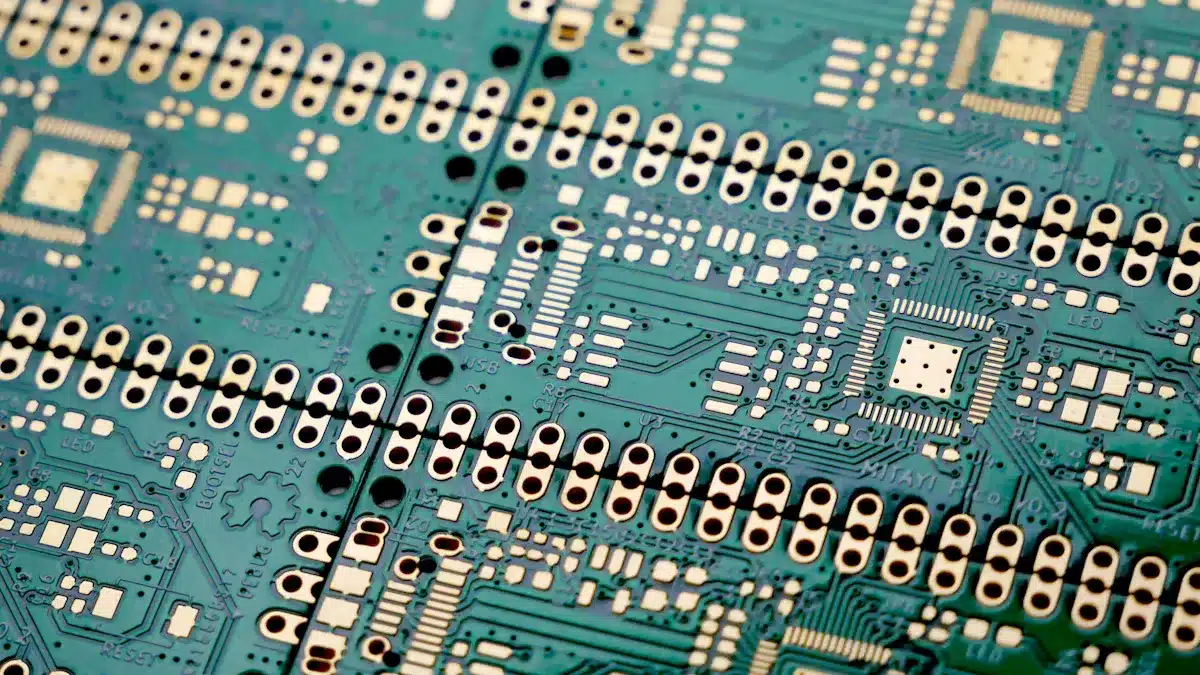

Selecting the right PCB manufacturer is very important in 2025. Companies have more demands for quality, speed, and new ideas. Things like how much they can produce, their tech skills, and customer help are key in making choices. Looking at these factors helps businesses match their needs with what partners can do. A good manufacturer can improve product reliability and support long-term success in a tough market.

Key Takeaways

Pick a PCB maker based on what you need. Choose large-batch for saving money and steady demand. Choose small-batch for flexibility and quick prototypes.

Top PCB makers like Unimicron, Jabil, Zhen Ding, and PCBWay have different strengths. They offer various technology, services, and customer support.

Look for makers with strong quality checks, good customer service, and reliable delivery times. This helps your project succeed.

New trends like AI and miniaturization make PCB design and production faster. Sustainability efforts also help protect the environment.

Matching your project needs with the right maker leads to better products. It also means faster development and stronger competition in the market.

Understanding Your PCB Needs

When choosing a PCB manufacturer, knowing your production needs is very important. There are two main types: large-batch production and small-batch production. Each type has its own needs and benefits.

Large-Batch Production

Large-batch production usually means making thousands or more printed circuit boards. This way is cost-effective and has steady processes. Manufacturers can lower costs for each unit because of economies of scale. But, this method is less flexible for design changes after production starts. Companies often use large-batch production for products that have high and steady demand.

Small-Batch Production

On the other hand, small-batch production makes fewer than 1,000 units. This method allows for quick prototyping and design changes. Companies often need fast turnaround times, sometimes in just days. The cost per unit is higher, but the ability to change designs makes it good for custom projects or new product launches.

The table below shows the main differences between large-batch and small-batch PCB production:

Aspect | Small-Batch PCB Production | Large-Batch PCB Production |

|---|---|---|

Quantity | Usually under 1000 units | Thousands or more units |

Cost per Unit | Higher cost for each unit | Lower cost for each unit |

Turnaround Time | Faster, often in days | Slower, takes weeks or months |

Flexibility | High flexibility; easy to change designs | Low flexibility; hard to change designs |

Suitability | Prototyping, small-scale, custom projects | Mass production, products with high demand |

Both types of production need good material quality and technology skills, like layer count and trace widths. However, the focus changes based on project needs. Companies must look at their specific needs to find the best production method for their goals.

Best PCB Manufacturers for PCB Manufacture

When looking for the best PCB manufacturers, some companies are better than others. They have special skills and abilities. Here is a summary of four top manufacturers in the field.

Unimicron Technology

Unimicron Technology is one of the best PCB manufacturers in the world. They focus on high-density interconnect (HDI) boards and flexible printed circuit boards (FPC). Their focus on new ideas and quality makes them a trusted partner for many industries, like telecommunications and consumer electronics.

Here are some key features of Unimicron Technology:

Advanced Manufacturing Techniques: They use the latest technology to ensure each board is precise and high quality.

Diverse Product Range: They offer multilayer PCBs, HDI boards, and FPCs for many uses.

Strong R&D Focus: Unimicron spends a lot on research and development to keep up with industry trends and customer needs.

Jabil

Jabil is another important company in PCB manufacturing. They are known for their complete manufacturing services. Jabil provides a full solution for PCB design, development, assembly, and testing. They can serve clients in many markets because of their global reach.

Here are some key features of Jabil:

Integrated Solutions: They provide all services from design to assembly, making projects run smoothly.

Customization: Jabil is great at offering solutions that fit specific customer needs, which helps with production flexibility.

Sustainability Initiatives: The company focuses on eco-friendly practices to lower their environmental impact while keeping high quality.

Zhen Ding Technology

Zhen Ding Technology is a leader in the global PCB industry. They are known for their creative products. Their partnership with DuPont helps them create advanced materials and technologies for tough performance needs.

Here are some unique products from Zhen Ding Technology:

Category | Details |

|---|---|

Product Offerings | Flexible Printed Circuit Boards (FPC), Surface Mount Assembly (SMA), Substrate-like PCBs (SLP), High-Density Interconnect (HDI) PCBs, Ultra-thin Mini LED Boards, Multilayer Rigid PCBs (RPCB), IC Substrates (ICS) |

Application Areas | Computer information, Consumer electronics, Communications networks, Automotive electronics, AI server high-speed computing, Optical modules, Medical applications |

Strategic Innovation | Partnership with DuPont to create new materials and technologies for advanced PCBs, meeting complex performance needs |

Innovation Focus | Improving end-user applications, advancing R&D, enhancing material performance, promoting sustainable development, smart manufacturing, corporate governance |

Industry Positioning | Leader in global PCB industry with a focus on innovation and sustainability initiatives |

Zhen Ding Technology’s focus on new ideas and sustainability makes them a strong choice for businesses needing advanced PCB manufacturing.

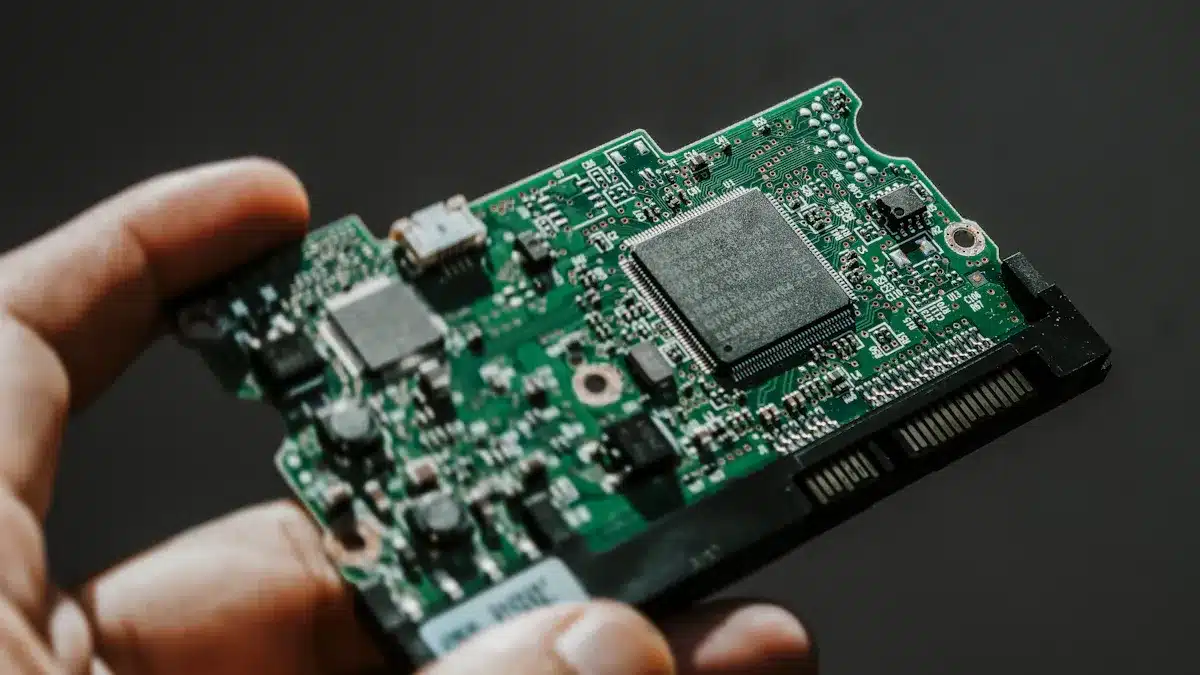

PCBWay

PCBWay is known for its great customer service and high-quality manufacturing. They mainly focus on small-batch production, making them perfect for startups and prototyping projects.

Customers often mention several strengths of PCBWay:

Many customers praise PCBWay for fast delivery, great product quality, and clear communication.

Reviews talk about successful assembly of PCBs and CNC parts with high precision and satisfaction.

Specific comments include “Perfectly finished and quickly delivered,” “Outstanding, quality is amazing,” and “Super fast manufacture and assembly.”

Positive feedback also highlights the help from the engineering team and consistency in prototyping phases.

Overall, PCBWay’s focus on quality and customer satisfaction makes them a top PCB manufacturer for those needing reliable PCB assembly services.

Evaluating Manufacturer Performance

Checking how well PCB manufacturers perform is very important. This helps companies get high-quality PCBs that fit their needs. Three main areas to think about are quality assurance, customer support, and delivery times.

Quality Assurance

Quality assurance is key for reliable PCBs. The best manufacturers use different quality control steps to make sure their products are dependable. These steps include:

Quality Control Aspect | Description |

|---|---|

Inspection Methods | Visual Inspection (manual checks for defects), Automated Optical Inspection (AOI), X-ray Inspection (for inner layers and solder joints) |

Testing Procedures | In-Circuit Testing (ICT) to check component function, Functional Testing to mimic device use, Environmental Stress Testing (heat, humidity, vibration) |

Quality Control Protocols | Statistical Process Control (SPC) to track defect rates, Six Sigma methods to cut defects and boost efficiency |

Industry Certifications | ISO 9001 (quality management system), IPC standards (IPC-A-600, IPC-6012 for PCB quality), AS9100D (aerospace quality management) |

Manufacturer Evaluation Criteria | Certifications, inspection and testing skills, history and experience (case studies, references, company background) |

These steps help manufacturers keep high standards and provide reliable products. Companies should choose manufacturers with strong quality assurance to get high-quality PCBs.

Customer Support

Customer support is also very important when looking at PCB manufacturers. Good communication and help can really affect project success. Companies should find manufacturers that provide:

Responsive Communication: Quick replies to questions and issues can help fix problems fast.

Technical Assistance: Access to skilled support staff who can help with design and manufacturing problems.

Post-Sale Support: Ongoing help after delivery, including troubleshooting and warranty services.

Good customer support builds a strong relationship between manufacturers and clients. This ensures projects go well and any problems are solved quickly.

Delivery Times

Getting PCBs on time is crucial for keeping project schedules and meeting market needs. Delays in PCB delivery can happen for many reasons, such as:

Raw material shortages: like substrates (e.g., FR-4, CEM-1 & 3), conductive materials (copper foil, copper-clad laminate), dielectric materials (fiberglass, solder masks), chemicals for etching and plating (ferric chloride, ammonium persulfate, copper plating solutions), and special packaging materials.

Logistical issues: like port congestion, container shortages, transportation delays, and effects from global events like the COVID-19 pandemic.

Production and technology problems: like old equipment causing defects and rework, manual processes that can lead to mistakes, poor workflow designs, and not enough operator training.

Quality control problems: defective PCBs needing rework or causing production stops, with quality control steps like automated optical inspections and functional testing being key to avoid delays.

External global factors: pandemic disruptions and geopolitical tensions making supply chain delays worse.

Manufacturers that always meet delivery deadlines show they are reliable and care about their clients. Companies should check a manufacturer’s history for on-time delivery when choosing one.

Trends in PCB Manufacturing

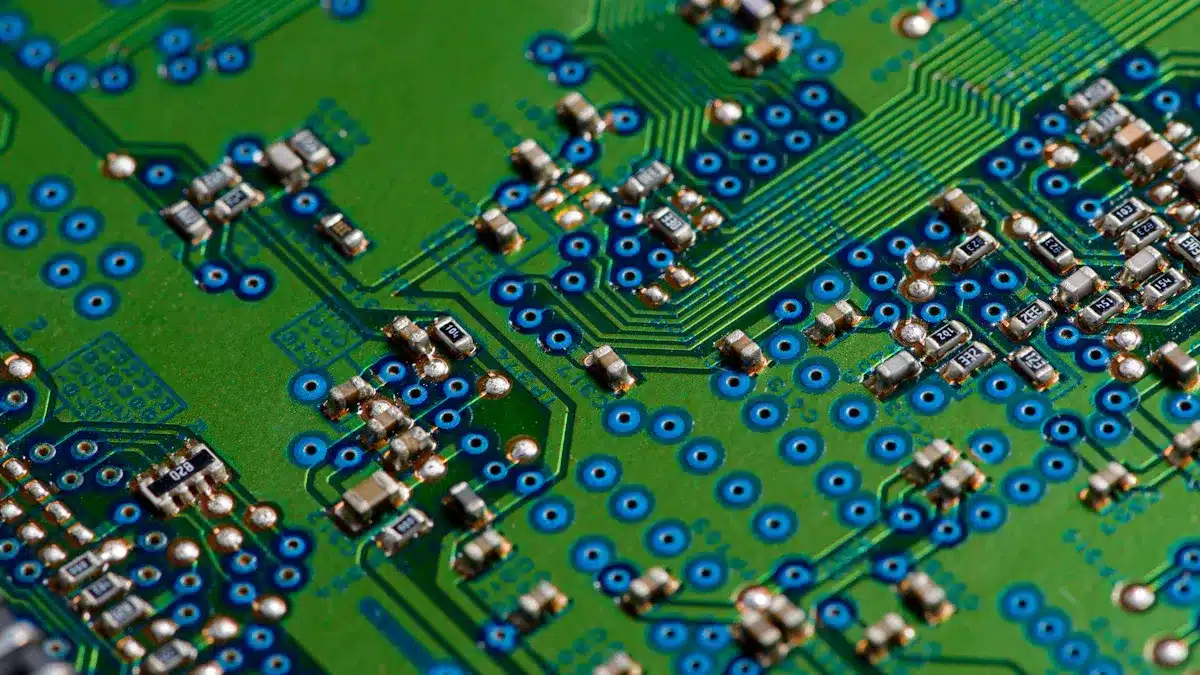

AI and Miniaturization

Artificial Intelligence (AI) is changing how PCBs are made. Manufacturers use AI to make designs better and production faster. AI looks at data to find possible problems and improve quality checks. This technology helps reduce mistakes and speeds up making PCBs.

Miniaturization is another big trend. As gadgets get smaller, PCBs need to change too. High-Density Interconnect (HDI) technology is important for this change. HDI boards can have more connections in less space. They use thinner lines and smaller holes, which makes them work better without getting bigger. This helps meet the need for smaller devices in areas like consumer electronics and medical tools.

Sustainability Practices

Sustainability is becoming more important in PCB manufacturing. Companies are using green practices to lessen their impact on the environment. Here are some main sustainability efforts:

Material Sourcing: Manufacturers pick materials that can be recycled and are safer for the planet.

Waste Reduction: Many companies have plans to cut down waste during production. This includes reusing materials and recycling leftover parts.

Energy Efficiency: Manufacturers buy energy-saving machines and use better processes. This cuts down on energy use and lowers carbon footprints.

Tip: When choosing a PCB manufacturer, think about their sustainability efforts. Being eco-friendly can improve your brand’s image and attract customers who care about the environment.

Picking the right PCB manufacturer is very important for project success. Companies need to think about their production needs. This could be large-batch or small-batch production. Important factors are quality assurance, customer support, and delivery times.

Tip: Check manufacturers based on their strengths and skills. This will help businesses match their needs with the right partner. This way, they can ensure reliable and efficient PCB production.

By looking closely at these points, companies can make smart choices. This will improve their product development and help them compete better in the market.

FAQ

What factors should I think about when picking a PCB manufacturer?

Think about how much you need to produce, their technology skills, quality checks, customer help, and delivery times. Looking at these things helps make sure the manufacturer fits your project needs.

How can I check a manufacturer’s quality assurance steps?

Look at their inspection methods, testing steps, and industry certifications. Find manufacturers that use statistical process control and follow IPC standards to keep their products high quality.

What is the difference between HDI and standard PCBs?

High-Density Interconnect (HDI) PCBs have thinner traces and smaller holes. This lets them have more connections in a small space. Standard PCBs have bigger features and are not as good for small applications.

How important is being eco-friendly in PCB manufacturing?

Being eco-friendly is becoming more important. Manufacturers that focus on green practices can improve your brand’s image and attract customers who care about the environment. Look for those that use recyclable materials and waste-cutting plans.

Can I get prototypes from large-batch manufacturers?

Yes, many large-batch manufacturers provide prototyping services. But, they might take longer and be less flexible for design changes than small-batch manufacturers. Always check their abilities before moving forward.

See Also

Tips For Finding The Ideal PCBA Manufacturer For Business

Guide To Choosing The Top PCB Prototype Maker For Projects

Selecting The Right PCBA Factory To Meet Custom Demands

Finding The Best PCB Fabrication Partner For Your Needs

Choosing The Perfect PCB Contract Manufacturer For Lasting Success