Printed Circuit Boards (PCBs) are the base of electronics.

They are flat boards made of materials that don’t conduct electricity.

PCBs are designed to hold and link electronic parts together.

But a PCB alone doesn’t work; it’s just a base.

An Industrial sensor interface PCBA has all the parts added.

These parts include resistors, capacitors, and microchips.

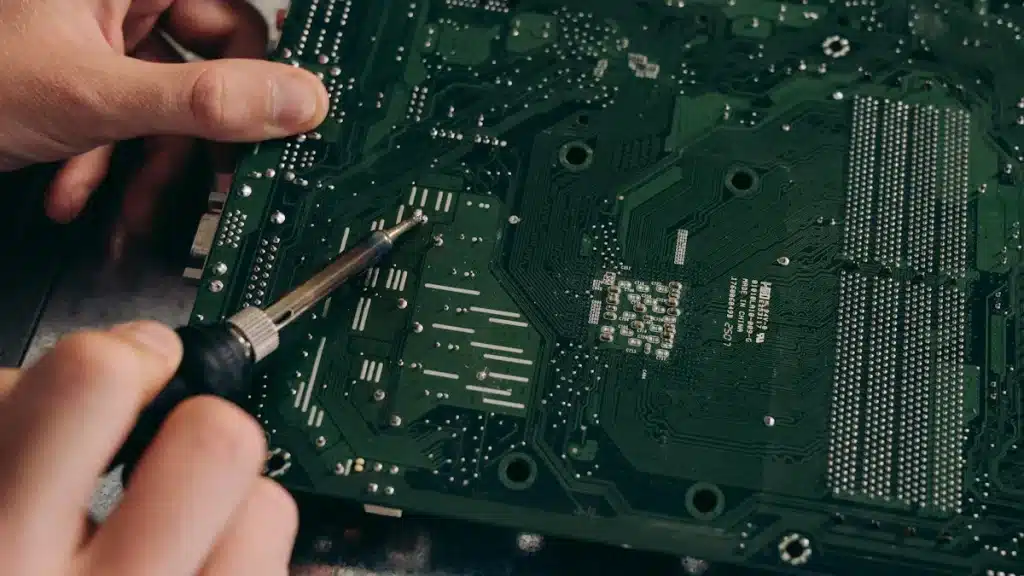

The parts are attached to the PCB using solder.

This makes the board ready to do tasks, like running sensors.

Knowing the difference between PCB and Industrial sensor interface PCBA is important.

It helps you pick the right one for sensor systems.

This choice improves how well your system works and lasts.

Key Takeaways

A PCB is a simple board for electronic parts. A PCBA is a finished board that works right away.

Picking the right PCBA boosts how well systems work and last, especially for factory sensors.

PCBAs are checked to make sure they are strong and work well in hard factory conditions.

Knowing how PCB and PCBA are different helps you choose better for electronics projects.

PCBAs make sensor data faster and better, which helps modern factories run smoothly.

What is a PCB?

Structure and Composition

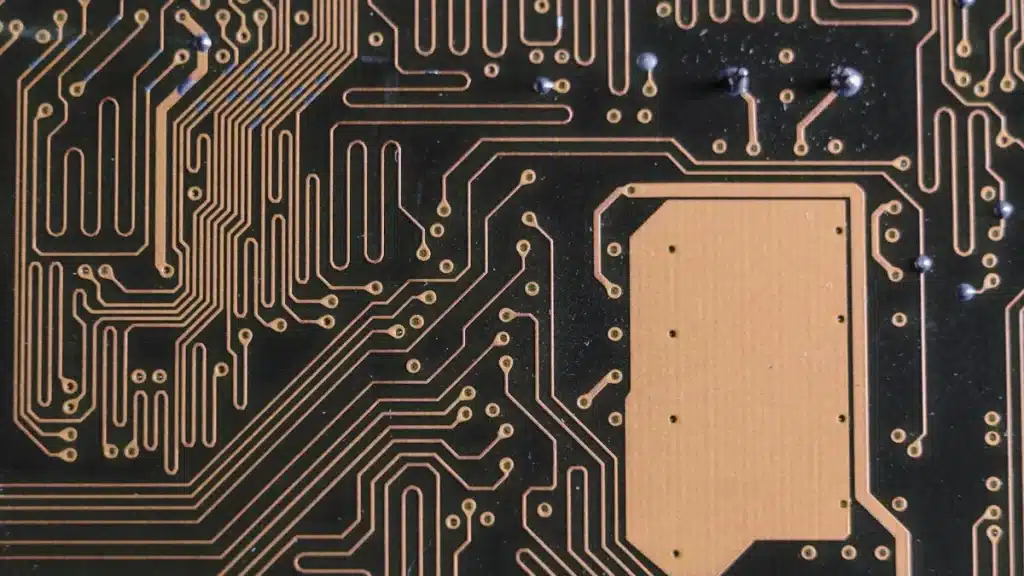

A PCB is the base of electronic gadgets. It is made from strong, non-conductive materials like fiberglass. This material keeps the board firm and safe for parts. Thin copper lines are added to carry electricity between the parts.

Some PCBs use special materials like aluminum or ceramic. These help with heat or bending needs. For fast signals, polymer-ceramic mixes work better. These designs make PCBs tough, safe, and good for many uses.

Types of PCBs

PCBs come in different styles for different jobs. Single-sided PCBs have parts on one side and are cheap. Double-sided PCBs have parts on both sides for more features. Multi-layer PCBs stack layers for small and powerful designs.

HDI PCBs are used in small gadgets like phones. They have tiny holes and thin lines for fast data. Metal-core PCBs, often aluminum, handle heat well for power devices. Flexible PCBs bend easily for wearables and other uses.

Common Uses in Electronics

PCBs are in almost all modern gadgets. They help phones and computers send signals and manage networks. GPS devices use them to find locations. In factories, PCBs control sensors and machines. Their design makes them key for connecting parts and working well.

What is a PCBA?

A PCBA, or Printed Circuit Board Assembly, is a PCB with parts added. These parts make the board work and do specific tasks. Most modern gadgets, including industrial systems, use PCBA.

Components of a PCBA

Parts on a PCBA make it work. These include resistors, capacitors, diodes, and transistors. Each part has a job. Resistors control electricity flow. Capacitors store and release energy. Microcontrollers and processors handle data tasks. Together, these parts help the PCBA do its job.

Assembly Process

Making a PCBA means attaching parts to a PCB. There are two ways to do this:

Surface-Mount Technology (SMT): Parts go on the board’s surface.

Through-Hole Technology (THT): Parts go into holes and are soldered.

Tests check if the PCBA works well:

Temperature Cycle Test: Checks performance in hot and cold.

Heat and Humidity Test: Tests durability in tough conditions.

Vibration Test: Ensures stability during movement.

Impact Test: Tests strength against shocks.

Electrical Test: Confirms steady voltage and current.

These tests make sure the PCBA is ready for hard jobs.

Applications in Industrial Systems

In factories, PCBA does important jobs. It reads sensor data and controls machines. It helps devices talk to each other. For example, it can manage temperature sensors to keep conditions right. PCBA combines many parts into one board, making it great for complex systems.

Key Differences Between PCB and PCBA

Physical Differences

A PCB is a plain board with no parts on it. It is made of fiberglass and has copper lines for electricity. It looks simple and is very light. A PCBA, however, has many parts like resistors and chips. These parts make it heavier and more complex.

Here’s a simple table to compare them:

Feature | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | A board with parts added, ready to work | |

Functionality | Needs parts to work | Works in devices after assembly |

Production Process | First step in making electronics | Includes adding parts and testing |

This shows that a PCB is just the base, while a PCBA is ready to use.

Functional Differences

A PCB cannot do anything by itself. It only holds parts together. It doesn’t process or send data. A PCBA, on the other hand, can do many tasks. It can control machines, process signals, and handle data.

For factories, this difference is very important. A PCB is just the start. A PCBA is the finished product that runs machines and reads sensor data.

Aspect | PCB | PCBA |

|---|---|---|

Assembly Complexity | Simple board, needs parts added | Fully built, ready to use |

Reliability | Depends on added parts | Tested to ensure it works well |

Application Range | Basic uses | Handles advanced tasks like automation |

PCBAs are made for tough jobs. They are tested to work well, even in hard conditions. This makes them perfect for factories and other demanding places.

PCBs are the starting point for electronics.

PCBAs are complete boards, tested and ready to work.

PCBAs are strong and reliable, great for tough environments.

Manufacturing and Cost Implications

Making a PCB is easier and cheaper than making a PCBA. A PCB only needs copper lines and a protective layer. A PCBA needs extra steps like adding parts, soldering, and testing. These steps make it cost more and take longer to produce.

For example, SMT and THT methods are used to attach parts to a PCBA. After that, the board is tested to ensure it works well. These steps make a PCBA more expensive but also more reliable.

If you’re working on a project, knowing these costs can help you decide. A PCB might be fine for simple tasks or testing. But for a fully working system, especially in factories, a PCBA is a must.

Tip: Think about how reliable a PCBA is when planning costs. It may cost more at first, but it works better in tough conditions, making it worth the price.

Importance of PCBA in Industrial Sensor Interfaces

Role in Sensor Data Processing

In factories, sensor data helps machines work smoothly. A PCBA acts like the brain, helping sensors collect and send data. Parts on the PCBA, like microcontrollers, process signals from sensors. Amplifiers and converters improve signal quality, even in noisy places.

For example, optical sensors like cameras use PCBAs to handle data. These sensors give detailed information for better factory work. PCBAs use smart algorithms to make data more useful. In smart factories, PCBAs manage data streams to improve tasks like repairs and inventory checks. This shows how important PCBAs are for modern sensor systems.

Benefits in Industrial Applications

PCBAs offer many benefits for factory systems. Their small size fits into tight spaces. Layers in the PCBA make signals faster and reduce interference. A ground layer helps high-frequency circuits stay stable and reliable.

Here are some key benefits of PCBAs:

Small size fits complex systems in tight spaces.

Short wires improve signal speed and quality.

Ground layers keep circuits stable and reliable.

These features make PCBAs great for tough factory jobs. Whether controlling machines or tracking conditions, PCBAs work well and efficiently.

Examples in Industrial Sensor Systems

PCBAs are used in many factory sensor systems. For example:

A PCB sensor finds Salmonella using special nanoparticles.

Motorola made a PCB for DNA tests, now a product platform.

A DNA chip uses copper for heating during testing.

A PCB sensor tracks chemical changes during DNA tests.

A PCB with gold electrodes finds cancer markers using fluid systems.

These examples show how PCBAs combine parts to solve hard problems. PCBAs use advanced designs to create smart solutions for factories.

Knowing how PCB and PCBA differ helps in making smart choices. A PCB is just the base, while a PCBA is complete and ready to work. PCBAs are key for handling sensor data and working well in tough places.

Tip: Picking the right PCBA makes systems last longer and work better, especially in industrial sensor setups.

Understanding these differences helps you choose wisely and improve how your systems perform.

FAQ

What is the main difference between PCB and PCBA?

A PCB is a plain board that holds electronic parts. A PCBA is a board with parts added to make it work. The PCBA can do tasks, while the PCB is just the base.

Why is the PCB assembly process important?

This process attaches parts firmly to the PCB. It includes soldering and testing to make sure it works. This step turns the PCB into a PCBA, ready for complex jobs.

How does a PCBA improve industrial sensor interfaces?

A PCBA handles sensor data quickly and accurately. It uses microchips and amplifiers to improve signals. This helps sensors give correct readings, even in tough places.

Can you reuse a PCB after assembly?

You might reuse a PCB if it’s still in good shape. If parts can be removed, the board can be used again. Testing is needed to make sure it works properly.

What tests are performed during the PCB assembly process?

Tests check heat, movement, and electricity performance. These tests ensure the PCBA works well in different conditions. Testing makes sure it lasts in tough factory jobs.