PCBs, which stands for printed circuit boards, are very important in modern electronics. Understanding pcb meaning helps highlight how these boards enable devices to be small, strong, and complex. Over the last few decades, printed circuit boards have revolutionized the way engineers design electronics. Advances in pcb technology have made devices much smaller and more sophisticated.

Surface Mount Technology allows components to sit directly on the pcb surface, increasing part density and reducing device size.

High-Density Interconnects and flexible pcb designs enable more components to fit into tiny spaces.

Rigid-Flex boards can bend and twist, making them ideal for compact or uniquely shaped devices.

These innovations show why printed circuit boards are used in so many applications, from smartphones to medical equipment. Knowing the pcb meaning underscores the critical role these boards play in modern technology.

Key Takeaways

PCBs link and support electronic parts. This helps devices get smaller, tougher, and work better. Miniaturization and flexible designs let engineers add more parts in small spaces. This is important for today’s gadgets. PCBs are used in many areas like medical devices, cars, planes, and home electronics. This shows they are used a lot. New PCB trends include boards with many layers, high-frequency designs, and green materials. These help devices work better and protect the environment. Good PCB design and materials make devices last longer. They also help devices work in hard places and get ready for new technology.

PCB Meaning

What Is a Printed Circuit Board

A printed circuit board is found in most electronics. It holds parts and connects them with copper lines. The board has layers of copper and layers that do not conduct electricity. These layers help keep the parts in place and make connections.

A regular printed circuit board has many layers:

Copper foil makes the paths for electricity.

The core is fiberglass and epoxy resin for strength.

The solder mask, usually green, keeps copper safe and stops shorts.

The silkscreen layer has labels and helps with putting parts on.

PCB meaning is more than just the layers you see. It is also about how the layers work together for hard circuits. The way these boards are made lets engineers build small and strong devices.

How PCBs Work

PCBs have copper lines that link electronic parts. These lines are like tiny roads for electricity to travel. Parts like resistors, capacitors, and chips are put on pads. Pads join to the lines and send signals where they need to go.

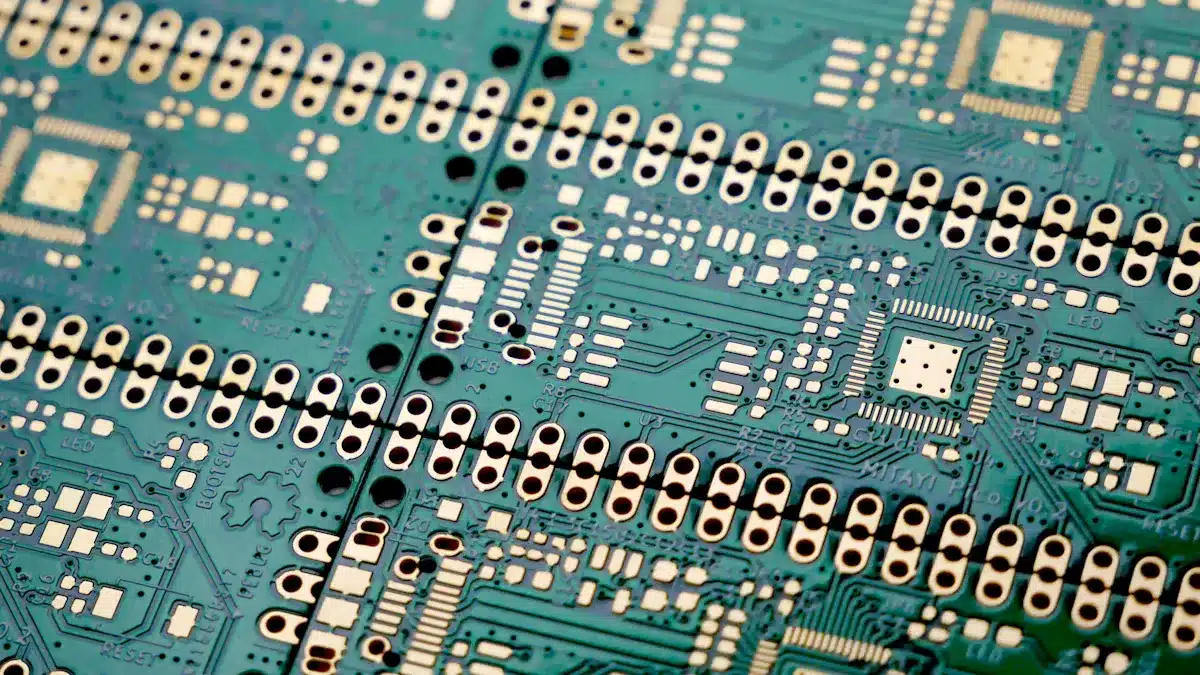

Multilayer printed circuit boards have vias, which are tiny holes with metal. Vias let signals move between layers and make the design better. This setup lets boards hold more parts and have tricky paths.

PCB design tools help engineers draw the lines and layers. They show how signals will move through the board. Good pcb design makes sure signals move fast and do not get lost. PCB design means both the way the board looks and how signals move.

Note: PCB meaning is about what the board is and what it does. Knowing pcb design shows why pcbs matter in today’s electronics.

Key Features of PCBs

Miniaturization

Miniaturization is a big part of pcb technology. Engineers have made pcbs much smaller over time. They use high-density interconnects and multi-layer boards. This helps fit more parts into tiny spaces. Fine-line circuit designs make very thin paths. Some paths are only 20 micrometers wide. Special methods like laser drilling and photolithography help make small and exact boards. New materials, like DuPont’s Riston® dry film photoresist, make boards more accurate and tough.

Devices get lighter and easier to carry.

Shorter signal paths help devices work better and save energy.

Small pcbs are used in wearables, medical implants, and IoT sensors.

These changes let electronics get smaller and stronger. Miniaturization also cuts costs and helps new uses in many areas.

Reliability

Reliability is also very important in pcb design. Engineers pick strong materials and plan layouts carefully. This helps pcbs last a long time. The solder mask keeps copper safe and stops short circuits. Surface treatments, like DuPont™ Circuposit™ desmear, help parts stick and lower the chance of problems. Microvia fillings and copper pillar plating make layer connections stronger.

Reliable pcbs help electronics work well in tough places. They can handle heat, water, and shaking. This is very important for medical, car, and space devices.

Versatility

Versatility lets pcbs work in many different things. Designers can change the shape, size, and number of layers. Flexible and rigid-flex pcbs can bend or twist for special shapes. Engineers use pcbs in phones, machines, and more.

PCB Applications and Roles | Key Requirements and Features | |

|---|---|---|

Industrial Equipment | Electric drills, presses, power inverters, industrial sensors | Power and control, automation, robotization |

Automotive | Entertainment systems, navigation, engine management, sensors | Real-time operation, safety, embedded systems |

Aerospace | Aircraft power supplies, control towers, satellites, sensors, communication equipment | Harsh conditions, critical systems |

Consumer Electronics | Smartphones, tablets, computers, smart home devices, TVs, gaming consoles | Miniaturization, complex functions |

Telecommunications | Mobile base stations, signal boosters, fiber-optic infrastructure, routers, modems | High-frequency, signal integrity |

Marine and Naval | Radar, sonar, satellite communication, engine control units | Corrosion resistance, moisture protection |

PCBs can work in many places and meet many needs. Their versatility makes them very important for modern electronics and many uses.

Common Uses for PCBs

Consumer Electronics

Consumer electronics use pcbs more than any other area. PCBs help run devices people use every day. Phones, tablets, and computers need pcbs for speed and small size. Wearables like smartwatches use flexible pcbs to fit tiny spaces. These boards help track health in real time. Home appliances, such as smart fridges and washing machines, use pcbs for control and connection. Kitchen tools like blenders and coffee makers use pcbs to work safely.

Asia Pacific makes most pcbs, with 56.69% of the market in 2023.

The pcb market was $69.69 billion in 2023. It may grow to $113.49 billion by 2032.

Consumer electronics help this growth. People want smaller, better, and safer devices every year.

PCBs let electronics have cool features and save energy. They help connect smart devices. These uses show how pcb design helps modern life.

Medical Devices

Medical devices need pcbs that are safe and work well. Flexible pcbs are used in things like pacemakers and neurostimulators. These boards must be tiny, bendy, and safe for the body. Machines like MRI and CT scanners use pcbs to be smaller and easier to move. Surgical tools and robots use small pcbs for better control.

Wearable health trackers use flexible pcbs to check body signs. Hearing aids use small pcbs to work well. Portable medical tools, like insulin pumps, need strong pcbs for comfort and safety.

Medical pcbs must pass tough tests and meet rules like FDA 21 CFR Part 820, ISO 13485, and IEC 60601. Clean rooms and IPC Class 3 rules make sure they work well in hospitals.

Regulatory Standard | Description |

|---|---|

FDA 21 CFR Part 820 | Rules for making safe medical devices |

ISO 13485 | Quality rules for medical device makers |

IEC 60601 | Safety rules for medical equipment |

IPC Class 3 | Best quality for pcb making |

Medical electronics use pcbs for good data and patient safety. These uses help doctors and support telehealth.

Automotive

Cars use pcbs in engine controls, radios, and safety systems. PCBs help engines run and control power. They help sensors and other parts talk to each other. Radios and screens use pcbs for music, maps, and controls. Safety systems like airbags and ABS use pcbs to work fast.

Car electronics need to handle heat and shaking. HDI and flexible pcbs help them last in tough places. The car pcb market was $9.79 billion in 2023. It will grow as electric cars and safety rules increase.

PCBs help cars work better and safer. These uses help new cars and car electronics.

Industrial Equipment

Factories use pcbs for control and automation. PCBs hold and connect parts in machines and robots. Surface mount technology helps make strong and exact boards. Special coatings protect pcbs from water, dust, and chemicals.

Industrial pcbs must handle heat, shaking, and stress. Rigid-Flex and Heavy Copper pcbs help with high power and heat. EMI/RFI shielding keeps signals clear in noisy places. Modular designs make building and fixing easier.

Industrial pcbs must pass heat, shock, and wet tests.

Strong materials and tough parts help them last.

Coatings and shielding keep them safe from harm.

Industrial electronics use pcbs for safe and smart control. These uses help factories work better.

Aerospace

Planes and space tools need pcbs that are very strong and exact. PCBs in flight controls and power systems must handle heat, shaking, and radiation. Multi-layer and HDI pcbs make boards small and light but complex.

Aerospace pcbs use special materials for heat control. They meet rules like AS9100 and IPC-A-610 Class 3. Tests check for shaking, heat, and radiation. These boards help with navigation, sensors, and talking to other systems.

Aerospace System | PCB Role |

|---|---|

Avionics Systems | Controls for flying, navigation, and talking |

Radar and Surveillance | Signal work for watching the sky |

Navigation Equipment | Data work for finding the way |

Power Distribution Units | Moving power for plane electronics |

Defense and space need pcbs for important jobs. These uses help keep flights safe.

Maritime

Ships use pcbs in navigation, talking, and radar. PCBs connect parts in GPS, sonar, and ship controls. Special pcb designs stop damage from saltwater, shaking, and heat. Coatings and materials like Rogers RO4003C help with water and heat.

HDI and high-frequency pcbs make small, strong boards for ships. Tests check for strength. Maritime pcbs help with radar and talking by keeping signals clear.

Waterproofing and rust protection are key for ship pcbs.

Heat control and shaking resistance help them last.

Stable power and safe wiring keep things working.

Defense and ship electronics use pcbs for safe travel and talking in hard places.

Lighting Systems

Lights use pcbs to save energy and last longer. LED lights use strong pcbs to use less power and stay cool. Aluminum and copper pcbs move heat away, so LEDs last longer.

Multi-layer and metal core pcbs handle more power and heat. Small pcbs help with dimming, sensors, and color changes. IoT and smart lights work because of new pcb designs.

Thermal vias and copper help move heat out.

Good spacing stops hot spots and helps lights last.

Flexible pcbs let designers make cool light shapes.

Lighting electronics use pcbs for better, safer, and greener lights.

Safety and Security

Safety and security gear use pcbs for important jobs. Cameras, smoke alarms, and door locks use pcbs for pictures, sensing, and connecting. Motion sensors and alarms use pcbs to spot danger.

Cameras, locks, and fire alarms use pcbs to send data and sound alarms. Video doorbells and smart locks use pcbs for sound and video. Car alarms use pcbs for sensor control.

PCBs help safety gear work all the time.

Good pcb design helps with emergency calls and network safety.

Coatings and strong layouts make them last longer.

Safety and security electronics use pcbs for strong protection and watching.

Telecommunications

Telecom systems use advanced pcbs for strong and fast work. PCBs help with wireless systems, base stations, routers, and fast data. Multi-layer and HDI pcbs keep signals clear and stop problems.

PCBs stop mistakes by using machines to build them. Controlled wiring keeps things working right. Heat control stops overheating. Flexible pcbs help in tight spaces.

PCBs help telecom gear handle fast signals and big networks.

Machine building and testing keep quality high.

New networks like 5G need special pcb designs.

Telecom electronics use pcbs for strong, big, and safe connections.

Printed Circuit Board Trends

Multi-Layer PCBs

Multi-layer PCBs have changed how engineers design boards. These boards stack layers to fit more circuits in small spaces. Engineers use tools like Altium Designer, Autodesk Eagle, and KiCad. They keep signals strong by controlling impedance and trace size. They try to use fewer vias and manage trace length. Multi-layer boards are used in cars, electric vehicles, and wearables. New trends include flexible PCBs and built-in parts. Advanced materials help with heat and electricity. Good design means using quality materials and testing a lot. Engineers care about the environment and pick green materials. They also try to make less waste. Designing these boards is hard. Making them needs tight controls and good heat management.

6-layer PCBs balance performance and how they are made.

8-layer PCBs give more options but are harder and cost more.

Engineers place parts carefully and choose layers for better results.

High-Frequency PCBs

High-frequency PCBs are important for fast communication. These boards help 5G networks and other quick devices work well. Engineers use special materials like liquid crystal polymer and PTFE. These materials help signals stay strong and not get lost. They control impedance to keep signals clear. Heat is managed with thermal vias and heat sinks. EMI and RF shielding protect signals from noise. PCB designers and RF engineers work together for good layouts. They use advanced tests and simulations to check performance for 5G and IoT.

High-frequency PCBs make data move faster and lower delays.

They are used in phones, cars, AR/VR, and smart factories.

Companies work together to make new ideas for 5G and 6G.

Flexible and Rigid PCBs

Flexible and rigid PCBs help modern electronics in different ways. Flexible PCBs save space and weight. Engineers can design boards that fit small places. These boards are used in wearables, medical implants, and planes. Rigid PCBs are strong and last longer in devices that do not move. Rigid-flex PCBs mix both types for 3D shapes and better reliability.

Feature | Rigid PCBs | Flexible PCBs | Rigid-Flex PCBs |

|---|---|---|---|

Material | FR4, Metal-Core | Polyimide, Polyester | Mixed materials |

Flexibility | None | High | Partial |

Cost | Lower | Higher | Highest |

Applications | Computers, power | Wearables, medical | Aerospace, military |

Advantages | Durable, stable | Lightweight, bends | Space-efficient |

Challenges | Inflexible | Expensive, stress | Complex design |

Good pcb design helps flexible PCBs last longer. Engineers watch bend radii and use soft copper to stop cracks.

Sustainability

Sustainability matters more in pcb making now. Companies use lead-free solders and halogen-free laminates to make boards safer. Some boards use bio-based materials like cellulose and lignin. These materials break down and are better for nature. Green chemistry swaps bad solvents for water-based ones. Additive manufacturing makes less waste and allows tricky designs. Circular manufacturing uses closed systems and modular boards for easy recycling. Life Cycle Assessment helps companies lower harm to the planet. Energy and water are saved with recycling systems. Chemical management uses safer choices and follows ISO 14001 rules.

Green materials and recycling help save resources.

Machines that use less energy and renewable power cut carbon.

Water recycling systems help save water when making pcbs.

PCBs help make modern electronics work. They are small, strong, and can bend. This makes them important for many things. Engineers use new materials and smart tools. These help boards last longer and work better. The table below shows new trends that will change future devices.

Innovation Area | Description | Impact on Future Electronics |

|---|---|---|

Miniaturization & HDI | Thinner lines and tiny holes | Smaller devices with more power and tricky circuits |

Flexible and Rigid-Flex PCBs | Boards that can bend and twist | Phones that fold, bendy screens, and wearable gadgets |

Embedded Components | Parts put inside PCB layers | Smaller boards, better work, and stronger devices |

Advanced Materials | Materials that handle heat and signals | Fast systems and high-speed electronics |

Environmentally Friendly PCBs | Safer solders and recycling | Greener factories and eco-friendly gadgets |

Emerging Complementary Tech | 3D printed boards and light circuits | Quicker, smaller, and new kinds of electronics |

Engineers use AI and smart tools to help signals move right.

Flexible boards need new ways to ground for wearables and folding gadgets.

New materials help boards work in fast and high-frequency systems.

PCBs will keep getting better as technology grows. They will stay important in our lives and in future gadgets.

FAQ

What is the main purpose of a PCB?

A PCB holds and connects electronic parts. It uses copper lines to join pieces. This setup helps devices work well and last longer.

How do PCBs help with miniaturization?

PCBs let engineers put many parts close together. This makes devices smaller and lighter. Miniaturization lets us have things like smartphones and fitness bands.

Why are PCBs important in commercial applications?

PCBs give steady performance in business products. They help computers, medical tools, and cars work safely. Many businesses need PCBs for smart features and long life.

Can PCBs be recycled?

Yes, companies can recycle PCBs. They take out metals like copper and gold. Recycling cuts down on waste and helps the planet.

What materials are used to make PCBs?

Manufacturers use fiberglass, epoxy resin, and copper for PCBs. Some boards use special stuff for heat or bending. The material depends on what the device needs.

See Also

Understanding PCBA And Its Critical Role In Electronics

The Importance Of PCB Design In Electronic Devices

The Value Of Custom PCBA Production In Today’s Electronics