Choosing a capacitor for your project can be confusing. There are many types to pick from. Multilayer ceramic capacitors and single-layer ceramic capacitors are popular choices. Multilayer ceramic capacitors, or MLCCs, are small and work well. They are great for modern electronic devices. Single-layer ceramic capacitors are cheaper and fit certain uses. Knowing their differences helps you choose the right one.

Key Takeaways

Multilayer ceramic capacitors (MLCCs) are small and hold more energy. They are perfect for modern devices like phones and smartwatches.

Single-layer ceramic capacitors (SLCs) cost less and are simpler. They work well for basic jobs like filtering in circuits.

MLCCs are great for high-frequency uses. SLCs work well in steady conditions but can lose power over time.

Think about your project’s needs. MLCCs are good for advanced uses, while SLCs are better if you want to save money.

Combining MLCCs and SLCs can improve performance and lower costs in electronics.

Overview of Multilayer Ceramic Capacitors (MLCCs) and Single-Layer Ceramic Capacitors (SLCs)

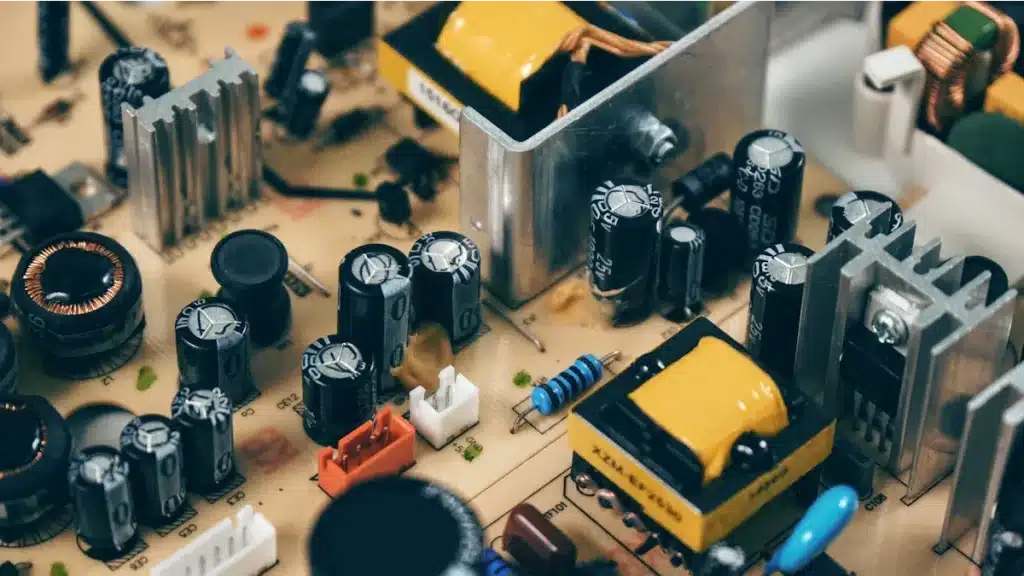

Structure of Multilayer Ceramic Capacitors

MLCCs, or multilayer ceramic capacitors, have many ceramic layers. Thin metal electrodes are placed between these layers. The ceramic material works as the insulator, or dielectric. The metal parts store and release electrical energy. This design gives more capacitance without making it bigger. MLCCs handle temperature changes well, so they work in many places. Their small size and high capacitance make them perfect for modern electronics.

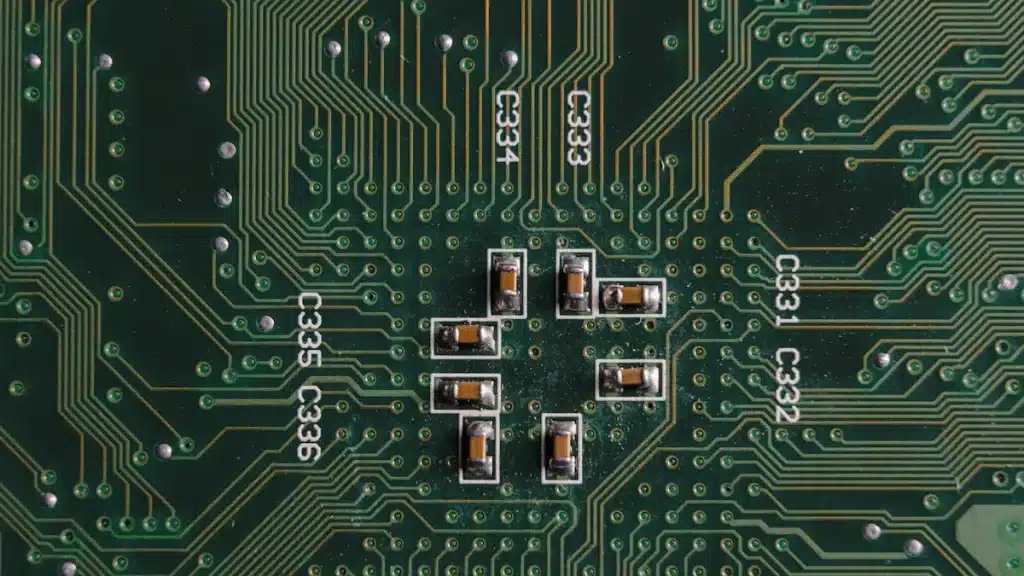

Structure of Single-Layer Ceramic Capacitors

SLCs, or single-layer ceramic capacitors, are simpler in design. They have one ceramic layer between two metal electrodes. This simple structure makes them cheaper to produce than MLCCs. But, their single layer means less capacitance and stability. SLCs are often bigger for the same capacitance as MLCCs. This can be a problem when space is tight. Still, their low cost and simplicity make them useful for certain tasks.

Key Differences in Design

The main difference between MLCCs and SLCs is their structure. MLCCs have many layers, while SLCs have just one. This gives MLCCs more capacitance and better temperature stability. MLCCs also stay stable in different temperatures, needing fewer adjustments. SLCs are stable in specific uses but are less flexible than MLCCs. MLCCs are smaller and fit dense circuits, while SLCs are larger and better for simple designs.

Advantages of Multilayer Ceramic Capacitors (MLCCs)

Compact Size and High Capacitance

Multilayer ceramic capacitors are small and store lots of energy. They are used in devices like smartphones and smartwatches. Their layered design helps them hold more energy in less space. This makes them perfect for modern gadgets that need high performance but have limited room.

📊 Performance Highlights:

The table below shows how MLCCs are efficient and compact:

Parameter

Value

Energy Density

Efficiency

> 95%

Breakdown Electric Field

Increased by 42%

Electric-Field-Induced Strain

Reduced by 37%

Versatility Across Applications

MLCCs can be used in many different devices and systems. They are found in electronics, cars, and factory machines. They work well with various voltages and temperatures, making them dependable. For example, low-voltage MLCCs are very popular, holding 46.6% of the market. Whether for phones or home gadgets, they offer the flexibility designers need.

Key Features of MLCCs:

Small size and toughness make them great for electronics.

High energy storage supports advanced devices like laptops and wearables.

In 2022, electronics made up 32.7% of their revenue.

Efficiency in High-Frequency Applications

MLCCs are excellent for circuits needing precision and stability. They are used in RF circuits, power supplies, and communication devices. Their design keeps performance steady even at high frequencies. This is important for new technologies like 5G and IoT devices.

Why MLCCs Are Efficient:

High-frequency capacitors stay reliable in tough conditions.

Their small size fits compact electronic designs.

As gadgets grow, MLCCs help keep performance strong in high-frequency tasks.

Limitations of Multilayer Ceramic Capacitors (MLCCs)

Voltage Dependence of Capacitance

A multilayer ceramic capacitor’s capacitance can change with voltage. When voltage increases, the capacitance may drop in a circuit. This happens because the dielectric material reacts to the electric field. For tasks needing exact capacitance, this can cause problems. You might need a capacitor with higher capacitance to fix this issue.

⚠️ Note: Always check the MLCC's voltage rating before using it. This ensures it works well in your circuit.

Susceptibility to Mechanical Stress

MLCCs can break under physical stress. Their ceramic layers may crack from bending or vibration. For example, if a circuit board flexes, the MLCC might fail. This makes them less reliable in rough conditions. Handle MLCCs carefully during assembly to avoid damage. Use flexible boards or coatings for extra protection.

Tips to Protect MLCCs:

Use soft termination MLCCs to handle stress better.

Avoid pressing too hard when soldering.

Design boards with fewer bending points.

Higher Cost Compared to SLCs

MLCCs cost more than single-layer ceramic capacitors. Their complex design and production make them pricier. If you have a tight budget, this might be a problem. But their small size and high capacitance often make them worth it. For simple tasks, single-layer capacitors might save money.

💡 Tip: Think about your project's needs. If cost matters, decide if an MLCC's benefits are worth the price.

Advantages of Single-Layer Ceramic Capacitors (SLCs)

Affordable Option

Single-layer ceramic capacitors are cheaper because of their simple design. They have one ceramic layer and two electrodes, making them easy to produce. This lowers their cost compared to multilayer ceramic capacitors. They are a good choice for projects with limited budgets. These capacitors work well in tasks like basic filtering or decoupling. Their low price lets you use many without spending too much money.

💡 Tip: If your project doesn’t need high capacitance or small size, single-layer ceramic capacitors are a budget-friendly option.

Reliable in Certain Uses

Single-layer ceramic capacitors are dependable in specific environments. They perform well in high-frequency circuits due to their simple design. This makes them great for tasks needing steady performance over time. For example, they are useful in RF circuits and oscillators. They are also less affected by voltage changes, which adds to their reliability.

Performance Highlights:

Work well in high-frequency circuits.

Less affected by voltage changes than multilayer capacitors.

Reliable for long-term use in stable environments.

Flexible Design Options

Single-layer ceramic capacitors can be customized for special needs. Manufacturers can adjust their shape, size, and features to fit your project. This makes them useful for unique applications like medical devices or industrial tools. New advancements have increased the variety of options available. This gives you more control over how the capacitor performs.

Feature | Details |

|---|---|

Affordable | Simple design keeps costs low, making them widely used. |

Reliable | Perform steadily, especially in high-frequency circuits. |

Customizable | New designs allow adjustments to meet specific engineering needs. |

📌 Note: Think about whether your project needs customization. Single-layer ceramic capacitors are great for tailored designs.

Limitations of Single-Layer Ceramic Capacitors (SLCs)

Lower Capacitance Range

Single-layer ceramic capacitors can’t store much energy. Their simple design limits how much they hold. This can be a problem for projects needing high energy storage. When voltage is applied, their capacitance may change. This is called the DC bias effect. It makes them less reliable for steady performance. If your project needs more energy storage, try other capacitor types.

Key Challenges:

Store less energy than multilayer ceramic capacitors.

Capacitance changes with voltage, lowering reliability.

Larger Physical Size

Single-layer ceramic capacitors are bigger than multilayer ones. They need more space to store the same energy. This can be an issue in tight spaces. While sometimes compact, their size can be a drawback in crowded circuits. Think about this when designing devices with limited room.

📌 Tip: For small spaces, consider using MLCCs instead.

Limited High-Frequency Performance

Single-layer ceramic capacitors work well at high frequencies but not for long. Over time, they lose capacitance due to stress and aging. This affects their performance in high-frequency circuits. If your project needs durability or long-term use, they might not be ideal. Stress makes them less reliable in tough conditions.

Performance Limitations:

Lose capacitance over time from stress and aging.

Less reliable for circuits needing long-term stability.

⚠️ Note: For high-frequency tasks, pick capacitors that handle stress better.

Applications of MLCCs and SLCs

Best Use Cases for MLCCs

Multilayer ceramic capacitors (MLCCs) are great for small, powerful devices. They are used in smartphones, laptops, and smartwatches. MLCCs work well with high frequencies, like in 5G and IoT systems. In cars, they are key for electric and self-driving vehicles. These circuits need to be precise and long-lasting.

MLCCs are becoming more popular in many industries. Studies show their market will grow from $11.84 billion in 2024 to $17.47 billion by 2031. This shows how important they are in fields like cars and communication. If your project needs advanced tech or small designs, MLCCs are a top pick.

Best Use Cases for SLCs

Single-layer ceramic capacitors (SLCs) are best for simple, low-cost tasks. They are often used for filtering and decoupling in circuits. SLCs are steady in certain environments, like RF circuits and oscillators. They are also less affected by voltage changes, making them reliable for stable tasks.

Another benefit of SLCs is customization. Manufacturers can change their design to fit special needs. This makes them useful for medical tools or industrial machines. If your project doesn’t need high energy storage or small size, SLCs are a smart, affordable choice.

Overlapping Applications

MLCCs and SLCs can work together in some circuits. For example, in power supplies, MLCCs handle high frequencies, while SLCs manage low ones. This teamwork improves performance across different frequencies.

In gadgets, both types help devices run smoothly. MLCCs store energy in small spaces, while SLCs are cheaper for simpler tasks. By knowing their strengths, you can use both to improve your designs.

Comparative Analysis of MLCCs and SLCs

Performance and Efficiency

Multilayer ceramic capacitors (MLCCs) work well in high-frequency circuits. They store lots of energy in a small space. Their layered design makes them great for advanced devices like smartphones. MLCCs are reliable for tasks needing precision, like 5G systems. They stay efficient even in tough conditions, making them dependable for modern gadgets.

Single-layer ceramic capacitors (SLCs) are better for simpler uses. Their basic design works well in stable environments. They are good for RF circuits or oscillators but not for high-frequency tasks. If your project needs basic filtering, SLCs are a simple and effective choice.

💡 Tip: Use MLCCs for advanced tasks and SLCs for basic ones.

Cost and Availability

Cost is important when picking a capacitor. MLCCs cost more because they are harder to make. Their price reflects their small size and strong performance. Even so, they are easy to find due to high demand in industries like electronics.

SLCs are cheaper because of their simple design. They are a good choice for projects with tight budgets. You can find SLCs easily for standard tasks. But, for some projects, you might need more SLCs to match an MLCC’s performance. This could increase costs over time.

📌 Note: Think about long-term benefits of MLCCs versus the low cost of SLCs.

Reliability and Longevity

Reliability matters when choosing between MLCCs and SLCs. MLCCs are durable and handle temperature changes well. But they can crack under physical stress, like bending or vibration. Careful handling and protective coatings can help them last longer.

SLCs are less durable in tough conditions but work well in stable environments. Their simple design makes them less affected by voltage changes. However, they may wear out faster in high-stress tasks, limiting their use in demanding projects.

⚠️ Caution: Check your project's needs carefully before picking MLCCs or SLCs.

Knowing the differences between MLCCs and SLCs is important. MLCCs are small, store more energy, and work well in high-frequency circuits. SLCs are cheaper, steady in certain uses, and can be customized.

When picking a capacitor, think about capacitance, ESR, and ESL. MLCCs are great for high-frequency tasks because they are reliable. SLCs are better for simple and low-cost projects. Experts recommend using several small capacitors together. This saves money, improves energy flow, and reduces interference.

By understanding your project’s needs, you can choose the best capacitor for long-lasting performance.

FAQ

What makes MLCCs and SLCs different?

MLCCs have many ceramic layers, giving them more capacitance. They are also smaller in size. SLCs have just one ceramic layer, so they cost less but are bigger. Use MLCCs for advanced gadgets and SLCs for simpler jobs.

Are MLCCs good for high-frequency tasks?

Yes, MLCCs work great in high-frequency circuits. Their layered build keeps them steady and precise. This makes them perfect for 5G and RF systems. For high-frequency needs, MLCCs are the best option.

Why do SLCs cost less than MLCCs?

SLCs are simpler, with one ceramic layer and two electrodes. This makes them cheaper to produce. If you’re on a budget, SLCs are a smart choice for basic uses.

Can MLCCs handle physical stress?

MLCCs can crack under bending or vibration. To protect them, use soft termination types or flexible boards. Be gentle during assembly to avoid breaking them.

Which capacitor is better for small devices?

MLCCs are better for small devices. They are tiny but store lots of energy. This makes them great for gadgets like phones and smartwatches. SLCs are bigger and not ideal for tight spaces.