8L | <0.5m2 | 7 Days | 72H |

10L | <0.5m2 | 9 Days | 96H |

12L | <0.5m2 | 10 Days | 96H |

Compare these times to pick a provider that fits your schedule. Always check if they can handle tight deadlines, especially for tricky designs.

Making Sure Projects Finish On Time

Finishing projects on time shows a provider is reliable. Providers track how often they meet deadlines. For example, finishing 18 out of 20 projects on time means a 90% success rate. This shows good planning and focus on deadlines.

To avoid delays, choose providers who:

Use tools like SPC to find problems early.

Train workers to reduce mistakes.

Use advanced machines for faster work.

These actions help projects stay on track. Picking a provider with a good record of on-time delivery gives you peace of mind.

Cost and Value in PCB Assembly Services

Balancing Cost with Long-Term Value

When choosing PCB assembly services, don’t just look at the price. A cheaper option might cost more later due to fixes or delays. The total cost includes making, assembling, testing, and repairs. Picking a provider based on overall costs ensures reliable boards that last.

For instance, using better materials and advanced tests may cost more upfront. However, it lowers the chance of defects and saves money on repairs. This method improves reliability and keeps your project on track. Focusing on long-term value instead of short-term savings leads to better results.

Understanding the Cost-Quality Tradeoff

PCB assembly decisions need a balance between cost and quality. Choosing the cheapest option can mean poor quality, causing failures or bad performance. Think about how your choice affects both cost and engineering. Good providers use top materials and strict tests, even if they charge more.

Here are key points about cost and quality:

Better quality means fewer defects and better performance.

Picking providers based on total costs gives better long-term value.

Knowing this tradeoff helps you make smart choices for your project.

Tips for Comparing Quotes

To compare quotes, start with clear design files. Include Gerber files, a Bill of Materials (BOM), and assembly instructions. These help providers give accurate prices and avoid mistakes.

When comparing quotes, check these factors:

Factor | Description | Impact |

|---|---|---|

Price | Total cost for assembly, based on quantity, parts, and services. | Affects budget; lowest price isn’t always the best value. |

Lead Time | Time from order to delivery of finished PCBs. | Affects timeline; shorter times are key for fast projects. |

Quality | Materials, processes, and testing used by the provider. | Impacts reliability; better quality means fewer problems. |

Support Services | Help with technical issues and communication during the project. | Ensures smooth progress and solves problems quickly. |

A correct BOM is crucial for accurate quotes. It lists all parts, details, and amounts needed. Mistakes in the BOM can cause wrong quotes and delays. By reviewing these factors, you can pick a provider with the best mix of cost and value.

Customer Support from the Best PCB Manufacturer

Why Quick Responses Matter

Fast replies are key for smooth project progress. When working with a PCB maker, quick answers save time and avoid mistakes. Companies with great customer service often score high in satisfaction. A score over 80% is excellent in the PCB world. This shows they solve problems quickly and communicate well. Happy customers return and stay loyal, helping the company succeed long-term.

To check a provider’s responsiveness, look at how fast they reply and handle urgent needs. A good manufacturer will focus on your concerns and keep you updated. This helps you feel confident about your project’s status.

Checking Customer Support Teams

A strong support team makes a big difference. Skilled teams help solve technical problems, answer questions, and meet your needs. Reviews from happy customers often praise these teams. For example:

“Your support team is always amazing.” – Mike Bell, ARCON Welding Equipment

“Tim was fantastic… Loving the experience so far.” – Jamie C., Customer

These comments show how great support improves satisfaction. When choosing a provider, look for reviews that mention extra effort. This shows they care about giving top-notch service.

Why Ongoing Support Helps

Support after delivery keeps your project successful. A manufacturer offering help later can fix issues, update designs, or increase production. This is especially useful for tricky projects needing long-term teamwork.

One customer said, “We got the order on time, and the boards were perfect.” This highlights the value of reliable support during and after production. Picking a provider with strong post-delivery help ensures your products stay high-quality and meet your needs over time.

Practical Tips for Choosing Quick Turn PCBA Services

Questions to Ask Potential Providers

When picking a quick turn PCB provider, asking smart questions helps. First, clearly explain your project needs. This avoids confusion and helps providers give accurate solutions. After that, focus on these important questions:

What is your experience with quick turn PCB projects?

Ask for details like how often they deliver on time. Also, check the percentage of boards made without mistakes. Providers with a good track record are more dependable.What types of PCBs can you produce?

Find out what they can handle, like layers, materials, or finishes. Providers with advanced tools and skills can manage more complex designs.What systems do you have to prevent delays?

See if they check designs before starting production. This step catches problems early and saves time.Can you provide references or case studies?

Good providers share examples of past work. These show their reliability and quality.What customer support tools do you offer?

Look for features like online quotes or design checks. These tools make the process easier and improve communication.

By asking these questions, you can find a provider who meets your needs and delivers quality work on time.

Reviewing Customer Feedback and Testimonials

Customer reviews are helpful when choosing a PCB provider. They show how well a company performs and treats its customers. Look for reviews about on-time delivery, board quality, and how they handle problems.

For example, a review saying, “The boards arrived on time and worked great,” shows they care about deadlines and quality. Reviews about good customer service also show they value their clients.

Check both good and bad reviews for a full picture. Watch for repeated complaints like delays or poor communication. These could mean trouble. Also, ask for case studies or references from happy customers. These give more details about their skills and success.

Requesting Detailed Quotes and Samples

Getting detailed quotes and samples is very important. A good quote should list all costs, like materials, assembly, testing, and shipping. This helps you compare providers and avoid surprise fees.

When asking for a quote, send clear design files like Gerber files and a Bill of Materials (BOM). This ensures the provider understands your needs and gives accurate pricing.

Samples let you check the provider’s work before ordering more. Look at the soldering, alignment, and finish. Good samples show the provider pays attention to detail and cares about quality.

Use this checklist to guide your choice:

Checklist Metric | Description |

|---|---|

Ask for on-time delivery rates and defect percentages. | |

PCB capabilities | Check the types of boards and tools they use. |

Support processes | Look for systems to catch problems early, like design checks. |

Past successes | Request examples or references from happy clients. |

Customer service | Check for tools like online quotes and design help. |

By following these tips, you can pick a provider that fits your budget, timeline, and quality needs.

Checking quick turn PCBA services in the USA needs careful thought. Focus on key things like experience, skills, and certifications. Good quality checks and helpful customer support are also important. Pick providers who finish on time and make good boards, not just cheap ones. Ask smart questions and read reviews to choose better. A wise choice keeps your projects on time and high-quality.

FAQ

What’s the difference between quick turn and standard PCBA services?

Quick turn PCBA delivers boards fast, often in 1-3 days. Standard PCBA takes longer, usually weeks, but handles bigger or harder projects. Quick turn focuses on speed while keeping quality high.

How can I make sure my design files are ready?

Create correct Gerber files, a full Bill of Materials (BOM), and clear instructions. Check for mistakes before sending them. This helps the manufacturer work faster without delays.

Can quick turn PCBA manage tricky designs?

Yes, many providers can handle tough designs like multi-layer boards. Choose manufacturers with advanced tools and skills for complex layouts to ensure success.

Are quick turn PCBA services more costly?

Yes, they usually cost more because of faster production. But the quick delivery can save money by avoiding delays in testing and development.

How do I pick the best quick turn PCBA provider?

Look for experience, certifications, and good reviews. Ask about their quality checks and how often they deliver on time. Request samples or examples of past work to check their reliability.

See Also

Improving Quality Control Measures in PCBA Manufacturing

Choosing Advanced PCBA Manufacturing Services for Your Needs

Best Practices for Ensuring Quality and Efficiency in PCBA

Essential Advice for Selecting Trustworthy PCBA Manufacturers