An industrial robot controller PCBA is like the robot’s “brain.” It controls how the robot moves and works. It helps robots follow instructions and do tasks correctly. The PCBA manages speed, movement, and reactions, making automation smooth in factories.

This technology is important for better manufacturing accuracy. For example, six-axis robots in AOI inspection can check over 700 PCB boards per shift. They replace manual work and save time. SCARA robots check circuit board coils, reducing mistakes and working faster. These tools show how PCBA improves factory work and product quality.

Using this system in robots boosts productivity and makes workplaces safer. It reduces human work in boring or dangerous jobs. This technology is key for modern industries to work faster and more precisely.

Key Takeaways

An industrial robot controller PCBA is like the robot’s brain. It controls movements and tasks to work better and faster.

Robots with PCBA help industries, like manufacturing and cars, work safer and more accurately.

PCBA makes upgrades simple and lets factories change easily for new needs.

Robots using PCBA cost less to run and need less fixing. This saves money over time.

Strong PCBA designs work well in hard factory conditions. They reduce breaks and make work smoother.

What is an Industrial Robot Controller PCBA?

Definition and Overview

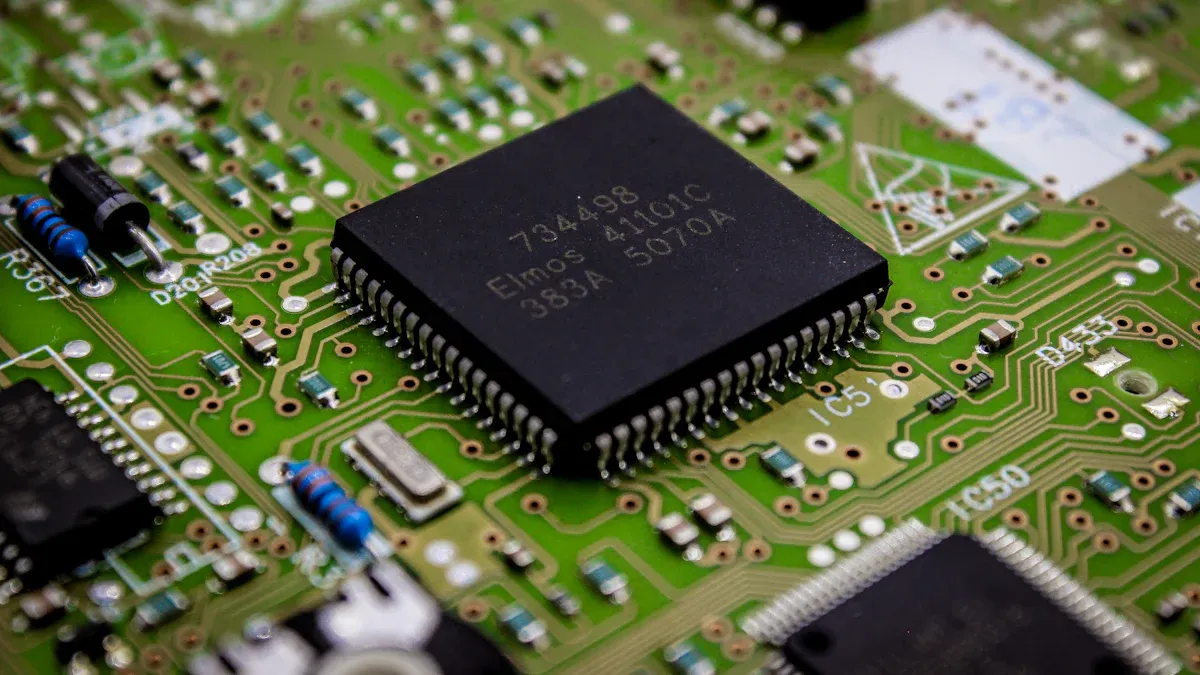

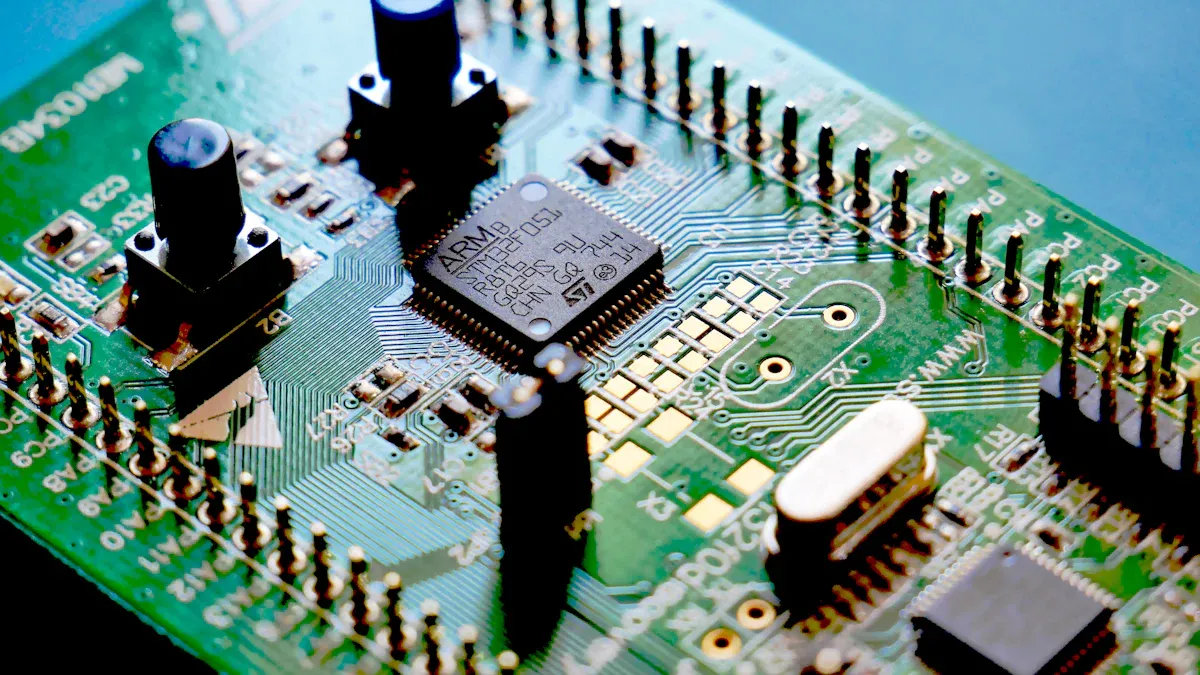

An industrial robot controller PCBA is the robot’s main control system. It works like a “brain” to guide the robot’s movements and tasks. This system combines small electronic parts, like processors and memory chips, on one board. These parts work together to make sure the robot runs smoothly and correctly.

Robotics PCBA has improved over time with better technology. Now, robots can do harder jobs faster and more accurately. For example, newer PCBA designs use advanced boards and better signal paths. These upgrades help robots perform well in industries like car-making, electronics, and food production.

Here’s a table showing the benefits of this technology:

Key Benefit | Description |

|---|---|

Increased Throughput | Robots work fast and handle lots of tasks nonstop. |

Enhanced Precision | Robots place parts exactly right, reducing mistakes. |

Improved Quality Control | Robots check products carefully and catch problems early. |

Cost Efficiency | Robots save money over time by working efficiently. |

Flexibility | Robots can be reprogrammed quickly for new tasks. |

This table shows how PCBA helps robots work better and adapt to changes, making it vital for modern automation.

Key Features and Characteristics

Industrial robot controller PCBA is strong and built for tough factory conditions. Below are some important features:

Environmental Adaptability

The PCBA can handle heat, moisture, and vibrations. Special materials and coatings protect it from damage. Flexible adhesives and nano-coatings keep it safe in harsh environments.Signal Integrity Assurance

The PCBA uses advanced methods to keep signals clear and accurate. It reduces signal problems and ensures stable communication between the robot and controller.Thermal Management Innovations

Good heat control is key for PCBA to last long. Copper and graphene parts help cool it down. In high-power robots, liquid cooling is used to prevent overheating.Integration with Robotic Systems

The PCBA connects easily with robots using communication systems like CAN and EtherCAT. This lets robots move precisely and adjust quickly to changes.

Countries like South Korea and Vietnam are using more robots because of rising costs and automation needs. These features show why industrial robot controller PCBA is important for improving robot technology and factory work.

How Does an Industrial Robot Controller PCBA Work?

Core Components of the PCBA

The industrial robot controller PCBA has key parts that make it work like the robot’s “brain.” Each part helps the robot move and work correctly.

Microprocessors and AI Chips: These parts decide what the robot should do. They take data from sensors and send commands for movement. AI chips help robots make quick decisions for hard tasks like controlling motion.

Embedded Components: Small parts like capacitors and resistors are built into the PCBA layers. This saves space and makes the board stronger. Strong boards are important for robots that move a lot, like humanoid robots.

Communication Modules: Systems like EtherCAT and CAN let the robot and controller talk to each other. These modules send data fast, which is needed for real-time control.

Power Management Systems: Power modules in the PCBA save energy and keep signals clear. This is important for robots that work all day in factories.

These parts work together to make a strong system for industrial robots.

Functionality and Processes

The industrial robot controller PCBA turns sensor data into commands for the robot. Here’s how it works:

Data Collection: Sensors gather details about the robot’s surroundings, like object locations.

Signal Processing: The PCBA cleans up the signals to make them clear and accurate. Special technologies reduce signal problems like interference.

Command Execution: The controller sends instructions to the robot’s arm or other parts. This makes sure movements are smooth and correct, like assembling items or checking products.

Continuous Operation: Robots with PCBA can work nonstop, doing repeated tasks quickly. This helps factories work faster and better.

These steps help robots work more accurately, improve product quality, and make workplaces safer. For example, six-axis robots are great for detailed tasks like optical inspections.

Integration with Industrial Robots

Connecting PCBA to robots improves how they work and adapt to changes. This link lets robots act quickly and do tasks precisely.

Benefits of Integration:

Cuts down signal problems, making robots respond better.

Makes robots stronger for movements like walking or bending.

Combines controllers, sensors, and power systems into one setup for better efficiency.

Sends data fast between sensors and controllers for real-time updates.

Helps controllers and robot arms work together for accurate movements.

Speeds up robot actions by improving communication between parts.

For example, IoT-enabled PCBA lets robots collect live data, making them smarter and faster. This is useful in industries like car-making and electronics, where speed and accuracy matter most.

The industrial robot controller PCBA is the main system that helps robots work well and adjust to automation needs.

Applications of Industrial Robot Controller PCBA

Manufacturing and Assembly Lines

Robots with controller PCBA have changed factory work. They do tasks like assembling, welding, and checking quality with great accuracy. For example, Toyo Electric Corporation used robots to mount circuit boards. This improved speed and reduced mistakes. It shows how robots make production faster and better.

Modern factories use robot flexible assembly cells (RFAC) for more flexibility. These systems let robots switch tasks quickly without much human help. This is helpful for industries like electronics and cars that often change production needs. Adding robot controllers speeds up work and makes factories more efficient.

Automotive Industry

Car-making depends on robots for welding, painting, and putting parts together. Small robot controllers help robots move precisely and work well. Companies like Toyota and BMW use welding robots to make cars faster and better. Robots also lower costs while improving quality.

Electric cars and self-driving technology need advanced robots even more. The compact robot controller market was worth $2.5 billion in 2023. By 2032, it may grow to $5.8 billion. This shows how important robots are for the future of car-making.

Electronics and Semiconductor Production

Making electronics needs very careful work, so robots are a big help. Companies like Foxconn and Samsung use robots with controller PCBA for assembly and soldering. Robots handle tiny parts carefully to avoid damage. In chip-making, robots work in cleanrooms to keep everything sterile.

Robots also work nonstop, which helps meet high demand for electronics. This keeps production fast and quality consistent. Using robot controllers gives manufacturers an edge in making better products quickly.

Logistics and Warehousing

Robots with controller PCBA have changed how warehouses work. They handle tasks like sorting, picking, and stacking items. These robots work nonstop, making jobs safer and needing less human effort.

Automation helps warehouses move goods faster and cheaper. Robots sort packages by size or destination, speeding up deliveries. This reduces costs and helps meet tight schedules.

Robots with PLC-based controls work well with existing systems. Many workers already know how to use PLCs, so training is easier. These controls are chosen for their cost, features, and availability. They are great for busy warehouses needing speed and accuracy.

Using robots in logistics improves inventory tracking and keeps businesses competitive.

Food Processing and Packaging

Robots with controller PCBA help pack food quickly and safely. They do jobs like slicing, sorting, and packing without harming the food. These robots keep everything clean and consistent, which is very important.

Robots work in clean spaces to follow health rules. Their controllers make sure movements are gentle to avoid breaking items. For example, robots can pack eggs or baked goods carefully.

These systems can be used for small or big operations. Robots can be reprogrammed to handle new packaging designs or products. This saves time and helps meet changing customer needs.

Using robots in food processing makes work faster and improves product quality. They are a smart choice for modern factories.

Advantages of Using PCBA in Industrial Robot Controllers

Better Precision and Efficiency

Robots with PCBA work very precisely. The PCBA reads sensor data and sends clear commands to robot arms. This helps robots do tasks like welding or checking products with fewer mistakes. For example, robots can place tiny parts on circuit boards perfectly. This accuracy reduces waste and makes better products.

PCBA also makes robots work faster and longer. Robots don’t get tired, so they keep working the same way all day. AI chips in the PCBA help robots move smarter and quicker. This mix of precision and speed is very useful in factories like car-making and electronics.

Easy to Change and Expand

PCBA lets you change and grow robot systems easily. You can add new parts or upgrade old ones without replacing everything. This is helpful for factories that often need new setups.

More companies are using flexible systems now. Since 2021, over 35% of new factory setups use these designs. Also, advanced software tools are in 62% of factories, cutting setup time by up to 60%.

Evidence Description | Statistic/Impact |

|---|---|

Drop in sales for basic software providers | |

New setups using flexible systems | Over 35% since 2021 |

Faster setup times with sensor upgrades | 40-60% faster than older systems |

More money from add-ons and custom parts | 48-55% for top suppliers, up from 32% in 2018 |

This flexibility keeps robot systems ready for future changes and needs.

Saves Money in Automation

PCBA helps save money in factories. Robots with PCBA need less fixing because they are built strong. This means less downtime and longer-lasting machines.

PCBA also uses energy wisely. Its power systems make sure robots only use what they need. This saves money, especially in big factories where energy costs are high.

You don’t have to buy new systems often with PCBA. You can just upgrade parts to make robots better. This saves money and reduces waste, which is good for the environment.

Using PCBA gives you high performance while keeping costs low. It’s a smart choice for modern factories.

Reliability and Durability

Industrial robots need strong PCBA to work well for a long time. These systems are built to handle long hours without breaking. They are made to last, even in tough factory conditions like heat and vibrations.

The PCBA’s durability comes from its materials. Makers use tough parts like copper and fiberglass to prevent damage. Special coatings protect the board from dust and moisture. These features help the PCBA stay reliable in hard-working industries.

Reliability also depends on how the PCBA handles data. It keeps communication smooth between sensors and the controller. This lowers mistakes and helps robots work better. For example, robots with strong PCBA can run for months on assembly lines without repairs. This saves time and money while keeping work going.

Managing heat is another key factor. Heat can harm electronics, but cooling systems stop overheating. Liquid cooling or heat sinks keep the PCBA safe during heavy tasks. This makes the controller dependable for long-term use.

Robots with durable PCBA last longer and need less fixing. This improves factory efficiency and reduces downtime, helping you meet production goals easily.

The industrial robot controller PCBA is the main system for robots. It helps robots do tasks accurately and efficiently. By handling data and giving commands, it keeps automation running smoothly. This technology is used in many industries, like manufacturing, cars, and food. Robots make work faster and safer in these fields.

This technology has a big impact. Research shows advanced controllers increase production and lower costs. For instance, AI systems help robots work faster and make fewer mistakes. This makes automation more useful and reliable.

Advantage/Application | Description |

|---|---|

Efficiency | Robots speed up processes, increasing production and saving time. |

Safety | Robots handle risky jobs, keeping workers safe from harm. |

Cost-effectiveness | Automation lowers costs by reducing waste and needing fewer workers. |

Precision | Robots are very accurate, which helps with quality control in factories. |

The industrial robot controller PCBA is key to modern automation. It boosts accuracy, saves time, and helps create new ideas in robotics, shaping the future of industries.

FAQ

1. What does PCBA mean in industrial robots?

PCBA stands for Printed Circuit Board Assembly. It is an electronic board with parts like processors and memory chips. These parts help control how robots move and do tasks.

2. How does PCBA make robots better?

PCBA helps robots work faster and more accurately. It manages power well and processes data quickly. This reduces mistakes and makes robots more productive.

3. Can PCBA survive tough factory conditions?

Yes, PCBA is made to last in factories. It uses strong materials like copper and fiberglass. Protective coatings keep it safe from heat, moisture, and vibrations.

4. Why is PCBA important for automation?

PCBA is like the robot’s “brain.” It helps robots do hard and repeated jobs. This saves human effort, improves efficiency, and keeps quality consistent.

5. Are robots with PCBA affordable?

Yes! Robots with PCBA cost less to fix and use less energy. You can upgrade parts instead of buying new systems. This saves money and helps the environment.

💡 Tip: Using PCBA robots can make your factory faster and save money over time.

See Also

Understanding PCBA: Its Definition and Significance Unveiled

Exploring PCBA in Electronics: Importance and Applications

Defining PCBA: Its Essential Function in Electronics

PCBA Manufacturing Explained: Importance in Modern Technology