Industrial PCB production is growing fast in 2025. The world will make $85.4 billion worth of PCBs. This is a 5.5% increase. AI servers, electric vehicles, and more mobile devices help this growth. The Asia-Pacific region is leading this change. Flexible and hybrid PCBs are now very important for new ideas in printed circuit boards:

Smaller size and stronger build help tough industrial places.

Better connections help smart factories and Industry 4.0 work better.

AI, automation, and new materials help PCBs work better and last longer. They also make PCB production more eco-friendly.

Key Takeaways

The industrial PCB market is growing quickly. Asia-Pacific leads this growth. People want more electronics, electric vehicles, and smart devices.

New PCB designs include flexible, rigid-flex, and 3D-printed boards. These boards help make products smaller and stronger. They also make products more reliable for cars and medical use.

Automation and AI help make PCBs faster. They also lower mistakes and make factories smarter.

Advanced materials and green processes help PCBs work better. These changes also protect the environment and support sustainability.

Nearshoring and strong supply chains help companies save money. They can react fast to changes and keep production steady.

PCB Trends 2025

Industry Growth

The world market for printed circuit boards is getting bigger in 2025. All regions are seeing growth, but some grow faster than others. The Asia Pacific region is the top area for industrial pcb production. China, India, and Southeast Asia make most of the pcbs. This region makes more than 80% of all pcbs in the world. India and Vietnam get new investments because of government support. China is still the biggest pcb maker. Thailand now makes more pcbs than the United States. It is the fifth-biggest pcb producer. North America and Europe are growing, but not as fast. The Middle East and Africa are behind because they do not have enough factories.

Note: Asia Pacific leads because people want more electronics and there are many factories.

The size of the pcb market shows how fast it is growing. The table below shows recent and future values:

Year | Market Size (USD Billion) | CAGR (%) | Notes |

|---|---|---|---|

2024 | 76.52 | N/A | Base year value |

2025 | 5.6 | Projected market size | |

2025 | 5.1 | Alternate projection | |

2035 | 117.5 | N/A | Mid-term projection |

2037 | 155.38 | N/A | Long-term projection |

The market is growing because more people want electronics, cars, healthcare, and telecom products. Smartphones and IoT devices are a big reason for this growth. The Asia Pacific market could be worth over $120 billion by 2033. This is because of more digital tools and better technology.

Market Drivers

Many things help the industrial pcb production market grow. More people want electronics like smartphones and smart home devices. This means more advanced pcb manufacturing is needed. IoT devices and 5G technology also make people want smaller and better pcbs. Cars with more electronics are another reason for growth.

Some main reasons for growth are:

More people want new electronics for homes, cars, planes, hospitals, and computers.

IoT devices, 5G networks, and smart gadgets are growing fast.

New technology like automation, miniaturization, high-density interconnects, and multi-layer pcb designs.

Rules for cleaner factories and lead-free processes.

More electric vehicles and renewable energy systems.

More companies use electronic manufacturing services and outsourcing.

Industry 4.0 uses IoT and AI to make factories smarter.

Smartphones and IoT devices change pcb trends. These devices need more electrical and communication parts. This means more pcbs are needed. PCBs are the base for circuits and connections in smart devices. Cars that connect to smartphones also need more pcbs. The communication sector is the biggest market because of new smartphones.

New technology changes how pcbs are made. Smart factories use IoT sensors and AI for better and faster work. Additive manufacturing and 3D-printed pcbs help make new shapes quickly. Materials like ceramic-filled polymers and graphene help with heat and electricity. Flexible, wearable, and stretchable electronics are used in medical devices and small gadgets. People are also trying to recycle metals and use materials that break down naturally.

Making pcbs smaller and with more connections has changed the industry. Small parts and more connections mean more things can fit in less space. HDI pcbs use microvias and fine lines for more connections. Surface mount technology helps use very small parts and keeps signals strong. Rigid-flex and flexible pcbs can bend and move, making them good for new shapes and lighter products. Good materials and careful machines are needed for strong and reliable pcbs.

Tip: Companies should work with skilled manufacturers to solve problems with small pcbs and stay ahead.

New trends like 3D pcb printing, built-in parts, and AI design help make pcbs smaller, stronger, and use less energy. In the future, pcb design will focus on being green, using more robots, and working in new things like wearables and bio-devices.

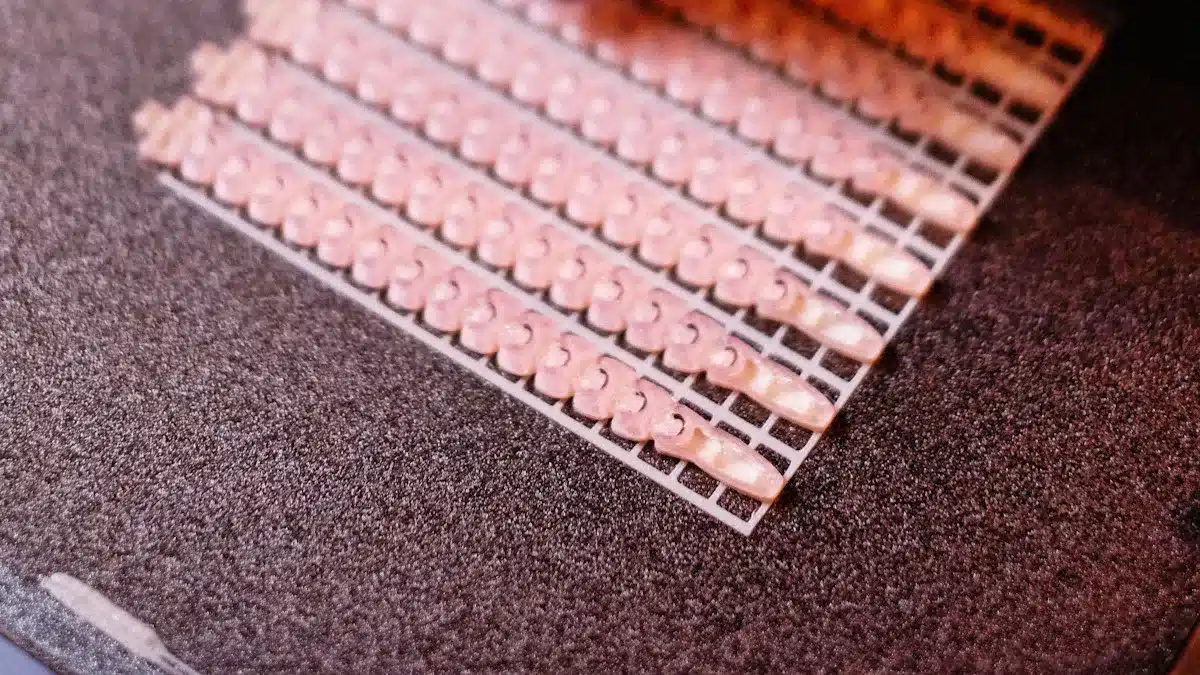

Hybrid and Flexible PCBs

Rigid-Flex Designs

Rigid-flex designs have changed how people make industrial pcbs in 2025. These circuits mix rigid, flexible, and stretchable pcbs together. This helps them give support and also move when needed. Engineers use air gaps to keep electricity safe. They use controlled impedance to keep signals steady. EMI shielding and stiffeners help protect and strengthen the pcbs.

New materials like liquid crystal polymers, conductive inks, and advanced composites help with heat and chemicals.

Nanotechnology and flexible electronics make parts thinner, lighter, and save more energy.

High-density interconnect technology and built-in parts let layouts be small and reliable.

3D pcb printing and optical interconnects help make new shapes and move data fast.

Industries like aerospace, automotive, and medical use these rigid-flex designs. They work well in tough places. These pcbs are small, strong, and work well even in hard conditions. Makers also try to be green by using halogen-free and bio-based materials.

Note: Industry 4.0 helps check quality right away and makes production faster and better.

Wearable Applications

Flexible and stretchable pcbs are important for new industrial wearables. These pcbs bend and fit the body. This lets devices fit well and keep good connections. Workers get better data and health checks all the time.

Flexible and stretchable pcbs can handle lots of bending, moving, and changes in heat or wetness.

Small designs let smartwatches and fitness bands have many sensors and safety tools.

High-density interconnects help small devices do many jobs.

Special materials and ways of making them keep these pcbs strong in hard places.

These pcbs keep signals clear and use power well, which is very important. Industrial wearables now help keep workers safe, watch their health, and make work better. Because these pcbs are light and thin, they are good for daily use in tough jobs.

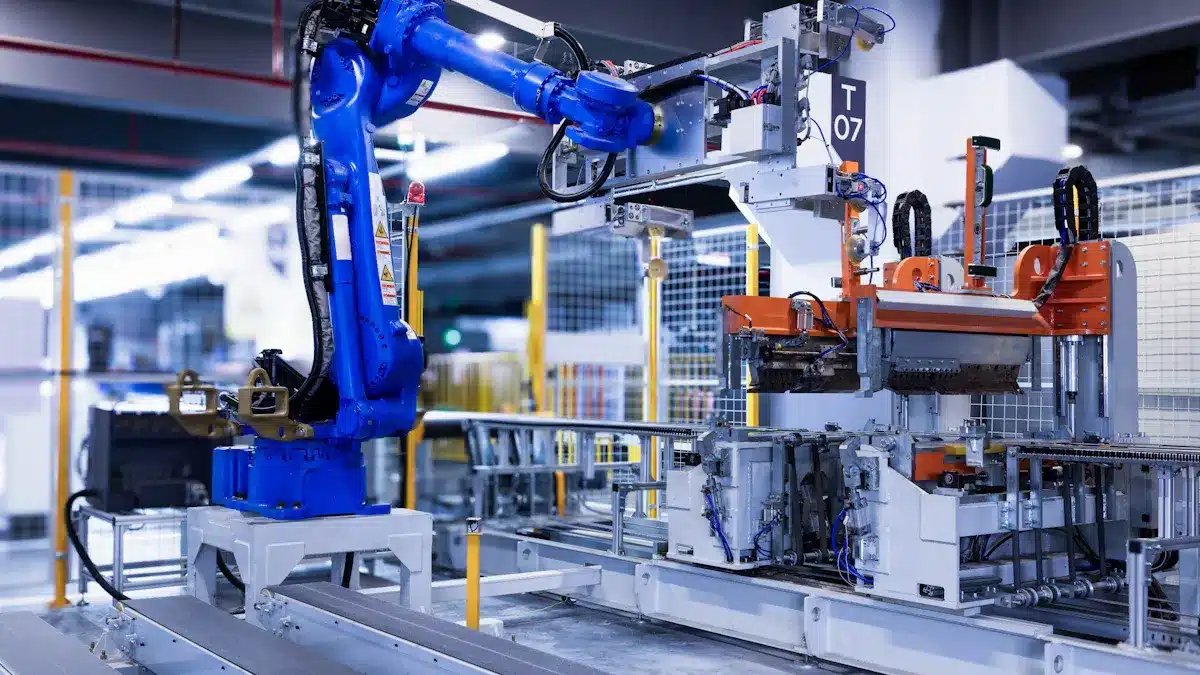

Automation in PCB Manufacturing

Smart Factories

Smart factories are changing how people make pcbs in 2025. These factories use machines, IoT sensors, and live data to help every step. Companies get many good things from smart factories:

They work faster by letting machines do jobs and change lines quickly.

They save money by using data to set up machines, waste less, and use tools better.

They make things faster by fixing slow spots with systems that react quickly.

They make products better and the same each time by following set steps.

They build teams of machines that work together and share jobs.

Smart factories also use special checks to stop machines from breaking. IoT sensors watch the machines and help stop surprise problems. This keeps pcb making going without stopping. Machines do hard jobs so people stay safe and make fewer mistakes. These factories can make more or less pcbs fast to match what people want. Watching machines and checking data helps see how well things work. Robots and machines put parts together very carefully and quickly.

Tip: Smart factories help companies see and fix problems faster and easier.

AI Integration

AI is making pcb making quicker and more steady. AI uses robots to move parts, which helps sort and place them fast. Smart systems watch parts all the time and help save space and money. AI checks how things are made and changes things right away to keep them good.

AI helps plan repairs before machines break. Special robots do the same job over and over so people can do harder work. AI cameras look at pcbs and find mistakes like parts in the wrong place or cracks. These cameras find problems faster and better than people.

AI also helps bring parts on time and keeps track of supplies. It makes pcb design faster by looking at old designs and giving new ideas. AI learns from checking pcbs and gets better, so there is less waste and better products. There are some problems, like high costs and needing skilled workers, but AI helps factories work better and make good pcbs.

Advanced Materials

Performance Enhancements

Engineers in 2025 use advanced materials for high-frequency jobs. These materials help pcbs work better in hard places. They also support new things like 5G and car radar. The table below lists important materials and what they do:

Advanced Material | Application / Purpose | Supporting Details |

|---|---|---|

PTFE (Polytetrafluoroethylene) | High-frequency pcbs for 5G and automotive radar | Low dielectric loss, stable at high frequencies |

Specialized Laminates | High-frequency pcb designs | Used in 5G infrastructure and radar systems |

Polyimide and Polyester | Flexible and stretchable pcbs | Allow bending and flexing without losing function |

Metal Core PCBs (MCPCBs) | Thermal management in high-power applications | High thermal conductivity, ideal for LED and EV charger pcbs |

Biodegradable Cellulose-based | Sustainable pcb substrates | Lower environmental impact, recommended by AI-driven design |

Rogers Laminates | High-frequency pcb designs | Very low dielectric loss, used in advanced pcb designs |

Special substrates like high temperature co-fired ceramic help with heat. Organic polymer laminates make pcbs stronger. These materials help pcbs last longer by stopping heat and signal loss. Engineers use flip-chip bonding and through-silicon vias for small, packed designs. These ways lower stress and make pcbs tougher. Moisture-resistant coatings protect pcbs in wet or rough places. This makes them good for factories and other hard jobs.

Sustainability in PCB Manufacturing

Sustainability is now very important in pcb making. Companies use eco-friendly materials like bio-based polyimides and halogen-free laminates. These new materials work as well as old ones. Bio-based polyimides can handle high heat, so they are good for car electronics. Halogen-free laminates keep signals strong even when things move fast.

Factories also try to save energy. They use systems that watch energy use during drilling and soldering. This helps them find waste and fix it fast. Many factories use laser etching and low-energy ways to put parts together. They recycle etchant solutions and use smart meters to check energy use. Checking machines often helps stop energy waste.

Note: Biodegradable pcbs made from natural fibers have a smaller carbon footprint and help make production carbon-neutral. These are best for short-term or throwaway electronics, but new plant-based materials are getting stronger.

Recycled copper is now used in many pcbs. It works well and helps the environment. Using surface-mount technology also saves energy and makes pcbs more reliable. Because of these changes, the industry is getting closer to real sustainability while keeping good performance and reliability.

Additive Manufacturing

3D-Printed PCBs

Additive manufacturing is changing how companies make pcbs in 2025. 3D-printed pcbs let engineers build special shapes and layouts. Old ways cannot do this. Companies use 3D printing to make test pcbs fast. They do not have to wait weeks for samples. This technology is better for the environment. It uses less material and makes less waste.

3D-printed pcbs are strong and light. They last a long time. They work well in tough places.

CAD files help engineers design flexible pcb shapes.

New 3D printing uses hollow traces and special materials. This gives more ways to design.

Industries like cars, medical devices, and telecom use these pcbs. They can make new products quickly and when needed. The cost of 3D printing pcbs is lower now. Companies use it for more than just testing. There are still some problems. Build sizes are limited. Some materials do not conduct well. Even with these problems, 3D-printed pcbs help companies sell products faster. They also help new uses like diagnostics and LED lighting.

Tip: 3D printing is best for small batches or custom pcbs. It is not good for making lots at once.

Low Volume Assembly

Additive manufacturing helps clients who need only a few pcbs. This way makes less waste and speeds up testing. Engineers can build hard 3D pcb shapes. Old methods cannot do this. This leads to better designs and more useful pcbs.

Companies can make special holders for small batches.

Making spare parts when needed is easier. This saves time.

Flexibility and custom designs get better. This helps industries with special needs.

Additive manufacturing lets companies change quickly when demand changes. They can make printed pcbs when needed. This saves time and money. This way helps new ideas and keeps businesses strong in a fast market.

Sustainability in PCB Manufacturing

Green Processes

Manufacturers now care more about green processes. They want to make pcb manufacturing better for the planet. They use eco-friendly materials to keep people and nature safe. Lead-free soldering is used instead of lead-based solders. Halogen-free pcbs help lower bad gases when thrown away. Many companies pick biodegradable paper-based laminates, bioplastics, and recycled materials for substrates.

Factories try to make less waste and recycle more. They use closed-loop systems to recycle copper and chemicals. PCB recycling programs help get back valuable metals. Advanced wastewater treatment, like reverse osmosis and biological treatment, keeps water clean and safe.

Energy-saving manufacturing is also important. Companies use LED-based curing systems and ovens that save energy. Some factories use solar or wind power to lower their carbon footprint. Green design helps too. Engineers design pcbs so they are easier to recycle, use less material, and avoid harmful chemicals. Modular designs help take products apart at the end of their life.

🌱 Companies using these green processes are leaders in sustainable pcb assembly and set new standards for others.

Regulatory Trends

Regulatory trends change how companies think about sustainability. Many countries now want lead-free solders, like SAC alloys, to follow RoHS rules. Halogen-free laminates are becoming normal to lower toxicity. The industry knows hazardous materials and e-waste cost a lot. This makes better recycling and sustainable design more important.

PCB makers must follow global green standards. These include RoHS, which bans lead, mercury, and other dangerous substances. ISO 14001 gives rules for managing the environment. REACH makes sure chemicals are used safely in production. Meeting these standards builds trust with clients who want eco-friendly products.

Governments make stricter rules. The EU, China, and the U.S. have laws to limit pollution and require safer processes. Not following rules can mean fines and lost business. Circular economy practices are growing. Companies fix old boards, recover metals, and work with clients to recycle old pcbs. New certifications, like IPC-1401, set goals for sustainability. Carbon tariffs may soon add costs for non-sustainable imports.

🏆 Companies that follow these trends get an advantage and help protect the planet for the future.

IoT and Connectivity

Smart PCBs

Smart pcbs are very important for industrial IoT systems. Engineers make these boards for fast communication. This lets them send data right away with little signal loss. They use strong ways to put the boards together, like special coatings and good soldering. This helps the boards work well in tough places. Many smart pcbs have sensors inside. These sensors check temperature, pressure, vibration, and humidity. They help factories watch machines and know if something might break soon.

Microcontrollers on the board handle data close by. This makes things faster and uses less internet. Power circuits help save energy and make batteries last longer. Wireless modules like Wi-Fi, Bluetooth, Zigbee, and LoRaWAN send data without lots of wires. This makes it easier to fix problems before they happen and keep workers safe.

Smart pcbs link machines, sensors, and controls. This helps factories work better and react quickly.

5G Integration

5g technology has changed how factories connect. Pcbs for 5g must work with higher frequencies, even millimeter waves. Engineers pick materials that lose less signal and keep data moving fast. They also use materials that move heat away so the boards do not get too hot.

Designers use new ways, like Any-Layer HDI and built-in parts, to make small and packed circuits. These ways let them add more antennas for MIMO, which is needed for 5g. Shields keep signals safe from other signals in busy places.

PCB designers and RF engineers work together to meet FCC EMC rules. Special computer tools check how 5g signals act. New cooling tricks, like thermal vias and metal core boards, help with more power. These ideas help pcbs stay ready for new 5g needs.

Factories with 5g-ready pcbs get faster and safer connections. This helps them use more robots and make quick choices.

Future Strategies

Nearshoring

Nearshoring is now a top plan for pcb companies. They move factories closer, like from Asia to Mexico or the U.S. This helps them spend less on shipping and get products faster. Companies can react quickly when the market or customers change. Mexico is a popular place for nearshoring. It is close by and has skilled workers. Trade deals like USMCA lower taxes and fees. These things make making pcbs cheaper overall.

MacroFab and Micro Technology Services, Inc. show nearshoring works well. They make products faster and check quality better. Customers also get more protection for their ideas. This is important for defense and other special markets. Nearshoring stops delays from far-away shipping and talking. Products go from factory to customer in hours or days. This helps companies keep up with fast changes in the world.

Nearshoring lets companies save money, control work, and protect their designs.

Supply Chain Resilience

PCB makers now want strong supply chains. They use many ways to stay ready if problems happen:

They buy parts from different places to avoid local trouble.

They keep extra parts so they do not run out.

They design pcbs to use other parts if needed.

They use tools to guess what people will want months ahead.

They make deals with suppliers for good prices and early news.

They mix just-in-time and backup parts for important items.

They watch world news to change buying plans.

They use tech for quick updates on supply chain status.

Makers also check if suppliers are good and deliver on time. Many now buy parts nearby to lower risks and fill orders faster. Digital tools like AI and blockchain help track shipments and find problems early. These plans help pcb companies stay flexible and ready for anything.

Industry experts see many big changes coming for pcb design. The table below shows the most important new ideas:

Trend / Technology | Impact in 2025 |

|---|---|

Miniaturization & HDI | Smaller, denser boards for wearables and IoT |

Flexible and Rigid-Flex PCBs | Essential for automotive, aerospace, and medical devices |

Embedded Components | Improved reliability and performance for 5G and IoT |

Advanced Materials | Better heat resistance and signal integrity |

Environmentally Friendly PCBs | Lead-free, recyclable, and sustainable production |

Faster design, fewer errors, and predictive maintenance |

Manufacturers can get ahead by using lean manufacturing and green materials. AI-driven automation helps make work faster and better. Quick-turn prototyping and smart factories help teams try new things and keep up with changes. Companies should check suppliers, use digital tools, and design strong products. These steps help keep supply chains safe and help businesses last in the changing pcb world.

FAQ

What are the main benefits of using flexible PCBs in industry?

Flexible PCBs can bend and fit into small spaces. They make devices lighter and stronger. Many companies use them in wearables, cars, and medical tools.

How does AI improve PCB manufacturing?

AI helps factories work faster by checking PCBs and spotting problems. It lowers mistakes and waste. AI also helps people make better designs and quick choices.

Why is sustainability important in PCB production?

Sustainability helps protect the environment. Companies pick eco-friendly materials and save energy. This meets rules and helps customers trust green products.

What challenges do manufacturers face with 3D-printed PCBs?

Manufacturers have trouble with material types and size limits. Some 3D-printed PCBs do not carry electricity as well as old ones. These problems can hurt how well PCBs work.

How does 5G technology affect PCB design?

5G needs PCBs that work with high frequencies and more antennas. Engineers use better materials and new designs. These changes keep signals strong and help control heat.

See Also

Emerging Innovations Shaping PCB And PCBA Manufacturing

The Importance Of Tailored PCBA Production In Electronics

Best Practices To Boost Quality And Efficiency In PCBA