Artificial Intelligence (AI) is very important in changing electronics manufacture. You can notice big improvements in how well things work and in product quality because of AI technologies. For example, predictive maintenance helps reduce downtime by predicting when machines will fail. Quality control gets better with real-time inspection, which helps find defects. Automation makes production processes easier, which increases productivity. Overall, AI helps you improve production schedules, manage resources better, and make high-quality electronics.

Key Takeaways

AI makes manufacturing better by speeding up production and cutting waste.

AI-powered inspection systems check quality by finding problems right away.

Predictive analytics helps keep track of inventory and maintenance. This cuts downtime and saves money.

AI technologies help make manufacturing more sustainable by using resources wisely and reducing waste.

It is important to invest in training programs to fill the skills gap in the electronics manufacturing workforce.

AI and Efficiency in Electronics Manufacturing

Streamlining Production

AI is very important for making production better in electronics manufacturing. By using different AI technologies, you can work faster and waste less. Here are some common AI technologies that help with production:

Predictive quality control

Optimized supply chain management

Smart inventory management

These technologies help you create prototypes faster by improving circuit layouts and where parts go. Predictive quality control uses AI to find defects right away, which makes product quality much better. Also, AI helps manage the supply chain by predicting demand and optimizing inventory.

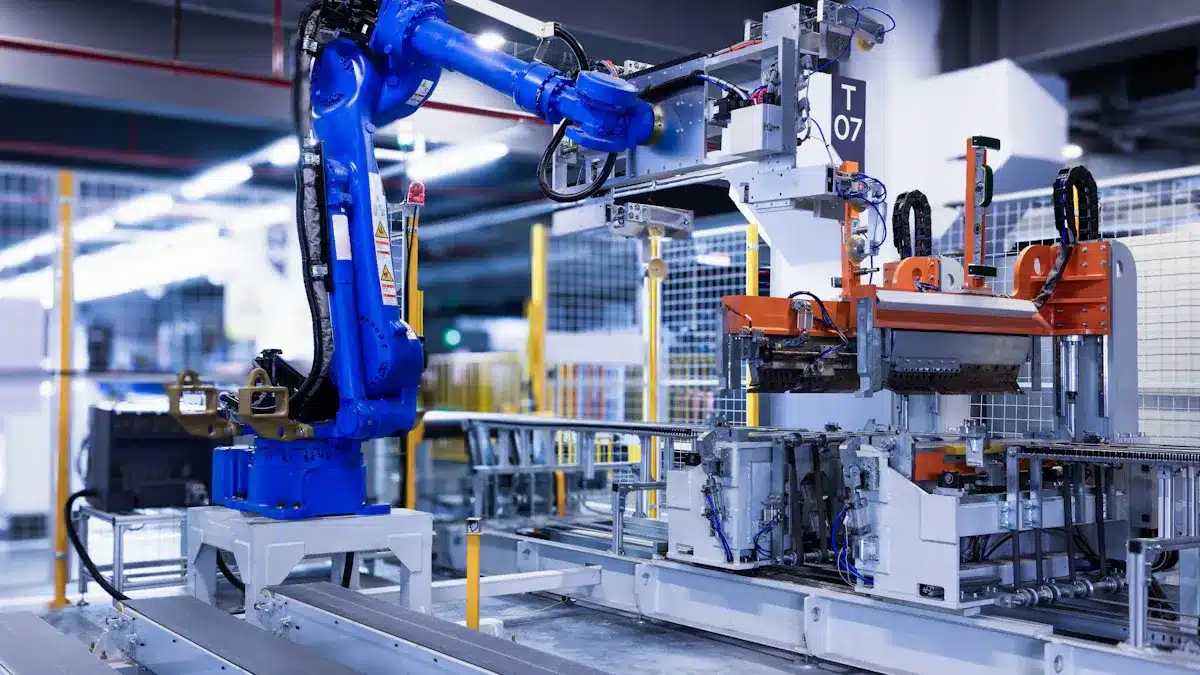

Many companies have used AI to make their production more efficient. For example, LG Electronics had trouble making its manufacturing processes better. By using AI automation systems and inspection robots, LG increased speed and efficiency while lowering costs. Similarly, Samsung Electronics used AI to automate assembly lines, which improved production efficiency and product quality.

Time-to-Market Reduction

AI is also key in reducing the time it takes to launch electronic products. Companies that use AI in product development can deliver products faster and respond better to market changes. For example, AI workflows can change assembly lines quickly for products that are low in volume but high in complexity, ensuring on-time delivery.

LG Electronics used AI design techniques to speed up product development and improve efficiency.

BMW uses AI in vehicle assembly to make production better and improve quality, which cuts down the time to launch new models. Innovations like Car2X and AIQX have been very important for these results.

PepsiCo uses generative AI and deep reinforcement learning to improve product features, leading to quicker product development and better market response.

Recent industry reports show that manufacturers have seen a big 50% drop in production time thanks to AI. Electronics assembly operations have 43% shorter cycle times, while AI-optimized facilities have an average 36% reduction in overall cycle time. These numbers show how much AI is changing electronics manufacturing.

Quality Control in Electronic Manufacturing Services

Automated Inspection

Automated inspection systems are very important for improving quality control in electronics manufacturing. These systems use smart technologies to find defects and make sure products are high quality. Here are some main features and benefits of AI-powered automated inspection systems:

Feature/Benefit | Description |

|---|---|

Automated parameter adjustments | AI learns from data to change inspection settings on its own, which saves setup time. |

Enhanced defect recognition | Deep learning models help find defects better, reducing mistakes and increasing accuracy. |

Reduction in skilled labor dependence | AI cuts down the need for skilled workers, making programming faster from hours to minutes. |

Adaptive learning and continuous improvement | AI systems get better at inspection over time, making them more accurate and flexible. |

Pattern recognition and predictive analytics | AI looks at trends to guess possible failures, helping to stop defects before they happen. |

You can find different AI technologies used in automated inspection, such as:

AI-Powered Machine Vision: This uses high-quality cameras and machine learning to find parts on printed circuit boards (PCBs) in real-time.

Deep Learning Algorithms: These algorithms check images to spot problems like missing parts and small defects, making detection more reliable.

3D Vision Integration: This combines 3D vision with AI to accurately find misalignments and height differences in parts.

For example, AI-driven automated X-ray inspection finds soldering defects, component misalignments, and missing connections. This technology greatly improves overall quality control in electronics manufacturing. A car seat maker reported a 30% drop in defect rates after using AI-driven inspection technology, showing how AI helps improve quality control.

Real-time Data Analysis

Real-time data analysis powered by AI is another big change for quality assurance in electronics manufacturing services. AI uses smart algorithms and machine learning to check products, find defects, and make sure they meet quality standards. This technology allows for quick analysis of production processes, helping you spot tiny defects more accurately than manual checks.

AI systems constantly look at visual, sensor, or process data. They can find defects right away, allowing for immediate detection as they happen on the production line. This ability leads to several measurable benefits:

Benefit | Quantifiable Impact |

|---|---|

Improved Accuracy | |

Speed | Reduced inspection time from 1 minute to 2.2 seconds |

Cost Reduction | Delivered a 30-fold cost reduction |

Lower Defect Rates | Lowered defect rates by 30% |

AI-driven systems can guess possible quality problems by looking at data from production machines. This proactive method helps avoid expensive downtime. Also, AI helps automate quality assurance processes, allowing for quicker inspections without losing accuracy.

By using these advanced manufacturing technologies, you can greatly improve quality control in your electronics manufacturing processes. The use of AI not only helps find defects but also makes operations smoother, leading to better overall performance.

AI-Driven Decision Making

Predictive Analytics

Predictive analytics is very important in electronics manufacturing. You can use smart tools and machine learning to predict demand and maintenance needs. These tools help you manage inventory better by guessing market demand. They also check equipment health in real-time. This lets you fix problems before they cause expensive failures. This way of working reduces downtime and makes operations run smoother.

Here are some results you can get by using AI-driven predictive analytics:

Metric | Description |

|---|---|

Shows the percentage of faulty units made, with AI finding problems early in production. | |

First Pass Yield (FPY) | Percentage of products that pass inspection on the first try, improved by finding defects early. |

Overall Equipment Effectiveness (OEE) | Measures how well equipment is used and works, improved by predictive maintenance. |

Cycle Time | Tracks how long it takes to make each unit, made faster by AI. |

For example, Siemens reached over a 99.99% product quality rate by predicting machine failures. General Electric (GE) saved millions each year using AI-powered digital twins for maintenance. These examples show how predictive analytics can change your manufacturing processes.

Supply Chain Optimization

AI greatly improves supply chain optimization in electronics manufacturing. By using AI solutions, you can make logistics easier, improve inventory management, and cut costs. Companies like Samsung and Intel have successfully added AI to their supply chain work.

Here are some results from recent case studies:

Company | AI Implementation | Results |

|---|---|---|

Samsung | AI-powered digital logistics platform | Cut risk response time from 24 hours to 2 hours; kept timely deliveries during conflicts |

Intel | Automated inventory planning system | Increased gross profits by over $1.3 billion; lowered finished-goods inventory by $321 million in 2013 and $280 million in 2014 |

AI in supply chain management can lead to a 15% drop in logistics costs and a 30% rise in inventory turns. These improvements help you find problems and use resources better. By using AI, you can keep up with trends and make sure your operations stay strong in the fast-moving world of electronics manufacturing.

New Trends in Electronics Manufacturing

Focus on Sustainability

Sustainability is now very important in electronics manufacturing. Companies are using eco-friendly materials and trying to reduce waste. AI technologies help a lot with this change. They make production more efficient and lessen harm to the environment. Here are some main trends that support sustainability:

Trend | Description |

|---|---|

AI for better production | AI technologies improve production efficiency and cut down on waste. |

Better recycling methods | New ways recycle materials more effectively, reducing environmental harm. |

Energy-saving practices | Companies use methods that lower energy use in manufacturing. |

Closed-loop systems | Focus on systems that recycle materials back into production, helping sustainability. |

Tracking environmental impact | Digital tools check and manage the environmental effects of manufacturing activities. |

You might also see digital product passports that track environmental impacts. Blockchain technology checks the use of renewable materials. AI-powered energy management systems change power use automatically, helping sustainability efforts even more.

Growth of Smart Devices

The rise of smart devices greatly affects trends in electronics manufacturing. As more people want smart technology, manufacturers are using AI to improve production. Here are some AI applications in this area:

AI Application | Impact Description | Example Company | Impact Metric |

|---|---|---|---|

Chip Manufacturing | AI finds tiny defects in silicon wafers, improving chip making. | TSMC, Intel | |

Robotic Assembly | AI robots do complex electronics assembly, lowering human mistakes. | Apple | Reduced human error by 25% |

Smart Factory Systems | AI IoT sensors monitor in real-time, making production better. | Samsung | Minimizes energy waste |

Predictive Maintenance | AI checks equipment to find problems before they happen. | Various | Reduced equipment downtime by 50% |

The market for smart devices and modular manufacturing is expected to grow a lot. For example, the modular automation market could reach $45.1 billion by 2030, growing at a rate of 9.9%. This growth shows how AI is being used more in manufacturing, making processes better and improving product quality.

Challenges in Integrating AI Technologies

Investment Concerns

Using AI technologies in electronics manufacturing services (EMS) can be very expensive at first. You have to think about many parts when planning your budget for AI. Here’s a list of common costs:

Cost Component | Estimated Cost Range |

|---|---|

Software licensing | $50,000 – $500,000 |

Hardware infrastructure | $20,000 – $200,000 |

Integration services | $75,000 – $250,000 |

Initial consulting | $100,000 – $300,000 |

Project management | $50,000 – $150,000 |

Infrastructure scalability planning | 15% – 25% increase |

User scaling considerations | $20,000 – $60,000 |

Geographic expansion requirements | $50,000 – $200,000 |

Opportunity cost of internal resources | 20% – 30% of capacity |

These costs can be scary, especially for smaller companies. Still, many businesses see the long-term benefits of AI. In fact, 83% of companies think AI will help their work. However, only 27% have seen real benefits from their AI projects so far. This shows how important it is to plan and invest wisely.

Skills Gap

The electronics manufacturing workforce has a big skills gap, especially with AI technologies. Here are some important points to think about:

More than a third of manufacturing leaders say they lack skilled workers.

The industry finds it hard to fill jobs because fewer young people are joining vocational training.

To fix this gap, companies should spend money on training programs. Updating job descriptions to show future skill needs is very important. Working with schools can help create the talent needed.

Training programs are key to closing this gap. For example, learning factories give real-life settings for education and training. They improve soft skills and build links between industry and schools. AI-driven training solutions provide personalized learning paths and interactive simulations, speeding up skill growth.

Generative AI is changing training in manufacturing. It offers easy and personalized learning experiences. AI-powered virtual tutors give real-time help, while interactive simulations let workers practice skills safely. This method helps traditional workers move into tech-focused jobs more easily.

Future of Electronics Manufacturing Services

Digital Twins

Digital twins are very important for the future of electronics manufacturing. This technology makes a virtual copy of real systems. It helps you watch and study processes as they happen. Here are some main benefits of using digital twins:

Real-time Data: Digital twins give you real-time data to help you make better choices.

Efficiency Improvements: They make manufacturing processes more efficient and lower costs.

Proactive Problem-Solving: This technology helps you fix problems before they get worse, speeding up time-to-market.

Also, digital twins can predict when machines will wear out. This helps with maintenance based on conditions, which cuts down on unexpected downtime and makes your machines last longer. Companies that use digital twins have saved 3% to 6% in costs, which is better than traditional methods.

Innovation Potential

There is a lot of room for innovation in electronics manufacturing, especially with AI. Here are some exciting areas where you can expect new ideas:

Advanced Design Processes: AI tools speed up idea creation and automate feedback for making things.

Smart Procurement: AI helps with buying processes, looks at big data for supply chain management, and improves vendor matching.

Automation: AI-driven automation boosts efficiency in manufacturing, including visual checks and predictive maintenance.

For example, Foxconn uses AI-powered visual inspection systems to monitor smartphone assembly lines in real-time. This innovation finds misaligned parts and tiny defects, greatly improving product quality. Similarly, Samsung Electronics has used AI in making semiconductors, leading to an 8-10% increase in yield and fewer defects.

Looking ahead, the future for electronics manufacturing looks bright. The growing need for electronics, along with reshoring efforts and regional supply chains, offers many chances for growth. By embracing these innovations, your business can succeed in a fast-changing world.

AI is changing how electronics are made in important ways. You can notice better efficiency and quality control through real-time updates, predicting maintenance needs, and better quality checks. Here are some main points:

AI improves manufacturing by constantly checking data for better quality control.

To use AI successfully, you need to fix data quality and cybersecurity issues.

The future looks bright, with AI likely to run whole factories with little human help.

By using these new technologies, you set your business up for success in a fast-changing industry. Adding AI not only makes operations smoother but also brings chances for new ideas and being eco-friendly. 🌟

FAQ

What is AI’s role in electronics manufacturing?

AI helps make production smoother, improve quality checks, and manage supply chains better. It uses data to guess when machines need fixing and helps with making decisions.

How does AI improve quality control?

AI makes quality control better with automated inspection systems. These systems find problems right away, making sure products are good before they go to customers.

What are digital twins in manufacturing?

Digital twins are virtual copies of real systems. They let you watch processes as they happen, guess problems, and make manufacturing work better.

What challenges do companies face when adopting AI?

Companies often deal with high starting costs and not enough skilled workers. Spending money on training and technology can help solve these problems.

How can AI contribute to sustainability in manufacturing?

AI helps with sustainability by using resources wisely and cutting down waste. It helps companies see their environmental effects and use energy-saving methods.

See Also

The Significance of Tailored PCBA Production in Today’s Electronics

Why PCBA Manufacturing Skills Are Crucial for Electronic Design

Exploring EMS and PCBA Solutions in Contemporary Electronics

Defining PCBA Services and Their Role in Electronics Production

Emerging Trends in PCB and PCBA Development and Manufacturing