DC-DC converters, particularly the industrial DC-DC converter assembly, are crucial for modern industries. They assist in changing and managing power efficiently across various sectors. These devices are utilized in industries such as automotive and communication, where a stable energy supply is essential.

Here are some recent facts:

The DC-DC converter market was valued at $8.3 billion in 2024 and is projected to grow to $14.7 billion by 2034, largely driven by the demand for electric and hybrid vehicles.

Smart devices, including home gadgets and factory sensors, rely on the industrial DC-DC converter assembly to optimize power consumption.

In the communication sector, converters play a vital role in the expansion of 5G networks, contributing an additional $211 million to the market in 2024.

These facts highlight the increasing demand for DC-DC converters. Industries are seeking improved energy efficiency and innovative technology. Evaluating the top industrial DC-DC converter assemblies can help you select the right solution for your specific needs.

Key Takeaways

DC-DC converters help manage power in cars, planes, and phones.

Pick the right converter for your needs: buck lowers voltage, boost raises it, and buck-boost does both.

Think about where you’ll use the converter. Isolated ones block electrical noise better, but non-isolated ones are simpler and cost less.

Choose converters with over 90% efficiency to save energy and money.

Plan ahead by picking converters that can handle more power later.

Types of DC-DC Power Converters

Knowing the types of dc-dc power converters helps you choose the right one. Each type has special benefits for different uses. The three main types are buck converters, boost converters, and buck-boost converters.

Buck Converters

A buck converter lowers input voltage to a smaller output voltage. It is often used in devices needing steady, low voltage. For example, it powers battery devices without overloading parts.

Buck converters are simple and work efficiently, often over 90%. They have fewer parts, which makes them cheaper and less complex. They work best in systems where input and output share the same ground.

Tip: Use a buck converter for powering sensors or microcontrollers. It gives accurate voltage control.

Boost Converters

Boost converters raise input voltage to a higher output voltage. They are common in solar panels and renewable energy systems. These converters match voltage to the needs of the load or storage.

Boost converters are small, affordable, and flexible. They are used in cars, wireless devices, and renewable energy. Below is a table showing their benefits:

Advantage/Application | Description |

|---|---|

Efficient Voltage Step-Up | Raises voltage levels effectively. |

Compact Size | Small and easy to use. |

High Flexibility | Works for many applications. |

Cost-Effectiveness | Saves money while working well. |

Applications in Renewable Energy | Used in solar panels and green systems. |

Usage in Automotive Electronics | Found in car electronics. |

Wireless Communication | Needed for wireless devices. |

Power Factor Correction | Helps balance power systems. |

Heating and Welding Machinery | Used in industrial tools. |

Boost converters work well in changing conditions. For example, one study showed a boost converter raising voltage from 24 V to 90 V. It stayed stable during power changes, making it reliable for systems needing steady voltage.

Buck-Boost Converters

Buck-boost converters can lower or raise input voltage as needed. This makes them useful for systems with changing input voltage.

Studies show buck-boost converters balance voltage gain, ripple current, and complexity. Below is a table comparing them to other converters:

Feature | Quadratic Boost Converter | Interleaved Boost Converters | Cascade Boost Converters | Conventional Boost Converters |

|---|---|---|---|---|

Voltage Gain | Very high | High | Very high | Moderate to high |

Ripple Current | Low to Moderate | Low | Low to Moderate | Moderate to High |

Size and Weight | Moderate | Moderate to Large | Large | Small to Moderate |

Components Count | Moderate | High | High | Low to Moderate |

Complexity | Moderate | High | High | Low to Moderate |

Buck-boost converters are great for battery devices. They keep output voltage steady even as the battery drains. Though more complex, they handle changing input conditions well.

Note: If your system has voltage changes often, use a buck-boost converter. It keeps performance steady.

Isolated vs. Non-Isolated Converters

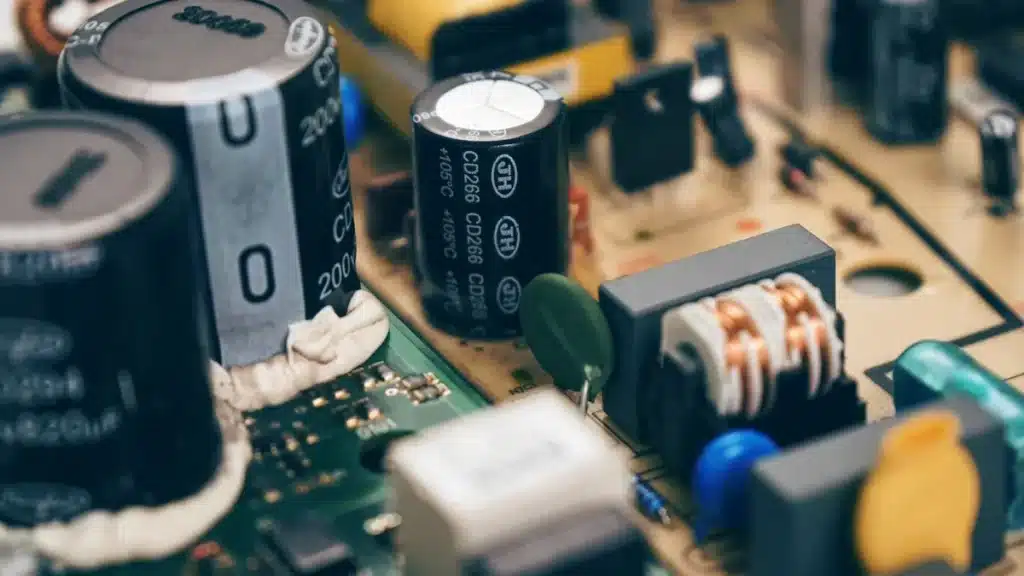

When picking a DC-DC converter, you’ll find two main types: isolated and non-isolated converters. Each type works best for certain uses. Knowing their differences helps you choose wisely.

What Are Isolated Converters?

Isolated converters keep the input and output separate. They use a transformer to move energy while staying safe. This design protects parts from voltage problems or electrical noise.

Advantages of Isolated Converters:

They block electrical noise well.

They handle voltage issues in tough environments.

They are used in medical tools, airplanes, and green energy systems.

But isolated converters cost more and are harder to build. They need extra parts like transformers and pulse generators.

What Are Non-Isolated Converters?

Non-isolated converters connect the input and output directly. They are simpler and smaller. These converters work well in devices where safety isolation isn’t needed, like phones or car electronics.

Advantages of Non-Isolated Converters:

They are cheaper and easier to use.

They work better in low-power systems.

Their small size fits tight spaces.

However, non-isolated converters don’t block electrical noise as well. This limits their use in noisy industrial areas.

Comparing Isolated and Non-Isolated Converters

Here’s a table showing how these converters differ:

Converter Type | Structure | Control Parameters | Components | Advantages & Limitations |

|---|---|---|---|---|

Isolated Converters | Uses a transformer | Regulates voltage and current | Diode = 2, Inductor = 1, Capacitor = 1, Switch = 2, Source = 1, Pulse generator = 2 | Strong protection, handles noise well, but costs more and is complex. |

Non-Isolated Converters | Direct connection | Regulates voltage and current | Diode = 2, Capacitor = 2, Switch = 2, Source = 1, Resistive load = 1 | Simple and cheap, but less noise protection and less durable. |

Which One Should You Choose?

Pick based on your needs. If your system faces noise or needs high safety, go with an isolated converter. For smaller, cheaper systems, a non-isolated converter works fine.

Tip: Check your system’s voltage needs, environment, and budget before choosing.

Key Applications of Industrial DC-DC Converter Assembly

Industrial DC-DC converter assemblies are important for many industries. They help manage power and keep systems working well. Below are three main areas where these converters are useful.

Automotive Industry

In cars, DC-DC converters are key for electric and hybrid vehicles. They move power between big batteries and smaller systems like lights and sensors. This helps cars use energy better and work more efficiently.

These converters are also used in driver-assistance systems. These systems need steady power for cameras, radar, and sensors. DC-DC converters make sure these parts work even when power changes.

Tip: For electric cars, pick converters that are small and efficient. They save space and waste less energy.

Aerospace and Defense

Aerospace and defense need power systems that are very reliable. DC-DC converters give stable power in tough conditions. They are used in satellites, drones, and military planes for communication and navigation.

Feature/Certification | Details |

|---|---|

Advanced Manufacturing | |

Rigorous Testing | Checked for shock, vibration, and temperature changes. |

Certifications | MIL-PRF-38534, IPC, NASA, and Nadcap ensure high reliability. |

Lightweight and energy-saving converters are helpful for space missions and drones. Electric planes also need these converters for better power systems.

Small converters are great for drones used in delivery or surveillance.

Efficient converters help with entertainment and controls in airplanes.

Partnerships between companies lead to new ideas and better designs.

Telecommunications

Telecommunication systems need DC-DC converters for stable power. They are used in 5G networks and data centers to keep signals clear and systems running.

These converters improve signal quality for better communication.

They save energy by converting power efficiently.

Fewer converters on a line mean better communication performance.

Telecommunication systems depend on these converters to handle high power needs. They are critical for modern communication setups.

Renewable Energy Systems

Renewable energy systems use dc-dc converters to improve power flow. These converters are important for solar panels, wind turbines, and batteries. They help move energy efficiently and keep voltage steady, even when conditions change.

Studies show how useful these converters are in renewable energy. For instance, Biswas et al. (2021) improved PV systems for tea farming. Raj, Arya, and Gupta (2020) showed a ZVS-Zeta converter working at 98.12% efficiency. Below is a table comparing converter efficiencies from different studies:

Study | Efficiency (%) | Notes |

|---|---|---|

Biswas et al. (2021) | N/A | Improved PV systems for tea farming |

Raj, Arya, and Gupta (2020) | 98.12 | ZVS-Zeta converter efficiency |

Original SEPIC | 88.59 | Base efficiency |

Zeta Converter | 93.98 | Base efficiency |

Dileep and Singh (2017) | N/A | PV optimization model |

Zhang, Zhong, and Ma (2021) | >95 | SEPIC with sliding mode control |

Tip: Pick converters with high efficiency for renewable energy. They save energy and boost performance.

Using advanced converters increases solar and wind energy output. These converters also store energy in batteries for later use. Whether for home solar systems or big wind farms, the right converter ensures better energy use.

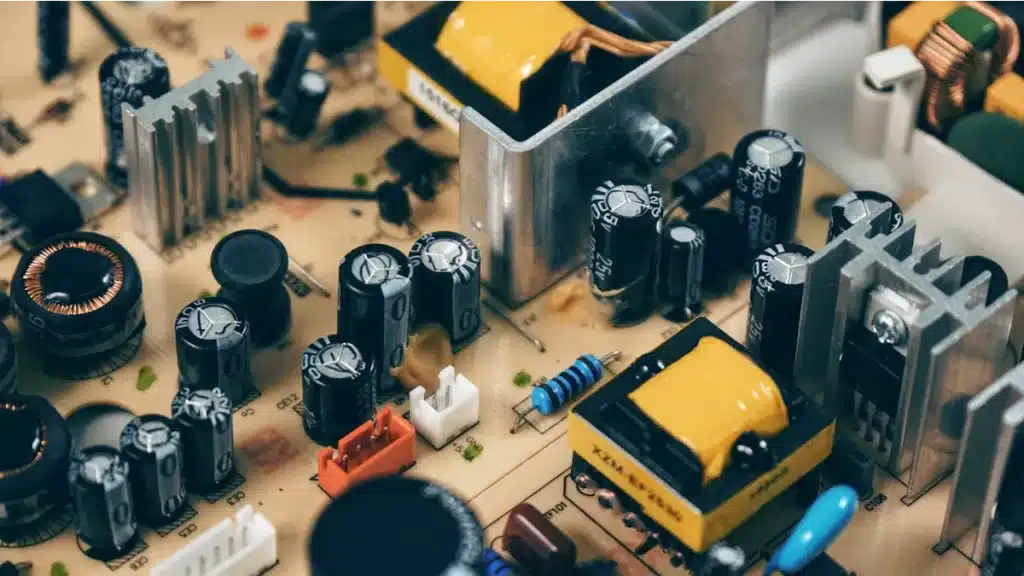

Industrial Automation

Industrial automation needs steady power to keep machines working well. DC-DC converters power sensors, motors, and control systems. They provide stable voltage, ensuring smooth operations in factories.

In automated factories, converters power robotic arms and conveyor belts. They also support PLCs, which need exact voltage to avoid errors. Converters reduce wasted energy, making operations more efficient.

Note: For automation, choose durable converters. They handle tough conditions and lower repair costs.

Modern converters have features like heat control and small designs. These make them fit tight spaces and work in hot areas. Picking the right converter improves factory efficiency and productivity.

Performance Comparison of DC-DC Converters

Efficiency and Power Output

Efficiency and power output are key for dc-dc converters. Efficiency shows how well a converter turns input power into usable output. High efficiency helps save energy and improves performance in industries.

Most converters work with efficiency between 75% and 95%. Designs with input voltage close to output voltage often perform better. Efficiency can change with different loads. A converter may work well with one load but lose efficiency with another.

Efficiency Range | Details |

|---|---|

Common range when input voltage matches output voltage. | |

Varies by Load | Efficiency shifts slightly across wide load ranges. |

Modern converters use advanced switching to reduce energy loss. These technologies cut losses during on-off transitions. This improves performance and keeps output voltage steady.

Tip: Pick converters with over 90% efficiency for less energy waste.

Reliability and Durability

Reliability and durability ensure converters work well over time. Reliable converters lower downtime and save on repairs, making them cost-effective.

Converters in controlled environments fail less often than those in harsh conditions. For example, controlled environments show 0.082 failures per million hours. Uncontrolled ones have 0.3645 failures per million hours. Controlled converters also last longer, with over 12 million hours between failures.

Metric | Controlled Environment | Uncontrolled Environment |

|---|---|---|

Failure Rate (F/10^6) | 0.082 | 0.3645 |

MTBF (hours) | 12,183,681 | 2,743,484 |

Reliability | 0.98863 | N/A |

Manufacturers use strong parts and smart designs to improve reliability. Features like heat control and power correction stop overheating and keep systems stable.

Note: For tough conditions, choose converters known for reliability.

Cost and Value for Money

Cost matters when picking a dc-dc converter, but value is important too. Spending more upfront can save money later with better efficiency and fewer repairs.

Cost studies look at several factors:

Cost Breakdown: Includes parts, production, and profit margins.

Pricing Trends: Regional prices depend on materials and new technology.

Market Growth: Past and future market sizes show economic trends.

Maintenance Costs: Helps calculate total ownership expenses.

Converters with extra cooling last longer and avoid overheating. Developers can also save by negotiating better deals with suppliers.

Tip: Match your budget with performance needs. High-efficiency converters save energy and money over time.

Environmental and Thermal Performance

Picking the right DC-DC converter means checking its environmental and thermal performance. These features show how well it works in different conditions and handles heat. Ignoring them can cause overheating, lower efficiency, or even damage.

Why Environmental Performance Is Important

Environmental performance shows how a converter works in tough conditions like temperature, humidity, or altitude. Many industries use converters in harsh places, so they must be built to last.

Temperature Range: Converters should work in extreme temperatures. For example, aerospace converters handle -40°C to 125°C.

Humidity Protection: High humidity can harm parts. Coated converters resist corrosion and short circuits.

Altitude Use: Thin air at high altitudes makes cooling harder. Aerospace converters are designed for this challenge.

Tip: Check the converter’s specs to match your environment.

Why Thermal Management Matters

Thermal management keeps converters cool and working well. Power conversion creates heat, but too much heat can harm parts or lower efficiency. Good thermal control prevents overheating.

Ways to Manage Heat

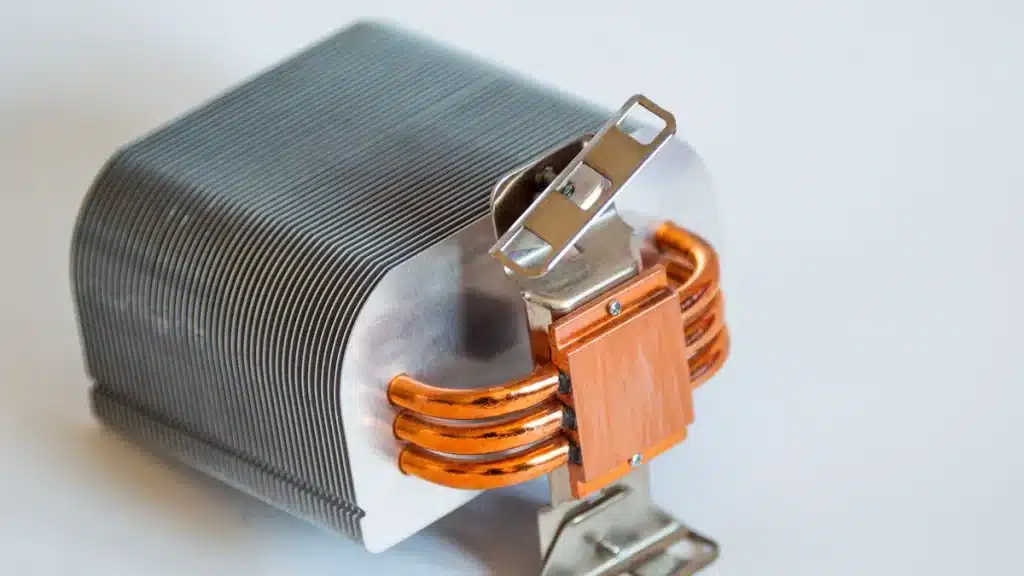

Heat Sinks: Metal parts that pull heat away from the converter.

Cooling Fans: Fans improve airflow to keep temperatures low.

Thermal Pads: Pads help move heat from parts to heat sinks.

Special Materials: Materials like SiC and GaN make less heat and work better.

Heat Control Method | What It Does | Best Use |

|---|---|---|

Heat Sinks | Pulls heat away | High-power systems |

Cooling Fans | Moves air to cool parts | Tight spaces |

Thermal Pads | Transfers heat efficiently | Compact designs |

Special Materials | Makes less heat | Advanced systems |

Checking Thermal Performance

To check thermal performance, look at efficiency, cooling methods, and temperature range. High-efficiency converters make less heat, which is great for saving energy. Converters with heat protection, like auto shutdown, are safer.

Note: For hot places, pick converters with strong cooling systems.

Industry Needs for Environment and Heat Control

Different industries need converters with special environmental and thermal features. Here are some examples:

Cars: Electric vehicles need converters that handle engine and battery heat.

Space: Spacecraft converters must work in freezing and vacuum conditions.

Solar Power: Solar systems need converters that stay cool under long sun exposure.

Knowing these needs helps you pick the right converter for your job.

Reminder: Good heat control makes converters last longer and work better.

Technological Advancements in DC-DC Converters

Wide Bandgap Materials (SiC and GaN)

Wide bandgap materials like silicon carbide (SiC) and gallium nitride (GaN) are changing DC-DC converters. These materials work better than silicon at high voltages, frequencies, and temperatures. They improve efficiency and cut energy waste, especially for powerful systems.

A study compared Si and SiC-based converters using CAD tools. Researchers optimized designs for two power levels. Results showed less energy loss and lighter weight. SiC-based converters are great for renewable energy and electric vehicles.

Tip: For high-performance systems, pick converters with SiC or GaN parts. They last longer and handle tough conditions well.

Advanced Control Techniques

New control methods make DC-DC converters work better. These techniques boost efficiency, lower costs, and simplify use. For example, bioinspired models and learning methods improve energy-saving systems.

Research introduced the Converter Control Rank Metric (CCRM). This metric checks efficiency, cost, and complexity. Studies showed advanced controls improve performance. They are key for systems needing precise power management.

Note: Choose converters with advanced controls for reliable and efficient power use.

Miniaturization and Integration

Smaller and smarter DC-DC converters are becoming popular. Compact designs save space and reduce complexity. They are ideal for small devices like wearables and IoT systems.

Metric Type | Description |

|---|---|

Power Efficiency | Designed for low standby currents and dynamic power scaling in battery systems. |

System Integration Trends | Focus on system-on-chip designs to simplify layouts and reduce parts. |

Miniaturization Advances | Smaller sizes while keeping reliability high. |

Better materials and manufacturing make these designs possible. Flexible substrates and dense circuits fit converters into tight spaces without losing performance.

Reminder: For limited space, pick a miniaturized converter with integrated features. It saves room and works efficiently.

Better Ways to Handle Heat

Managing heat is key to keeping DC-DC converters working well. Without good heat control, converters can get too hot. This can make them work poorly or even break. Learning about better heat management can make your system last longer and work better.

Why Controlling Heat Is Important

Power conversion creates heat naturally. Too much heat can harm parts and lower how well they work. Good heat control keeps converters cool and running smoothly. It also helps them last longer and cuts down on repair costs.

Tip: Before buying a converter, check its heat-handling ability. This ensures it can handle the heat it creates.

Smart Heat Control Methods

New converters use clever ways to manage heat. These methods improve how heat moves and make systems more reliable. Here’s a table showing some of the best techniques:

Heat Control Method | What It Does | How It Helps |

|---|---|---|

Handles high heat and power in car systems. | Wins awards for innovation. | |

Built-In Cooling | Adds cooling to parts inside the converter. | Improves heat flow and performance. |

Stronger Bonding Materials | Tests materials that stick parts together. | Makes parts last longer. |

Sintered Silver | Uses silver instead of regular solder. | Safer and lasts longer. |

Picking the Best Heat Features

Choose converters with advanced cooling features. Look for built-in cooling or materials that handle high heat. These features help converters work well in tough conditions.

Reminder: For hot places or high-power systems, pick converters with wide bandgap materials or sintered silver. They handle heat better and last longer.

Heat control isn’t just about stopping overheating. It’s about making converters work their best and stay reliable. By picking converters with strong heat management, you’ll save energy and avoid problems later.

Choosing the Right Industrial DC-DC Converter Assembly

Understanding Your System’s Needs

Picking the right dc-dc converters starts with knowing your system. Every system has specific power needs. Choosing a converter that fits these needs ensures it works well. First, figure out the input and output voltage your system requires. For instance, solar panels in renewable energy setups may need converters that handle changing voltages.

Next, think about the type of load. Some systems, like factory machines, need converters that handle changing loads without losing efficiency. Also, check the environment where the converter will be used. Tough conditions, like very hot or wet places, need converters with strong protection features.

Tip: Always read the converter’s datasheet to ensure it fits your system.

Finding the Right Balance Between Cost and Quality

Balancing price and quality is important when picking dc-dc converters. Cheap converters might save money at first but may not last long or work efficiently. Instead, focus on value. High-efficiency converters may cost more upfront but save money by wasting less energy over time.

Look for features like power correction and heat control. These features improve how the converter works and make it last longer. If you’re on a budget, choose converters that meet your system’s main needs without extra features you don’t need.

Reminder: Spending more on a good converter can save repair costs later.

Checking for Long-Term Dependability

Dependability is crucial for industrial systems. A dependable converter reduces breakdowns and keeps things running smoothly. To check dependability, look at the converter’s MTBF (mean time between failures) and how well it handles tough conditions. Converters with high MTBF ratings and strong designs last longer in hard environments.

Heat control also affects dependability. Converters with good heat management, like built-in cooling or parts that handle high heat, avoid overheating and last longer. Also, consider the brand. Well-known brands often provide reliability data and warranties.

Note: Reliable converters protect your system and save money in the long run.

Thinking About Future Growth

When picking a DC-DC converter, consider how your system might grow. Scalability means your power solution can handle more demands or new tech without needing a full replacement.

Why Growth Flexibility Is Important

Scalability helps your system manage bigger loads or new parts as it changes. For example, in factories, adding more robots or sensors needs extra power. A scalable converter adjusts to these changes while keeping performance steady.

Tip: Pick a converter with a wide voltage range. This makes it ready for future upgrades.

Key Features to Check

To ensure scalability, look for these important features:

Modular Design: Modular converters let you add or remove parts easily. They work well for systems with changing power needs.

High Power Density: Small converters with high power density save space and give more power.

Programmable Controls: Converters with adjustable settings fit new setups quickly.

Feature | Benefit | Example Use Case |

|---|---|---|

Modular Design | Easy to expand or shrink capacity | Data centers with changing loads |

High Power Density | Saves room for future upgrades | Electric cars with tight spaces |

Programmable Controls | Adjusts to system changes | Smart grids with shifting power needs |

Planning for Future Needs

Think about how long your system will last. If big growth is expected, choose a converter that handles more than you need now. It may cost more at first but saves money by avoiding replacements later.

Reminder: Talk to your team or supplier to match the converter’s features with your future plans.

By focusing on scalability, you prepare your system for growth and avoid extra costs. This ensures your power solution stays strong and efficient as your needs change.

DC-DC converters are important for managing power in industries. Studies show SiC-based converters save energy and weigh less. These are great for electric cars and green energy systems. For cars, pick small and efficient converters. In aerospace, choose reliable and lightweight ones. Telecommunication systems need converters that keep signals steady. Renewable energy systems work best with high-efficiency converters. Always select converters that match your system’s needs for better performance and durability.

FAQ

What is a DC-DC converter, and why is it important?

A DC-DC converter changes one type of DC voltage to another. It helps devices get the right voltage to work well. These converters are used in cars, planes, and green energy systems.

How do you choose the right DC-DC converter for your system?

First, figure out your system’s voltage and power needs. Think about conditions like heat and moisture. Pick a converter with features like efficiency, durability, and flexibility for your use.

Can DC-DC converters handle extreme temperatures?

Yes, many converters are made for tough conditions. Some can work in temperatures from -40°F to 257°F. This makes them great for planes, cars, and factories.

Are DC-DC converters energy-efficient?

Modern converters are very efficient, working between 75% and 95%. High-efficiency converters save energy, cut costs, and improve how systems work.

What industries benefit most from DC-DC converters?

Industries like cars, phones, green energy, and factories use these converters. They provide steady power and make systems more reliable.