The cost of a pcb printed circuit board for modern electronics depends on many things. These things are materials, layer count, board size, how many are made, design complexity, and supply chain issues. Each part is important:

Materials like copper foil and epoxy resins can be 40% to 60% of the total cost. Copper prices can change by over 40% each year.

High layer counts, often more than 24 for advanced computing, make boards harder to make and more expensive.

Board size, how many are made, and special design features also change the final cost.

Supply chain problems, like tariffs and changes in where things are made, add 5-10% to costs.

Key Takeaways

The material you pick affects 30% to 60% of PCB cost. Choosing common materials like FR-4 saves money. You do not lose quality when you use these materials. Using fewer layers makes the design simpler. Simple designs are easier to make and cost less. If you order more PCBs at once, the price for each board goes down. Panelization also helps lower waste and cost. If you work with suppliers and plan ahead, you avoid extra fees. Planning lead times helps you get better prices. Picking the right finishes, vias, and board sizes is important. This helps you balance quality and cost. You get PCBs that work well and do not cost too much.

PCB Printed Circuit Board Cost Drivers

Materials

Picking the right material is a big part of PCB cost. Most makers use FR-4 because it works well and is not expensive. FR-4 costs about $0.05 for each square centimeter in 2025. This is why it is used in most electronics. Rogers materials are made for high-frequency jobs. They can cost up to $0.30 for each square centimeter. Polyimide is used for flexible PCBs. It costs two to five times more than regular rigid boards. CEM-3 is cheaper and works for medium-level needs.

PCB Material Type | Typical Cost (2025) | Notes on Usage and Properties |

|---|---|---|

FR-4 | ~$0.05 per cm² | Most common, good electrical insulation and mechanical strength |

Rogers Materials | Up to ~$0.3 per cm² | Specialized for high-frequency applications, higher cost |

Polyimide (Flexible PCBs) | 2-5x cost of rigid PCBs | Used in flexible PCBs, significantly more expensive |

CEM-3 | Lower than FR-4 | Cost-effective for moderate requirements |

Tip: Material costs can be 30% to 60% of the total PCB price. Picking the best material for your project helps save money.

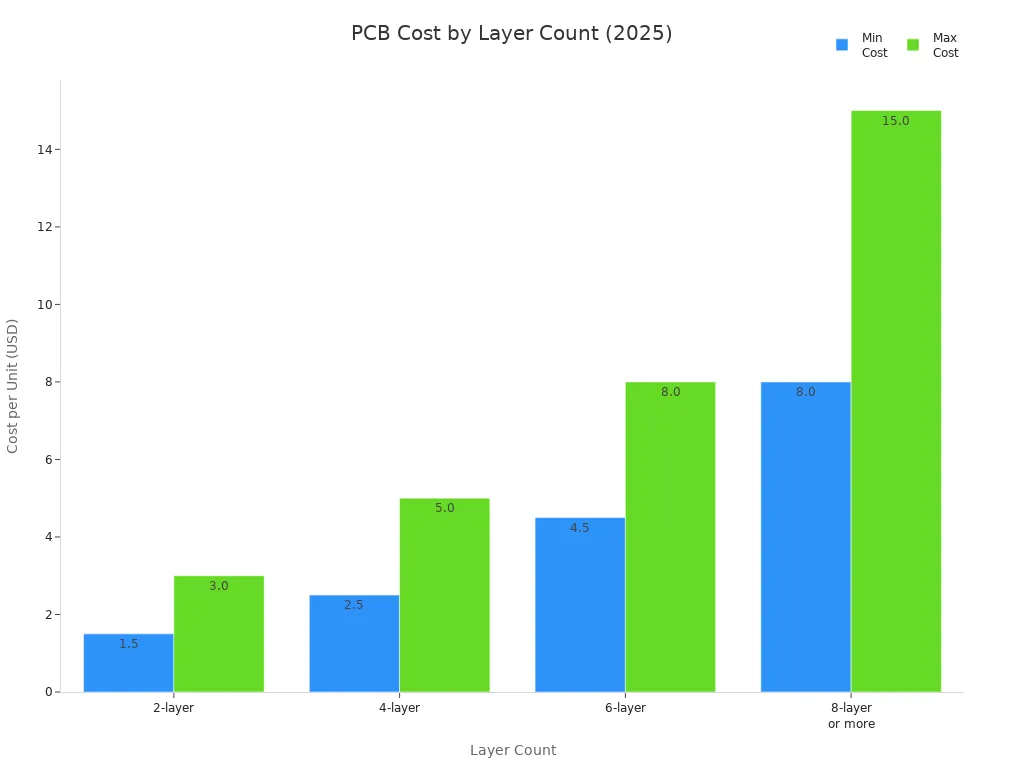

Layer Count

The number of layers changes how hard and costly a PCB is to make. Boards with only one layer are the cheapest. If a board has eight or more layers, it costs a lot more because it takes more work to build.

Layer Count | Typical Cost Range (per unit, large volume) | Notes |

|---|---|---|

$1.50 – $3.00 | Base cost for simple industrial PCBs | |

4-layer | $2.50 – $5.00 | More complexity and material use |

6-layer | $4.50 – $8.00 | Extra drilling and lamination |

8-layer+ | $8.00 – $15+ | High complexity, premium pricing |

Note: More layers mean more drilling and checking. This makes the board cost more because it needs extra work and care.

Board Size

The size of the board affects how much material is used. It also changes how fast boards can be made. A normal 100mm x 100mm, 1.6mm thick, 4-layer PCB costs $3.00 to $4.00 each if you make a lot. Bigger boards or thicker boards cost more, sometimes $5.00 to $8.00 or even higher.

Parameter | Typical Cost Range (per unit, large volume) | Notes/Impact on Cost |

|---|---|---|

100mm x 100mm, 1.6mm thick, 4-layer | $3.00 – $4.00 | Standard size and thickness |

Increased thickness (e.g., 2.4mm) or heavier copper | $5.00 – $8.00+ | More material and handling complexity |

Bigger boards need more material. Fewer boards fit on each panel, so each board costs more.

Surface Finish

Surface finish keeps copper safe and helps with soldering. HASL is the cheapest finish and adds about $0.10 to each board. ENIG is better but costs $0.50 to $1.00 more for each board. Immersion silver and OSP are in the middle for price.

Surface Finish | Additional Cost (per board) | Notes |

|---|---|---|

HASL | +$0.10 | Most affordable |

ENIG | +$0.50 to $1.00 | Premium, better solderability |

Immersion Silver | +$0.30 to $0.60 | Mid-range |

OSP | +$0.10 to $0.30 | Organic preservative |

Picking the right finish helps balance cost and quality. Some jobs need the best finish, even if it costs more.

Via Technology

Via technology connects layers inside the PCB. Regular through-hole vias are the cheapest and work for most boards. Blind and buried vias, or microvias, cost more because they need extra steps. These special vias help make tiny and packed boards but add more cost for tools and work.

Through-hole vias: Cheapest, good for most boards.

Blind/buried vias: Cost 20–40% more because of extra steps.

Microvias: Used in HDI boards, can double the cost for vias.

Engineers should check if fancy vias are needed. Using simple vias saves money and keeps things easy.

Materials

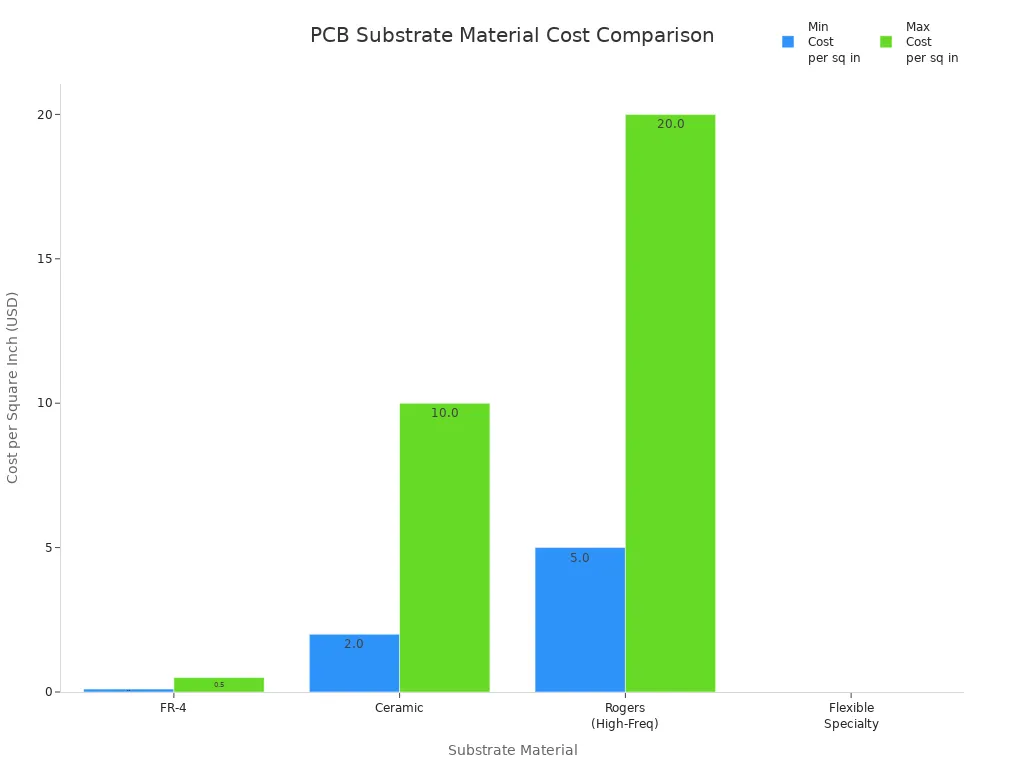

Substrate Types

The substrate material you pick changes how well a pcb printed circuit board works and how much it costs. FR-4 is the most common choice for electronics. It is strong, safe, and not expensive. FR-4 usually costs between $0.10 and $0.50 for each square inch. Ceramic substrates cost a lot more, from $2.00 to $10.00 for each square inch. They are better at moving heat and handling electricity. Rogers materials are used for high-frequency jobs. They cost from $5.00 to $20.00 for each square inch. Some special types can even cost $75.00. These materials are harder to make and take longer to get.

Substrate Material | Cost Range (per square inch) | Key Cost Influences and Notes |

|---|---|---|

FR-4 | $0.10 – $0.50 | Cost-effective, general use |

Ceramic | $2.00 – $10.00 | High thermal/electrical performance |

Rogers (High-Frequency) | $5.00 – $20.00 (up to $75.00) | Specialized, complex manufacturing |

Flexible/Specialty (PTFE, Polyimide) | Higher than FR-4 | Used for critical layers, higher cost |

FR-4 is picked a lot because it is cheap and works well. High-frequency and special substrates are used in things like telecom, planes, and defense.

Thermal Performance

How well a material handles heat also changes its price. FR-4 is fine for most jobs that do not get too hot. It does not move heat very well. If a device gets hot, like power electronics, it may need aluminum-based IMS or ceramic PCBs. These cost more and need special ways to make them. Ceramic PCBs are great at moving heat but cost much more than FR-4. You have to think about both heat needs and how much you can spend.

Materials that handle heat well can take higher temperatures and last longer.

Aluminum-based IMS and ceramic PCBs cost more but are needed for powerful devices.

Making these boards costs more because they need special care and higher heat.

Even though better thermal materials cost more at first, they can save money later by making products last longer.

Specialty Materials

Specialty materials and fancy finishes make a pcb printed circuit board cost more. PTFE, polyimide, and finishes like ENEPIG use pricey materials and need tricky steps to make. These choices help with soldering, electricity, and how long the board lasts. They are important for jobs that need high quality or work at high frequencies. But they also make boards take longer to build and are harder to make.

Specialty substrates and finishes are picked for important jobs where quality matters more than price.

Designers sometimes use costly materials only in some layers to save money.

Finishes like ENIG and ENEPIG cost more but protect the board better.

Material costs can be 30% to 60% of the whole PCB price. Picking the right material helps balance how well the board works and how much it costs.

Design

Complexity

How complex the design is changes how much a pcb printed circuit board costs. Engineers add more layers and use special materials for tough jobs. They also set tight rules to make sure the board works well. Each thing makes building the board take more steps. If there are more layers, you need extra copper and more drilling. Odd shapes or thick boards use more material and take longer to make. High standards like Class III or ITAR need extra checks and paperwork. Fancy finishes and special impedance also make the price go up.

Impact on Manufacturing Cost | |

|---|---|

Layer Count | More layers increase cost |

Dimensions (Size & Shape) | Irregular shapes waste material |

Material Choice | Premium materials cost more |

Thickness | Thicker boards need more time |

Classification | Higher standards increase scrutiny |

Surface Finish | Advanced finishes cost more |

Trace Spacing & Impedance | Tighter spacing needs special processes |

Hole Size & Quantity | Smaller holes require specialized drilling |

Tight Tolerances | Precise manufacturing raises cost |

Copper Weight | Heavier copper increases expenses |

Tip: Making the design simpler helps save money and makes building faster.

Trace Width

Trace width changes how much a pcb printed circuit board costs and how well it works. Wider traces are easier to make and have fewer mistakes. Very thin traces, less than 5 mils, need special tools and careful work, so they cost more. Big traces can handle metal loss better when etched, but very wide traces can cause problems when putting parts on. Talking to makers early helps pick the best trace width for cost and how the board works.

Wider traces cost less and make more good boards.

Thin traces are harder to make and cost more.

Boards for 5G and AI need special trace widths, which cost more.

Panelization

Panelization puts many boards on one panel to save money. This uses more material but cuts assembly time by half and lowers waste by 10-15%. Testing and handling cost less because there are fewer single boards to check. For big orders, panelization can cut costs by 20-30%. But you need to think about the cost to design and cut the panels apart. Making panels and board sizes standard helps save even more.

Note: Panelization is important for making lots of boards, especially as boards get smaller and more complex for 5G.

New tech like AI, miniaturization, and 5G make designers build smaller, faster, and smarter boards. AI helps make layouts and find mistakes faster, so design takes less time. Smaller boards and 5G need special materials and tighter rules, which cost more at first but help boards work better and get to market faster.

Manufacturing

Process Controls

Process controls are very important for how much PCBs cost and how good they are. Factories with better process controls hire skilled workers and spend more on setup. This makes the price go up. They use exact machines and strong tests to find problems early. These steps cost more but help make boards that work well. Companies that follow rules must use special steps and approved parts. This also makes the price higher. Buyers often pick suppliers with good controls for better boards and fewer problems.

Setup and skilled workers make manufacturing cost more.

Better controls and checks mean higher prices but better boards.

Following rules needs extra steps and special parts.

Note: Using advanced process controls costs more, but it helps stop mistakes and makes boards last longer.

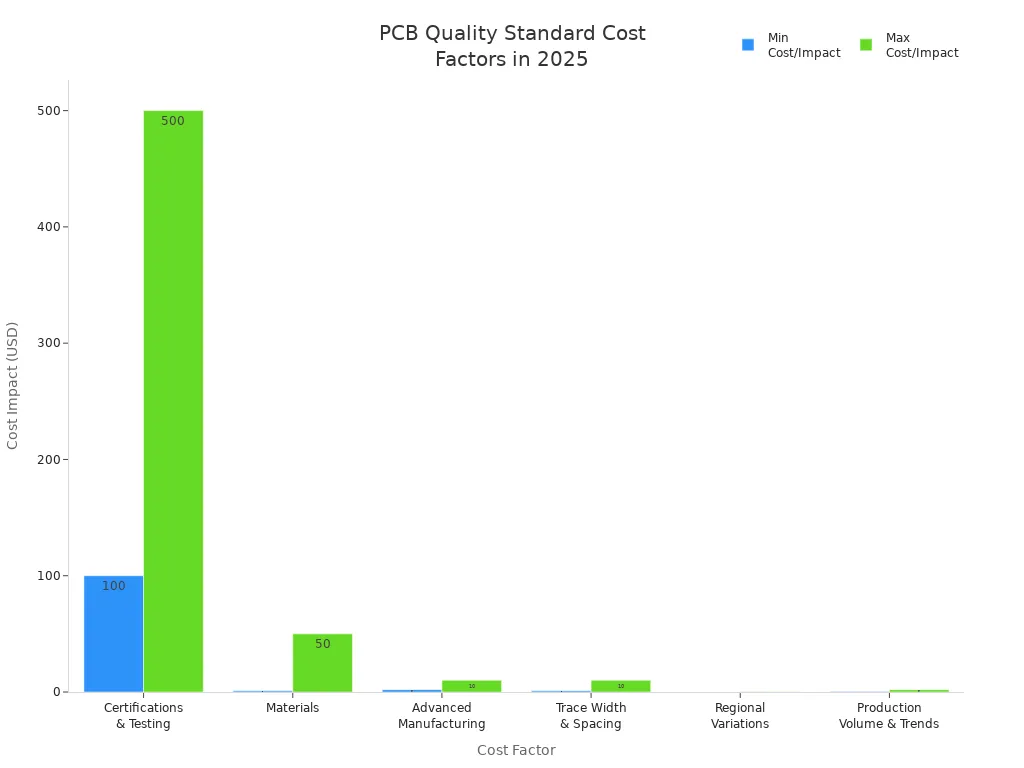

Quality Standards

Quality standards change both the price and how well PCBs work. Boards for medical, cars, or planes must pass hard tests and get special papers. These include UL and IPC-A-600, plus X-ray checks. Each test and paper adds to the cost for each design and board. The materials and how tricky the board is also change the final price. HDI boards and tiny traces need special tools, which cost more.

Cost Factor | Description/Impact | Cost Range/Impact | Example/Notes |

|---|---|---|---|

Certifications & Testing | UL, IPC-A-600, and X-ray checks make boards safer | Medical PCB with UL & X-ray: $300/design vs. $50 for non-certified prototype | |

Materials | What the board is made of changes cost and how it works | FR-4: $1-$10/sq.ft; Rogers: $20-$50/sq.ft | FR-4 is used for most boards; Rogers is for special jobs |

Advanced Manufacturing | HDI, microvias, and new ways to make boards cost more | +$2-$10 per sq.ft | HDI smartphone PCB (50 sq.cm): $20/board vs. $10 for standard 4-layer PCB |

Trace Width & Spacing | Smaller traces and spaces need better machines | $1-$2/sq.ft standard; $3-$10/sq.ft fine | HDI PCB with 4 mil traces: $30/board vs. $10 for 8 mil traces |

Regional Variations | Where boards are made changes labor and material costs | Asia 10-20% cheaper than West | 6-layer PCB (200 sq.cm): $15/board in China vs. $18 in U.S. |

Production Volume & Trends | Making more boards and using robots saves money; supply chain can add costs | Automation saves $0.50-$2/board; supply chain adds 5-15% | Use robots to save money; sign contracts to avoid price jumps |

Tip: Higher quality standards cost more, but they make products safer and more dependable.

Technology Level

The technology level of a factory changes both the price and what the board can do. Suppliers with better technology charge more, but their boards last longer and break less. Hard designs, like ones with microvias or tight rules, need special machines and skilled workers. This makes assembly cost more and take longer.

Better technology lets factories make multi-layer and HDI boards with special vias.

Fancy machines and extra steps make material, labor, and running costs go up.

Laser drilling for microvias costs more to set up, but the number of microvias does not change the price much.

High-tech factories can make harder projects, but their work costs more.

In 2025, new ways to make boards and caring for the environment are changing things. Additive manufacturing, like 3D printing with special inks, uses less material and energy. It uses fewer chemicals and makes less waste, which is better for nature. But the machines cost a lot, so this way is best for custom or small jobs.

Aspect | Conventional PCB Manufacturing | 3D PCB Additive Manufacturing |

|---|---|---|

Manufacturing Process | Subtractive: lamination, cutting, and chemical etching | Additive: direct ink writing (DIW) with special inks |

Material Waste | Makes a lot of waste | Makes much less waste |

Energy Consumption | Uses a lot of energy for cutting and chemicals | Uses less energy, mostly for heating and printing |

Chemical Usage | Uses many wet chemicals, bad for the environment | Uses few chemicals, better for nature |

System Cost | Needs workers and machines that wear out | High starting cost because 3D printers are expensive |

Waste Management Cost | High because of all the waste | Much lower because there is less waste |

Suitability | Good for making lots of boards fast | Best for custom, small batches, and testing |

Design Flexibility | Only works for flat, 2D layers | Can make tricky, 3D, and multi-layer boards |

Cost Impact Summary | High material and waste costs; uses lots of energy | High machine cost but saves on materials and waste |

Caring for the planet and using new tech will change how PCBs are made. Companies that try these new ways may pay more at first, but they can save money and help the earth later.

Supply Chain

Volume

How many PCBs you order changes the price for each board. If you buy only a few boards, each one costs more. This is because setup fees are split between fewer boards. When you order a lot, the cost for each board goes down. The factory can spread setup costs over many boards. Big orders often get discounts from the maker. Buying in bulk helps save money and makes planning easier.

Small orders cost more for each board because of setup fees.

Large orders save money because costs are shared.

Bulk buying usually gets you a discount.

Lead Time

How fast you need your PCBs changes the price. If you want boards quickly, you pay more. Factories must work faster and may need extra workers. Normal wait time is about 20 days. If you need boards in less than 20 days, it costs extra. Waiting longer lets factories plan better and costs less. Planning ahead and working with your supplier helps save time and money.

Tip: If you manage wait times well, you can save up to 15% and get boards 30% faster.

Supplier Location

Where your supplier is matters for price and speed. Local suppliers can ship faster and cost less for delivery. They talk to you quickly and help fix problems fast. It is easier to work with local suppliers for quick jobs. Suppliers in other countries, like Asia, may be cheaper. But you must think about quality and shipping delays. Many companies now pick suppliers by looking at both price and how fast they deliver.

Local suppliers help save on shipping and get boards faster.

Overseas suppliers are cheaper but take longer to deliver.

Talking and working with local suppliers is easier.

Note: In 2025, getting materials is harder, and trade problems make things tricky. Companies need to use more suppliers, buy machines, and care about the planet to keep up.

Cost Optimization

Design Tips

Designers can save money by making smart choices early. They should pick FR-4 material and OSP finishes for most boards. Keeping the layer count at four or less helps lower costs. Four-layer boards cost about 40% less than six-layer boards. Arranging boards well on a panel cuts waste and saves money. Making holes bigger than 0.3 mm makes drilling easier and cheaper. Avoiding blind or buried vias keeps things simple. Putting all parts on one side of the board saves time and money. Using green solder resist ink and regular copper thickness also helps control costs.

Pick FR-4 and OSP finishes for most boards.

Use four layers or fewer to save money.

Arrange boards well on panels to cut waste.

Make holes bigger to lower drilling costs.

Do not use blind or buried vias.

Put parts on one side of the board.

Use green solder resist ink and regular copper thickness.

Avoid tiny features that need special machines.

Tip: Designers should balance quality and cost. They can work with suppliers to get better prices by ordering more boards.

Common mistakes are putting parts too close to the edge, using too many layers, and putting parts on both sides when not needed. Designers should check their work and use design tools to find mistakes early. Working with fabricators from the start helps make sure the design can be built.

Material Selection

Picking the right materials helps control costs. FR-4 is a good choice for most jobs because it works well and is not expensive. Using thinner boards, like 0.8 mm instead of 1.6 mm, saves material if the design allows. Fewer layers, especially for simple boards, can cut costs in half. Designers should avoid very small vias and tight trace spacing because these need costly steps. Making trace widths and spaces match standard sizes makes building easier and cheaper.

Pick FR-4 for most boards to save money.

Use fewer layers for simple designs.

Plan panel layouts to fit more boards.

Avoid tiny vias and tight trace spacing.

Make trace widths and spaces standard.

Designers should work with fabricators to set design rules. This makes sure the pcb printed circuit board works well without costing too much. Thinking about batch sizes, tariffs, and exchange rates also helps pick the best materials.

Note: Making designs easy to build helps lower costs and keeps boards working well.

Supplier Negotiation

People who buy PCBs can get better prices by negotiating well. They should ask for quotes from different suppliers and let them know prices are being compared. Big price gaps can help get better deals. Inviting suppliers to visit helps build trust and may lead to better prices. Keeping track of supplier performance helps ask for better terms. Paying on time makes it easier to get good deals.

Use big orders to get better prices.

Be open and talk clearly with suppliers.

Check market prices and supplier performance often.

Ask suppliers about other materials or ways to save money.

Try to make deals that help both sides.

Negotiators should talk with suppliers and place small orders to test them. Focusing on important contract points, like delivery times and protecting ideas, helps keep things reliable and high quality.

Tip: Good relationships with suppliers lead to better prices and support.

Volume Planning

Planning how many PCBs to order can save a lot of money. Ordering more boards at once lowers the price for each board. Bulk orders help get discounts from makers. Panelization puts many small boards on one panel, cutting waste and saving time. Good panel layouts make manufacturing cheaper.

Bulk orders help save money.

Planning volume helps get better deals and makes buying easier.

Ordering more boards lets makers buy materials in bulk, which costs less. Panelization can cut assembly costs by up to 40% for big orders. For example, making 1,000 small boards one by one costs $5,000. Panelizing them on 50 panels costs $3,000, saving $1,900 even after cutting them apart.

Note: Planning order size and using panelization are great ways to save money when making pcb printed circuit boards.

Good pcb printed circuit board cost control needs smart design. You should pick materials carefully and work well with suppliers. Engineers and buyers should use fewer layers. They should choose regular shapes and finishes that do not cost a lot. Checking designs early and writing clear instructions helps stop mistakes. The table shows the main things that change cost and what to do in 2025:

Recommendation | |

|---|---|

Use fewer layers | |

Via Technology | Avoid tricky vias |

Board Size/Shape | Pick regular, right-sized boards |

Material Choice | Use standard materials |

Using these tips helps make boards cheaper and more dependable.

FAQ

What is the most expensive part of a PCB?

The material you pick costs the most. Special substrates like Rogers or ceramic can make the price go up by 60%. FR-4 is the cheapest for most electronics.

Tip: Using regular materials keeps prices lower.

How does order volume affect PCB pricing?

Factories charge less for each board if you order a lot. Setup fees are shared when you buy more, and you get discounts. Small orders cost more for each board.

Order Size | Cost per Board |

|---|---|

10 units | High |

1,000 units | Low |

Why do surface finishes matter for cost?

Surface finishes keep copper safe and help with soldering. HASL is the cheapest finish. ENIG and ENEPIG cost more but work better. The finish you pick changes how much you pay and how strong the board is.

HASL: Cheapest option

ENIG: Costs more, works better

Can design changes reduce PCB costs?

Designers save money by using fewer layers and simple shapes. They also avoid blind vias. Putting many boards on one panel and using wider traces helps too. Working with factories early makes designs cheaper.

Note: Easy designs cost less and are made faster.

See Also

Benefits And Obstacles Of Flex PCBA In Electronics

Simplifying Quick PCBA Solutions For Electronics Projects

The Importance Of Custom PCBA In Today’s Electronics