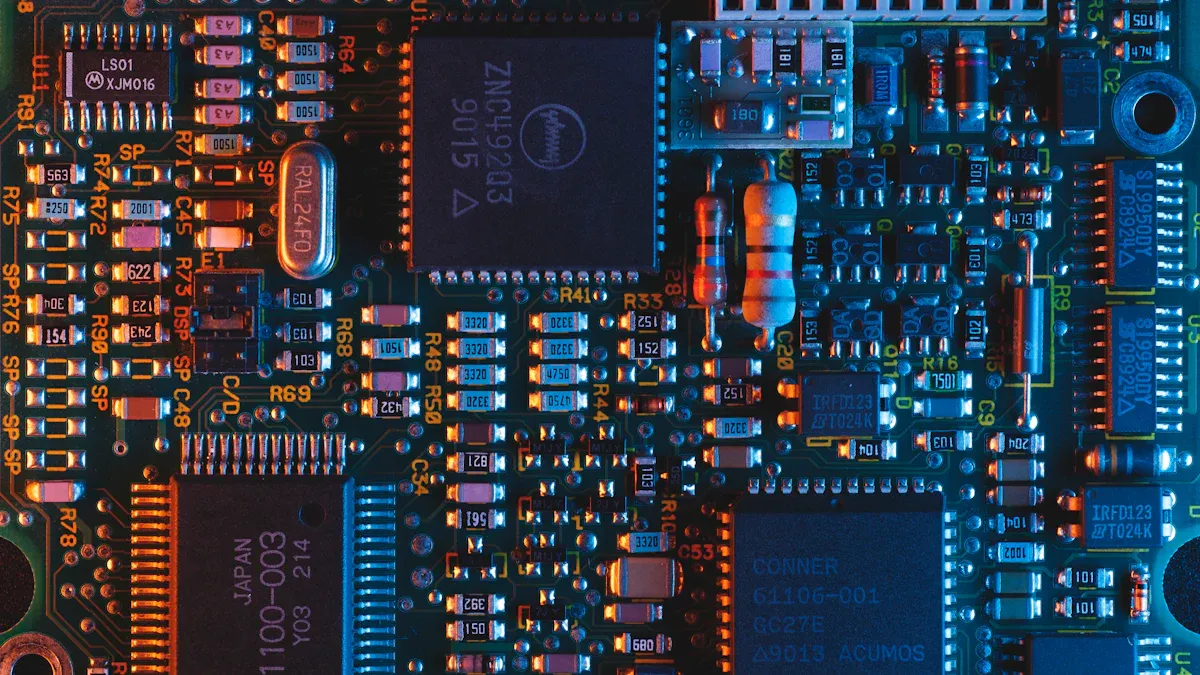

Getting the right parts for PCBA is very important, especially when it comes to industrial-grade component sourcing for PCBA. Good suppliers provide parts that are strong and work well. New studies show that better materials and flexible designs are changing how parts are made. This helps meet the need for smart devices and IoT gadgets. If you don’t plan well, you might face delays, spend more money, or have bad products. Quick deliveries and strong supply chains keep things running smoothly. Always choose good-quality parts to protect how your product works and what people think of it.

Key Takeaways

Pick suppliers with top certifications like ISO 9000 or AQL.

Read reviews to check supplier reputation and avoid delays.

Make sure suppliers are financially stable to reduce supply risks.

Order samples first to check quality before buying more.

Communicate clearly and do regular checks to build trust.

Key Criteria for Trustworthy Suppliers

When buying parts for PCB assembly, picking good suppliers is key. Reliable suppliers give you top-quality parts that fit your needs. Below are the main points to check when choosing trustworthy suppliers.

Certifications and Compliance with Industry Standards

Certifications show a supplier cares about quality. Suppliers with ISO 9000 or ISO 9001 prove they follow strong quality systems. These standards help reduce mistakes, improve quality, and make customers happy.

For PCB assembly, find suppliers who follow Acceptable Quality Levels (AQL). This ensures they meet industry rules and deliver great parts. Suppliers who follow these rules are more likely to meet your needs.

Tip: Always ask suppliers for proof of their certifications to confirm they follow the rules.

Supplier Reputation and Customer Feedback

A supplier’s reputation shows how reliable they are. Check reviews and feedback to learn about their service. Pick suppliers with a history of delivering good parts on time.

Some important facts to know:

77% of companies have ethical sourcing rules, showing the need for responsible suppliers.

83% of businesses find supplier risks after working with them, so research is important.

Choosing suppliers with good reviews lowers the chance of delays or bad parts.

Note: Working with socially responsible suppliers can boost your brand and attract eco-friendly customers.

Warehouse Management and Storage Practices

Good warehouse management affects how reliable parts are. Trustworthy suppliers keep their warehouses organized to avoid problems. Key things to check include:

What It Means | Why It Matters | |

|---|---|---|

Inventory Accuracy | Matches recorded stock with actual items. | Stops shortages, ensures correct orders, avoids supply chain issues. |

Order Picking Accuracy | Measures how often orders are picked without mistakes. | Cuts down returns, improves efficiency, builds customer trust. |

Order Cycle Time | Time from getting an order to shipping it. | Makes customers happy, speeds up processes, finds problem areas. |

Suppliers with good warehouse systems deliver parts in great shape. This keeps your PCB assembly process smooth and problem-free.

Tip: If you can, visit the supplier’s warehouse or ask for a virtual tour to check their storage methods.

Financial Stability and Market Longevity

When buying parts for PCBA manufacturing, check if suppliers are financially stable. Suppliers with good finances and long experience are more reliable. They can provide steady quality and keep your production running smoothly.

Key Financial Indicators to Check Stability

Looking at financial numbers shows if suppliers can stay in business. Reports often focus on these key points:

What It Shows | |

|---|---|

Current Ratio | Checks if they can pay short-term bills. |

Debt-to-Equity Ratio | Measures how much debt they use. |

Return on Assets | Shows how well they make profits. |

These numbers help you see if suppliers use resources wisely. Suppliers with good ratios are less likely to have money problems that could slow your supply chain.

Signs of Market Longevity

Good suppliers usually show they can last in tough markets. Look for suppliers who:

Hold a strong place in the market.

Have special skills or lower costs than others.

Can adjust to market changes to stay successful.

Suppliers with these qualities are more dependable over time. This lowers risks of sudden shutdowns or failures.

Steps to Check Financial Stability

Follow these steps to find reliable suppliers:

Look at audited financial reports for accuracy.

Check credit scores for any money troubles.

Review payment records to see if they pay on time.

Look for steady revenue growth as a good sign.

Study liquidity, profit, and debt ratios for overall health.

These steps help you pick suppliers who won’t risk your product quality or delivery times.

Tip: Work with suppliers who are both stable and flexible. This reduces risks and ensures a steady flow of parts for your PCBA manufacturing.

Actionable Strategies for Ensuring Quality in Component Sourcing

Requesting and Testing Sample Orders

Testing samples is a smart way to check component quality. By asking for samples, you can see if parts match your needs. This helps ensure they work well in your PCB assembly process. Good suppliers often give samples to show they care about quality.

When testing, focus on these key points:

Metric | What It Means |

|---|---|

Shows how many items fail quality checks. | |

Return Rate | Tracks how often items are sent back due to problems. |

Compliance with Specs | Checks if parts meet agreed rules and standards. |

Order Accuracy | Measures how often orders are correct. |

Lead Time | Tracks how long it takes to get your order. |

On-Time Delivery | Shows if suppliers deliver when they promise. |

Looking at these points helps you see if a supplier is reliable. For example, low defects and accurate orders mean the supplier values quality.

Tip: Write down your test results. This helps compare suppliers and choose wisely.

Verifying Supply Chain Transparency

Knowing where parts come from is very important. Transparent suppliers share details about how they make and deliver parts. This helps you check if parts meet industry rules and standards.

Transparency has many benefits:

Mechanism | Why It’s Important |

|---|---|

Makes it easier to follow laws by sharing supply chain details. | |

Enhanced brand loyalty | Customers trust companies that are open about their products. |

Stronger partnerships | Builds trust and teamwork between you and suppliers. |

Improved risk management | Helps track parts better and avoid problems. |

When suppliers share clear details, you can spot risks early and fix them. For example, knowing where materials come from ensures they meet ethical and environmental rules.

Note: Ask for documents like origin certificates to confirm suppliers are transparent.

Leveraging Online Component Databases

Online tools make finding parts easier and faster. These platforms let you search for parts from many suppliers. You can compare options and pick what works best for your needs.

With these tools, you can:

Search for parts by size, material, or performance.

Read detailed specs to check if parts fit your PCB assembly.

See supplier reviews to find trusted ones.

Some databases also show real-time stock updates and prices. This helps you avoid delays and make smart choices.

Tip: Use trusted sites like Octopart or Digi-Key to find reliable suppliers.

Working with Authorized Distributors

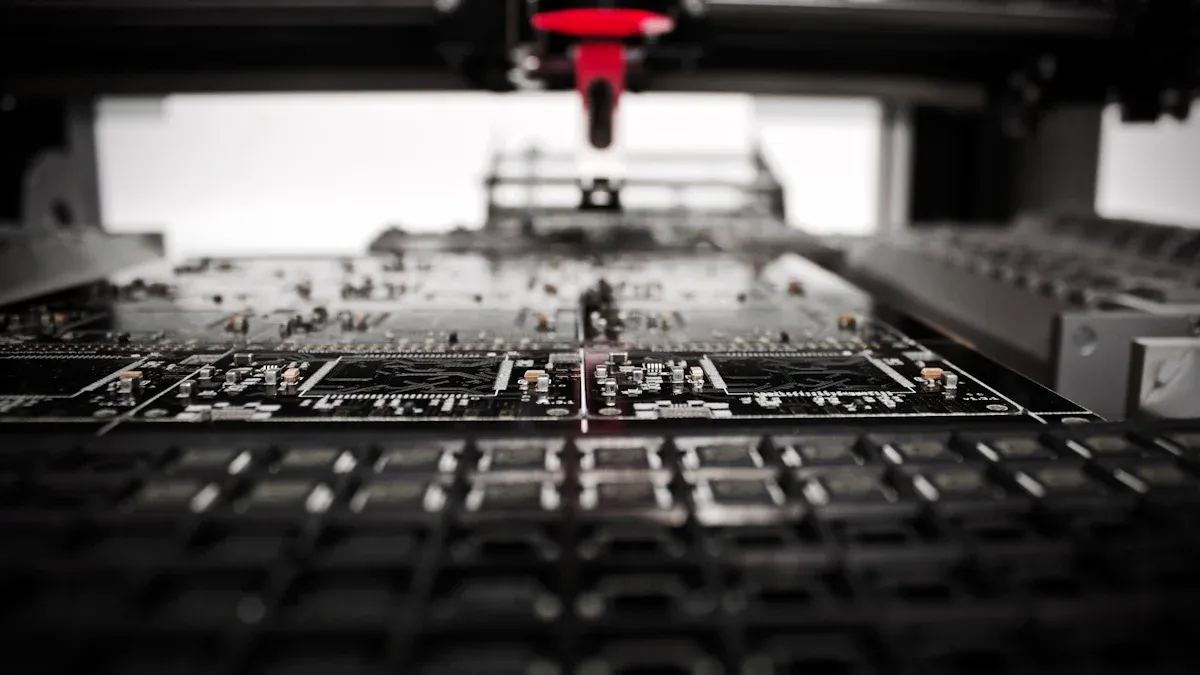

Teaming up with authorized distributors makes getting parts easier. These distributors connect manufacturers and buyers, giving you real, high-quality components for your PCBA manufacturing.

Why Pick Authorized Distributors?

Authorized distributors have many benefits that make them a smart choice:

Faster delivery times: Local distributors deliver quicker than overseas suppliers.

Lower shipping costs: Buying locally saves money on transportation.

Stronger relationships: They offer better communication and personalized help.

Choosing authorized distributors helps avoid delays and keeps production on track.

Ensuring Quality and Authenticity

Authorized distributors focus on quality. They get parts straight from trusted manufacturers. This ensures the components meet industry rules and are not fake or poor quality.

Authenticity guarantee: They confirm parts come from reliable sources.

Reliable inventory: They keep enough stock to avoid production stops.

Tip: Always ask for proof, like authenticity certificates, to check the parts’ origin.

Saving Costs and Improving Efficiency

Authorized distributors can help you save money. They keep parts in stock, so you don’t need to store large amounts. This lowers storage costs and lets you buy only what you need.

Streamlined supply chain: They make sourcing easier by offering all parts in one place.

Reduced overhead: You save on storage and shipping, using resources better.

Note: Building a long-term relationship with a distributor can bring extra perks, like discounts and faster service.

Working with authorized distributors gives you top-quality parts, saves money, and ensures a steady supply for your PCBA manufacturing. This approach improves efficiency and keeps your products reliable.

Building Strong Relationships with Suppliers

Having good relationships with suppliers is very important. It helps keep your supply chain steady and your PCBA manufacturing process smooth. Trust and teamwork improve when you work well with suppliers.

Setting Clear Communication and Expectations

Clear communication is key to working well with suppliers. When you explain your needs clearly, suppliers can meet them better. Use metrics like delivery time, order accuracy, and quick replies to check how well communication works.

Metric | What It Tracks |

|---|---|

On-Time Delivery (OTD) | Checks if suppliers deliver on promised dates. |

Order Accuracy | Makes sure orders match what you asked for. |

Communication and Responsiveness | Measures how fast suppliers reply to questions or problems. |

Good communication builds trust. Sharing your needs and staying open helps suppliers adjust to changes and do their best.

Tip: Have regular meetings and give feedback to stay on the same page with suppliers.

Doing Regular Quality Checks

Checking quality often helps keep high standards. These checks find problems early and make sure suppliers follow your rules. Metrics like defect rates and returns show how well suppliers are doing.

Metric | What It Shows |

|---|---|

Tracks defects and rejections to ensure good quality. | |

Percentage of Poor-Performing Suppliers | Shows how many suppliers are not meeting standards, with fewer being a good sign. |

Do these checks once or twice a year to keep suppliers accountable. Using clear metrics helps you make smart choices about who to work with.

Note: Write down what you find during checks to track progress and follow rules.

Making Long-Term Deals

Long-term deals with suppliers have many benefits. They save money, keep prices steady, and make your supply chain stronger. Fair bidding gets good prices, and rewards encourage suppliers to do better.

Save Money: Long-term deals often include discounts and stable prices.

Better Quality: Agreements push suppliers to focus on quality.

Steady Supply: Reliable deals lower risks of delays or shortages.

Trust grows with long-term deals, leading to better teamwork. Big companies like Toyota show how trust with suppliers can lead to new ideas and better parts.

Tip: Add performance goals to contracts to make sure suppliers meet your standards every time.

Fostering Collaboration and Mutual Trust

Working well with suppliers makes your supply chain stronger. It also helps your PCBA manufacturing process run better. A good partnership benefits both you and your suppliers.

Trust starts with clear communication. Explain your goals and needs clearly. Talk openly about challenges and performance to build teamwork. When suppliers feel trusted, they solve problems faster. This lowers risks and keeps production smooth.

Teamwork is also important for meeting rules and certifications. Solving problems together helps you and your suppliers stay on track. For example:

Clear communication keeps everyone focused on quality standards.

Shared goals make suppliers care about your needs.

Working together helps meet industry rules more easily.

Involving suppliers early in projects adds value. Starting together speeds up product creation and fixes problems quickly. Suppliers with special knowledge can suggest better ideas for your products. This saves time and cuts costs.

Managing supplier performance (SPM) makes teamwork even better. Focus on shared goals to build a strong relationship. Open talks about performance help find ways to improve. This reduces risks and keeps business steady for both sides.

Tip: Think of suppliers as partners, not just sellers. Trust and teamwork lead to long-term success.

Risks of Neglecting Reliable Industrial-Grade Component Sourcing

How Product Quality and Performance Are Affected

Using bad components can harm your product’s quality. Weak parts may not meet industry rules, causing failures or shorter lifespans. This leads to more defects, slowing production and upsetting customers. If parts don’t work well, your product becomes less reliable and less competitive.

Suppliers without proper certifications or poor storage practices may send bad materials. These problems hurt your PCBA manufacturing process. For instance, parts stored poorly can break down, leading to uneven performance. High-quality parts are key to keeping your product trusted and meeting customer needs.

Tip: Pick suppliers with a good history of delivering top-quality parts to keep your product working well.

Higher Costs from Fixes and Delays

Skipping reliable sourcing can cost you more in fixes and delays. Fixing mistakes can take up to 20% of your project budget. It also wastes materials when bad parts need replacing. Delays from sourcing problems can slow projects by 10%, lowering productivity and upsetting customers.

Unreliable suppliers might deliver late or send faulty parts, stopping production. This messes up your supply chain and raises costs. Fixing these issues can cut productivity by 300%, using up more resources. Choosing dependable suppliers early saves time and money.

Note: Check how well your suppliers perform often to avoid costly fixes and delays.

Harm to Your Brand’s Reputation

Bad sourcing can hurt how people see your brand. Customers blame your company for bad products, even if the parts were the problem. Aon Global Risk Management Survey says reputation damage is a top risk, often tied to supply chain issues.

When suppliers send bad parts, it makes your brand look bad. Customers lose trust, and bad reviews spread fast online. Working with honest and reliable suppliers helps protect your brand. Good sourcing keeps your products meeting customer expectations.

Tip: Build strong ties with suppliers who focus on quality to protect your brand’s image.

Legal and Compliance Challenges

Skipping reliable sourcing can cause big legal problems. Make sure your suppliers follow all rules and keep proper records. If they don’t, your business could face fines, lawsuits, or even shut down.

Keeping good records is very important for following rules. Bad data management can cause trouble. For example:

Almost half (47%) of new data has at least one big mistake.

These facts show why working with suppliers who keep accurate records matters. Good suppliers help you avoid risks by giving clear and correct documents.

A real-life example shows what happens when compliance fails. Colleen Kimmel, a lawyer for Sterling Bank, faced legal trouble because the bank didn’t have a strong compliance program. This shows how ignoring rules can lead to big fines and hurt your reputation. Picking reliable suppliers lowers the chance of these problems.

Being open about your supply chain helps meet legal rules. Suppliers who share details about their work make it easier to check if they follow laws. This includes rules about the environment, worker rights, and product safety. If suppliers don’t meet these rules, your business might face recalls or bans.

To stay safe, always check if suppliers follow rules and ask for their certifications. These steps help keep your business legal and protect it from risks.

Tip: Work with suppliers who have a history of following rules. This helps avoid legal problems and keeps your business running smoothly.

Getting good parts is key for successful PCB assembly. It helps your products work well and meet quality rules. Checking suppliers carefully avoids problems like delays, bad parts, or breaking rules. Good supplier ties also speed up deliveries and keep supplies steady.

Finding reliable parts needs correct data and trusted sources. Suppliers with clear methods and strong quality checks give better parts. As noted, “favoring some parts unfairly can cause resource issues and system failures.” This shows why quality and trust matter in choosing parts.

Choosing quality parts and smart sourcing protects your production process. It also builds a strong brand and ensures success over time. Focus on sourcing to keep your PCB assembly running smoothly and staying ahead.

FAQ

What are industrial-grade components, and why are they important for PCBA manufacturing?

Industrial-grade components are strong parts made for tough conditions. They handle extreme heat, cold, or vibrations. These parts help PCBA products work well in hard environments. This lowers the chance of failures and makes products last longer.

How can you verify a supplier’s certifications?

Ask suppliers for official papers like ISO 9001 or AQL certificates. These show they follow industry rules. You can also check with certification groups to confirm they are real.

Tip: Always ask for the latest certificates to avoid using old ones.

What are the risks of sourcing components from unauthorized distributors?

Unauthorized distributors might sell fake or bad-quality parts. These parts can break during use or production. This causes expensive fixes, delays, or even recalls. Using authorized distributors ensures you get real, reliable parts.

How do online component databases help in sourcing?

Websites like Octopart or Digi-Key help you find and compare parts. They show stock levels, reviews, and details about the parts. These tools save time and help you choose the right parts quickly.

Why is supply chain transparency crucial in component sourcing?

Transparency lets you track where parts come from. This ensures they follow ethical and legal rules. It also helps avoid fake parts or delivery problems, keeping your PCBA products reliable.

Note: Ask for supply chain records to check transparency and rule-following.

See Also

Key Considerations When Selecting A PCBA Manufacturer

Guidelines for Finding The Ideal PCBA Factory

Why PCBA Manufacturing Skills Matter In Electronics Design

Best Practices for Selecting A Trustworthy PCBA Manufacturer

Choosing PCBA Services That Offer Advanced Manufacturing Options