When you hear “PCB” and “PCBA,” you might wonder how they differ. A PCB, or Printed Circuit Board, is the base of electronic devices. It’s a flat board with copper lines that connect parts. PCBA, which stands for Printed Circuit Board Assembly, refers to a PCB with added parts. These parts include resistors, capacitors, and microchips to make it work, highlighting the pcba meaning in the context of electronic assembly.

The global PCB market is changing in exciting ways. Companies now use AI and machine learning for better designs. New methods like 3D printing make production more flexible. In Europe, the focus is on quality and eco-friendly ideas. In Latin America, saving energy is a big goal. These changes show how PCB and PCBA are improving to meet today’s needs.

Key Takeaways

A PCB is a flat board that links electronic parts. A PCBA is a PCB with extra parts that make it work.

Knowing the difference between PCB and PCBA helps you understand how gadgets work.

PCBs are used in many fields like electronics, cars, and healthcare. They help devices work properly.

Making a PCBA has many steps, like adding solder paste and testing. This ensures good-quality electronics.

Recycling PCBs and PCBAs is important to protect the environment. They have useful materials and cut down on e-waste.

PCB: What Is a Printed Circuit Board?

PCB Definition

A printed circuit board (PCB) is the base of most electronics. It connects and holds parts using copper pathways. These pathways let electricity flow, making the device work. IPC standards ensure PCBs are reliable and easy to make.

IPC Standard | Description |

|---|---|

IPC-2221 | General rules for designing reliable PCBs. |

IPC-6012 | Sets material and reliability rules for rigid PCBs. |

IPC-A-610 | Explains quality checks for assembled PCBs. |

Construction of a PCB

Making a PCB involves steps to ensure it works well. It starts with design tools to plan the board. Designers decide the size, part placement, and layers needed.

Copper layers are added to carry signals and power.

Parts are placed, considering heat and space needs.

Signal paths are drawn using special tools for connections.

Files like Gerber files are made for manufacturing.

Modern PCBs use lasers to drill holes connecting layers. Materials like solder, tin, or gold are used to coat surfaces for strong connections.

Types of Printed Circuit Boards

PCBs come in different types for various uses:

Single-layer PCBs: One copper layer, used in simple gadgets like calculators.

Double-layer PCBs: Two copper layers, common in home devices.

Multi-layer PCBs: Many layers, used in complex devices like phones.

Rigid PCBs: Hard boards, used in computers.

Flexible PCBs: Bendable boards, great for wearables.

Rigid-flex PCBs: Mix of hard and bendable, used in medical tools.

PCBs are also grouped by quality:

Class 1: For basic items like remote controls.

Class 2: For everyday devices like TVs.

Class 3: For critical tools like medical machines.

Each PCB type is made for specific jobs, ensuring it works best for its purpose.

Common Uses of PCBs

Printed circuit boards (PCBs) are key to modern technology. They are found in almost every electronic device you use daily. Their flexibility makes them important in many industries.

Industries and Uses

PCBs are made to fit the needs of different industries. Here’s a list of where they are often used:

Industry/Use | Description |

|---|---|

Consumer Electronics | Found in phones, laptops, and smart home gadgets. |

Automotive Industry | Used in car engines, safety systems, and entertainment systems. |

Medical Industry | Found in imaging machines, monitors, and surgical tools. |

Defense and Aerospace | Used in radios, navigation tools, and satellites. |

Industrial Manufacturing | Found in robots, controllers, and smart sensors for factories. |

Telecommunications and 5G | Used in cell towers, antennas, and mobile devices. |

Smart Transportation | Found in train control and safety systems. |

Smart Agriculture | Helps with farming by automating and monitoring systems. |

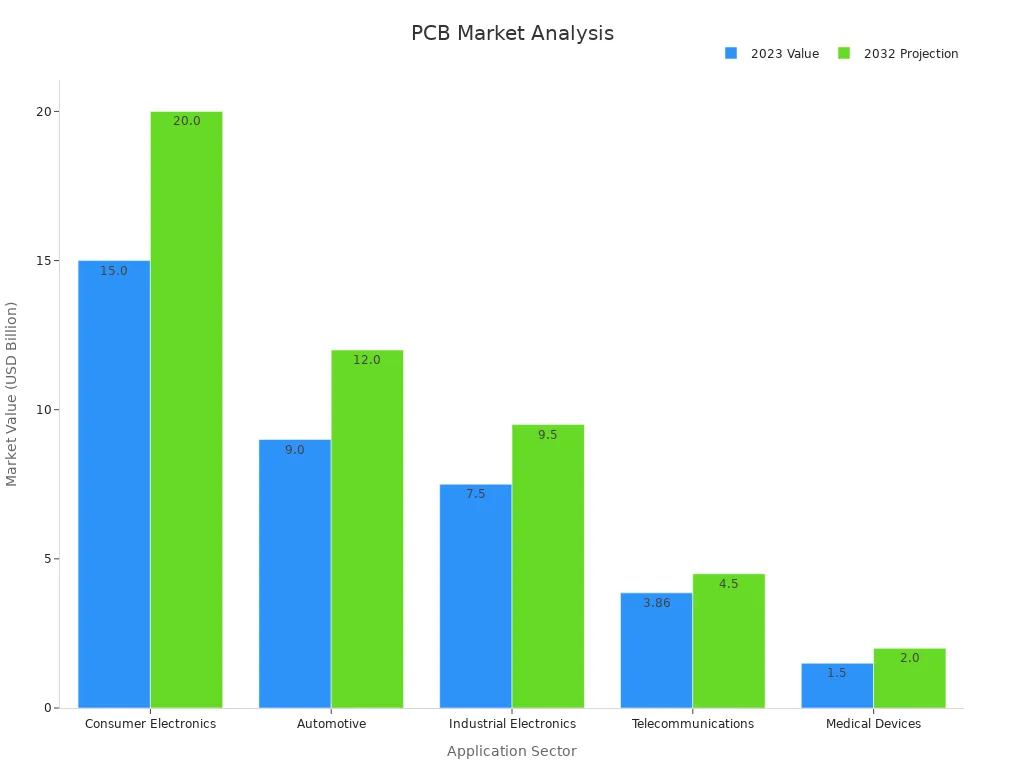

Why PCBs Are So Common

The global PCB market shows their importance. In 2023, it was worth $67.9 billion. By 2024, it may grow to $70.9 billion and reach $92.4 billion by 2029. This growth proves industries depend on PCBs to improve products.

PCBs are in phones, connecting chips and processors. In cars, they control engines and safety features. Medical tools use PCBs for accurate imaging and monitoring. Satellites rely on PCBs for communication and navigation.

PCBs are the heart of technology. They help devices work well, from simple gadgets to complex systems. As industries grow, PCBs change too, supporting new ideas in automation, connectivity, and eco-friendly designs.

PCBA Meaning and Process

PCBA Definition

PCBA means printed circuit board assembly. It is the process of adding parts to a PCB to make it work. Think of it as turning a plain PCB into a working device. This step includes attaching parts like resistors, capacitors, and microchips using solder.

PCBA is also called circuit card assembly. It is very important in making electronics because it allows the PCB to do its job. After the PCB is made, the assembly process starts. It includes steps like adding solder paste, placing parts, and testing quality.

Tip: PCBA connects a simple PCB to a working device. Without it, gadgets wouldn’t function!

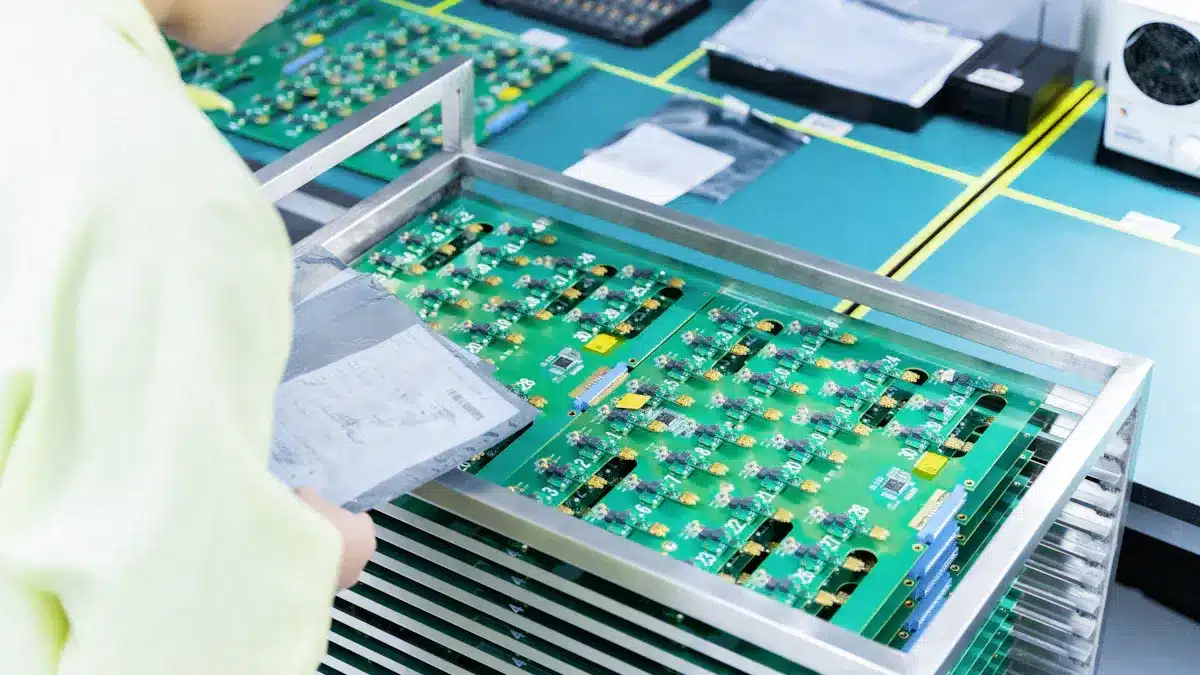

Assembly Process of PCBA

The PCBA process has many steps to make sure the product works well. Here’s a simple list of the main stages:

Solder Paste Printing: Solder paste is added to the PCB using a stencil. This paste helps hold the parts during assembly.

Component Placement: Machines place parts like resistors and chips on the board. They follow the design to ensure everything is correct.

Soldering: The board is heated to melt the solder paste. This creates strong connections for the parts.

Cleaning and Inspection: The board is cleaned to remove leftover materials. Checks are done to make sure it meets design rules.

Functional Testing: The board is tested to see if it works. This includes checking signals, power, and overall performance.

Each step is important. For example, solder paste printing keeps parts in place, and testing ensures the board works properly.

Components Used in PCBA

The parts used in PCBA depend on the design and purpose. These parts are chosen to match the electrical, mechanical, and heat needs of the device. Below is a table showing common details:

Specification Type | Details |

|---|---|

Preliminary Component List | Lists part numbers, makers, and backup options for cost. |

PCB Specifications | Includes board size, layers, material, thickness, copper weight, and finish. |

Design Rules and Constraints | Minimum trace width, spacing, drill sizes, and critical nets. |

Signal and Power Integrity Requirements | Info on fast signals and power networks. |

Compliance and Regulatory Requirements | Standards like IPC, UL, RoHS, CE compliance. |

Test and Validation Requirements | Steps for testing and checking the design. |

Bill of Materials (BOM) | Final list of parts, numbers, descriptions, and suppliers. |

CAD Files | 2D or 3D models of the PCB and parts. |

Gerber Files | Layout details for making the PCB. |

Pick and Place Files | Coordinates for placing parts automatically. |

Assembly Drawings and Schematics | Visual guides for checking part placement and connections. |

Functional Test Procedures | Steps to test the PCB and tools for testing. |

Regulatory and Compliance Information | Info on meeting RoHS, REACH, and other rules. |

These parts and details help make sure the PCBA process meets high standards. For example, FR-4 is used for regular electronics, while aluminum and ceramic are better for high-power or special devices.

Substrate Material | Electrical Properties | Mechanical Properties | Thermal Properties | Applications |

|---|---|---|---|---|

FR-4 | Good | Good | Moderate | Regular electronics |

Aluminum | Moderate | Good | Excellent | High-power devices like LED lights |

Ceramic | Excellent | Excellent | High | Special electronics like military tools |

Choosing the right parts and materials ensures the PCBA fits your project’s needs.

Importance of PCBA in Electronics

PCBA is very important in electronics. Without it, devices like phones, laptops, and smartwatches wouldn’t work. It turns a plain PCB into a working system by adding parts like resistors and microchips. This process helps the PCB do its job, making PCBA a key part of today’s technology.

PCBA helps make small and powerful gadgets. As devices shrink, precise assembly becomes more important. PCBA allows complex circuits to fit into tiny spaces. This keeps gadgets light and easy to carry. For example, in phones, PCBA helps high-speed processors and cameras work in slim designs.

PCBA also helps industries like healthcare and renewable energy. In healthcare, it powers tools like heart monitors and imaging machines. These tools need to be accurate and reliable. In renewable energy, PCBA helps solar panels and wind turbines manage power. These uses show how PCBA improves lives and helps the planet.

The need for electronics shows why PCBA matters. Devices like tablets and gaming consoles need advanced assembly for better performance. Wearable tech and IoT devices are growing fast. Flexible PCBs and precise assembly make foldable phones and smart glasses possible.

Here’s how PCBA affects modern electronics:

Aspect | Key Insights |

|---|---|

PCBA helps make small, automated devices like smartphones. | |

Future Applications | Flexible PCBs and IoT drive wearable tech growth. |

Renewable Energy Impact | PCBA helps solar and wind systems manage power. |

Demand Drivers | Consumer electronics need high-quality PCBA for better gadgets. |

Consumer Electronics Growth | Smart devices need compact and efficient PCBA to improve. |

PCBA isn’t just about adding parts; it ensures devices work well. Every step, like soldering and testing, checks for quality. This is why PCBA is so important in electronics. Whether it’s a medical tool or a gaming console, PCBA makes it work.

Note: PCBA turns a simple PCB into a working device. It’s why your gadgets function, making it vital in modern electronics.

Comparing PCB and PCBA

Definitions and Functions

To compare PCB and PCBA, you need to know their roles. A PCB is a flat board made of insulating material. It has copper lines that connect electronic parts. This board gives support and paths for electricity. But by itself, a PCB cannot do any electronic work.

A PCBA is a PCB with electronic parts added to it. These parts include resistors, capacitors, and microchips. Once built, the PCBA becomes a working circuit. It can send signals and power devices.

Here’s a table to show the differences:

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Bare board with no parts | Board with parts, making it a working circuit |

Function | Provides support and paths for electricity | Performs specific electronic tasks |

Components | None (empty board) | Includes resistors, capacitors, and microchips |

Appearance | Flat board with tracks and holes | Board with attached electronic parts |

Applications | Used for testing and early designs | Found in finished products like phones and computers |

A PCB is the base, while a PCBA makes it work. Without a PCB, there’s no structure. Without a PCBA, the board stays useless.

Tip: Think of a PCB as a skeleton and a PCBA as the body with working organs.

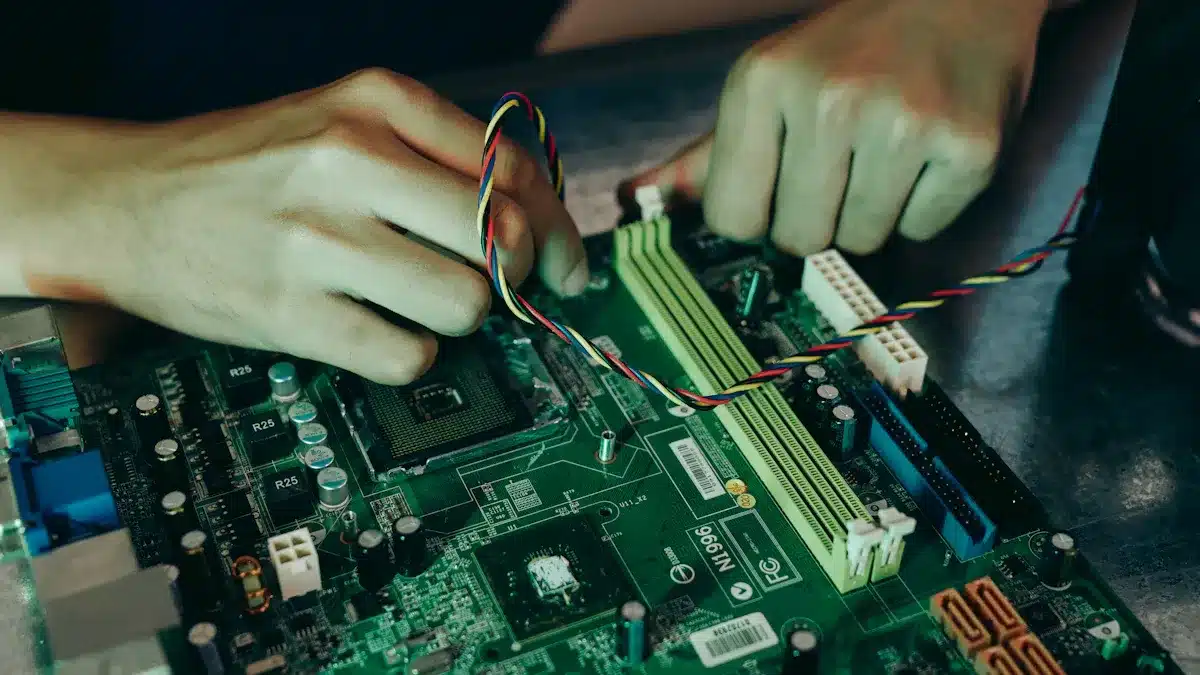

Manufacturing Processes

Making a PCB and a PCBA involves different steps. A PCB is made by adding copper layers to a base. These layers form paths for electricity. A solder mask is added to protect the copper. Labels are also added to guide part placement.

For a PCBA, parts are added to the PCB. Steps include applying solder paste, placing parts, and soldering them. Machines handle most of this work for accuracy. After assembly, the PCBA is tested to ensure it works.

Here’s a comparison of inspection methods:

Aspect | Automated Inspection | Manual Inspection |

|---|---|---|

Cost | Cheaper over time due to fewer mistakes | More expensive because of human errors |

Speed | Faster at finding problems | Slower, depends on the person inspecting |

Consistency | Very consistent as machines follow set rules | Less consistent due to human differences |

Quality Philosophy | Focuses on stopping defects early | Focuses on finding defects after production |

Machines are often used for checking both PCB and PCBA. They are faster and more accurate than people. Manual checks are slower and less reliable.

Note: Testing is key for both PCB and PCBA. For PCBs, it checks the copper paths. For PCBAs, it ensures the whole circuit works.

Cost Differences

A PCB costs less than a PCBA. A PCB is just a plain board with no parts. Its price depends on size, layers, and materials. For example, a single-layer PCB is cheaper than one with many layers.

A PCBA includes the cost of the PCB, parts, and assembly. Parts like microchips and capacitors can be pricey. The assembly process, especially advanced methods like SMT, adds to the cost.

Here’s a breakdown of costs:

PCB Costs:

Materials like FR-4 or aluminum

Number of layers

Size and design complexity

PCBA Costs:

Cost of the PCB

Price of parts like resistors and chips

Assembly costs for soldering and testing

While a PCB is cheaper, it cannot work alone. A PCBA is more expensive but provides a complete solution. When planning a project, consider both PCB and PCBA costs.

Tip: Spending more on good PCBs and PCBAs can save money later by avoiding failures.

Role in Electronics Lifecycle

PCBs and PCBA are key in electronics’ life stages. They affect how devices are designed, used, and recycled. Knowing their lifecycle shows their importance in technology.

Design and Manufacturing Phase

PCBs are the base for electronic devices. Designers plan how parts will connect and work. This ensures the PCB meets the device’s needs. After designing, the PCB is made, and PCBA adds parts like chips and resistors. This turns the PCB into a working unit.

Material choices affect performance and the environment. Using eco-friendly materials cuts waste and saves energy. Recycling parts during PCBA also helps the planet.

Research highlights how PCB materials and recycling impact the environment. It stresses the need for greener practices in PCB and IC production.

Usage Phase

PCBA makes devices work as intended. It powers gadgets like phones, medical tools, and car systems. Good PCBA ensures devices last longer and work well.

For example, PCBA in smartwatches handles tasks like health tracking. In simple devices like remotes, the PCB material affects durability more.

Studies show smartwatches have higher IC costs, while remotes rely on PCB materials. This shows the need for better recycling and substrate choices.

End-of-Life Phase

Recycling is crucial when devices stop working. PCBA parts like chips can be reused in new products. Recycling saves resources and reduces waste. Some PCB materials are easier to recycle than others.

Research explains how recycling and material choices affect environmental impact. It shows benefits for both high-value and basic electronics.

Using sustainable methods in design, production, and recycling lowers electronics’ environmental harm. PCBA ensures devices are useful and eco-friendly.

Uses of PCB and PCBA in Different Industries

Industries That Use PCBs

PCBs are important in many industries because they connect electronic parts. They are key to modern devices. In consumer electronics, like phones and laptops, PCBs help make gadgets small and powerful. Cars also use PCBs in safety features, entertainment systems, and electric parts. Factories rely on PCBs for machines that automate tasks and control systems.

The telecom industry needs PCBs for 5G networks. These PCBs handle fast data speeds and large amounts of information. Medical tools, like scanners and monitors, use PCBs for accuracy and dependability. As devices get smaller and more complex, PCBs are used even more in these fields.

Industries That Depend on PCBAs

PCB assembly is needed to make electronics work properly. Consumer gadgets, like tablets, smartwatches, and gaming devices, need advanced PCBAs. Cars also depend on PCBAs for electric systems that are small and handle heat well.

Telecom companies use PCBAs for 5G towers and network gear. Factory machines use PCBAs to improve automation and reliability. Medical tools, like heart monitors and imaging devices, need PCBAs for precise and long-lasting performance.

Products That Use Both PCB and PCBA

Many products combine PCBs and PCBAs. Fitness trackers use PCBAs to save power and last longer. Phones use both PCBs and PCBAs to run fast processors and high-tech cameras. In factories, improved PCBs help machines work better and send clear signals.

Electric cars are another example. They use PCBs for battery systems and PCBAs for sensors and controls. Medical tools, like patient monitors, rely on PCBAs for accurate results. These examples show how PCBs and PCBAs work together to make smart and reliable devices.

Knowing the difference between PCB and PCBA is important. A PCB is the base that carries electricity. A PCBA adds parts like microchips to make it work. Checking a PCB is easier than a PCBA. A PCBA has many parts and uses advanced tools like AI for quality checks.

Understanding this helps you see how electronics work. PCBs are the starting point, but PCBAs make devices function. From phones to factory machines, this knowledge helps you learn more about technology.

Takeaway: A PCB is the base, and a PCBA makes it work.

FAQ

What is the main difference between PCB and PCBA?

A PCB is a plain board with copper lines. A PCBA has parts like resistors and chips added. The PCB gives the shape, while the PCBA makes it work. Think of the PCB as the frame and the PCBA as the working machine.

Why are PCBs important in electronics?

PCBs hold and connect electronic parts. They let electricity move between components, making devices work. Without PCBs, gadgets like phones and laptops wouldn’t exist. They are the base of most electronics.

How does PCBA improve device performance?

PCBA adds parts to the PCB, creating a working circuit. This helps devices do tasks like running a phone or controlling a car. PCBA also makes gadgets smaller, faster, and better.

Can you recycle PCBs and PCBAs?

Yes, both can be recycled. PCBs and PCBAs have valuable materials like copper and gold. Recycling saves resources and reduces waste. Some materials, like FR-4, are harder to recycle, but new methods are improving this.

What industries rely on PCBAs the most?

Industries like electronics, cars, healthcare, and telecom use PCBAs. Phones, cars, 5G towers, and medical tools need PCBAs to work. These industries require accurate and dependable assemblies.

Tip: Learning about PCB and PCBA helps you understand how gadgets work every day.

See Also

Defining PCBA: Key Insights and Its Importance

Exploring PCBA: Definitions and Essential Uses in Electronics

The Significance of PCBA in Electronics Explained