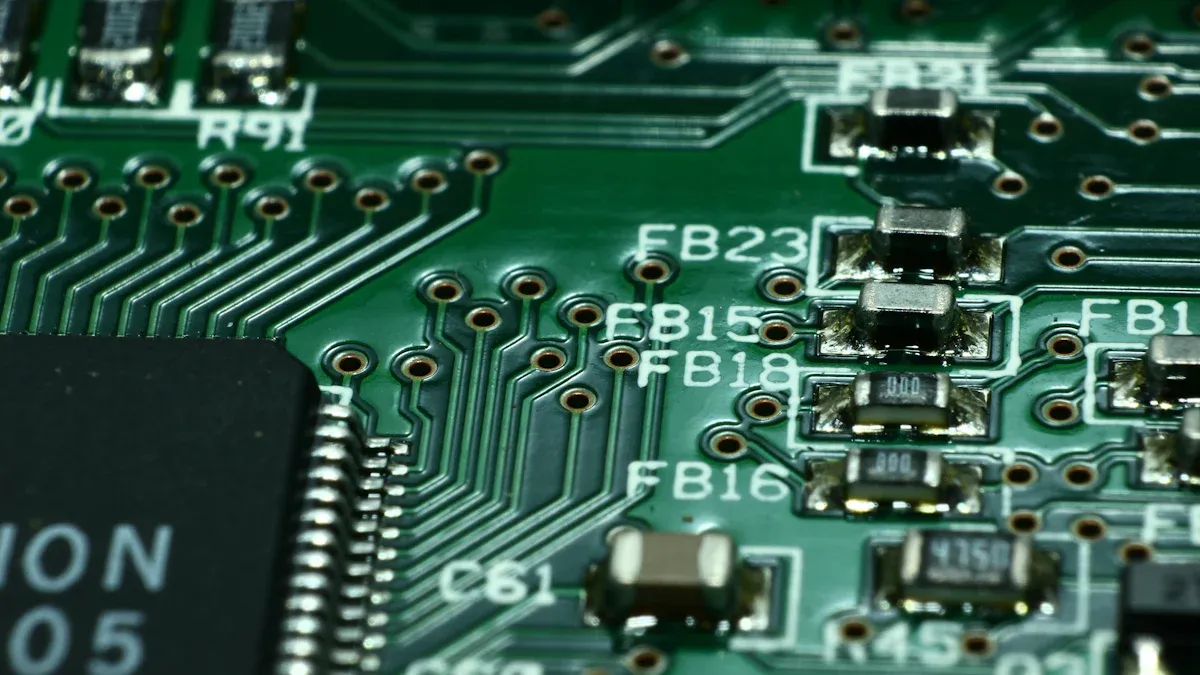

You depend on printed circuit board assembly (PCBA) for devices to work. Maintaining PCBA cleanliness standards is very important for good performance. Dirt like flux, ionic residues, or water can harm PCBs. This can cause them to fail or not last long. Following PCBA cleanliness standards helps prevent these problems. It also contributes to creating strong and long-lasting electronics. In making electronics, clean PCBs ensure good quality and happy customers.

Key Takeaways

Clean PCBAs stop problems. Dirt like flux or water can cause shorts and damage.

Cleaning and checking often make devices work better. Following cleaning rules keeps electronics high quality.

Picking the right way to clean is important. Different dirt needs special cleaning methods to work well.

Working with good manufacturers helps keep things clean. Trusted makers use smart tools to lower mistakes and keep standards high.

Clean PCBAs make customers happy. Good devices mean happy buyers and a better brand name.

The Risks of Contamination on PCBAs

Common Contaminants and Their Sources

Contaminants on PCBAs come from many places. Flux, ionic residues, and moisture are common. Flux stays behind after soldering. Ionic residues come from bad cleaning or pollution. Moisture builds up during storage or in humid air.

Old electrical devices with PCBs are a big contamination source. The U.S. stopped making PCBs in 1977. But, they still exist in old devices and some foods like fish, meat, and dairy.

Impact of Ionic Residues and Flux on Performance

Ionic and flux residues hurt PCBA performance. They can cause short circuits or ECM. ECM happens when moisture reacts with contaminants. This makes dendrites grow and connect conductive parts. It can lead to device failure.

A study on flux residues showed:

Conductivity rises in humid air.

Surface changes seen under SEM analysis.

Tests proved ECM happens faster with residues.

These problems make PCBAs less reliable, especially in humid places.

Role of Moisture and Environmental Factors in Degradation

Moisture and the environment speed up PCBA damage. Humidity causes hydrolysis, which weakens boards. UV light breaks down materials like PVC. Mechanical stress changes the board’s structure and shortens its life.

Environmental Factor | Effect on Damage | Notes |

|---|---|---|

Humidity | Causes hydrolysis | Long exposure worsens damage |

UV Light | Breaks down PVC | Speeds up damage in some materials |

Mechanical Stress | Weakens structure | Can release harmful substances |

Knowing these risks helps keep PCBAs clean and working well.

Real-World Failures Caused by Contaminated PCBAs

Dirty PCBAs have caused big problems in real life. When things like flux or water stay on boards, bad things happen. These problems hurt devices, cost money, and can be dangerous.

Industrial Equipment Failures: In factories, dirty PCBAs caused machines to break. Leftover flux and ionic dirt made short circuits in controls. This stopped production and cost a lot of money.

Consumer Electronics Breakdown: Gadgets like phones and laptops often stop working early. Water trapped during making reacts with dirt. This makes paths that short circuits, breaking the gadgets.

Environmental and Health Impacts: One case showed people harmed by PCB and PAH in water. Long exposure caused more sickness and deaths. A $500 million lawsuit showed why testing for toxins is key.

Tip: Clean and check PCBAs often to stop dirt problems. This keeps devices safe and working well.

Failures from dirty PCBAs show why cleaning rules matter. Fixing dirt risks keeps devices working and saves money.

Benefits of Keeping Circuit Boards Clean

Better Performance and Reliability

Clean PCBAs help devices work well and last longer. Dirt like flux can mess up connections and cause problems. Even “no-clean” flux often needs removal to avoid issues. Cleaning removes dirt, making sure everything works smoothly.

A study compared clean and dirty PCBAs to show the difference. Clean boards had a leakage current of only 0.05 mA. Boards with flux residues had much higher leakage currents.

PCBA Type | Max Leakage Current (mA) | Surge Start Time (hrs) |

|---|---|---|

Clean | 0.05 | 0.01 |

With non-activated flux residue | 10 | 1 |

With activated flux residue | 7 | 10 |

Cleaning also stops electrochemical migration. This happens when flux causes metal to corrode and grow dendrites. Dendrites can connect parts and cause short circuits. Following cleanliness rules avoids these problems and makes devices more reliable.

Longer Life for Electronics

Clean PCBAs help devices last longer. Dirt like flux speeds up damage and shortens their life. Keeping boards clean protects parts and helps them work for years.

Studies show clean boards stop tin whiskers from growing. Tin whiskers can cause problems and make devices fail. Clean parts also reduce e-waste by lasting longer. This helps the environment and saves money.

Fewer Failures and Complaints

Dirty PCBAs often cause defects and failures. Flux and dirt can make devices unreliable and lead to complaints. Following cleanliness rules lowers these risks and keeps customers happy.

Clean PCBAs also improve your brand’s image. People like products that work well and last. By keeping boards clean, you deliver quality devices and reduce problems after sales.

Improved Customer Satisfaction and Brand Quality

Clean PCBAs help make customers happy and improve your brand. High-quality circuit boards mean better devices. They work well, last longer, and break less often. This makes customers trust and stay loyal to your brand.

Surveys show how clean boards affect your brand. Happy customers talk about reliable and strong electronics. These reviews help you improve how you make products. When people see you care about quality, they tell others about your brand.

New cleaning tools also make products better. Machines clean boards the same way every time. This lowers mistakes and makes devices work better. These tools also save energy and protect the environment. Customers like brands that care about nature and quality.

Keeping PCBAs clean lowers returns and fixes. This saves money and makes your brand stronger. People think of your products as dependable. This keeps them coming back and builds good relationships.

Tip: Always deliver clean PCBAs to keep customers happy. Happy customers help your brand grow.

When you focus on clean boards, your products work better. This also makes your brand look good. Clean PCBAs show you care about quality and new ideas. This keeps customers loyal and confident in your products.

Common PCBA Cleaning Methods

Water-Based Cleaning: Advantages and Applications

Water-based cleaning is a common way to clean PCBAs. It uses deionized (DI) water mixed with detergents or saponifiers. This helps remove dirt like flux residues. It works well, especially for water-soluble fluxes.

To check how well it cleans, tests like ion chromatography and conductivity rinse testing are used. Ion chromatography finds ionic dirt levels. Conductivity rinse testing checks how well rinse water removes dirt. For example:

Testing Method | What It Does |

|---|---|

Measures ionic dirt on PCBAs, shown as sodium chloride per area. | |

Conductivity Rinse Testing | Tracks rinse water conductivity changes during cleaning to check effectiveness. |

Water-based cleaning also works with organic solderability preservative (OSP) coatings. Studies show water-based sprays keep OSP safe while removing flux dirt. This makes it a good choice for clean and working PCBAs.

Semi-Aqueous Cleaning: When and Why to Use It

Semi-aqueous cleaning mixes organic solvents with water to clean better. Use this when water-based cleaning can’t remove tough dirt. First, a solvent dissolves the dirt. Then, water rinses away the dissolved dirt.

This method is great for cleaning tricky shapes or delicate parts. It combines strong cleaning with the eco-friendliness of water-based systems. But, you must ensure the cleaning agents don’t harm your PCBA materials.

Semi-aqueous cleaning is often used in industries needing high reliability, like aerospace and medical devices. It cleans thoroughly without damaging sensitive parts.

Ultrasonic Cleaning: How It Works and Its Benefits

Ultrasonic cleaning uses sound waves to clean PCBAs. These waves make tiny bubbles in a cleaning liquid. The bubbles pop and release energy, which removes dirt from the PCBA surface.

Mechanism | What It Does |

|---|---|

Ultrasonic Sound | Uses sound waves above 20 kHz for cleaning. |

Cavitation | Bubbles form and pop, removing dirt. |

Frequency Impact | High frequencies clean gently; low ones clean heavy dirt. |

Comparison to Manual | Ultrasonic cleaning is safer and better than manual cleaning. |

This method cleans hard-to-reach areas and is gentle on parts. It’s better than manual cleaning, which can damage components. Ultrasonic cleaning is perfect for industries needing precision, like electronics and medical devices.

Tip: Use ultrasonic cleaning for complex designs or when manual cleaning doesn’t work well.

Vapor Phase Cleaning: Advanced Techniques for Technical Cleanliness

Vapor phase cleaning is a top method for cleaning PCBAs. It uses heated solvent vapor to remove dirt from boards. This process cleans even hard-to-reach spots, making it great for complex designs.

Here’s how it works. A machine heats a solvent until it becomes vapor. The vapor rises and touches the cooler PCBA surface. As it cools, the solvent turns to liquid and dissolves dirt like flux and oils. The board dries as the solvent evaporates.

This method has many benefits. First, it cleans evenly. The vapor reaches all parts of the board. Second, it is gentle on fragile parts. There’s no mechanical stress to damage them. Third, it reduces waste. The solvent is often reused, making it eco-friendly.

Vapor phase cleaning is useful for high-reliability needs. Industries like aerospace and medical devices use it. It helps meet strict cleanliness rules and ensures reliable performance.

Tip: Pick the right solvent for your needs. Some solvents clean specific materials better.

Using vapor phase cleaning improves PCBA reliability. It also supports cleaner and greener manufacturing.

Best Practices for Meeting PCBA Cleanliness Standards

Following Industry Cleanliness Standards and Guidelines

Sticking to industry rules keeps your PCBAs reliable and working well. Standards like IPC-5704 and IPC-A-610 explain how much dirt is okay. These rules help stop problems like corrosion and electrochemical migration, which can damage devices.

For example, acidic dirt left on boards can raise conductivity. This may cause leakage currents and other issues. A study showed that cleaning before and after soldering stopped tin whiskers from growing. Dirty boards had this problem. Using methods like conformal coating and deep cleaning makes boards last longer in tough conditions. By following these steps, you can keep your PCBAs clean and dependable.

Tip: Check and update your processes often to match new standards.

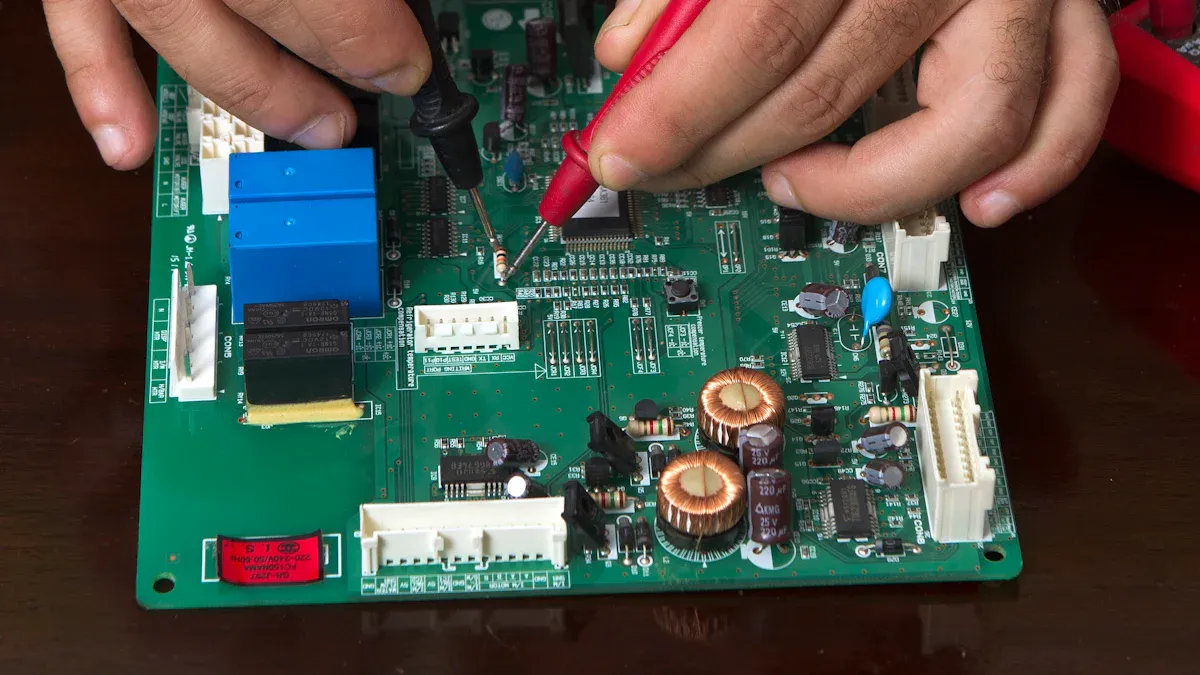

Inspecting and Testing for Contaminants Often

Checking and testing your PCBAs regularly is very important. These steps help find dirt early, keeping boards high-quality and reducing defects. Common tests include ion chromatography and surface insulation resistance (SIR) testing.

Benefit Type | What It Does |

|---|---|

Quality Assurance | Regular checks ensure good boards, making products reliable. |

Defect Detection | Finding problems early saves money on repairs and rework. |

Process Improvement | Inspection data shows where to improve manufacturing steps. |

Customer Satisfaction | Good boards build trust and make customers happy, boosting your reputation. |

Adding regular testing to your process improves quality and builds customer trust.

Note: Use test results to improve cleaning methods for better outcomes.

Picking the Right Cleaning Method for Your Needs

Choosing the best cleaning method is key for reliable PCBAs. Different dirt types and designs need specific cleaning ways. For example, water-based cleaning works for water-soluble flux. Semi-aqueous cleaning is better for tough dirt.

Modern electronics are smaller and harder to clean. New methods like ultrasonic and vapor phase cleaning solve these problems. These methods remove dirt that can cause damage, helping boards last longer.

Tip: Study your PCBA materials and dirt types to pick the best cleaning method.

By using the right cleaning methods, you can keep your PCBAs clean and make your products more reliable.

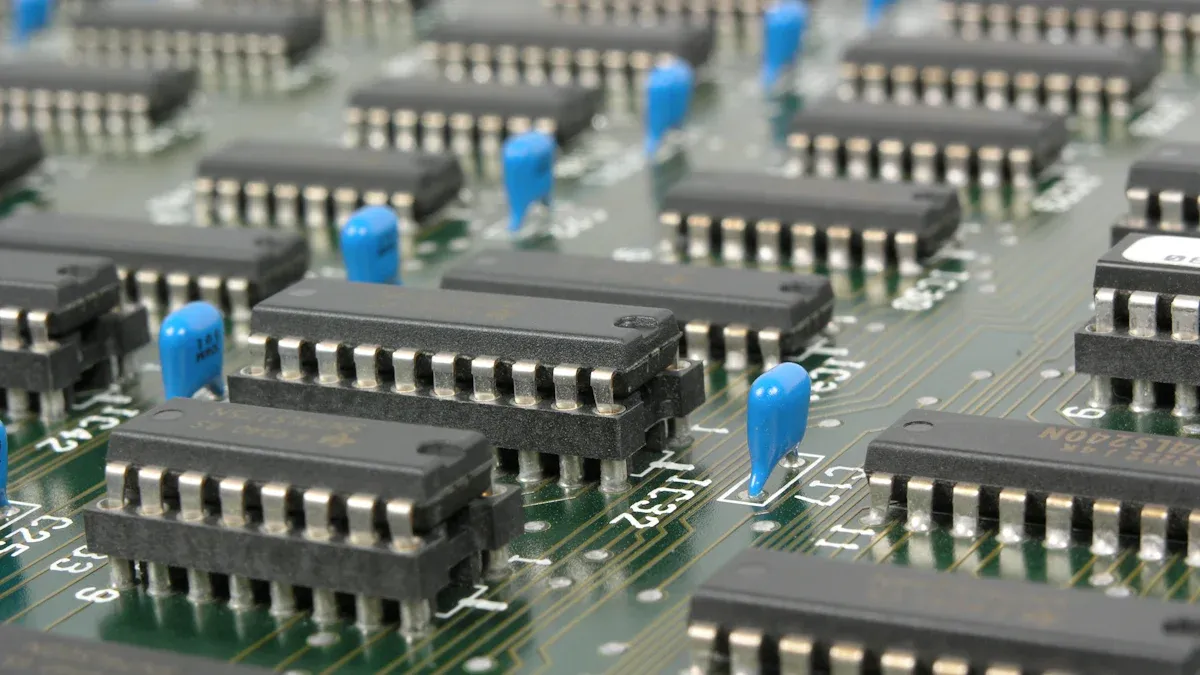

Partnering with Reliable PCBA Manufacturers and Service Providers

Picking a good PCBA manufacturer is very important. They help keep boards clean and reliable. A trusted partner makes sure your boards meet high standards. This lowers risks and improves how devices work.

Reliable makers use smart tools to find and fix problems. AOI spots solder mistakes and misplaced parts. X-ray checks hidden solder joints in tricky designs. Functional tests confirm the board works correctly. These steps ensure every board is clean and performs well.

Evidence Type | Description |

|---|---|

Quality Assurance | PCBasic’s product quality is outstanding, with all PCBA units undergoing strict testing to ensure performance and reliability. Our cooperation with them has significantly improved our product cleanliness and overall quality. |

Inspection Methods | Automated Optical Inspection (AOI) detects soldering defects and misaligned components, while X-ray Inspection examines hidden solder joints for complex PCB designs. Functional Testing ensures the PCBA performs as intended. |

Advanced Technology | PCBasic employs advanced reflow soldering technology to securely affix electronic components onto printed circuit boards, ensuring robust electrical connections. |

Cleanliness Assurance | The three anti-paint technique confirms the surface of the PCBA is free of dust and other soldering residues. |

Modern tools also make boards better. Reflow soldering attaches parts firmly to boards. This creates strong electrical links. Trusted makers use methods like three anti-paint to clean boards. This removes dust and solder dirt, making them cleaner.

Working with a reliable partner boosts product quality. It cuts down on mistakes and saves time. You’ll spend less fixing problems and handling complaints. A good partnership ensures your products meet rules and make customers happy.

Tip: Check manufacturers carefully. Pick ones with great skills, smart tools, and a focus on quality.

Teaming up with a trusted PCBA maker improves cleanliness and builds your brand. It makes your products reliable and gives you an edge in the market.

Keeping PCBAs clean is key to making devices reliable. Dirt like flux and moisture can cause damage and failures. For example, high humidity can create short circuits in just 168 hours. Industries like aerospace and medical devices need very clean boards for safety and reliability.

Using good cleaning methods and protective coatings helps protect your products. This improves how they work, lowers failures, and builds customer trust. Clean PCBAs make sure devices work well and last a long time.

Tip: Focus on cleanliness to make top-quality electronics that customers trust.

FAQ

Why do we clean PCBAs?

Cleaning PCBAs gets rid of dirt like flux and moisture. These can cause problems like short circuits or corrosion. Clean PCBAs help devices work better, last longer, and stay reliable.

How often should PCBAs be cleaned?

Clean PCBAs after soldering during making or fixing. Regular checks and cleaning are also important. This is especially true for devices in humid or dusty places.

Can tap water be used to clean PCBAs?

No, tap water has minerals that leave dirt behind. Use deionized (DI) water or special cleaners. These clean well without adding new dirt.

What is the safest way to clean delicate PCBAs?

Ultrasonic cleaning is best for delicate PCBAs. It uses sound waves to make bubbles that clean gently. This method reaches small spaces without harming parts.

Why follow cleanliness rules for PCBAs?

Cleanliness rules like IPC-5704 keep PCBAs high-quality. They stop problems like corrosion and make devices more reliable. Following these rules also keeps customers happy.

Tip: Check for new rules often to keep your PCBAs top-notch.

See Also

Ensuring Quality And Reliability Through PCBA Functional Testing

Best Practices For Achieving Quality And Efficiency In PCBA Production

Understanding PCBA Services And Their Importance In Electronics Manufacturing

Why PCBA Test Jigs Are Crucial For Modern Electronics Production