Designing PCBs for industrial IoT requires a focus on low power industrial IoT PCB design and assembly to ensure energy efficiency. Low power PCB design enables devices to perform effectively in challenging environments. Energy-saving designs consume less power, extending battery life and reducing costs. Low power devices are crucial for operation in remote or difficult-to-access locations. By adhering to these principles, you can create systems that are both durable and efficient.

Key Takeaways

Use low power parts to save energy in your designs. This lowers costs and makes batteries last longer.

Plan energy use wisely with budgeting and profiling methods. This helps devices work well in different situations.

Pick strong materials and follow testing rules for durability. This keeps devices reliable in tough conditions.

Add power-saving modes and sleep settings to your devices. These cut energy use when devices are not in use.

Try simulation tools to check power use before testing. This saves money and makes designs more accurate.

Key Design Principles for Low-Power Industrial IoT PCB Design and Assembly

Understanding Power Consumption in Low-Power Devices

When making PCBs for industrial IoT, knowing power use is key. Using less power lowers costs and helps devices last longer. For example, in big tracking devices, batteries can be 70% of the cost. This shows why saving energy in designs is so important.

Think about power early when designing. Work with firmware, mechanical, and electrical teams to save energy. Pick processors with low power modes and plan how much power is needed. Use tools like LTE-M networks and eDRX to cut power use when devices are idle or active.

By using these ideas, you can make devices that save energy and work well in tough industrial places.

Energy Budgeting and Power Profiling for IoT Applications

Planning energy use is important for low power IoT PCBs. It helps you use energy wisely and find ways to save power.

New studies show ways to make IoT systems use less energy. For example, some models help manage energy in smart grids. Other research on hybrid energy systems gives tips on saving power. These ideas help you plan energy use and save power in different tasks.

Using smart city energy-saving ideas can improve your designs. Check power use during different times to find waste and fix it. This keeps devices energy-efficient and ready for industrial IoT needs.

Designing for Long-Term Reliability in Industrial Environments

Industrial IoT devices face tough conditions, so they must last long. To make strong PCBs, choose good materials, parts, and follow testing rules.

Follow rules to meet industry standards. For example, IPC-9701A checks heat and movement, and MIL-STD-810G tests for tough environments. The table below shows some testing methods:

Testing Method/Standard | Description |

|---|---|

IPC-9701A | Tests heat and movement for PCBs. |

IPC-TM-650 2.6.7 | Checks how PCBs handle temperature changes. |

MIL-STD-810G | Tests for harsh environments. |

IEC 61000-4-2 | Tests for static electricity problems. |

MIL-STD-461 | Checks electronics for electromagnetic issues. |

By following these rules, your PCBs can handle tough industrial jobs. This makes them last longer, need less fixing, and saves money.

Component Selection and Optimization for Low-Power Devices

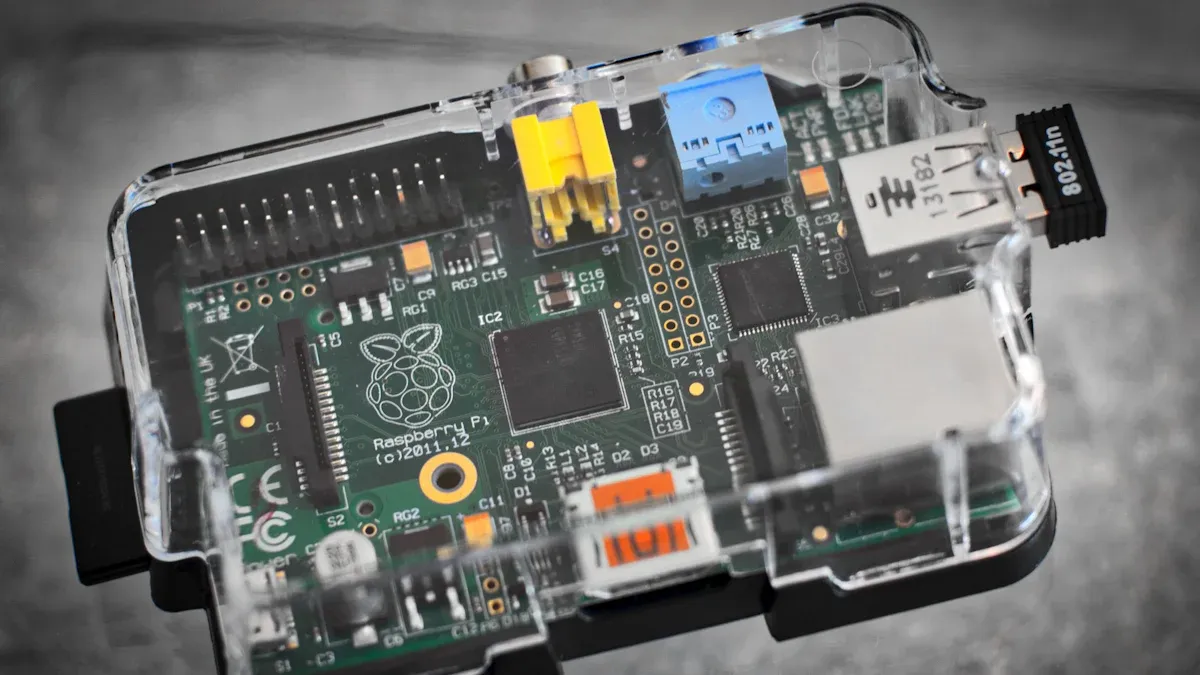

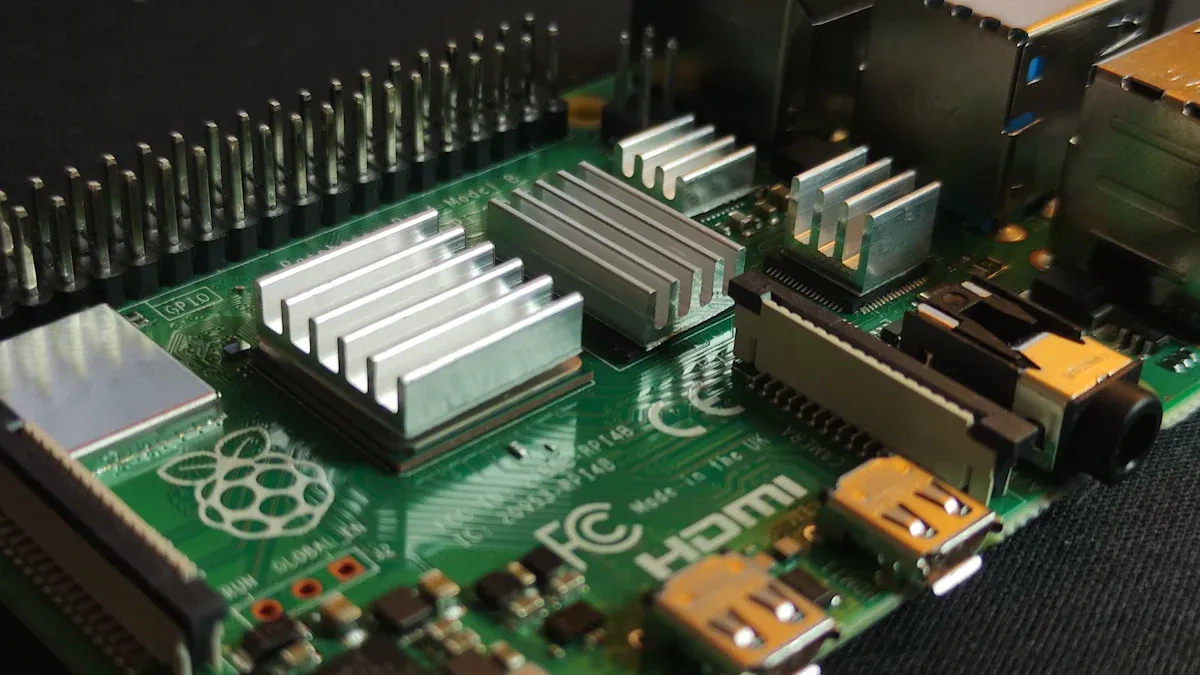

Picking Low-Power Microcontrollers, Sensors, and Passive Components

Choosing the right parts is key to saving power in industrial IoT. Microcontrollers, sensors, and passive parts affect how much energy your design uses. Focus on parts that work well but use little power.

Microcontrollers like the STM32F0 Series and ESP32 are great for low power needs. They balance speed and energy use. For example, the STM32F0 Series runs up to 48 MHz and has flexible memory, making it good for battery devices. Sensors with low power modes, like MEMS accelerometers, save energy when not in use.

The table below shows features of popular microcontrollers:

Feature | Arduino Uno | Arduino Nano | ESP32 | ESP8266 | STM32F3 Series | STM32F0 Series |

|---|---|---|---|---|---|---|

Clock speed | 16 MHz | 16 MHz | 240 MHz | 80 MHz | 72 MHz | Up to 48 MHz |

Memory size (RAM) | 2 KB | 2 KB | 520 KB | 64 KB | Up to 40 KB | 4-32 KB |

Flash memory | 32 KB | 32 KB | 4-16 MB | 1 MB | Up to 256 KB | 16-256 KB |

Passive parts like resistors and capacitors also matter. Pick ones with low leakage and high reliability for long-lasting performance.

Adding Power-Saving Modes and Sleep States

Power-saving modes help cut energy use in IoT devices. These modes let devices use less power when idle but still work well.

Modes like deep sleep and standby can make batteries last longer. For example, the ESP32 uses very little power in deep sleep mode. You can set firmware to switch between active and idle states based on needs.

Tests show how power-saving modes help. In one case, enabling service management cut energy use by 1 mA while keeping the system reliable. Without it, energy use was higher, and resources were wasted. The table below shows these results:

Test Scenario | Energy Consumption | Outcome |

|---|---|---|

Service Management Enabled | Reduced by 1 mA | System remained functional and reliable |

Traditional Approach | Higher energy usage | System continued sending faulty data |

Using these modes helps save energy and keeps devices efficient in tough environments.

Using Power Management Integrated Circuits (ICs)

Power management ICs are important for saving energy in IoT devices. They control voltage, manage power flow, and add features like dynamic voltage scaling.

Studies show power management ICs lower energy use. For example, a DARPA program showed circuits could use as little as 0.01 mW/gate-MHz. This proves the value of adding these ICs to your designs.

New silicon technology makes power management ICs even better. Smaller sizes and lower energy needs make them perfect for IoT. By focusing on low power, you can follow industry trends and build reliable systems.

Tip: Look for ICs with low quiescent current and high efficiency. These features are great for battery-powered devices.

PCB Layout and Power Management Techniques

Smart Routing to Save Power

Good routing helps save power in PCB designs. Keep signal paths short to avoid energy loss. Shorter paths lower resistance and keep signals strong. Use wider traces for high-current paths. Wider traces carry more current safely and prevent overheating.

Adding ground planes is important for strong signals. Ground planes give signals a steady return path, improving quality. Avoid using too many vias, as they can block smooth current flow. Fewer vias mean better signal strength and less resistance.

Multilayer designs can also help. They let you fit more traces in small spaces. This improves performance and reduces signal noise. By following these tips, you can design PCBs that use less energy and work well.

Stable Power Distribution and Voltage Control

A good power network gives all parts steady power. Place capacitors near power pins to stop voltage changes. Design vias carefully to avoid power drops in high-current paths. This keeps power even across the board.

Managing heat is also important. Too much heat can harm parts and lower performance. Use materials that spread heat well and add thermal pads to cool hot areas. Placing parts smartly also helps remove heat and keeps the board working smoothly.

Studies show good power networks improve performance. For example, one system worked 20.50% better at startup with smart power management. This shows how important it is to plan power use in IoT designs.

Cutting Down Electromagnetic Interference (EMI)

EMI can mess up low-power designs. You can lower EMI by keeping PCB layers balanced. Internal power planes reduce noise and protect parts from outside interference.

Plan signal paths carefully to avoid problems. Short traces and proper impedance levels reduce noise. Ending signal traces properly stops reflections that weaken signals.

Choose materials that handle heat and electricity well. These materials make the board stronger and less affected by interference. By fixing EMI issues early, your devices will work better in tough industrial settings.

Prototyping, Testing, and Iteration

Building and Testing Prototypes for Energy Efficiency

Making prototypes helps improve designs and save energy. Build a working model that is like the final product. Test it in real-life conditions to find where energy use can be reduced. Use tools like multimeters and oscilloscopes to check power use in different parts.

Focus on making the prototype work well for industrial IoT. Test how it handles changes in temperature and humidity. This ensures it stays reliable in tough environments. By studying the prototype’s energy use, you can find problems and fix them to make it better.

Tip: Write down all test results to track changes and stay consistent in future updates.

Using Simulation Tools for Power Optimization

Simulation tools help plan and improve power use before testing. These tools let you create a model of your PCB and see how it works in different situations. For example, tools like KBC’s solutions use years of knowledge to improve power use.

Simulations can also lower costs. They show where energy is wasted, helping you save money and reduce labor. Watching key performance indicators (KPIs) during simulations shows quick results and helps you improve designs over time.

Benefits of Simulation Tools:

Save money by finding and fixing waste.

Use energy better by improving power use.

Make designs more accurate with clear KPIs.

Iterative Design Process for Continuous Improvement

Improving designs step by step helps make PCBs better for energy use. After testing your prototype, use what you learn to make changes. Track things like energy use, design time, and mistakes to see progress.

Metric | Goal / Target |

|---|---|

Energy Consumption | Save 20% more energy with smart tools |

Design Cycle Time | Shows how fast work gets done |

First Pass Yield | Measures how accurate the design is |

Defect Density | Tracks the quality of the design |

Each update should focus on fixing one part of the design. For example, lowering mistakes makes the design more reliable. Saving energy matches the goal of low power industrial IoT PCB design. By improving your design each time, you can make a product that is both energy-efficient and dependable.

Challenges and Tradeoffs in Low-Power Industrial IoT PCB Design

Finding the Right Balance: Energy, Performance, and Cost

Making low-power PCBs for industrial IoT needs careful planning. You must balance energy use, performance, and cost. Devices should work well without wasting power or going over budget. For example, newer GPUs are faster and save more energy. But as GPUs get better, they use more power and create more carbon. The table below shows these patterns:

Aspect | Observation |

|---|---|

Embodied Carbon Trends | Better GPUs use more power and increase embodied carbon. |

Energy Efficiency | New GPUs are faster and use energy more wisely. |

Cost Implications | Mainboards, memory, and storage add high carbon costs to systems. |

To balance these factors, pick the right parts and improve designs. This helps meet energy and performance goals while keeping costs low.

Meeting Environmental Needs and Staying Durable

Industrial IoT devices often face tough conditions. They need to last long and meet environmental rules. Smart sensors can track production lines and sort recyclable items. IoT sensors also measure greenhouse gases for accurate reports. Waste management tools cut transport costs and help the planet. The table below explains these ideas:

Strategy | Evidence |

|---|---|

Smart Sensors | Track production lines to sort recyclable materials. |

Emissions Monitoring | IoT sensors give accurate greenhouse gas data. |

Intelligent Waste Management | Real-time waste data saves transport costs and helps the environment. |

Smart Agriculture | Sensors help farmers use resources wisely and protect nature. |

Using these methods, you can make devices that are strong and eco-friendly.

Handling Heat in Low-Power Devices

Managing heat is important for reliable IoT devices. Good cooling keeps parts at safe temperatures, even on crowded PCBs. But tight spaces make cooling harder. Smart PCB design can solve this and save money. Here are some tips for handling heat:

Place high-power parts, like microcontrollers, to spread heat evenly.

Use special layouts for crowded boards to improve cooling.

Choose materials that spread heat and lower stress on parts.

By solving heat problems, you can make IoT devices that work well in all conditions. This keeps them reliable and prevents overheating.

Making low-power PCBs for industrial IoT needs smart energy use. Focus on using low-power parts, better layouts, and good power-saving methods. These steps help devices work well in tough places.

Testing and improving prototypes is very important. By testing, you can find problems and fix them to save energy. This makes your designs stronger and more reliable.

Tip: Try new simulation tools and technologies to save more energy. Keep learning and testing to stay ahead in making great industrial IoT designs.

FAQ

What matters most when designing low-power PCBs for IoT?

Focus on saving energy. Pick parts that use little power. Add features like sleep modes to save more energy. Good PCB layouts and smart power management also help reduce energy use.

How do you check if your PCB design saves energy?

Use tools like multimeters to measure power use. Test your design in different conditions to find problems. Try it in real-life settings to make sure it meets energy-saving goals.

Why is picking the right parts important for low-power designs?

The parts you use decide how much energy is needed. Low-power microcontrollers and sensors help save energy. Choosing good parts makes your device work well and use less power.

How do power-saving modes make batteries last longer?

Power-saving modes, like standby, use less energy when not active. These modes help batteries last longer by lowering energy use during downtime.

What problems can happen in low-power PCB design?

It’s hard to balance energy use, performance, and cost. You also need to handle heat, tough environments, and durability to make sure your design works well.

See Also

Streamlined PCBA Solutions for Your Electronics Projects

Essential Strategies to Enhance PCB Assembly Productivity

Benefits and Drawbacks of Flexible PCBA in Electronics

Best Practices for Maximizing Quality and Efficiency in PCBA