Choosing the best custom PCBA maker is very important. A good circuit board maker gives quality, saves money, and delivers on time. Key things to check are how fast they work, how many mistakes they make, and if they deliver on time. These affect how good your product is and if customers are happy. A good partner for circuit board assembly keeps mistakes low and quality high. Your choice affects your product and how well you can grow and meet market needs.

Key Takeaways

Pick a PCB maker that focuses on quality for better products.

Check for certifications like ISO 9001 and IPC-A-610 to ensure they follow safety rules.

Make sure they can handle big or tricky orders on time.

Ask how they test to catch problems early and keep quality high.

Talk clearly with them and get updates often to avoid mistakes.

Why the Right PCB Manufacturer Matters

Impact on Product Quality and Reliability

Picking the right PCB maker affects product quality. A good manufacturer ensures every board works well and has fewer problems. They study mistakes to improve designs, pick better parts, and fix production issues. This makes products more reliable and work as they should.

Evidence Aspect | Explanation |

|---|---|

PCB Design Improvement | Finding problems helps make better designs. |

Component Selection | Choosing the right parts avoids problems later. |

Manufacturing Process | Fixing process issues improves quality and consistency. |

Working with a quality-focused PCB maker helps your brand stay trusted.

Cost and Efficiency Considerations

A dependable PCB company helps save money and work faster. They track production data to reduce mistakes and cut costs. For example:

Tracking production helps save money and make more boards.

Quality checks ensure standards are met without wasting time.

Watching costs per unit helps stay within budget.

Companies that check these numbers often improve efficiency by 15%. Better cost control can also lower production costs by 15%. Choosing a tech-savvy PCB maker gives better savings and profits over time.

Importance for Scaling and Timely Delivery

Growing your business and meeting deadlines depends on your PCB maker. Things like order size, design difficulty, and shipping distance affect delivery times. A manufacturer with big capacity and good supply chains delivers on time, even for tough orders.

Factor | Effect on Production Time | Effect on Shipping |

|---|---|---|

PCB Complexity | Takes longer to make and deliver. | Needs special shipping plans. |

Order Quantity | Big orders take more time to finish. | Requires careful shipping planning. |

Manufacturer’s Capacity | High capacity speeds up production. | Matches production with delivery needs. |

Supply Chain Management | Avoids delays by having parts ready. | Makes shipping smoother. |

A reliable PCB maker helps you grow while keeping quality and meeting deadlines.

Key Factors for Picking the Right PCB Supplier

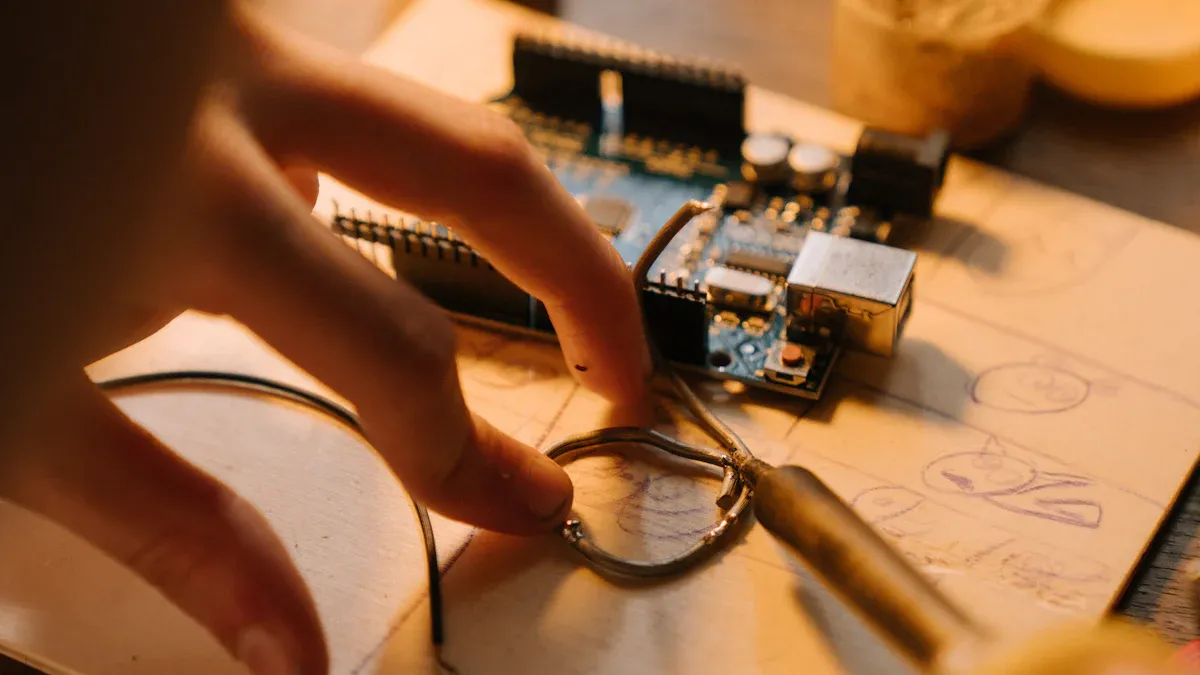

Quality Checks and Testing Steps

A good PCB maker focuses on quality to ensure products work well. They use tests like visual checks, solder float tests, and in-circuit tests to find problems early. Advanced tests, like accelerated life testing (ALT), mimic tough conditions to check long-term reliability. These tests save money and time by catching mistakes before they grow.

Pick a manufacturer that offers many testing options. This helps them handle different board designs and challenges. For example, peel tests and function tests check if boards are strong and work properly. Focusing on quality reduces big failures, keeping your reputation and customer trust safe.

Certifications and Standards

Certifications show a PCB maker cares about quality and safety. A certified company follows important rules and standards. For example, ISO 9001 ensures steady quality, and IPC-A-610 guarantees reliable PCBs.

Certification Type | Why It Matters |

|---|---|

ISO 9001 | Keeps quality consistent |

IPC-A-610 | Ensures reliable PCBs |

When choosing a PCB maker, ask for proof of their certifications. This shows they can meet your needs and follow industry rules. Certified companies deliver trustworthy products and boost your confidence in their skills.

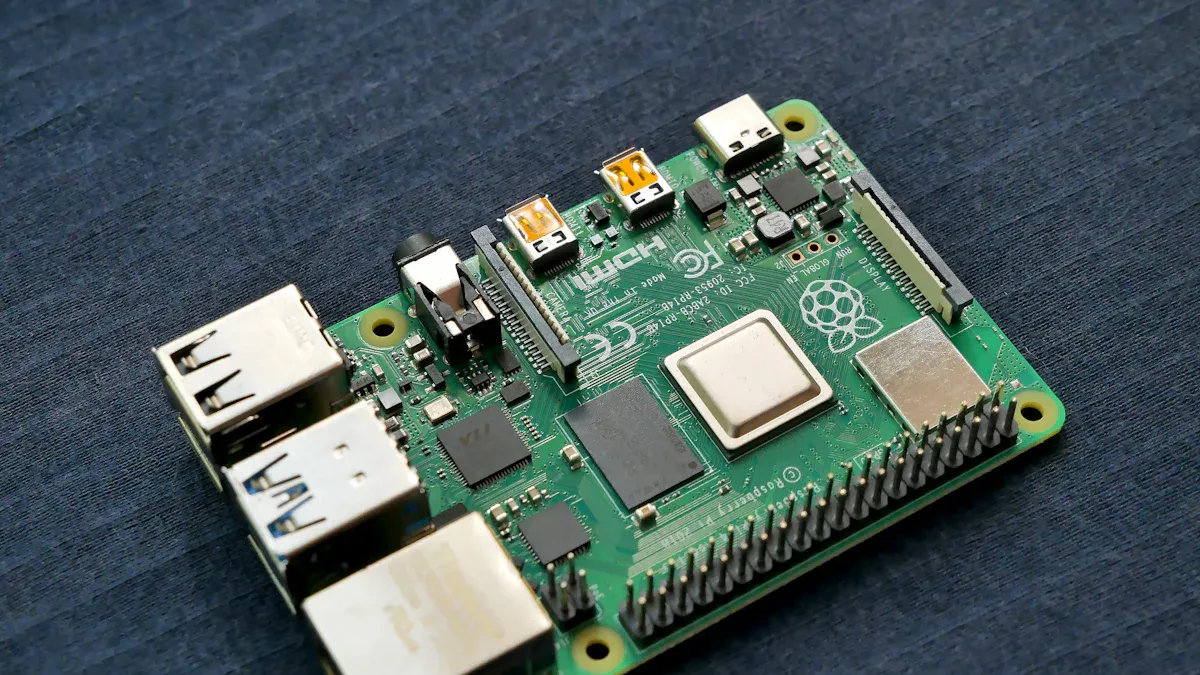

Advanced Technology and Skills

Top PCB makers use advanced tools to meet different project needs. They use modern tech to make complex boards with great accuracy. For instance, they can handle up to 64 layers and tight tolerances of ±0.1mm.

Specification | Value |

|---|---|

Tolerance of the dimension size | ±0.1mm |

Max layer count | 64 layers |

Min trace width/spacing (Inner) | 2/2mil |

Max aspect ratios | 20:1 |

These skills let them create high-quality boards for tough projects. A full-service PCB maker handles everything from making boards to finding parts. This smooth process avoids delays. Picking a skilled manufacturer ensures your boards meet top standards.

Customer Support and Communication

Good communication is key when working with a PCB maker. A trustworthy PCB company listens to your concerns and keeps you updated. Look for one with helpful support options like email, phone, or live chat. These tools make it easy to fix problems or ask questions quickly.

Clear updates are also important during design and production. For example, a PCB company that shares progress reports helps you track your project. This reduces confusion and ensures everything is on time. Companies with multilingual teams can also help clients worldwide, making them a great choice for different needs.

Pricing Transparency and Value

Knowing how much a PCB costs helps you plan better. Clear pricing shows what you’re paying for, like parts and assembly. Some companies work with you during design to save money and improve production.

Evidence Type | Description |

|---|---|

Working together lowers costs and improves efficiency. | |

Clear Supply Chains | Reliable suppliers ensure fair and honest sourcing. |

Smart Tools | Advanced tools reduce mistakes and save money. |

Quality Checks | Strong quality checks lower defects and extra costs. |

Certifications | Following rules ensures better products and fewer problems. |

Think about long-term value when comparing prices. A top PCB company uses good tools and quality checks to avoid mistakes. This saves money and gives you reliable products that meet your needs.

Delivery Reliability and Lead Times

Getting your PCBs on time is very important. A good PCB maker delivers when promised, keeping your projects on track. Most simple PCBs take 20 working days, but some companies offer faster options.

Technology | 1 Day | 2 Day | 3 Day | 4 Day | 5 Day | 6 Day |

|---|---|---|---|---|---|---|

1-4 Layers | X | X | X | X | X | X |

6-10 Layers | X | X | X | X | X | |

> 10 Layers | X | X | X | X |

For example:

Boards with up to 8 layers can be ready in 2-3 days.

Boards with 8-18 layers often take 5 days, even overseas.

Every board is tested to ensure it works perfectly.

Pick a PCB maker with strong supply chains and enough capacity to handle big orders. This ensures on-time delivery, keeps customers happy, and helps you meet your goals.

How to Evaluate Custom PCBA Manufacturers

Questions to Ask About Custom PCB Production

When choosing a PCB maker, ask smart questions. This helps you learn what they can do. Check if they handle tricky designs, limits in making boards, and costs. For example:

Aspect | Description |

|---|---|

Hard designs can cause problems like signal mix-ups or power issues. Fixing these needs special methods like good grounding and signal balancing. | |

Manufacturing Limitations | Some limits include tiny trace sizes and drill holes. Designers and makers must work together to make sure boards can be built. |

Cost Considerations | Saving money means placing parts smartly and wasting less. It also means working with suppliers to get better parts for less. |

These questions help you see if the maker fits your needs. They also show if they can keep quality high and costs low.

Reviewing Testimonials and Case Studies

Reviews and case studies show how reliable a PCB maker is. Look for reviews about their quality, like ISO 9001 or IPC certifications. Ask for sample boards before ordering a lot. This helps check their quality.

Evidence Type | Description |

|---|---|

Certifications and Standards | Good makers have certifications like ISO 9001 and IPC. These prove they follow quality rules. |

Sample Testing and Inspection | Getting samples lets you check quality before big orders. |

Customer Feedback and Reviews | Reading reviews shows if the maker is reliable and offers good service. |

By checking these things, you can pick a partner who delivers on time and makes good boards.

Identifying Red Flags in Processes

Finding problems early saves money and trouble. Watch for signs like broken machines or bad quality cycles. Weather changes, like heat or humidity, can also hurt boards. Look out for these warning signs:

Machines breaking often may mean bigger problems.

Bad quality cycles show issues in fast assembly lines.

Heat or humidity changes can make boards weaker.

Pressure or shaking can mean machines are wearing out.

Spotting these problems helps you avoid bad makers. It ensures your boards are strong and meet high standards.

Conducting On-Site or Virtual Audits

Audits help check if a PCB manufacturer meets your needs. They let you review their tools, processes, and quality checks. You can choose an on-site or virtual audit based on your project and budget.

On-Site Audits

Visiting the factory lets you see how they work. You can watch how they make PCBs, check their machines, and confirm certifications. Walking around helps spot problems like old equipment or bad storage. You can also ask questions in person and build trust with the team.

Virtual Audits

Virtual audits are useful if you can’t travel. Many companies now offer live video tours of their factories. You can ask to see specific areas, like assembly lines or testing spots. Reviewing digital files, like quality reports, also gives helpful details. While virtual audits don’t let you touch or see things up close, they save time and money.

Tips for Effective Audits

Make a checklist of things to check, like testing steps and storage.

Ask for clear explanations to understand their processes better.

Write down what you find to compare different manufacturers later.

Doing audits carefully helps you pick a reliable PCB manufacturer. This step ensures your boards are made well and delivered on time.

Picking the right custom PCBA maker is very important. Checking things like quality, certifications, and delivery helps you choose well.

Research carefully to find a manufacturer that fits your needs.

Check if they can handle tricky designs.

Taking these steps helps you find a good partner. This makes production smoother and gives better results. Spend time choosing wisely for great PCB production. 😊

FAQ

What matters most when picking a PCBA manufacturer?

The top priority is quality assurance. A trustworthy manufacturer makes sure your PCBs work well and meet industry rules. Check for certifications like ISO 9001 and IPC-A-610 to confirm their focus on quality.

How can I check if a manufacturer is reliable?

You can check reliability by reading customer reviews, case studies, and certifications. Ask for sample boards to test their quality. You can also do on-site or virtual audits to review their tools and processes.

Why do delivery times differ between manufacturers?

Delivery times depend on things like order size, PCB design difficulty, and the company’s capacity. Manufacturers with better tools and strong supply chains can deliver faster, even for hard designs.

Should I focus on cost or quality when choosing a manufacturer?

Always focus on quality. Cheap manufacturers might skip important steps, causing bad products. A quality-focused company avoids mistakes, saving money in the long run and ensuring good performance.

How can I communicate well with my manufacturer?

Pick a manufacturer with clear ways to talk, like email, phone, or live chat. Regular updates about production and multilingual support make teamwork easier and avoid confusion.

See Also

Essential Factors To Consider When Selecting PCB Or PCBA

Selecting The Ideal PCBA Manufacturer For Your Unique Needs

Important Steps To Identify A Reliable PCBA Supplier

Determining The Best PCBA Manufacturer For Your Success

Locating The Most Suitable PCBA Manufacturer For Your Budget