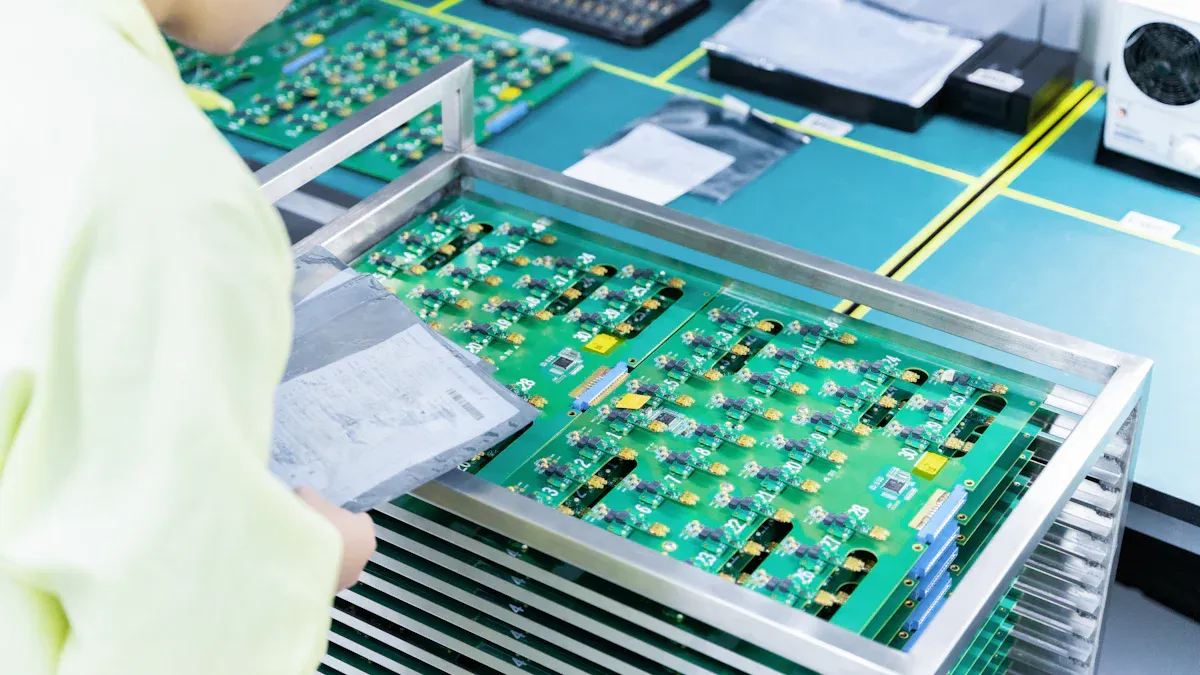

Industry 4.0 has changed how we do modern manufacturing. It uses smart tools to make circuit board assembly better. These tools improve speed, quality, and how much you can produce.

You can watch production live with real-time tracking. Predictive maintenance stops problems before they happen. Automation makes work faster and reduces mistakes.

With Industry 4.0 PCBA services, you can stay ahead in a fast-moving market. These tools help you handle more work while keeping great quality. Using Industry 4.0 keeps your business strong and ready for the future.

Key Takeaways

Industry 4.0 uses smart tech like IoT, AI, and robots. These tools make production faster and lower errors.

Live tracking lets you watch production as it happens. This helps fix problems quickly and keeps work running smoothly.

Automation in PCBA makes production 30% faster and cuts costs by 15%-20%. This helps businesses meet customer needs better.

Predictive maintenance stops machines from breaking by fixing them early. This saves time and keeps machines working longer.

Industry 4.0 tools make scaling and customizing easier. You can quickly change production to fit client needs without losing quality.

Understanding Industry 4.0 in PCBA Services

Key technologies like IoT, AI, robotics, and data analytics

Industry 4.0 uses advanced tools to improve PCBA processes. These tools include IoT, AI, robotics, and data analytics. Each one helps make manufacturing faster and better.

IoT (Internet of Things) links devices for smarter production. It lets you watch operations live and fix issues quickly.

AI (Artificial Intelligence) helps with smart decisions. It studies data to find problems before they happen.

Robotics does repeated tasks quickly and accurately. This lowers mistakes and boosts productivity.

Data analytics shows useful information about operations. It helps you spot patterns and improve processes.

Technology Type | What It Does |

|---|---|

IoT | Connects devices for smarter and faster manufacturing. |

AI | Helps predict problems and make better decisions. |

Robotics | Speeds up tasks and reduces errors in production. |

Data Analytics | Gives insights to improve how things are done. |

These tools solve problems like handling complex factories and saving money. They also help businesses adapt to changes while staying reliable and cost-effective.

Integration of smart manufacturing in PCBA processes

Smart manufacturing combines these tools into PCBA workflows. IoT sensors check every production step for accuracy. AI finds defects or slowdowns by studying data. Robotics handles assembly with care, and data analytics gives tips for better results.

For example, IoT devices can warn about machine problems early. This lets you fix them before they break. AI can plan production schedules to avoid delays. Robotics ensures high-quality work, even for tricky designs. Data analytics shows how to improve performance.

Using smart manufacturing means better speed, quality, and flexibility. It helps meet customer needs and stay competitive worldwide.

Transition from traditional to Industry 4.0-driven PCBA

Switching from old methods to Industry 4.0 PCBA is a big change. Older ways often depend on manual work and outdated tools. These methods can’t keep up with today’s fast and complex demands.

Industry 4.0 fixes these issues with advanced technologies. IoT connects machines into one system. AI studies lots of data to give helpful advice. Robotics automates tasks, making fewer mistakes and more products. Data analytics turns raw data into useful ideas for decisions.

Many companies are still starting with Industry 4.0. McKinsey says factories make tons of data yearly. But it’s hard to use this data because there’s so much of it. Moving to Industry 4.0 needs money and training.

By adopting this change, you can solve these problems and find new chances. Industry 4.0 PCBA helps you make great products faster and easier. This shift keeps your business strong and ready for the future.

Benefits of Industry 4.0 PCBA Services

Enhanced production efficiency through automation

Automation helps make PCBA manufacturing faster and more efficient. It replaces manual work with smart tools like robots. These tools speed up production and reduce mistakes. Industry 4.0 uses robotics and digital twins to improve workflows. This means you can make more products quickly while keeping quality steady.

The results of automation are clear. Companies using Industry 4.0 tools see 30% faster production. Deliveries are on time 98% of the time. Costs per unit drop by 15%-20%. Also, fewer defects mean yield rates reach up to 95%.

Metric | Improvement |

|---|---|

Production Efficiency & Throughput | 30% faster than older methods |

Delivery Timelines | 98% on-time delivery |

Cost Per Unit | 15%-20% lower costs |

Quality Control & Defect Reduction | Yield rates up to 95% |

Using automation helps you save money and meet customer needs. It makes PCBA manufacturing better and ready for future challenges.

Improved quality control and defect detection

Industry 4.0 changes how quality checks are done in PCBA. Automated tools use machine learning and computer vision to find defects fast. These tools are very accurate, spotting 90% of problems, much better than old methods.

Digital twins and real-time data help track production steps. They find issues early, so you can fix them before they grow. Automated systems also adjust inspection settings for better results. This reduces waste and boosts productivity.

Automated tools find defects quickly and accurately.

Machine learning improves defect detection to 90%.

Real-time data helps fix problems early.

Better inspections mean less waste and more productivity.

By using these tools, you can make high-quality PCBs that meet today’s strict standards.

Real-time monitoring and predictive maintenance

Real-time monitoring is key in Industry 4.0 PCBA services. IoT sensors and digital twins let you watch production all the time. You can see problems right away and fix them fast. This avoids delays and keeps things running smoothly.

Predictive maintenance goes further by using data to predict machine issues. Instead of waiting for a breakdown, you can fix machines early. This saves time, reduces downtime, and makes equipment last longer. It also helps use resources wisely, making operations more efficient.

Tip: Real-time monitoring and predictive maintenance are must-haves for modern manufacturing. They help cut costs, improve efficiency, and keep up with industry demands.

By using these tools, you can keep your PCBA processes reliable and efficient. This prepares your business for success in the Industry 4.0 era.

Scalability and customization for diverse client needs

Industry 4.0 tools have changed how we handle scalability and customization in PCBA. These tools help you adjust to new demands while keeping quality high. Whether making a few prototypes or producing many items, Industry 4.0 makes it easier.

How Industry 4.0 Enables Scalability

Scalability means you can change production size without losing quality. Factories with IoT and robots can quickly adjust production lines. For example, IoT sensors check machines to improve workflows. Robots do repeated tasks, so large orders are faster to complete.

Digital twins are virtual copies of your production process. They let you test changes before using them. This lowers risks and makes scaling up or down smoother. With these tools, you can meet deadlines and handle changing customer needs easily.

Customization for Diverse Client Needs

Customization is very important today. Clients often need special PCBA designs for their projects. Industry 4.0 makes customization faster and cheaper. AI tools help design PCBs that match exact client needs.

Real-time data shows what clients want. By studying this data, you can adjust production to make custom solutions. For example, if a client needs a specific circuit board, you can quickly change your production line to make it.

Benefits of Scalability and Customization

Faster Turnaround Times: Automation and live tracking help finish work on time.

Cost Efficiency: Scaling or customizing is cheaper with Industry 4.0 tools.

Improved Client Satisfaction: Custom solutions make clients happy and loyal.

Flexibility: Easily switch between projects or production sizes smoothly.

Note: Scalability and customization are must-haves in today’s market. Using Industry 4.0 keeps you ready to meet different client needs.

Adding these features to your PCBA services makes you flexible and responsive. Whether working on small or big projects, Industry 4.0 gives you the tools to succeed.

Why Industry 4.0 Matters for PCBA Today

Growing need for advanced and reliable PCBs

The need for better PCBs has grown a lot recently. Industries like cars, phones, and healthcare now need more advanced PCBs. These PCBs support their latest technologies. In 2023, the high-end PCB market was worth $60.17 billion. By 2032, it may grow to $100 billion, increasing by 5.81% each year. This shows how important precision and reliability are in making PCBs.

Industry 4.0 helps meet this growing demand. Tools like IoT and AI keep PCBA processes fast and flexible. Automated systems and live data checks ensure high standards and fewer mistakes. This means you can make complex PCBs faster and more accurately. It helps meet what the market wants.

Competing in a tough global market

The global PCBA market is very competitive now. To stay ahead, you need Industry 4.0 tools. These tools improve speed and lower costs. Automation, IoT, and robots make production lines better. For example, pick-and-place machines save time by assembling parts quickly.

Competitive Factor | How It Helps |

|---|---|

Speeds up work and lowers costs in PCB assembly. | |

IoT Technology | Tracks production live and predicts machine issues to avoid delays. |

Eco-Friendly Practices | Meets customer demand for green products and builds brand trust. |

Using these tools makes your work better and faster. It helps you compete globally and keeps your customers happy.

Focus on sustainability and saving resources

Sustainability is now very important in manufacturing. Industry 4.0 helps you save resources and go green in PCBA. Using renewable energy and cutting waste lowers your environmental impact. Live monitoring and AI insights help find and fix inefficiencies.

Sustainability Area | Benefit |

|---|---|

Energy Saving | Cuts energy use and costs with better equipment and live tracking. |

Waste Control | Reduces waste by recycling and using lean manufacturing methods. |

Circular Economy | Reuses materials and extends product life to save resources. |

Renewable Energy | Uses less fossil fuel and more green energy for better energy security. |

For example, one electronics company used digital twins to test production changes. This cut cycle time by 20% and reduced material waste by 15%. By adopting these methods, you can follow environmental rules and meet the demand for green products.

Industry 4.0 tools are changing how PCBA is made. They make processes smarter, faster, and greener. Tools like IoT, AI, and robots help improve speed and quality. For example, smart factories use live tracking to avoid delays. AI checks for defects to make better products and happier customers.

Evidence Type | Description |

|---|---|

Smart Factory | Uses IoT and automation to track data and prevent problems. |

AI in Quality Control | AI finds defects quickly, improving product quality and customer trust. |

Sustainability Efforts | Focuses on reducing waste and reusing materials to protect the planet. |

Using these tools helps you compete in today’s fast market. European factories using automation work 30% faster and save money. By using Industry 4.0, your business can grow and succeed in the PCBA world.

FAQ

What is Industry 4.0, and how does it connect to PCBA services?

Industry 4.0 uses smart tools like IoT, AI, and robots in factories. For PCBA, it makes production faster, better, and more flexible. It automates tasks, tracks progress live, and reduces mistakes.

How does real-time monitoring help in PCBA manufacturing?

Real-time monitoring lets you see production as it happens. It finds problems quickly, cutting downtime and keeping things running smoothly. This method boosts efficiency and ensures top-quality circuit boards.

Can Industry 4.0 work for small PCBA projects?

Yes, Industry 4.0 tools like AI and IoT help small projects. They allow custom designs, reduce waste, and keep quality high. Even for small batches, these tools make work easier for all businesses.

What are digital twins, and why are they useful in PCBA?

Digital twins are virtual copies of real products or processes. In PCBA, they help test changes before using them. This lowers risks, saves materials, and improves results.

How does Industry 4.0 help make PCBA more eco-friendly?

Industry 4.0 helps save energy, cut waste, and recycle materials. Tools like AI find inefficiencies, while green energy and smart methods lower harm to the planet.

Tip: Using Industry 4.0 improves your work and supports eco-friendly goals. Customers care more about green practices today.

See Also

Understanding PCBA Services And Their Significance In Electronics

The Significance Of Custom PCBA Manufacturing In Today’s Electronics

Defining PCBA Manufacturing And Its Importance In Electronics

Why PCBA Manufacturing Skills Are Crucial For Electronics Design