Choosing the best low volume IIoT PCB assembly partner is crucial. A reliable partner ensures your designs comply with industry standards while adapting to your unique requirements. Low volume IIoT PCB assembly allows for small-batch production, enabling you to make adjustments based on market feedback. Tailored solutions ensure consistent quality in the ever-evolving IIoT landscape.

Making the right choice offers numerous benefits. It reduces costs, enhances product performance, and accelerates delivery timelines. By thoroughly evaluating providers, you can achieve reliable outcomes and maintain a competitive edge in your industry.

Key Takeaways

Know how many PCBs you need and your budget. This helps you save money while getting good quality.

Pick a company with good Design for Manufacturability (DFM) skills. This makes your designs easier to build and avoids mistakes.

Find companies with modern tools and technology. New machines make work more accurate and allow creative designs.

Choose a company that offers small orders and testing options. This helps you try designs and change plans without wasting money.

Make sure the company communicates clearly and is honest. Regular updates and truthful reports help you trust them and stay on track.

Understanding Your Low-volume IIoT PCB Assembly Needs

Determining Production Volume and Budget

Knowing your production needs and budget is the first step. Think about how many units you want to make. Also, check how much money you can spend on the project. Small-batch production means balancing cost and quality.

Look at how many units you need to decide on automation. Automation, powered by Industry 4.0, improves quality and keeps results consistent.

The IoT market is growing fast and may hit $616.75 billion by 2032. This shows why spending on advanced tech for assembly is important.

By studying these points, you can use your money wisely and avoid waste.

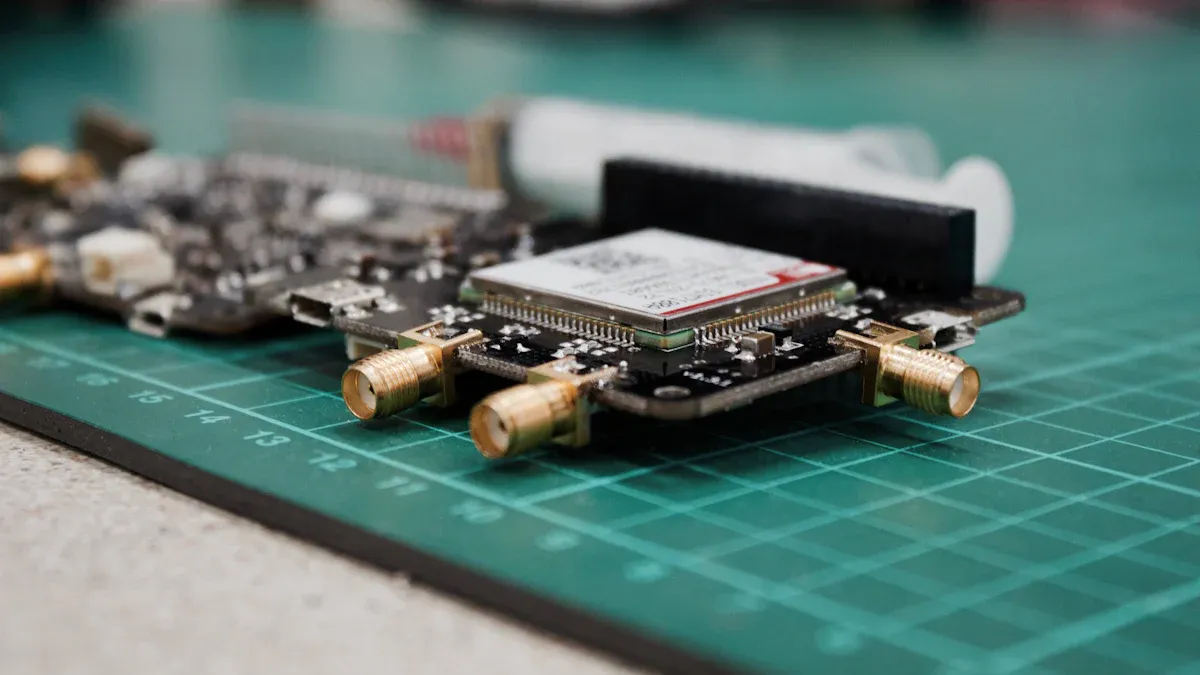

Identifying Specific IIoT Application Requirements

Your IIoT device needs specific features for its PCB assembly. For example, industrial IoT devices must handle tough conditions. Focus on these key areas:

Power requirements: Make sure the PCB handles your device’s energy needs.

Connectivity standards: Check if it works with Wi-Fi, Bluetooth, or Zigbee.

Environmental factors: Think about heat, moisture, and vibration resistance.

A turnkey PCB service provider can help meet these needs. Their skills ensure your design fits your device’s special requirements.

Setting Quality and Performance Standards

Setting clear quality goals is key for low-volume PCB assembly. Industry rules help ensure your PCBs meet high standards. Here’s a simple guide:

Standard/Regulation | What It Covers | Why It Matters for PCB Assembly |

|---|---|---|

IPC-9592 | Rules for automated equipment performance | Ensures precise builds and ESD safety |

RoHS | Limits harmful materials | Promotes safer, eco-friendly materials |

ISO 13849-1 | Safety for fail-safe systems | Adds backup systems for reliability |

Following these rules makes sure your PCBs work well in real life. It also helps with tracking and meeting regulations, which are vital for small-batch production.

Evaluating Low-volume PCB Assembly Manufacturer Capabilities

Checking Design for Manufacturability (DFM) Skills

Pick a manufacturer with strong Design for Manufacturability (DFM) skills. DFM helps make your PCB designs easy to produce without losing quality. Skilled manufacturers spot design problems early, saving time and money. For instance, they can find issues like parts placed incorrectly or not enough space between components.

DFM also makes moving from design to production smoother. Using the right tools, manufacturers give tips to improve your design. This lowers risks and ensures your PCB works as expected. Studies show catching design problems early cuts costs and boosts quality. It also makes it easier to scale up production later if needed.

DFM Practice Area | How It Helps PCB Assembly |

|---|---|

Choosing Design Tools | Improves quality by fixing design issues early |

Spotting Problems Early | Saves money and avoids risks before production |

Preparing for Production | Makes scaling up faster and cheaper |

Working with a skilled DFM service provider ensures your PCB assembly goes smoothly.

Looking at Equipment and Technology

The tools and tech a manufacturer uses affect your PCB’s quality. Advanced machines like robots and 3D printers make work more accurate and reduce mistakes. These are especially helpful for tricky designs where small errors can cause big problems.

Modern tools also allow using new materials like flexible boards and special inks. These materials make PCBs stronger and better for tough IIoT tasks. Special assembly methods also meet the needs of fast and high-tech devices.

Robots and 3D printers improve accuracy and reduce mistakes.

Flexible boards and special inks make PCBs last longer.

Special methods handle fast and high-tech device needs.

Manufacturers using new tech often work faster and cut costs. Partnering with them helps you get reliable results and stay ahead in the market.

Confirming Certifications and Experience

Certifications and experience show if a manufacturer is trustworthy. Certifications like IPC and ISO prove they follow quality rules. IPC ensures safe and accurate builds, while ISO supports eco-friendly and consistent processes.

Experienced manufacturers know how to handle low-volume PCB projects. They offer smart solutions for your specific needs. Their skills in finding materials, checking quality, and managing production ensure top-notch PCBs.

What They Mean for Your Project | |

|---|---|

Manufacturing Skills | Can handle your project’s size and complexity |

Uses tools that improve speed and quality | |

Quality Checks | Ensures the final product is reliable |

Ethical Material Sourcing | Uses good-quality materials responsibly |

Ask about certifications and past work when choosing a manufacturer. This helps you pick one that can deliver great results for your PCB project.

Ensuring Flexibility for Successful Low-volume PCB Assembly

Minimum Order Quantity (MOQ) and Prototyping Options

Having flexible MOQ and prototyping options is very important. You need a service that fits your production needs. Whether you’re testing a new idea or improving an old one, flexibility matters. A low MOQ lets you make small batches. This avoids wasting materials and saves money.

Prototyping is just as important. It helps you test designs before making many units. This way, you can fix problems early and improve quality. Many manufacturers offer support from prototypes to full production. This makes it easy to grow without changing suppliers.

Tip: Pick a manufacturer with low MOQs and good prototyping. This keeps your project affordable and easy to adjust.

Benefit | Description |

|---|---|

Helps move from small tests to big orders with one supplier. | |

Minimum Order Quantities Flexibility | Allows small orders, helping both startups and large companies. |

Supply Chain Management and Component Sourcing

Good supply chain management is key for low-volume PCB assembly. You need a manufacturer who can get quality parts quickly. Delays in getting parts can slow down your project and cost more money. A turnkey service handles this for you, ensuring steady supplies.

Choose manufacturers with strong supplier connections. They can find rare parts for your devices. They should also have backup plans for supply issues, like keeping extra stock or using multiple suppliers.

Note: A well-managed supply chain keeps your production on time and high-quality.

Customization and Scalability for Future Needs

Customization and scalability are crucial for future growth. Your devices may need special features to stand out. A manufacturer offering custom options can design PCBs to fit your needs. For example, modular designs make adding new parts easy. Upgradable layouts help meet changing industry rules.

Scalability is also vital. As your business grows, you may need more units. A flexible manufacturer can handle both small and large orders. This ensures your PCBs stay competitive in a fast-changing market.

Feature | Description |

|---|---|

Modular Designs | Make adding new parts simple. |

Upgradability | Adjust to new industry standards. |

Design Reusability | Use old designs for future devices. |

Impact | Custom PCBs help tech companies stay competitive. |

Small or large production runs, from one unit to thousands

Scalable capacity to match growing needs

Tip: Work with a manufacturer focused on customization and scalability. This keeps your PCBs ready for future challenges.

Focusing on Quality Assurance in Low-volume PCB Assembly

Inspection and Testing Methods

Checking and testing are key to good low-volume PCB assembly. Finding problems early saves money and reduces wasted materials. Useful methods like Automated Optical Inspection (AOI) and X-ray testing spot issues. These include soldering mistakes, misplaced parts, or electrical problems. These checks make sure your PCBs work as planned and are reliable.

Testing also makes products last longer and keeps customers happy. For instance, functional testing checks if the PCB works well in real-life situations. This is very important for industrial IoT devices, where dependability matters most. By focusing on testing and inspection, you save time, resources, and meet industry rules.

Catching problems early makes products more reliable.

Early fixes lower waste and save on rework costs.

Full testing ensures top-quality final products.

Following Industry Rules (e.g., IPC, ISO)

Sticking to industry rules is important for low-volume PCB assembly. Standards like IPC-A-610 and IPC-A-600 set clear rules for quality. These ensure your PCBs are safe and perform well. For example, following IPC rules lowers the chance of failures, which is critical for fields like healthcare and aerospace.

ISO certifications show that manufacturers use eco-friendly and steady processes. Following these rules not only ensures quality but also helps meet global standards. This makes it easier for your products to sell worldwide and stay competitive.

IPC rules help make high-quality PCBs for many uses.

ISO certifications support green and reliable production.

Meeting rules helps products succeed in global markets.

Tracking and Recording Processes

Tracking is a big part of quality in low-volume PCB assembly. It helps you know where every part comes from and how it’s made. This ensures only good parts are used, lowering the risk of bad products. Keeping records also shows you follow rules and meet industry standards.

Tracking also helps find errors fast. If something goes wrong, you can quickly find and fix the issue. This reduces delays and keeps customers happy. A good PCB service provider with strong tracking systems keeps your project on time and high-quality.

Feature | Benefit |

|---|---|

Following Rules | Keeps records to meet regulations and pass audits. |

Quality Checks | Spots bad or fake parts to ensure reliability. |

Fixing Problems Fast | Finds and fixes errors quickly to save time. |

Happy Customers | Fewer bad products improve trust and brand image. |

By focusing on tracking, you ensure great quality and build customer trust.

Delivery and Communication for Low-volume PCB Assembly Success

Lead Times and On-time Delivery

Getting your PCBs on time is very important. Meeting deadlines helps you save money and stay competitive. It also keeps your inventory and cash flow in good shape, which is crucial for small-batch production.

On-time delivery (OTD) shows how well a service performs. It helps you track progress, find problems, and improve processes. For example, you can check if deliveries are always on time or see what causes delays. These details help make your production smoother and more efficient.

Tip: Pick a PCB assembly partner that focuses on OTD and gives clear schedules. This avoids delays in your projects.

Responsiveness and Customer Support

Good customer support makes a big difference in your experience. You need a partner who listens and solves problems quickly. Many people like talking directly to experts about their concerns. For example, engineers often work with the manufacturer’s team to fix design issues.

Feedback from users shows how important responsiveness is. Comments like “Great support!” and “Altek is always there to help!” show why having a reliable partner matters. Whether it’s urgent needs or updates on parts, quick support keeps your project moving forward.

Note: Choose a PCB assembly service known for great customer care and teamwork.

Transparency in Communication and Reporting

Clear communication builds trust with your PCB assembly partner. Honest updates keep you informed about progress, delays, or material issues. This helps you make better decisions and adjust plans when needed.

A good service should share detailed reports about production, quality checks, and delivery. This openness helps you spot and fix problems early. Clear communication creates a strong partnership and ensures both sides understand each other’s needs.

Tip: Find a manufacturer that values honesty and gives regular updates to keep your project running smoothly.

Picking the right PCB assembly service is key to success. Choose providers skilled in DFM to spot design issues early. This saves money and avoids costly mistakes. Good supply chain management ensures parts arrive on time and at fair prices. Certifications like ISO9001 and ISO13485 show they meet quality standards. Matching their skills to your needs boosts reliability and performance. Look for open communication, flexibility, and a good track record. Providers with over 80% positive reviews are usually dependable partners.

FAQ

What does a turnkey PCB provider do, and why pick one?

A turnkey PCB provider takes care of the entire PCB assembly process. They handle design, part sourcing, production, and testing. Choosing one makes your project easier, reduces mistakes, and saves time by having one expert manage everything.

How does small-batch PCB assembly help your IIoT project?

Small-batch PCB assembly lets you test and improve designs without making too many units. It cuts waste, lowers costs, and ensures your product is high-quality before moving to large-scale production.

What testing methods check quality in small-batch production?

Testing methods like Automated Optical Inspection (AOI) and functional testing check for errors. These tests find soldering mistakes, misplaced parts, and performance problems, ensuring your PCBs work well and meet industry standards.

How can you make sure your PCB project is delivered on time?

Pick a provider known for meeting deadlines. Look for clear updates, detailed timelines, and strong supply chain management. These help keep your project on schedule and avoid delays.

Why is customization important for PCB assembly?

Customization makes sure your PCB fits your device’s needs. Features like modular designs and upgradable layouts help your product adjust to new rules and future changes, keeping it competitive in a fast-changing market.

See Also

Essential Guidelines for Choosing Top PCB Assembly Services

Key Factors in Selecting the Right PCB Fabrication Manufacturer

Tips for Finding the Ideal PCB Prototype Manufacturer for Projects

Strategies for Choosing the Right PCBA Manufacturer for Business