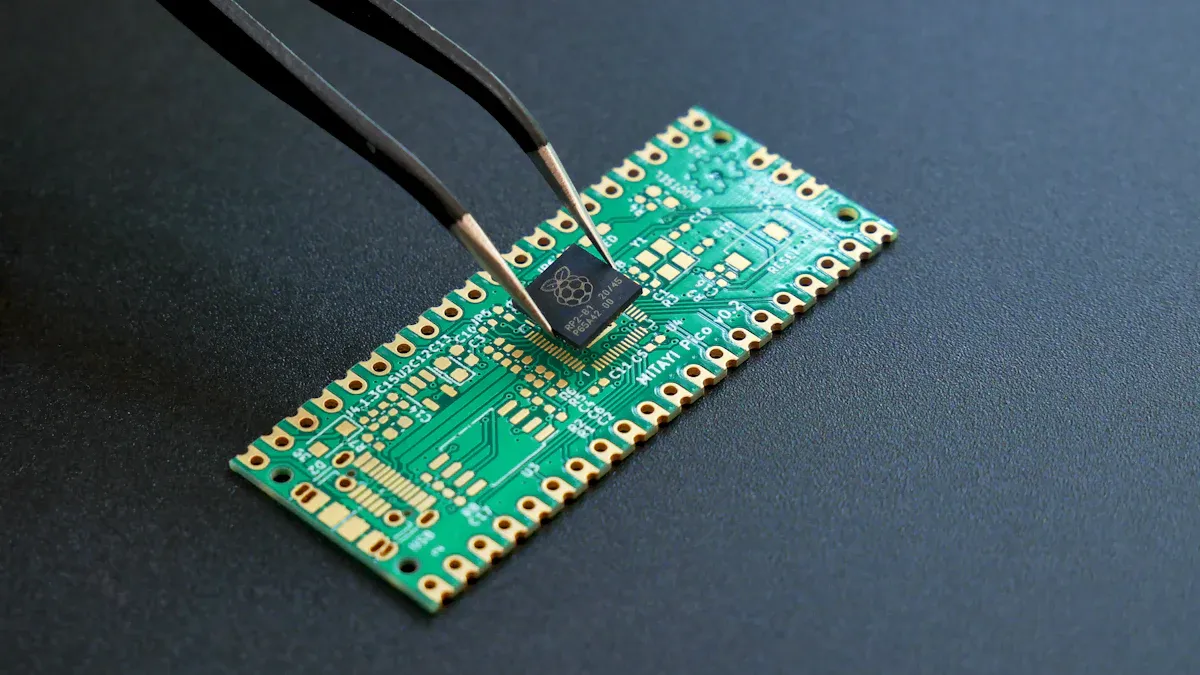

Fast PCBA, or Printed Circuit Board Assembly, makes building electronics faster. It helps turn designs into working prototypes very quickly. This method is great for urgent projects with tight deadlines. Using fast PCBA lets you test ideas, fix designs, and release products faster.

For example, a startup used PCB assembly to improve a wearable gadget. They checked their design and got user feedback, speeding up their launch. Similarly, a company upgraded control boards using fast prototyping, avoiding expensive mistakes. These examples show how fast PCBA makes projects efficient and reliable.

Key Takeaways

Fast PCBA helps make electronics projects quicker and easier.

It cuts costs and skips extra steps, good for all project sizes.

Careful testing ensures high-quality work and fixes problems early.

Fast PCBA works for many industries like electronics, medical tools, and cars.

Picking a certified provider with good support is very important.

What is Fast PCBA?

Overview of the Fast PCBA process

Fast PCBA, or quick PCB assembly, is a faster way to build circuit boards. It focuses on saving time and working efficiently. This method is perfect for making prototypes quickly or producing small batches. The process has important steps to ensure good quality and avoid delays.

A digital tool keeps all design details in one place.

Teamwork helps solve problems early.

The steps in the process include:

Making a plan to design the device.

Matching the plan with a digital version.

Designing the board layers to avoid signal problems.

Setting rules for spacing and wiring.

Placing parts for the best performance.

Adding holes for mounting and connections.

Drawing paths to link parts together.

Labeling parts for easy understanding.

This organized process makes fast PCB building quick and reliable.

Differences between traditional PCBA and Fast PCBA

Fast PCBA is much quicker and simpler than the old way of making circuit boards. The table below shows how they are different:

Feature | Traditional PCBA | Fast PCBA |

|---|---|---|

Time to Make | Much shorter | |

Steps Needed | Many steps like soldering and testing | Fewer steps |

Difficulty | Harder with extra steps | Easier |

PCB Build Time | 1 to 3 weeks | Not needed |

Fast PCBA skips extra steps, making it faster and easier. This is why it’s great for quick projects and testing ideas.

Importance of Fast PCBA for rapid prototyping

Fast PCBA is very important for testing new ideas quickly. A study of 31 PCB factories showed that flexible systems make testing better. These systems improve results without raising costs or lowering quality.

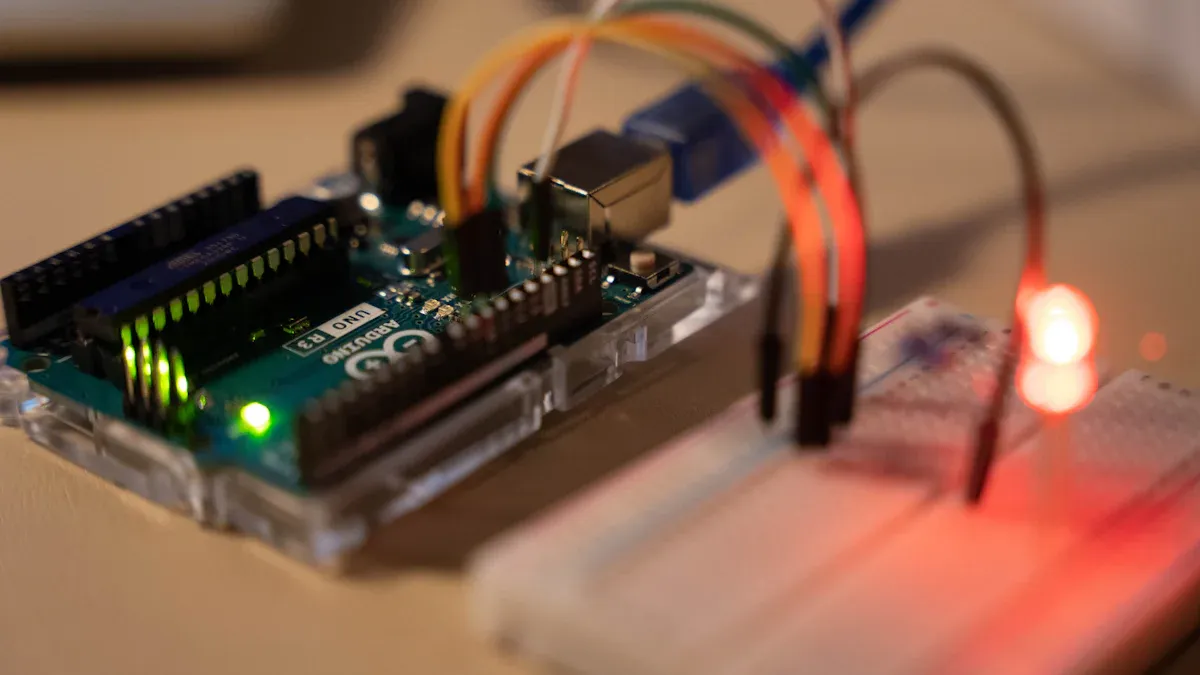

Using fast PCB building, you can test ideas and improve designs faster. This saves time and helps meet tight deadlines. Whether for gadgets or industrial tools, fast PCBA gives dependable results.

By choosing fast PCB assembly, you get quick and helpful services. This supports creativity and speeds up making new products. It’s a key tool for today’s electronics projects.

Key Benefits of Fast PCBA

Faster turnaround times for electronics projects

Fast PCBA helps finish projects much quicker. Old methods take weeks, but fast PCBA can be done in days. For example, quick prototypes let you test and fix designs fast. Simple boards can be ready the same day. Complex ones take only 3-5 days. This speed is great for urgent projects where time matters.

Fast PCBA services are very quick. PCB making can finish in 1-2 days. Assembly takes just 3-5 days. Full services, including both steps, take 5-7 days. These short times help you stay ahead and meet deadlines without losing quality.

Cost-effectiveness and streamlined processes

Fast PCBA saves both time and money. It skips extra steps, making work faster and easier. Ordering systems are simple, reducing mistakes and saving time. Quick checks improve designs, cutting down on delays and fixes.

Better communication tools also help a lot. They make teamwork between design and building teams faster. Using tools like Altimade and MacroFab improves accuracy and speeds up production. These changes make fast PCBA a smart choice for small or big projects.

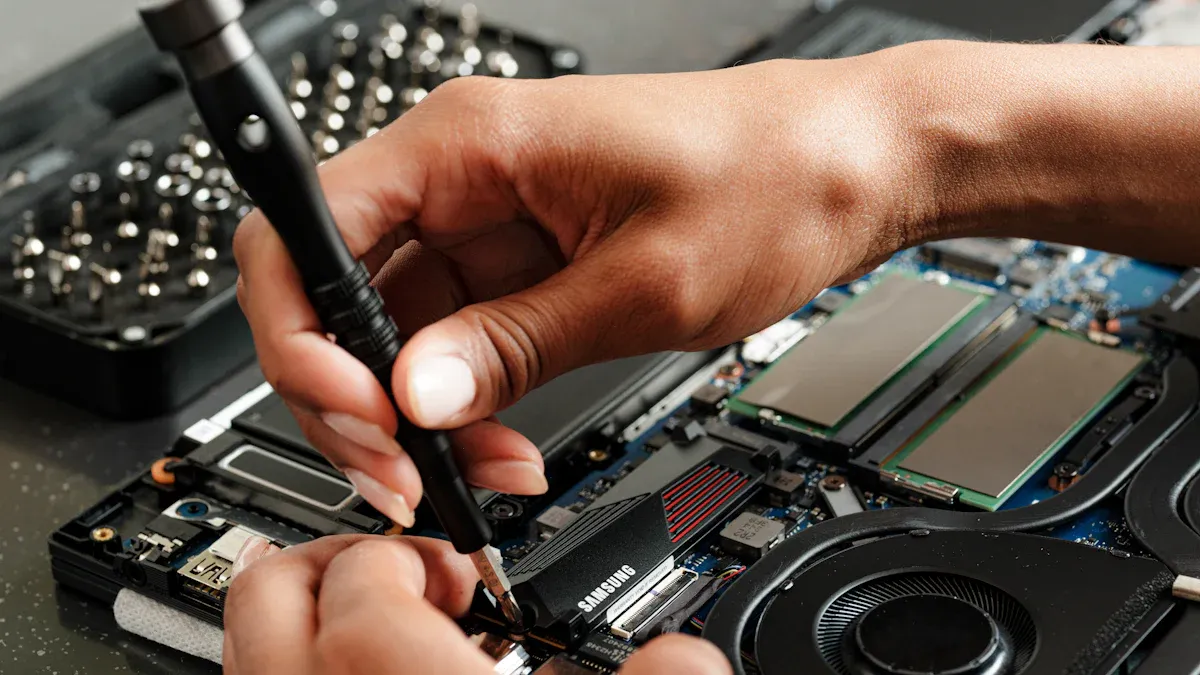

High-quality assembly with rigorous testing

Fast PCBA focuses on high quality with careful testing. These tests check if boards work well in different conditions. For example, stress tests mimic real-life use, and temperature tests check heat resistance. Other tests check strength against shaking and shocks.

These tests stop problems before they happen and make customers happy. They follow rules and save money by finding issues early. Whether for gadgets or tools, these tests ensure your boards are reliable and work great.

Scalability for different production needs

Fast PCBA works well for projects big or small. It’s a flexible way to meet your electronics needs. Whether making one prototype or many products, it keeps quality high. This process helps you move from an idea to a finished product easily.

A big benefit of fast PCBA is handling different amounts of work. For example, MacroFab supports small and large projects. They offer services from testing ideas to full production. This flexibility keeps your project on track, no matter the size.

Here’s how fast PCBA helps with scaling:

Feature | Description |

|---|---|

Works for All Sizes | Handles small and big projects without losing quality. |

Full Services | Offers tools for any project size or difficulty. |

Many Factories | Over 100 factory lines ensure steady production. |

Quick Completion | Fast steps help you finish and sell products sooner. |

Early Problem Solving | Finds and fixes design issues quickly to avoid delays. |

Fast PCBA uses smart tools to make scaling easier. AI tools help avoid supply problems and adjust to changes. These tools also find and fix design mistakes early. This saves time and money.

By using fast PCBA, you can grow your production as needed. Whether making one board or thousands, it gives you the speed and trust to succeed.

Applications of Fast PCBA Across Industries

Consumer electronics: Smartphones, IoT devices, and wearables

Fast PCBA is very useful for making consumer electronics. Devices like phones, smart gadgets, and wearables need small, efficient boards. Quick PCB services help create and improve designs fast. The market for PCB prototypes is growing quickly. This is because people want devices that do more and work better. Industries like 5G phones and smart homes need strong and compact boards.

New tech has increased the need for special PCBs. Fast PCBA helps meet this need with quick and accurate assembly. Whether making a fitness tracker or smart thermostat, fast PCB services get products ready faster.

Medical devices: Diagnostic tools and precision instruments

Fast PCBA is key for making medical tools and devices. These products must follow strict safety and quality rules. Quick PCB services help meet standards like ISO 13485:2016 and FDA rules. These rules focus on safety, risk control, and good performance.

Testing during PCB assembly makes sure devices work well. This is important for tools like heart monitors and imaging machines. Fast PCBA speeds up production and improves device quality. It helps companies compete in the healthcare industry.

Automotive: EV components and ADAS systems

The car industry depends on fast PCBA for advanced systems. Electric cars and driver-assist systems need smart circuit boards. Quick PCB services help test and build these parts fast. This ensures they meet safety and performance needs.

As cars use new tech like self-driving and smart maps, better PCBA solutions are needed. Fast PCBA supports these changes with flexible and efficient processes. Whether working on EV batteries or crash prevention tech, fast PCB services help bring ideas to market quickly.

Industrial automation: Robotics and control systems

Fast PCBA helps improve industrial automation. Robots and control systems need accurate circuit boards to work well. Using fast PCBA, you can make strong parts for modern machines.

In factories, PLCs (programmable logic controllers) control complex tasks. Fast PCBA makes these controllers dependable and efficient. Robots also gain from fast PCBA. They perform exact movements in jobs like welding and assembly. AGVs (automated guided vehicles) use fast PCBA to move in warehouses and complete tasks smoothly. Machine vision systems depend on fast PCBA for quality checks and object detection. Smart sensors, powered by fast PCBA, track real-time conditions and equipment health for smooth operations.

Fast PCBA improves robots with advanced materials. Flexible boards and special laminates help robots move better. Additive manufacturing, used in fast PCBA, makes detailed PCBs quickly and with less waste. Smart PCBs from fast PCBA let robots connect with devices and sensors. This makes robots smarter and more independent for tasks like car assembly and healthcare.

Fast PCBA helps lower costs, speed up production, and make systems more reliable. Whether for robots, controllers, or sensors, fast PCBA gives you the tools to succeed in automation.

Choosing the Right Fast PCBA Service Provider

Checking skills and experience in the industry

When picking a fast PCBA provider, focus on their skills. Their professionalism shows in their tools and management systems. Look for certifications like ISO 9001 to ensure quality work. Providers with strong testing, like following IPC-600G and UL rules, make reliable circuit boards.

Check their past work to see their success. Companies like Benchmark Electronics and Celestica Inc. are great examples. They offer custom solutions and global production. These providers are experts in quick prototypes and precise assembly, perfect for your needs.

Metric | Description |

|---|---|

Professionalism | Tools and systems show the provider’s abilities. |

Certifications | ISO 9001 proves focus on quality work. |

Testing Processes | Following IPC and UL rules ensures great assembly. |

Looking at technology and production abilities

A good PCBA provider uses advanced tools and methods. Check if they can make different PCBs, like single-layer or flexible ones. Look at details like track width, hole size, and finishes. These affect the board’s quality.

Make sure they follow rules like IPC-A-600 and ISO 9001. These show they are reliable and care about quality. Also, check their speed. Fast providers help meet deadlines without losing quality.

Other important things include their machines and support. Tools like automated inspection systems ensure accuracy. Good customer service helps with smooth communication during your project.

Production Abilities: Can make many PCB types and meet designs.

Quality Rules: Follows IPC and ISO for consistent results.

Advanced Tools: Uses modern machines for precise assembly.

Customer Help: Quick responses for easy project management.

Why certifications and quality rules matter

Certifications are key for good PCBA services. Standards like IPC J-STD-001 and IPC-A-610 set rules for soldering and assembly quality. Providers who follow these make strong and dependable boards.

ISO certifications, like ISO 9001, show focus on managing quality. These ensure your PCBA projects meet industry needs. Providers with good quality checks reduce mistakes and save time.

Certification | Description |

|---|---|

IPC J-STD-001 | Rules for soldering and electronic assemblies |

IPC-A-610 | Standards for electronic assembly quality |

IPC-6012 | Rules for rigid printed board performance |

Picking a certified provider ensures top-quality PCBA services. This gives you trust in the final product.

Customer support and communication

Picking a PCBA provider with good support is important. Reliable providers ensure clear communication during your project. This helps avoid delays and confusion. Choose a team that answers quickly and explains things clearly.

A single contact person makes updates easier. They share progress and solve any issues you have. Some providers use online tools for real-time updates. These tools let you check order status and details anytime.

Technical help is another big part of good support. You might face design problems or need material advice. A strong provider gives expert tips to guide your choices. They also review your designs to match their processes.

Check how the provider fixes problems. Mistakes happen, but good providers solve them fast. Look for clear rules on handling errors or delays. This shows they care about your time and satisfaction.

Support doesn’t stop after your project ends. Some providers offer help like repairs or maintenance. This ensures your products work well even after delivery.

Focusing on support and communication builds trust with your provider. This leads to better results and smoother projects for your electronics needs.

Fast PCBA is important for today’s electronics projects. It helps finish work quickly and test ideas fast. This method saves time, cuts costs, and ensures good quality. Whether for urgent tasks or big production, it makes work easier and faster.

To pick the best service, check their skills and certifications. Look at their tools and how they help customers. Good providers prevent delays and give reliable results. With the right team, your project can be done quicker and better.

FAQ

How long does Fast PCBA usually take?

Fast PCBA takes about 5-7 days for full assembly. Simple boards can be done in 1-2 days. This quick process helps you finish projects faster.

Can Fast PCBA handle tricky designs?

Yes, it works for complex designs like multi-layer boards. Skilled teams and advanced tools ensure great results. It’s good for both testing and production.

Is Fast PCBA a good choice for small projects?

Yes! Fast PCBA skips extra steps, saving money for small jobs. Easy processes and clear communication make it great for startups and hobbyists.

💡 Tip: Pick a provider that adjusts to your project size.

How can I make sure Fast PCBA is high quality?

Choose providers with certifications like ISO 9001 and IPC rules. These show they focus on quality. Careful testing also ensures your boards work well.

Does Fast PCBA work for quick prototypes?

Yes, it’s made for fast prototyping. You can test and improve designs quickly. It’s perfect for tight schedules or frequent changes.

🚀 Note: Tell your provider your deadlines to get the best results.

See Also

Exploring PCBA Uses and Advantages in Today’s Electronics

Defining PCBA and Its Essential Uses in Electronics

Top 10 Tips for Cost-Effective PCBA Assembly Success