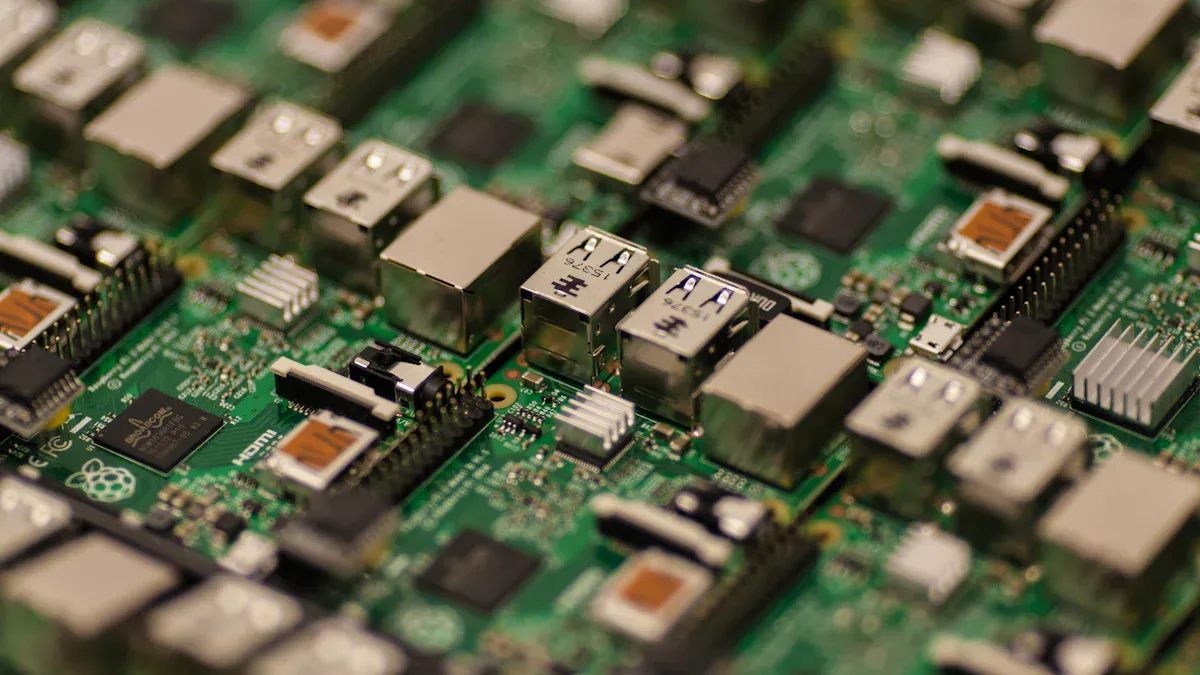

Industrial IoT hardware solutions are the tools that make the industrial internet of things work. These include sensors, edge devices, and gateways. They gather and process data to help run smart systems. These tools are important because they improve factories, make work easier, and help people make better choices.

The hardware part of the industrial IoT market is the biggest, showing how important it is today.

It will likely stay this way, showing people still need these tools.

New industrial technologies already offer many types of hardware for IIoT setups.

With IoT tools, you can automate jobs, fix problems before they happen, and create new ways to do business. Adding IIoT to industry 4.0 means smarter, safer, and better ways to work.

Key Takeaways

Industrial IoT hardware, like sensors and gateways, helps factories work better and stay safe.

Picking the right IoT platform is very important. Find one that fits your business needs, like growing easily and being secure.

Using IoT tools for predictive maintenance cuts downtime and makes machines last longer, saving money.

Edge computing processes data nearby, making decisions faster and safer.

Green IoT solutions help the planet and make businesses run better while improving their image.

Types of Industrial IoT Hardware Solutions

Sensors and Actuators

Sensors and actuators are key parts of industrial IoT systems. Sensors gather data like temperature, pressure, or movement. Actuators use this data to perform actions. For example, a sensor might notice a machine overheating. An actuator could then turn on a cooling system to stop damage.

Today’s sensors are much more advanced. They allow industries to use connected devices for real-time monitoring. These tools make factories safer and more efficient. With better IoT hardware, industries now use special sensors for predictive maintenance. This helps machines work longer and reduces downtime.

Tip: Pick sensors that work well with your current systems. This avoids problems when setting them up.

Edge Devices for Industrial IoT

Edge devices are important in industrial IoT. They process data nearby instead of sending it all to the cloud. This makes decisions faster in factories. For example, edge devices can check data from machines to find problems early. This stops failures before they happen.

Performance Metric | Description |

|---|---|

Better Performance | Handles data locally, making systems faster and smoother. |

Quick Data Analysis | Analyzes data instantly, helping industries act quickly. |

Predictive Maintenance | Watches machines to predict issues, cutting downtime. |

Smart Data Management | Saves bandwidth and improves how data is handled. |

Machine Condition Tracking | Monitors machines, even old ones, for useful insights. |

Problem Detection | Spots issues early to avoid big failures. |

More Machine Uptime | Keeps machines running longer and more efficiently. |

Edge devices help industries use advanced IoT solutions. They manage data better and keep machines running smoothly.

IoT Gateways and Connectivity Solutions

IoT gateways connect devices to the cloud, allowing smooth data sharing. They protect devices from hackers and improve security. Gateways can also run apps locally, helping industries make decisions without always using the cloud.

Factor | Edge Gateway | Gateway-less Systems |

|---|---|---|

Security | Protects devices from hackers and other threats. | Less secure; devices lack local app hosting. |

Failure Impact | Affects all devices if it fails. | Smaller impact; one device failing won’t stop others. |

Maintenance | Needs updates and regular care. | Similar to managing many devices differently. |

Local App Hosting | Can run apps locally for quick access. | Cannot run apps locally. |

IoT gateways are crucial for industries moving to IIoT. They ensure strong connections, secure data, and smooth device communication.

Industrial IoT Platforms and Management Tools

Industrial IoT platforms and tools help manage devices and analyze data. They connect devices, store data, and provide useful insights. These platforms make it simple to add IoT hardware to your systems. This helps you monitor and control operations easily.

Key Features of Leading IoT Development Platforms

Some IoT platforms are known for their great features. They meet different industrial needs. Below is a table comparing popular platforms:

Platform | Key Features |

|---|---|

Siemens MindSphere | Tracks assets in real-time, Predicts maintenance needs, Works with Siemens services, Compatible with many devices, Offers strong analytics |

ChirpStack | Manages LoRaWAN networks, Scales for big businesses, Monitors data live, Uses secure communication |

GE Predix | Tracks asset performance live, Predicts maintenance, Provides advanced analytics, Ensures high security, Manages data smoothly |

These platforms help improve operations, reduce downtime, and boost security. For instance, Siemens MindSphere works well with many devices. ChirpStack focuses on secure communication and scaling for growth.

Benefits of Using IoT Hardware Platforms with Management Tools

Using IoT hardware with management tools has many advantages:

Improved Operational Efficiency: Automating tasks reduces mistakes and saves resources.

Predictive Maintenance: Watching machines helps prevent breakdowns and plan repairs early.

Enhanced Safety and Security: Live monitoring keeps workplaces safe, and security features protect data.

These tools make industries smarter and more efficient. They let you focus on new ideas instead of fixing problems.

Choosing the Right Platform for Your Needs

Pick a platform based on what your business needs most. Think about how it scales, works with your systems, and offers analytics. GE Predix is great for advanced analytics. ChirpStack is best for managing LoRaWAN networks. Match your goals to the right platform.

Tip: Choose platforms with strong security and easy integration. This ensures they work well and last long.

Adding IoT platforms to your business unlocks IoT hardware’s full power. These tools help you make better decisions, work smarter, and stay ahead in your industry.

Applications and Benefits of Industrial IoT Hardware

Predictive Maintenance in Industrial IoT

Predictive maintenance is a powerful use of industrial IoT. Sensors and real-time data track equipment performance. They spot early signs of wear or problems. This helps schedule repairs before breakdowns happen, avoiding delays.

Uptime can improve by 10–20%, according to Deloitte.

Repairs during off-peak hours reduce work interruptions.

IoT systems catch issues early, keeping projects on schedule.

For example, sensors in factories check vibrations or temperature changes. If a machine overheats, the system sends an alert. This prevents sudden failures and extends equipment life. Predictive maintenance keeps factories running smoothly and efficiently.

Tip: Use IoT tools with advanced analytics for better maintenance. This reduces downtime and boosts productivity.

Safety Monitoring and Compliance

Industrial IoT improves workplace safety. Sensors and wearables monitor conditions and worker health. These tools help follow safety rules and create safer environments.

Sensor data has cut downtime incidents by 25–30%.

Wearable devices have lowered workplace accidents by 40%.

Environmental sensors reduced work-related illnesses by 15%.

For instance, wearables track workers’ heart rates and warn of overexertion. Environmental sensors detect gas leaks or unsafe temperatures. These tools protect workers and ensure safety standards are met.

Adding IoT to safety plans reduces risks and keeps workplaces secure. This protects employees and improves overall efficiency.

Energy Efficiency and Optimization

Energy savings are another big benefit of industrial IoT. IoT hardware helps monitor and adjust energy use in real time. This reduces waste and improves efficiency.

Aspect | Details |

|---|---|

Study Focus | |

Methodology | Data from 357 firms analyzed with advanced methods. |

Key Findings | IIoT boosts resource use and supports eco-friendly practices. |

Contribution | Shows how IIoT helps create greener, efficient industries. |

IoT enables closed-loop processes for better control. For example, wireless systems automate tasks like oil level checks. This lowers labor costs and saves energy. IoT also identifies energy-heavy processes to cut waste.

Using industrial IoT saves energy and supports green manufacturing. It reduces costs and helps industries become more sustainable.

Note: Pick IoT tools with strong energy tracking features. This helps manage and save energy effectively.

Supply Chain and Asset Tracking with IoT in Manufacturing

Industrial IoT has changed how supply chains work in factories. Using IoT devices, you can track goods, watch assets, and improve operations live. This makes workflows smoother and decisions easier.

Real-Time Tracking and Data Collection

IoT lets factories track products and assets live. Sensors gather data about location, movement, and condition. This helps you decide quickly. For example:

Check inventory to avoid running out or having too much.

Track product conditions to keep quality during shipping.

Live updates make work faster and cut delays.

Tip: Pick IoT tools that work well with your current systems. This makes setup easier and more useful.

End-to-End Visibility in Supply Chains

IoT gives full visibility of supply chains. You can follow goods from raw materials to finished items. This helps find problems and fix workflows. For example:

IoT shows differences between actual and expected stock.

Tracking tools find delays in making or shipping products.

Monitoring tools check quality at every step.

This visibility helps reduce waste and fix issues faster. It keeps operations smooth and avoids big disruptions.

Enhanced Operational Efficiency

IoT makes supply chains better by automating tasks. Automatic data collection avoids mistakes and saves time. Here’s how:

IoT devices check production steps and find problems.

Predictive tools spot delays before they happen.

Alerts warn you about big issues so you can act fast.

These tools boost productivity and keep customers happy with on-time deliveries.

Benefits of IoT in Asset Tracking

IoT asset tracking has many benefits:

Accurate tracking stops losses and theft.

IoT tools help find misplaced equipment quickly.

Tracking improves how assets are used, cutting idle time.

For example, sensors track machine use. This data helps plan maintenance and avoid breakdowns. It also ensures machines are used properly.

Why IoT is Essential for Modern Manufacturing

Using IoT in factories is now a must to stay ahead. With industrial IoT, you can:

Make supply chains clearer.

Manage assets better.

Save money and increase profits.

IoT devices help you make smarter choices. They give insights to improve every part of your work.

Note: Choose IoT tools that match your business needs. This ensures you get the best results from your investment.

Key Considerations for Choosing Industrial IoT Hardware

Scalability and Future-Proofing

When picking IoT hardware, make sure it grows with you. Scalability lets you add devices as your business expands. Future-proofing ensures your tools stay useful as tech improves.

Think about these factors when choosing hardware:

Criteria | Description |

|---|---|

Scalability | Pick tools that grow with your needs and add features easily. |

Compatibility | Make sure tools work with your current systems to avoid issues. |

Security | Choose tools with strong security like encryption and updates. |

User-Friendliness | Go for easy-to-use tools to help workers adapt quickly. |

Support and Community | Check if the vendor offers help and has a strong user community. |

Pricing Models | Look at costs carefully to avoid hidden fees. |

Performance Metrics | Read reviews and case studies to see how well tools work. |

Testing Before Commitment | Try free demos or trials to see if tools fit your needs. |

By focusing on these points, your IoT hardware will meet your goals and adapt to changes.

Security and Data Protection in Industrial IoT Solutions

Keeping IoT systems safe is very important. You need to protect data and devices from hackers. Strong security, like encryption and updates, keeps your systems safe.

For example, IoT gateways often block unauthorized access. This protects factories from problems. Secure communication also keeps data safe while it’s being sent.

To improve security, limit access to trusted people only. Watch your systems for weak spots and fix them fast. By making security a priority, you can keep your operations running smoothly and safely.

Compatibility with Existing Systems

Connecting IoT hardware to old systems can be tricky. Check your current setup to find the best way to connect. You might need to update hardware or use adapters for older devices.

Steps to ensure compatibility:

Check old systems to see which devices can be upgraded for IoT.

Use ready-made parts to connect older devices to IoT networks.

Make sure old software supports updates and network connections.

Hire experts to upgrade old machines, but compare costs first.

For example, linking old PLCs (Programmable Logic Controllers) to the Internet improves operations. Using existing ports for IoT saves time and money. Fixing compatibility issues helps you get the most out of IoT in your factory.

Cost and ROI Analysis

Looking at the cost and ROI of industrial IoT hardware is important. You need to know how much it costs and what it gives back. This helps you get the most value and avoid wasting money.

Steps to Conduct Cost and ROI Analysis

You can use simple methods to check IoT hardware value. Here’s how:

Finding Opportunities and Setting Goals: Think about how IoT can help your work. Set clear goals like cutting downtime or saving energy.

Checking Costs: Look at all costs, like buying hardware and training workers. This shows the full price of the investment.

Measuring Results and Calculating ROI: Use numbers to see the benefits. Compare these to the costs to find the ROI.

Tip: Pick numbers that match your goals, like energy savings or faster production. This makes your analysis useful.

Balancing Costs and Benefits

When picking IoT tools, compare the cost now to future savings. For example, predictive maintenance tools may cost more upfront. But they save money by reducing downtime and fixing machines early.

Cost Factor | Description |

|---|---|

Hardware Costs | Price of sensors and devices |

Installation Costs | Cost to set up and connect systems |

Maintenance Costs | Money for repairs and updates |

Training Costs | Teaching workers how to use the tools |

By looking at these costs, you can find the best tools for your money.

Why ROI Analysis Matters

Checking ROI stops you from spending too much. It shows how IoT tools can save money and boost work. It also helps you find ways to cut costs, like using less energy. With a good analysis, you can choose tools that help your business grow.

Note: Keep checking your ROI to make sure your IoT tools still meet your needs as your business changes.

Emerging Trends in Industrial IoT Hardware in 2025

AI Integration in Industrial IoT Hardware Solutions

AI is changing how industries use IoT hardware. It helps predict problems and improve work. Sensors collect data from machines. AI studies this data to find patterns and warn about issues. Fixing problems early avoids delays and keeps systems running.

AI also makes asset tracking and maintenance smarter. Combining IoT data with AI creates better learning models. These models help improve decisions and make processes more efficient.

Evidence Type | Description |

|---|---|

Application | IoT helps with tasks like tracking assets and planning maintenance. |

Benefit | IoT data builds better AI/ML tools that improve industries. |

Tip: Choose IoT hardware with AI features for smarter systems and better results.

Advancements in Edge Computing for Industrial IoT

Edge computing processes data near its source, making it faster. This allows real-time decisions, which are important for industries. For example, edge devices check machine data locally. This helps you act quickly to fix problems.

It also saves bandwidth by sending only key data to the cloud. This lowers costs and reduces network traffic. Keeping data local improves security, protecting your systems from risks.

Faster Decisions: Real-time data helps industries act quickly.

Lower Costs: Less data sent to the cloud saves money.

Better Security: Local data stays safer from hackers.

Edge computing makes IoT systems quicker, safer, and more cost-effective. It’s shaping the future of industrial IoT.

5G Connectivity in IoT in Manufacturing

5G is transforming IoT in factories. It offers very fast response times, as low as 1 millisecond. This is great for controlling machines in real time. Its high speed lets many devices work together smoothly, improving smart factories.

With 5G, you can monitor systems remotely and automate tasks better. It’s perfect for jobs needing lots of data, like predictive maintenance. Stronger connections mean smoother work and higher output.

Fast response times allow precise machine control.

High speed supports instant data sharing between devices.

Remote monitoring improves efficiency and saves time.

Note: Use 5G-ready IoT hardware to prepare for smarter factories in the future.

Sustainable and Green Industrial IoT Hardware

Sustainability is now a big goal for industries. Using green IoT hardware helps the planet and boosts efficiency. These devices track energy use, cut waste, and lower emissions. They also promote eco-friendly habits, making operations greener.

Green IoT tools include energy-saving sensors, smart meters, and recyclable devices. These tools check resource use in real time to find waste. For example, smart sensors can track electricity use and suggest savings. This saves money and lowers your carbon footprint.

You can measure green IoT impact with specific metrics. These show how well your systems protect the environment. Here’s a table of key metrics:

Metric Type | Description |

|---|---|

Energy Use | kWh used for each product made |

Waste Levels | Amount of waste created and recycled |

Carbon Emissions | Greenhouse gas cuts and emission levels |

Tracking these metrics helps you reach eco-friendly goals. Watching energy use shows wasteful processes. Checking waste levels improves recycling efforts.

Green IoT tools also work with renewable energy. Solar-powered sensors and wind monitors make clean energy easier to use. This reduces fossil fuel use and supports long-term sustainability.

Choosing green IoT hardware helps the planet and your business. These tools improve your reputation with customers and partners. People value companies that care about the environment. Investing in green IoT is a smart and responsible choice.

Industrial IoT hardware, like sensors and gateways, has changed industries. These tools make work safer, faster, and more flexible. For instance, alerts can boost machine uptime by 1–2%. This saves millions each year. Better data also cuts labor costs and improves planning.

Impact Area | Benefit |

|---|---|

Safer Workplaces | Early IIoT tools, like gas detectors, lower accident risks. |

More Machine Uptime | Alerts improve machine use by 1–2%, saving big money. |

Higher Efficiency | Detailed data helps save on labor costs. |

Smarter Planning | IIoT data helps businesses adjust to demand changes. |

When picking hardware, focus on growth, safety, and compatibility. Many businesses (60%) face connection issues, losing billions yearly. With 30.5 billion IoT devices expected by 2025, secure and flexible tools are vital.

Insight | Value |

|---|---|

Percent of companies with connection problems | 60% |

Yearly cost of connection issues | Billions of dollars |

Expected IoT devices by 2025 | 30.5 billion |

Global IoT market size by 2025 | $1.06 trillion |

Industrial IoT market by 2025 | $275.70 billion |

Healthcare IoT market by 2025 | $534.3 billion |

Keep up with trends like AI and eco-friendly IoT tools. These updates protect your investments and help you succeed. By choosing wisely and staying flexible, you can lead in a smarter, safer future.

FAQ

What is Industrial IoT hardware?

Industrial IoT hardware includes tools like sensors, gateways, and edge devices. These tools gather and handle data to improve factory work. They help you watch systems, automate tasks, and make quick decisions.

How do IoT sensors improve factory efficiency?

IoT sensors check things like temperature, pressure, or movement. This helps find problems early, improve processes, and avoid delays. For example, sensors can spot overheating and turn on cooling systems.

Why is edge computing important for Industrial IoT?

Edge computing handles data close to where it’s made. This cuts delays, saves internet use, and keeps data safer. It helps factories make fast choices, which is key for real-time work.

How does 5G enhance IoT in manufacturing?

5G gives faster speeds and quicker responses for device communication. It improves automation, remote system checks, and early problem fixes. With 5G, more devices can connect easily, boosting factory output.

What should you consider when choosing IoT hardware?

Think about growth, compatibility, and safety. Pick tools that work with your current setup and can expand later. Look for hardware with strong security and regular updates to keep data safe.

Tip: Try free demos to see if the hardware fits your needs before buying.

See Also

The Role of PCBA in Elevating Today’s Electronics

Benefits and Drawbacks of Flex PCBA in Electronics

Achieving ITAR Compliance in PCBA Production Processes