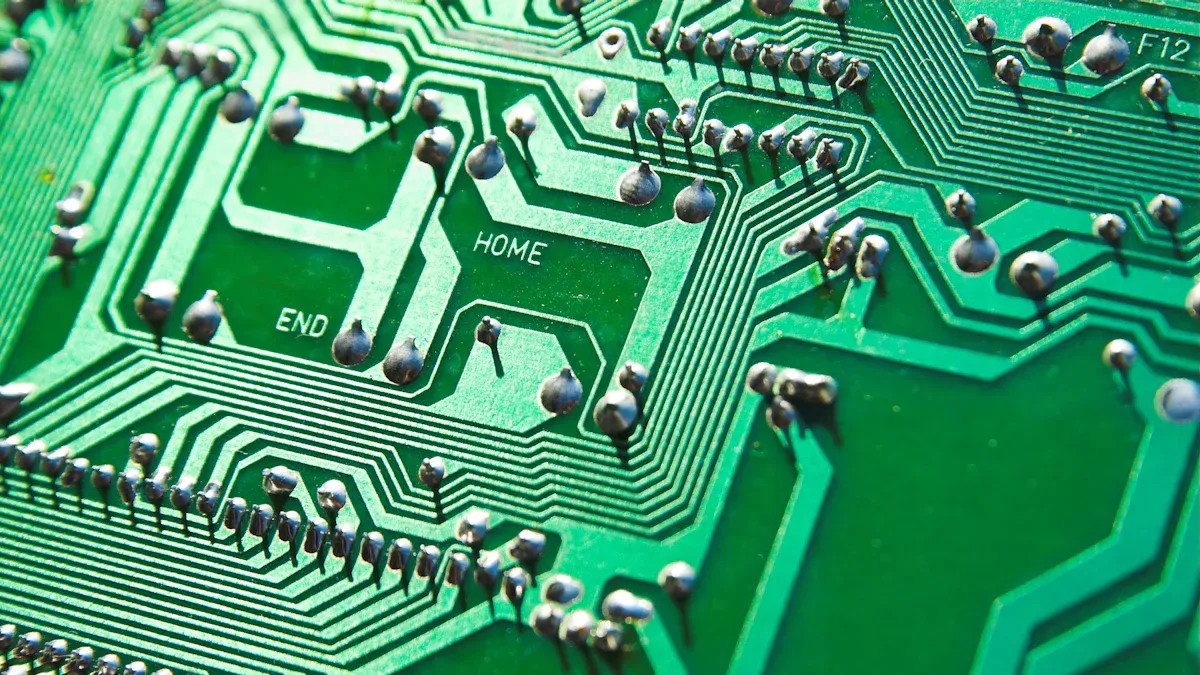

Staying ahead in the fast-changing world of PCB and PCBA is crucial. The market is projected to grow from $7.36 billion in 2024 to $21.42 billion by 2033, driven by an impressive annual growth rate of 12.6%. This highlights the increasing demand for innovative and intelligent pcb pcba solutions.

Major shifts, such as miniaturization, automation, and sustainability, are transforming the industry. For example, advancements in IoT and 5G technology are fueling the demand for High-Density Interconnect (HDI) and flexible PCBs. These trends emphasize the importance of future-ready pcb pcba designs to address global needs effectively.

Key Takeaways

The PCB market will grow a lot, reaching $21.42 billion by 2033. Knowing the latest trends is important to do well.

Automation and AI are changing how PCBs are made. These tools make work faster, fix mistakes, and make better products.

Smaller devices need smaller PCBs. HDI technology helps make tiny, strong PCBs for small gadgets.

Using eco-friendly materials is now very important. Biodegradable parts and recycling help protect the planet.

New markets and ideas bring chances to grow. Companies should keep up with changes and try new technologies to stay ahead.

Automation and AI in PCB PCBA Production

AI-driven design optimization

AI is changing how we design PCBs. It studies large amounts of data to suggest better layouts, parts placement, and wiring paths. This saves time and reduces mistakes. For example, Company B uses AI tools to find defects instantly. This has cut down errors, made products more reliable, and kept customers happy.

Company | Problem | AI Solution | Results |

|---|---|---|---|

Company B | Defects and quality issues | AI tools for instant defect detection |

AI also helps improve processes over time. With data tools, companies like Company E have sped up production, shortened cycles, and reduced mistakes. These changes show how AI is shaping the future of PCB and PCBA production.

Automation for enhanced manufacturing efficiency

Automation is key to smart factories. It makes production faster, more consistent, and higher in quality. Automated systems plan tasks to avoid delays and keep things running smoothly. They also check product quality to ensure everything meets standards.

Main benefits of automation in PCB production:

Faster production

More consistent results

Fewer mistakes

Easier to make small designs

Without automation, making complex, multi-layer circuit boards would be very hard.

Automation also reduces human mistakes and ensures rules are followed. This is very important for advanced tech like HDI and 5G devices. Using automation helps you stay ahead in PCB trends and meet the need for top-quality boards.

Predictive maintenance and quality assurance

Predictive maintenance uses AI to watch machines and predict problems before they happen. This cuts downtime and saves money on repairs. For example, predictive tools have cut testing time by 30%, speeding up production and finding issues faster.

Improvement Type | Change | Details |

|---|---|---|

Testing time | Faster testing with predictive tools | |

Lead time | Better | Quicker production with improved processes |

Defect detection | Better | Finds issues and fixes them earlier |

AI also helps with quality checks. It watches production in real-time and adjusts settings to keep products perfect. This ensures every PCB meets top standards. By using predictive maintenance and AI for quality checks, you can make production more reliable and efficient.

Miniaturization and High-Density Interconnects (HDI)

Need for smaller and lighter devices

People want smaller and lighter gadgets more than ever. This is clear in wearables, medical tools, and smartphones. These devices need smart designs to fit in small spaces. Flexible PCBs are important because they bend and fit tricky designs. The market for tiny PCBs is growing fast. This is due to the need for small, powerful devices with advanced packaging.

Reasons for this trend:

IoT is growing in smart homes and factories.

Flexible PCBs are used in lightweight gadgets.

Many industries want compact designs.

Making smaller devices shows why new PCB methods are so important.

HDI technology for advanced designs

HDI technology has changed how PCBs are made. It helps create complex designs in tiny spaces. It allows more parts, better signals, and good heat control. For example, HDI PCBs are key in phones and cameras. These devices need to be small but work well.

Feature | Benefit |

|---|---|

Better Signal Quality | Keeps communication clear in complex designs. |

Heat Control | Helps manage heat for high-performance gadgets. |

Smaller Designs | Fits more features into tiny spaces. |

High Circuit Density | Adds complex circuits without losing performance. |

Using HDI technology helps combine parts while keeping great performance. HDI is a big part of future PCB trends.

Solving problems in tiny PCB production

Making tiny PCBs is not easy. Smaller devices make it harder to ensure they work well. Magnetic current sensors help by combining many functions in one small part. These sensors save space, make assembly easier, and cut costs.

Other problems include tough Ultra HDI assembly and soldering. Experts say better designs are needed to fix these issues. Using advanced tools and materials can solve these problems. This helps companies stay ahead in the market.

Making smaller devices needs smart PCB methods. Using HDI technology helps meet the demand for tiny, powerful gadgets.

Flexible and Advanced Materials in PCB PCBA

Flexible PCBs for wearable gadgets

Flexible PCBs are changing how wearable gadgets are made. They help create thin, soft, and powerful devices. For example, smartwatches now track heart rates, fitness, and payments. These features fit into one small, lightweight design. As wearable tech improves, flexible PCBs are becoming more popular.

The rise of IoT and edge computing also boosts demand for flexible PCBs. Gadgets like fitness bands and smart glasses need these PCBs to work smoothly. Reports show flexible and rigid-flex PCBs are key for modern electronics. They offer adaptable and efficient solutions for today’s tech needs.

Source | Evidence |

|---|---|

Future of Circuit Board Assembly | Flexible PCBs are growing due to wearable tech and flexible electronics. |

PCB Assembly Market Size Report | IoT and edge computing drive demand for flexible and advanced PCBs. |

Eco-friendly and biodegradable materials

Making PCBs eco-friendly is now very important. Biodegradable materials like cellulose and PLA break down naturally. This reduces waste and pollution. For example, water-based recycling can recover metals faster and cut carbon emissions.

New green tech uses wood-based materials called LCNFs. These are strong and work with current manufacturing methods. Using biodegradable materials helps the planet and meets rules for sustainability.

Benefits of eco-friendly materials:

Break down naturally, reducing waste.

No harmful emissions from halogen-free materials.

Better recycling saves valuable resources.

Lower carbon emissions help the environment.

Strong and heat-resistant materials

New materials are making PCBs tougher and better at handling heat. Insulated metal substrates and high-temperature FR4 manage heat well and work in tough conditions. Polyimide PCBs can handle up to 260°C, perfect for military and space use.

Ceramic-based materials are another big step forward. They can handle over 500°C and work well in high-frequency devices. These materials improve PCB performance in extreme environments.

Material Type | Key Features | Applications |

|---|---|---|

Insulated Metal Substrate PCB | Manages heat well, keeps devices cool | LED lights, car systems |

High Temperature FR4 | Resists damage, handles high temperatures | Electronics in tough conditions |

Polyimide | Stays stable at up to 260°C | Space and military devices |

Ceramic-Based Substrates | Handles over 500°C, great for high-frequency devices | Harsh environments, advanced electronics |

Using these materials makes PCBs stronger and more reliable. They meet the needs of modern tech while staying efficient.

Sustainable PCB Manufacturing Practices

Using eco-friendly production methods

Eco-friendly methods are changing how PCBs are made. These methods lower harm to the environment and boost efficiency. Many companies now use lead-free materials to make products safer. They also follow RoHS rules to reduce health risks. Recyclable materials like copper and aluminum are becoming popular. These materials save resources and support sustainability. Green coatings and technologies help cut down on harmful chemicals and waste. This leads to better and safer products.

Evidence Type | Description |

|---|---|

Sustainability Benchmarking | |

Emerging Materials | Shows recyclable and biodegradable PCB materials. |

Etching Methods Comparison | Looks at wet and dry etching to cut waste and costs. |

Additive Manufacturing Evaluation | Reviews new ways to make sustainable circuit boards. |

By using these methods, companies can follow green trends and meet the demand for eco-friendly PCBs.

Recycling and reusing PCB materials

Recycling and reusing are key to making PCBs sustainable. A circular economy focuses on reusing valuable materials from old electronics. Urban mining helps by reducing the need for harmful traditional mining. New tools like AI improve recycling by identifying parts and predicting needs.

Benefits of recycling:

Recover important materials like copper and gold.

Reduce damage caused by mining.

Use AI to make recycling faster and smarter.

Create PCBs that can be recycled in the future.

These efforts save resources and help companies stay competitive in the PCB industry.

Rules and market trends for sustainability

Laws and market demands push for greener PCB production. In the US, the Electronic Waste Recycling Act aims to cut down on 7 million tons of e-waste each year. In Europe, RoHS rules require lead-free solder, reducing harmful substances by 67%. Innovations like Jiva Materials’ dissolvable PCBs make recycling easier and set new standards for eco-friendly practices.

Initiative | Description | Impact |

|---|---|---|

Electronic Waste Recycling Act | Cuts down on electronic waste in the US | Reduces millions of tons of e-waste |

RoHS | Uses lead-free solder alloys | Lowers harmful substances by 67% |

Jiva Materials’ Soluble PCB | Creates fully recyclable PCBs | Makes PCBs more eco-friendly |

By following these rules and trends, companies can stay compliant and help build a greener future for PCB production.

IoT and 5G Integration in PCB Design

IoT-driven design requirements

IoT is changing how PCBs are made. These devices need smaller, smarter PCBs for tight spaces. This has led to using tiny parts and advanced tech like Flex and HDI PCBs. Power use is also very important. Many IoT devices run on batteries, so saving power helps them last longer. Picking the right power chips can make a big difference.

High-density PCBs are key for IoT because space is limited. Multilayer PCBs let you add more parts without losing function. IoT devices also face challenges like heat and moisture. Testing for these during design makes them more reliable. Security is another big deal. Since IoT devices connect to networks, they need protection to stop hackers.

PCBs for 5G-enabled devices

Making PCBs for 5G devices is tricky. These devices work at high speeds and need special materials. For example, materials with low dielectric constants, around 3, keep signals strong. Managing heat is also important. Faster speeds create more heat, so tools like heat sinks and thermal vias help cool things down.

Adding RF parts directly onto the PCB improves signals and reduces losses. But this needs materials that handle heat well and don’t lose signal quality. These upgrades are vital for things like self-driving cars and AR, where quick responses are a must.

Addressing connectivity and speed challenges

Speed and connection are key for IoT and 5G. To handle this, good radio frequency designs are needed. Space and power limits must also be managed. Adding RF parts to PCBs keeps signals clear, even at high speeds.

Using eco-friendly materials is also important. Rules and customer demands push for greener options. By going green, you can make PCBs that work well and help the planet. These steps keep your designs ready for the future.

IoT and 5G are changing PCB design. Solving these problems helps create smart solutions for today’s tech needs.

Industry-Specific Applications of PCB PCBA Trends

Automotive: PCBs for electric and self-driving cars

The car industry is using advanced PCBs more than ever. Electric and self-driving cars need PCBs for power, signals, and battery systems. Multi-layer PCBs help make these cars reliable and energy-efficient. They also support the electronics needed for self-driving, like sensors and computers.

High-quality PCBs are important for motors, chargers, and safety systems. Flexible PCBs are popular because they are light and small. This fits the need for compact and efficient parts in modern cars.

Benefits of PCBs in cars:

Better energy use and reliability.

Support for features like self-driving and safety systems.

Small designs save space.

Aerospace: Reliable PCBs for tough conditions

In aerospace, PCBs must be very strong and reliable. They are used in airplane controls, satellites, and defense systems. Any failure can cause big problems, so materials and designs are very important. Polyimide materials are common because they handle heat well. Military-grade parts make them even more reliable.

Good design, like managing heat and keeping signals clear, helps these PCBs work in extreme conditions. Reliable PCBs are key for communication and satellite systems.

Uses of aerospace PCBs:

Airplane controls and navigation.

Satellite communication tools.

Defense and missile systems.

Healthcare: Small PCBs for medical tools

Tiny PCBs are changing healthcare by making devices smaller and better. These PCBs allow small designs without losing features. Flexible PCBs are great for wearable medical tools because they are light and bendable. They make devices more comfortable and useful for patients.

Small PCBs are also durable and send signals clearly. They lower interference, making sure data is accurate. From heart devices to testing tools, these PCBs are used in many medical technologies.

Benefit | Description |

|---|---|

Smaller device designs | Makes medical tools compact and portable. |

Extends device life and performance. | |

Clearer signal transmission | Ensures accurate data sharing. |

Less interference | Reduces disruptions in device function. |

More features in small spaces | Adds advanced functions to tiny devices. |

Small PCBs are improving healthcare by making devices better and easier to use.

Challenges and Opportunities in PCB PCBA

Supply chain and material shortages

The PCB industry faces big problems with supply chains. Events like COVID-19 and global conflicts have caused delays. There’s also a shortage of materials like copper and rare earth metals. The demand for electronics, such as IoT and 5G devices, makes this worse.

Problem | Reason |

|---|---|

Higher demand | Growth in IoT, 5G, and electric cars. |

Material shortages | Mining issues and strict environmental rules. |

Global events like pandemics and trade issues. |

To fix these problems, advanced manufacturing can help. Digital tools can track inventory and predict material needs. This makes production smoother and lowers costs.

Tip: Use local suppliers and have more options to avoid risks.

Emerging markets and growth opportunities

New markets bring great chances for the PCB industry. Countries like Thailand are growing in manufacturing. But they face problems like not enough skilled workers and weak infrastructure. Training local workers and using automation can solve these issues.

The global PCB market is expected to grow by 5.5% by 2025. This is due to the rise of AI servers and electric cars. By following these trends, businesses can grow. Offering custom PCB designs can also give companies an advantage.

Reasons for growth:

More demand for electric cars.

Expansion of AI and IoT tech.

Investments in new markets.

Innovation as a solution to industry challenges

Innovation helps solve PCB production problems. New tech like 3D printed PCBs is changing the industry. These allow quick prototypes, custom designs, and fit into complex devices. For example, aerospace uses them for light parts, and healthcare uses them for wearable devices.

Innovation Type | How It Helps |

|---|---|

Additive Manufacturing | Cuts waste, speeds up prototypes, and allows complex designs. |

Boosts productivity, ensures quality, and lowers costs. | |

Robotics Technology | Improves accuracy, reduces mistakes, and speeds up production. |

Using these innovations can solve problems like high labor costs and slow inspections. They also make production faster and more eco-friendly.

Note: Staying innovative keeps your business strong in a fast-changing industry.

The PCB and PCBA industry is changing fast. Big trends for 2025 include automation, smaller designs, and eco-friendly methods. The table below highlights these key changes:

Trend Description | Key Points |

|---|---|

High-Density Interconnect (HDI) PCBs | Will be common in phones, cars, and gadgets by 2025. |

Advancements in Automated PCBA | Robots and AI tools will improve speed and accuracy. |

5G and PCB Technology Integration | New materials will help faster data transfer for 5G devices. |

Green and Sustainable PCB Manufacturing | Eco-friendly methods will meet stricter rules and customer needs. |

Miniaturization and Integration of Components | Smaller, smarter PCBs will lead the market. |

To succeed, focus on new technology and green practices. Using advanced tools improves products and saves money. Eco-friendly methods meet customer needs and future rules.

“This finding shows how fixing environmental issues in production… reusing parts through circular models lowers carbon footprints a lot.”

Following these trends helps you stay competitive. By focusing on innovation and sustainability, you can shape the future of PCB and PCBA production.

FAQ

What is the difference between PCB and PCBA?

A PCB is just the board with no parts. A PCBA has the board with all parts attached, so it works.

Why is HDI technology important for modern electronics?

HDI helps make small, powerful circuit boards. It fits more parts, improves signals, and handles heat well. This is great for phones and smart gadgets.

How does AI improve PCB production?

AI makes better designs and spots problems fast. It also predicts repairs, saves time, and keeps quality steady.

Are flexible PCBs durable?

Yes, they are strong and can bend without breaking. This makes them perfect for wearable gadgets and other flexible uses.

How can you make PCB production more sustainable?

Use green materials and recycle old boards. These steps cut waste, save resources, and follow eco-friendly rules.

See Also

Best Practices for Achieving Quality and Efficiency in PCBA

Important Factors to Consider When Selecting PCB or PCBA

The Role of PCBA in Advancing Modern Electronic Technologies

The Importance of PCBA Prototyping for Innovative Electronics