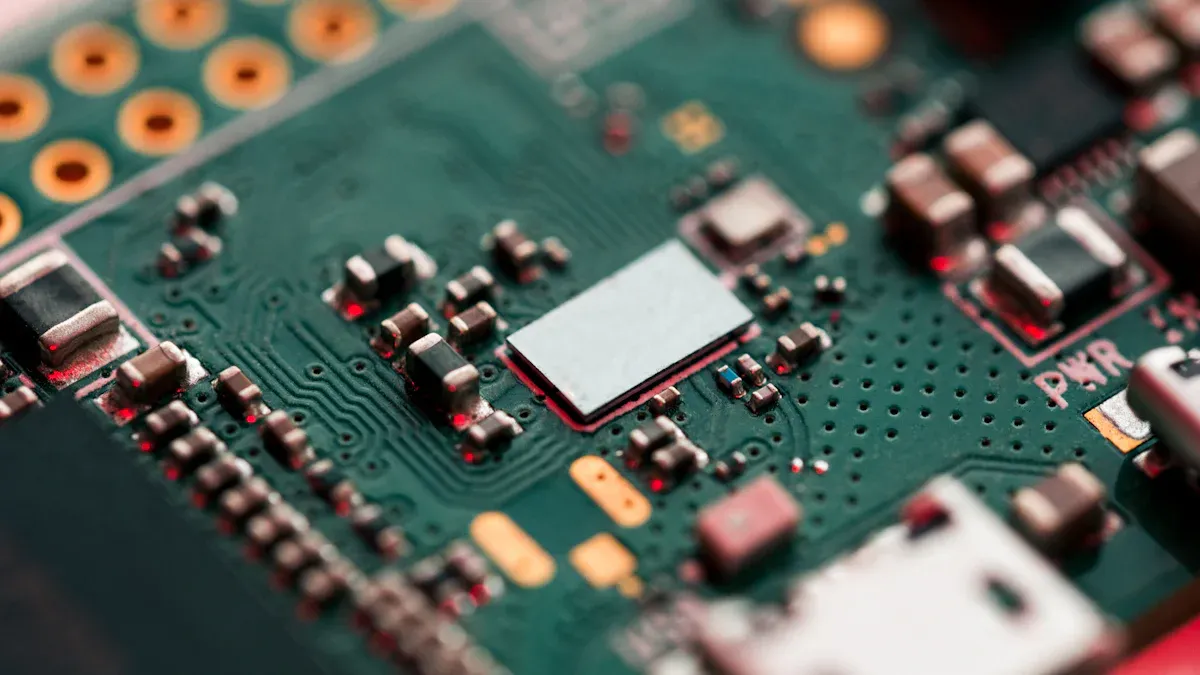

High-reliability PCBA for industrial automation refers to circuit boards specifically designed to perform effectively in challenging environments. In the realm of industrial automation, these high-reliability PCBAs are essential components of systems that operate machines, robots, and factory processes. They play a crucial role in ensuring smooth operations, which is vital for industries that demand precision and speed.

The value of high-reliability PCBA for industrial automation is validated through rigorous testing that simulates real-world challenges. For instance:

Environmental tests assess their functionality under various conditions.

Life tests evaluate their longevity and sustained performance.

Temperature tests confirm their reliability in both high and low temperature settings.

Vibration and humidity tests demonstrate their ability to withstand harsh environments.

These attributes minimize downtime and enhance productivity. Some studies indicate an improvement of up to 30% in engineering efficiency. Implementing high-reliability PCBA for industrial automation significantly enhances system performance and durability.

Key Takeaways

High-reliability PCBA works well in harsh factory conditions.

These boards are tested to handle heat, water, and shaking.

They use strong materials and smart designs to last longer.

Using high-reliability PCBA can boost production by 30%.

Future plans include using AI for designs and eco-friendly methods.

Understanding High-Reliability PCBA

Definition and Key Features

High-reliability PCBA means circuit boards made for tough jobs. They work well in places with heat, shaking, or moisture that can harm regular boards.

Main features of high-reliability PCBA include:

Enhanced Durability: Strong materials like FR-4 or Teflon last longer.

Precision Engineering: Careful design of parts like traces and solder joints.

Rigorous Testing: Tests check strength under stress and electrical performance.

The table below shows how these features are measured:

Metric Type | |

|---|---|

Prevention Mechanism | Careful design, good manufacturing, and strict quality checks |

Process Management | Safe systems, clear designs, strong materials, and advanced processes |

Quality Assurance Audit | High quality, reliability, and long time between failures |

Test Verification | Checks for heat resistance, signal strength, and corrosion protection |

These features make high-reliability PCBA important for tough industrial tasks.

Importance in Industrial Automation

In factories, high-reliability PCBA keeps machines running smoothly. These boards help robots, IoT devices, and control systems work without stopping. Unlike regular boards, they handle tough conditions and don’t fail easily.

For example, special cooling methods, like copper pillars or graphene pads, lower heat by 20°C. This stops overheating in powerful machines. Also, nano-coatings protect against water and rust, making them last longer in wet or salty places.

With these features, high-reliability PCBA reduces downtime and boosts work output. This is crucial for industries where even small delays cost a lot.

Differences Between High-Reliability and Standard PCBs

High-reliability PCBs are different from regular ones in key ways. Regular boards are fine for simple tasks, but high-reliability ones are built for hard jobs and long use.

Here are the main differences:

Material Quality: High-reliability PCBs use trusted, top-quality materials.

Manufacturing Standards: They follow strict rules like thicker plating and IPC Class 3.

Testing and Qualification: These PCBs pass many tests for stress and strength.

Design Precision: They have exact designs for solder masks and hole sizes.

Other rules include:

No fixing broken tracks or open circuits.

Clear rules for looks and repairs.

Deeper via fills (70% vs. IPC’s 60%).

Special checks for every order.

These differences make high-reliability PCBs a must for factories where machines can’t fail.

Key Characteristics of High-Reliability PCBA for Industrial Automation

Durability and Longevity

High-reliability PCBA is known for being very strong. These boards work well for a long time, even in tough places. Makers use sturdy materials like FR-4 and Teflon to stop damage. Careful design also helps by fixing weak spots like bad solder joints.

Strong boards are important because downtime costs money. For example, thicker copper layers and stronger vias make them handle stress better. These designs help them carry more current and resist breaking. Picking high-reliability PCBA lowers the chance of sudden problems and makes machines last longer.

Resistance to Harsh Environments

Factories can be hard on PCBAs with heat, water, and shocks. High-reliability PCBA handles these tough conditions well. They go through hard tests to prove they can survive.

Testing Results:

The table below shows how tests check toughness:

Description | |

|---|---|

Steady-State Testing | Long tests with heat and moisture (e.g., 85°C/85% RH). |

Thermal Cycling | Switching between hot and cold, sometimes with moisture. |

Power Cycling | Turning boards on and off while under stress. |

Step-Stress Testing | Slowly adding stress until the board breaks. |

Industry Standards | Rules like IPC-TM-650 and MIL-STD-202 guide testing. |

These tests make sure boards stay strong in bad conditions. For example, shock and vibration tests are key for cars and planes.

High-Frequency and Compact Design Capabilities

Modern machines need small boards that handle fast signals. High-reliability PCBA uses smart designs to meet these needs.

Key Features for High-Frequency Performance:

Shorter paths reduce noise and interference.

Ground shields block unwanted signals.

Compact Design Techniques:

Adjust trace sizes for fast signals.

Put small parts inside board layers to save space.

Use many layers to fit complex circuits.

These designs make high-reliability PCBA perfect for robots and IoT devices. They work well in tight spaces and keep signals clear.

Achieving High-Reliability PCBA

Design and Material Considerations

To make strong PCBAs, choose good materials and designs. Materials like BT epoxy and Teflon are very durable. They resist heat, electricity, and damage. These materials help PCBAs work well in tough factory settings.

Rules like IEC-60950-1 and IPC-2221 guide material choices. For example, the CTI test checks how well materials resist electrical breakdown. Using ceramic or halogen-free materials makes boards last three times longer in heat cycles. Flexible solder and underfill glue also stop damage from shaking, meeting IEC 60068-2-6 rules.

These steps improve quality and make PCBAs last longer in factories.

Manufacturing Standards and Processes

Making reliable PCBAs needs strict rules and certifications. IPC Class 3 ensures strong boards for important jobs like in planes or hospitals. ISO 9001 keeps quality high during production.

Methods like SPC and Six Sigma help find and fix problems early. SPC watches production for mistakes, and Six Sigma reduces errors to improve quality. These methods ensure reliable boards are made.

Special coatings, like parylene, protect boards from heat and water. These coatings pass tough tests like MIL-STD-810H salt spray tests. This makes PCBAs ready for harsh factory conditions.

Testing and Quality Assurance

Testing is key to making sure PCBAs are reliable. Tests like ICT check circuits, while FCT tests simulate real use. Fatigue tests show how long boards can last. Harsh tests expose boards to extreme heat, cold, and moisture to ensure they survive.

Advanced tools, like section analysis, find problems and improve designs. Testing also checks soldering and overall strength. Cooling designs, like copper pillars, lower heat by 20°C, keeping parts safe.

With strong testing and quality checks, PCBAs can meet tough factory needs.

Benefits and Applications of High-Reliability PCBA in Industrial Automation

Enhanced Performance and Reduced Downtime

High-reliability PCBA improves how industrial systems work. These boards are made to handle tough jobs. They keep machines running smoothly without stopping. Less downtime means steady production and fewer costly delays.

For example, nano-coatings protect PCBAs from water and rust. This makes them last longer and work better. The table below shows how high-reliability PCBA boosts efficiency and cuts downtime:

Metric | Effect on Performance |

|---|---|

Production Efficiency | Cuts lead times by almost 20% |

Innovation Rate | Faster PCB production boosts market response by 30% |

Customer Retention | A 5% retention increase raises profits by 25% |

Sustainability Metrics | Eco-friendly methods lower costs by 10% |

Using high-reliability PCBA helps factories work better and safer while reducing risks.

Applications in Robotics, IoT, and Control Systems

High-reliability PCBA is key for robots, IoT devices, and control systems. These technologies need reliable boards to work well.

Robotics: Robots use PCBAs to move and do tasks. Strong designs help them work in hot or shaky places.

IoT Devices: IoT gadgets need small, fast PCBAs to send data. Special designs keep signals clear and accurate.

Control Systems: PCBAs help control machines and temperatures. Cooling methods stop overheating and keep systems steady.

These uses show how high-reliability PCBA helps modern factories stay ahead in technology.

Meeting Demands of Harsh Industrial Conditions

Factories can be tough on PCBAs with heat, water, and stress. High-reliability PCBA is built to survive these challenges.

Environmental Adaptability: Ceramic and halogen-free materials last longer in heat cycles. Flexible glue stops damage from shaking.

Protection Against Corrosion: Nano-coatings shield PCBAs from water and salt, passing strict tests.

Thermal Management: Cooling pads and liquid systems lower heat by 20°C. This stops overheating and makes PCBAs last longer.

The table below lists the benefits of using high-reliability PCBA in tough conditions:

Benefit | Description |

|---|---|

PCBAs work well for a long time. | |

Safety | They make machines safer and reduce risks. |

Service life | PCBAs last longer, saving money. |

Competitiveness | Reliable boards help companies compete better. |

Economic benefits | Better boards improve profits and reputation. |

Choosing high-reliability PCBA helps factories handle tough conditions and succeed in the market.

Future Trends in High-Reliability PCBA for Industrial Automation

New Materials and Technologies

Big changes in materials and tools are shaping PCBA’s future. Machines like robotic arms make assembly faster and more accurate. These systems cut mistakes and save time during production. Reports show costs drop by 30%, and output grows by 50%.

Cooling is also improving for high-speed PCBA designs. Built-in cooling keeps boards working under heavy use. AI tools now check for problems and study data in real-time. This helps make better boards with fewer errors. These updates make PCBA stronger and more efficient.

Using AI and Machine Learning

AI and machine learning are changing how PCBAs are made. AI studies lots of data to improve designs and find weak spots. This ensures boards are reliable and meet high standards. Machine learning also makes robotic assembly more precise.

In factories, AI watches machines and predicts when repairs are needed. This stops delays and keeps work going smoothly. Adding AI to your process boosts both reliability and efficiency.

Going Green with Eco-Friendly Practices

Eco-friendly methods are now important in PCBA production. Recycling can recover 95% of valuable metals, cutting down mining. This helps keep materials available for making strong PCBAs.

Working with green suppliers also supports the environment. Engineers can design boards that last longer and are easier to recycle. These steps reduce waste and meet the need for cleaner factory solutions.

High-reliability PCBA is crucial for keeping factories running smoothly. It helps machines work better, reduces breakdowns, and improves safety. For example:

Quality Systems: Ensure reliable products and save money.

Robots and Automation: Speed up production and cut down mistakes.

New Materials: Make smaller, cheaper, and stronger circuit boards.

In the future, better testing tools and green practices will lead the way. The PCBA market will grow as factories go digital and eco-friendly. These changes give you chances to use new tech and stay ahead in the industry.

FAQ

How is high-reliability PCBA different from regular PCBA?

High-reliability PCBA uses tougher materials and stricter rules. It goes through hard tests to work well in tough places. Regular PCBA is fine for easier jobs.

Why does industrial automation need high-reliability PCBA?

It keeps machines running without stopping. High-reliability PCBA survives heat, water, and shocks, making it great for systems that need to work all the time.

How do tests make PCBA more reliable?

Tests find weak spots and check if boards handle stress. They use heat, cold, and moisture to make sure the boards stay strong.

Can high-reliability PCBA work in very hot or cold places?

Yes, it can. Special cooling and strong materials help it work in extreme temperatures without breaking.

Which industries use high-reliability PCBA the most?

Factories, airplanes, and cars need these boards. They help machines stay safe and work better in tough conditions.

See Also

Why PCBA Manufacturing Skills Matter in Electronics Development

Ensuring Quality and Reliability Through PCBA Functional Testing

Best Practices for Achieving Quality and Efficiency in PCBA

Essential Advice for Selecting a Trustworthy PCBA Manufacturer